15 years one-stop China custom CNC machining parts factory

1563 |

Published by VMT at Aug 02 2024

1563 |

Published by VMT at Aug 02 2024

Flanges are indispensable components in the connection of pipes, equipment, valves, and other mechanical devices. Their intricate design and powerful functionality find widespread application across various industrial fields. This article delves into the definition, types, connection mechanisms, application areas, and processing techniques of flanges, aiming to provide readers with a comprehensive and in-depth understanding.

Simply put, a flange is a disc-shaped, ring-like component used to connect pipes, valves, pumps, or other mechanical equipment. Typically, flanges are secured together by bolts or other fasteners, achieving the purpose of sealing and connection. Flanges not only bear the pressure of the fluid but also ensure the sealing and stability at the connection points, making them essential elements in industrial piping systems.

The main purpose of a flange is to achieve detachable connections between pipes, valves, pumps, and other components while ensuring the sealing at the connection points. During maintenance, replacement of parts, or system upgrades, the design of flange connections simplifies these operations, significantly improving work efficiency. Additionally, flanges can be used to regulate flow, pressure, and even to divert or merge fluid streams.

Detachability: Flange connections allow easy disassembly and reassembly of connecting components without damaging the piping system.

Sealing: Achieving a good sealing effect through the tight fit between the flange face and the gasket, preventing fluid leakage.

Adaptability: Flanges can be selected and designed according to different working pressures, temperatures, and medium characteristics to meet various operating conditions.

Standardization: The dimensions, specifications, and connection standards of flanges follow international or industry standards, facilitating interchangeability and general use.

Flange fittings are widely used in various industrial fields, including but not limited to automotive, medical, electronics, petrochemical, power generation, marine, construction, and manufacturing. Each field has specific demands and challenges, and flanges and their fittings, with their unique advantages, play an irreplaceable role in these fields.

Automotive: In automotive manufacturing, flanges are used to connect engine, transmission, chassis, and other components. They not only ensure the tight fit between parts but also enhance the overall performance and safety of the vehicle.

Medical: In medical equipment, flange connectors are used to connect various fluid transfer pipes, valves, and filters. These connectors need to have high sealing performance and corrosion resistance to ensure the normal operation of medical equipment and patient safety.

Electronics: In the electronics industry, flanges are used to connect cooling systems, gas transfer pipes, and other components. Their high precision and reliability ensure the stable operation and longevity of electronic devices.

Petrochemical Industry: The petrochemical industry is one of the most extensive fields of flange application. Due to the flammable, explosive, toxic, or highly corrosive nature of the substances involved, flange connectors must have high sealing performance and corrosion resistance. Furthermore, due to the large size and complex structure of petrochemical equipment, the standardization and interchangeability of flanges are particularly important.

Power Generation: In power plants, flanges are used to connect boilers, turbines, generators, and other critical equipment. They not only withstand high-temperature and high-pressure working environments but also need to ensure the sealing and stability at the connection points to guarantee the normal operation of the power plant.

Marine Industry: Flange connectors in the marine industry need to withstand seawater corrosion, wave impact, and other harsh environments. Therefore, these flanges are usually made of special materials and undergo special anti-corrosion treatments to ensure their long-term stable performance.

Construction and Manufacturing: In the construction and manufacturing industries, flanges are used to connect various pipes, valves, and equipment. They not only simplify the installation process but also improve the reliability and maintainability of the system.

The working principle of flange connections mainly relies on the pretension of bolts and the sealing action between the flange face and the gasket. When the bolts are tightened, they generate a pretension force that tightly compresses the two flanges together. At the same time, the gasket is clamped between the two flange faces, deforming elastically and plastically to fill the small gaps between the flange faces, achieving a sealing effect. As the working pressure increases, the gasket is further compressed, enhancing the sealing performance.

Flanges come in a variety of types, each with specific uses and advantages. Below are some common flange types and a brief introduction:

Socket Weld Flange: The pipe is inserted into the socket of the flange and welded to connect. This flange has a simple structure and low cost, suitable for low-pressure, normal-temperature fluid transfer systems.

