15 years one-stop China custom CNC machining parts factory

CNC Machining: Stainless Steel Underwater Temperature and Water Flow Thermometer Housing

Client Company Name: Institute of Geology, Chinese Academy of Geological Sciences

Customer requirements: Because the production of pipe materials is more cost-effective, how many processes do we use to complete it, the appearance is beautiful and the stainless steel tube can withstand 10MPA pressure, and it will not rust when used below 50 meters in seawater, all imported from South Korea SUS316L.

Quantity: 60000 pieces

Material: SUS316L South Korea Pohang

CNC machining method: CNC machining + preliminary welding + fine welding + CNC turning + polishing

Delivery time: 35 days

Some time ago, we received an inquiry from the Institute of Geology of the Chinese Academy of Geological Sciences. We need to make an underwater temperature and water flow detector shell. The customer requires the stainless steel tube of the product to withstand 10MPA pressure, and it will not rust when used under 50 meters of sea water.

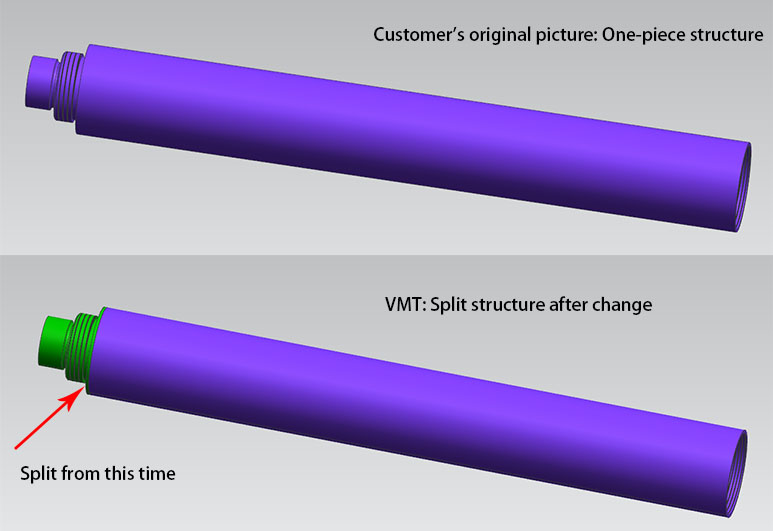

This product is called a seawater temperature measuring stick. The main body material is SUS 316 L. According to the original structure of the customer, this product is not mass-produced because the main body has an inner hole diameter of 23.5mm and a depth of 21 4mm. According to conventional practices, The processing cost will be very high.

After careful research and verification by the Weimat engineering department, the split + welding scheme was finally adopted, that is, the head thread and the main body shell are processed separately. After the two parts are processed, the parts are welded by seamless welding, finally Use a CNC lathe to smooth the overall surface, process the dimensions in place, and remove the solder joints produced by welding. According to this process, the cost of the product made is directly reduced by 10 times, and the product has also passed the strength and tightness test.

Because the use of tube materials to produce has an advantage in cost, we use a variety of processes to complete it. We use CNC machining + preliminary welding + fine welding + CNC turning + polishing to complete this product. In the end, VMT also helps customers succeed. The mass production of this product.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!