Lap Joint Flange: Consists of a flange body and a loose ring. The loose ring can slide on the flange body, facilitating installation and disassembly. Suitable for situations requiring frequent disassembly and cleaning.

Blind Flange: Has no central hole and is used to seal the end of a pipe or for pressure testing. It has the same pressure rating and sealing performance as the piping system.

Slip-On Flange: The pipe is slid into the flange and then welded. This flange offers high strength and rigidity, suitable for high-pressure, high-temperature fluid transfer systems.

Threaded Flange: Screwed onto pipes with corresponding threads. This quick and convenient connection method is suitable for low-pressure, small-diameter piping systems.

Long Weld Neck Flange: Features a long neck that provides better strength and rigidity, reducing welding stress on the flange itself. Commonly used in high-pressure, high-temperature, or corrosive media piping systems.

Orifice Flange: Typically used to install orifice flow meters to measure the flow rate of fluid in the pipe. Designed to meet the installation requirements of flow meters and ensure measurement accuracy.

Expander Flange: A special flange designed to allow some expansion or contraction of the piping system during temperature changes, avoiding stress concentration and damage. Commonly used in long-distance, large-diameter hot water or steam piping systems.

Nipo Flange: A special weld-neck flange designed to address welding stress issues, providing better welding quality and sealing performance. Used in high-pressure, high-temperature piping systems.

Reducing Flange: Has a bore smaller than the outer diameter of the pipe, connecting the pipe to the flange through a reduced section. Suitable for situations requiring reduced fluid velocity or changes in flow direction.

High-Hub Flange: Features a higher hub part, providing better rigidity and strength, increasing the contact area between the flange and the pipe, and enhancing sealing performance. Commonly used in heavy-duty equipment and high-pressure piping systems.

Ring-Type Joint (RTJ) Flange: Uses a metal ring as a sealing element, achieving sealing through high pressure. This flange connection offers high sealing performance and resistance to high temperature and pressure, suitable for highly corrosive media.

T&G (Tongue & Groove) Flange: Achieves connection through tongue-and-groove fit, offering high connection precision and sealing performance. Suitable for situations requiring precise control of fluid flow direction or high sealing requirements.

Lens Flange: A special blind flange designed like a pair of glasses, allowing internal inspection and maintenance without disassembling the entire piping system. Used in piping systems that are difficult to access or require frequent inspections.

The flange face type is a crucial factor influencing the sealing performance of flange connections. Different flange face types are suitable for different operating conditions and requirements.

Raised Face (RF): One of the most common flange face types, its surface is convex. When used with a gasket, it achieves a good sealing effect, suitable for medium and low-pressure piping systems.

Male and Female Faces (M&F): Achieves connection through concave-convex fit, providing higher connection strength and sealing performance. Commonly used in high-pressure, high-temperature, or corrosive media piping systems.

Flat Face: The surface is flat, suitable for low-pressure, normal-temperature fluid transfer systems. Its simple structure and easy processing result in lower costs.

Ring Joint Face (RTJ): Uses a metal ring as the sealing element, achieving sealing through high pressure. This flange connection has high sealing performance and resistance to high temperature and pressure, suitable for highly corrosive media.

The dimensions of flanges are critical for their performance and connection effectiveness. It is essential to ensure the correctness and consistency of flange dimensions during selection and use.

Thickness

The thickness of a flange directly impacts its strength and rigidity. Flange thickness varies depending on working pressure and pipe diameter. Proper calculations and selections based on actual requirements are necessary.

Nominal Bore

The nominal bore refers to the size of the central hole in the flange, which should match the outer diameter of the pipe. An incorrect bore size can affect the sealing performance and stability of the connection.

Bolt Circle Diameter

The bolt circle diameter refers to the diameter of the circle formed by the bolt holes on the flange. It determines the number and distribution of bolts, significantly affecting the connection strength and sealing performance.

Pipe Dimensions

Pipe dimensions include the pipe's outer diameter, wall thickness, and length. Flanges must be matched to the actual dimensions of the pipe to ensure a tight fit and effective sealing.

Nominal Diameter

The nominal diameter (DN) is an essential parameter of flange dimensions, representing the nominal diameter of the connected pipe. Different nominal diameters correspond to various flange sizes and connection capacities, so selecting the appropriate flange specification based on the pipe's nominal diameter is crucial.

Flange Dimension Tables

To facilitate selection and use, detailed tables of flange dimensions are often provided. These tables list key parameters such as flange outer diameter, bolt circle diameter, number of bolt holes, bolt specifications, and flange thickness for various nominal diameters. These tables are vital references for engineers in designing, procuring, and installing flanges.

Flanges are classified and rated based on their ability to withstand working pressure, temperature, and media characteristics. Different classifications and service ratings entail varying structural designs and material requirements to meet different operating conditions.

Common Classifications Include:

150#: Suitable for low-pressure piping systems, typically with a working pressure not exceeding 1.6 MPa.

300#: Designed for medium-pressure piping systems, with a working pressure between 1.6 MPa and 4.0 MPa.

600#, 900#, 1500#, 2500#: These ratings are used for high-pressure and ultra-high-pressure piping systems, with increasing working pressures for different high-pressure conditions.

In pipeline systems and pressure vessels, flanges are disc-shaped components used for connection or assembly. They are paired with another flange and fastened with bolts to form a sealed container or pipeline connection. Adhering to standards and marking conventions is crucial for ensuring proper selection and use of flanges.

Flange Standards

Flange standards define the design, dimensions, materials, and manufacturing processes for flanges. These standards are typically set by international or national standardization organizations such as ISO (International Organization for Standardization), DIN (German Industrial Standards), ANSI/ASME (American National Standards Institute/American Society of Mechanical Engineers), JIS (Japanese Industrial Standards), and GB (National Standards of China). These standards specify requirements for flange dimensions, tolerances, materials, and testing methods.

Flange Markings

Flange markings provide detailed information about the flange, usually including the manufacturer's logo or code, ASTM material specifications, material type, pressure-temperature rating, service rating, dimensions, thickness, and bore size. This information helps users quickly identify and utilize flanges, ensuring compliance with relevant standards and specifications.

Manufacturer's Logo or Code: Each flange manufacturer marks their products with a logo or code, aiding in product identification, quality assurance, and traceability.

ASTM Material Specifications: ASTM (American Society for Testing and Materials) provides material specifications defining the chemical composition and mechanical properties of materials used for flanges.

Material: The material of the flange is a critical attribute, affecting mechanical performance and corrosion resistance. Common materials include carbon steel, stainless steel, alloy steel, and copper alloys.

Pressure-Temperature Rating: This rating specifies the operational limits of the flange under specific pressure and temperature conditions to ensure safe system operation.

Dimensions: Flange dimensions include outer diameter, inner diameter, and bolt hole center distances, which must conform to relevant standards for compatibility with other flanges and pipeline components.

Thickness: Flange thickness is a key factor in its strength and stability, usually determined based on working pressure and pipe diameter.

Heat Index: The heat index indicates the flange's performance at high temperatures, including heat resistance and oxidation resistance.

Bore Size: The bore size refers to the diameter of the bolt holes on the flange, related to bolt size and flange strength.

Special Identifiers: Special identifiers such as "QT" for quenching and tempering, "W" for welded repair, etc., provide information about special treatments or characteristics of the flange.

By following these detailed standards and markings, users can accurately select and use flanges suited to their specific application needs, ensuring the safety and reliability of the system.

The flange production process involves a series of steps and procedures to ensure the quality and performance of the product.

Different Production Processes

Forged Flanges: Made by forging metal into the desired shape, resulting in high strength and wear resistance. The forging process improves the internal structure and mechanical properties of the flange, suitable for high-pressure, high-temperature working conditions.

Plate Flanges: Made from steel plates cut and machined into the required shape. This simple and cost-effective process produces flanges suitable for low-pressure, normal-temperature fluid transfer systems.

Welded Flanges: Connected by welding, forming a strong bond between the flange and the pipe. Welding ensures high strength and sealing performance, suitable for high-pressure, high-temperature fluid transfer systems.

Threaded Flanges: Screwed onto pipes with corresponding threads, providing a quick and convenient connection method. Suitable for low-pressure, small-diameter piping systems.

Casting Flanges: Made by pouring molten metal into a mold, producing flanges with complex shapes. This process ensures high precision and surface quality, suitable for piping systems with special shape or size requirements.

Conclusion

Flanges play a crucial role in various industrial fields, providing reliable and detachable connections for pipes, valves, pumps, and other equipment. Understanding their types, applications, connection methods, and production processes is essential for selecting the right flange for specific needs and ensuring the efficiency and safety of piping systems.

The machining process of flange components involves multiple stages, including material selection, cutting and forming, heat treatment, machining, surface treatment, and inspection and quality control. Each stage significantly impacts the quality and performance of the final product.

Choosing the right material for flanges is crucial based on the working environment and performance requirements. Common flange materials include carbon steel, stainless steel, alloy steel, and special alloys. These materials offer different strengths, corrosion resistance, and high-temperature performance to meet various operational needs.

Material Cutting and Forming

Flange manufacturing typically starts with material cutting. This can be done using methods like sawing, shearing, or flame cutting to cut the raw material into appropriate sizes. Subsequently, the material is shaped into the flange form through stamping, forging, or machining processes.

Heat Treatment

For flanges requiring improved material properties, heat treatment is often necessary. Heat treatment processes include annealing, normalizing, quenching, and tempering, aimed at enhancing the material's strength, hardness, and toughness.

Forming and Forging

For large or complex flanges, forming or forging processes may be required. Forming processes include rolling and pressing, while forging involves using a forging press to shape the metal into the desired form and size.

CNC Machining is a critical stage in flange manufacturing, involving processes such as drilling, tapping, milling, and turning. These processes ensure precise dimensions and shapes of the flange, conforming to relevant standards and specifications.

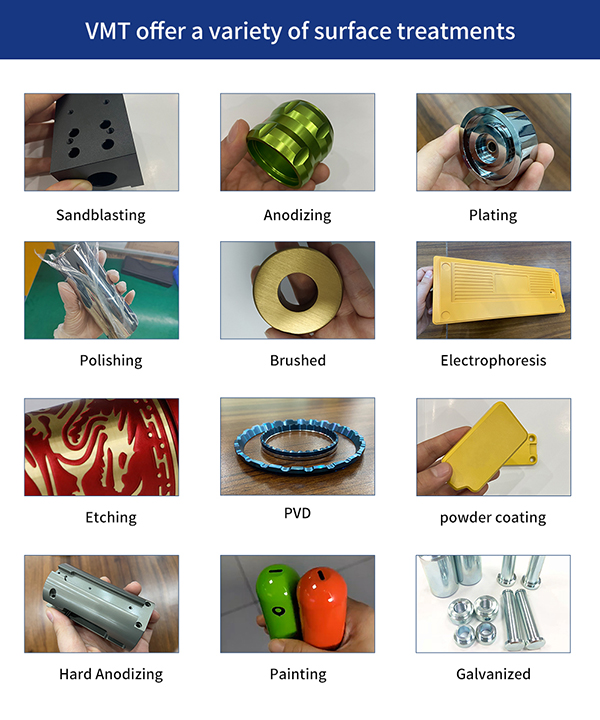

Surface treatment enhances the corrosion resistance and appearance of the flange. Common methods include sandblasting, painting, plating, and thermal spraying. These methods remove oxidation and dirt from the flange surface and apply a protective layer or coating.

Inspection and Quality Control

Strict inspection and quality control are essential throughout the flange manufacturing process. This includes material inspection, dimensional checks, non-destructive testing (such as ultrasonic testing and radiographic inspection), and performance testing. These measures ensure that the flange meets relevant standards and specifications.

Flanges play a crucial role in piping systems as essential components for connecting pipes, valves, and other equipment. Understanding flange types, applications, connection mechanisms, and machining processes is vital for engineers and technicians. This comprehensive overview aims to provide readers with a thorough understanding and valuable reference for their work in relevant fields.

What material is best for making flanges?

The best material for flanges depends on various factors including medium characteristics, working environment, cost, reliability, and sustainability. Common materials include:

Carbon Steel: Economical and easy to process, suitable for non-corrosive or mildly corrosive media. However, it is prone to rust in moist or oxygen-rich environments, requiring corrosion protection.

Stainless Steel: Known for excellent corrosion resistance and mechanical properties, widely used in corrosive environments such as chemical, pharmaceutical, and food industries. Various types include austenitic, ferritic, and martensitic stainless steels to meet different medium needs.

Alloy Steel: Enhanced with alloying elements to significantly improve strength, hardness, wear resistance, and corrosion resistance. Commonly used in high-temperature, high-pressure, heavy-duty, or corrosive conditions.

Cast Iron: Cost-effective but relatively weak in mechanical performance and corrosion resistance. Mainly used in low-pressure, non-corrosive media systems such as water supply and fire protection.

Special Alloys: Such as nickel-based alloys and titanium alloys, suitable for extreme conditions like high temperature, high pressure, or strong corrosive environments.

What are the specifications of flanges?

Flange specifications are typically indicated by their nominal diameter (DN), such as DN25, DN40, DN50, DN100, DN125, DN450, DN500, DN600, etc. These specifications represent the nominal size of the pipe or equipment being connected. Additionally, flange specifications include thickness, bolt hole quantity, and bolt hole diameter, which are determined according to specific standards and design requirements.

When is it best to use flange fittings?

Flange fittings are widely used in scenarios where pipes, valves, and equipment need to be connected with high sealing requirements. Ideal applications include:

Oil, Chemical, Pharmaceutical Industries: Where flanges ensure the sealing and safety of connections handling corrosive, high-temperature, high-pressure, or flammable substances.

Marine and Hydraulic Engineering: In these fields, flanges provide stable connections and reliable sealing for pipes and equipment subjected to high pressure and vibration.

Construction Sites: For pumps, pipes, and HVAC systems, flanges ensure proper operation and smooth medium transfer.

What types of flanges are there?

Flanges come in various types based on different classification standards:

By Connection Type: Weld neck flange, slip-on flange, blind flange, threaded flange, socket weld flange, lap joint flange, etc.

By Sealing Face Type: Raised face (RF), male and female face (M&F), tongue and groove (T&G), ring joint (RJ), etc.

By Special Use: Vacuum flange, high-pressure flange, special alloy flange, etc.

What are the three types of flanges?

The three common types of flanges are:

Weld Neck Flange: Features a long neck and is welded to the pipe, providing strength and reducing stress.

Slip-On Flange: Slides over the pipe and is welded on the outside, suitable for high-pressure applications.

Blind Flange: Used to seal the end of a pipe or for pressure testing, it has no central hole.

What is the difference between flanges and threads?

Flanges and threads are different methods of pipe connection with notable differences:

Structure: Flange connections use bolts to join two flanges together, while threaded connections use screw threads to connect pipes.

Application: Flanges are suitable for high-pressure, large-diameter systems, often used in industrial applications, while threads are used for low-pressure, small-diameter systems, common in residential and small-scale projects.

Performance: Flanges offer better sealing and can handle higher pressure, while threaded connections are easier to install and remove but offer less sealing performance.

What is the difference between couplings and flanges?

Couplings and flanges are distinct mechanical components with differences:

Structure: Couplings connect two shafts to transmit torque and motion, while flanges connect pipes, valves, and equipment.

Function: Couplings ensure synchronous rotation of connected shafts, while flanges provide a seal and stability for pipe connections.

Application: Couplings are used in machinery like lathes and pumps, whereas flanges are used in piping systems in industries like oil, chemical, and pharmaceutical.

Are flanges considered fasteners?

While flanges are not classified as fasteners themselves, they work closely with fasteners (such as bolts and nuts) to form a connection system for pipes, valves, and equipment. Flanges provide the connection surface, and fasteners create the necessary clamping force to ensure a tight seal and connection.

In summary, although flanges are not standalone fasteners, they play a crucial role in connection systems, working with fasteners to ensure stability and sealing. Flange connections are common and vital in pipeline systems, allowing for maintenance and replacement without affecting other parts of the system.