15 years one-stop China custom CNC machining parts factory

Home / Product / Aluminum Parts /

As your aluminum CNC machining manufacturer, we have 40+ aluminum alloy materials, 100 CNC machining equipment, and 12 quality inspection processes. can provide you with a solution tailored to your specific needs.

Product Specification:

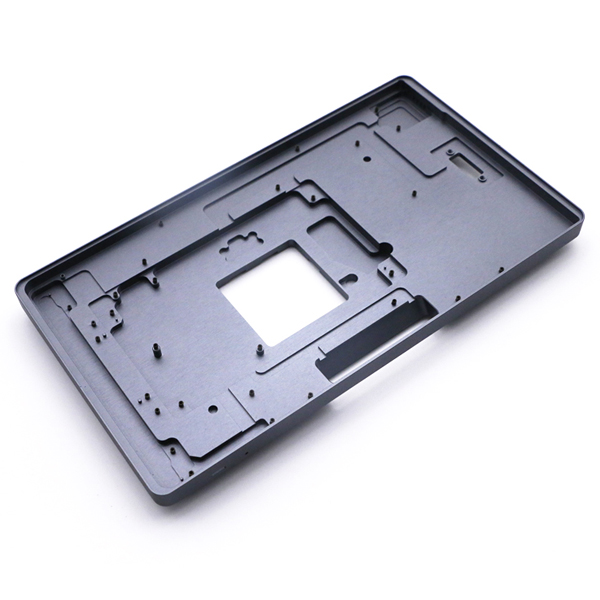

Custom Face Recognition Door Access Control System Shell CNC Machining Zkteco Face Biometric Recognition Terminal Housing

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

|

Welcome to our world of custom CNC machining for face recognition door access control system shells. We excel in creating shells that not only protect but also enhance the aesthetics of this critical security component. Here's an insight into our comprehensive services, including prototyping, surface treatment, and material selection: |

Custom CNC Face Recognition Door Access Control System Shell Prototyping Machining

Our journey begins with precise prototyping. We work closely with you to understand your design preferences and functionality requirements. Prototypes allow us to fine-tune the design and ensure it aligns perfectly with your vision. |

|

|

|

|

||

Custom CNC Face Recognition Door Access Control System Shell Surface Treatment |

Custom CNC Face Recognition Door Access Control System Shell Material |

||

|

Enhance the visual appeal and protection of your access control system shell with our exceptional surface treatments. Options include polished finishes, matte coatings, anodized colors, and more, each tailored to your style preferences. |

Selecting the right material is essential for durability and aesthetics. We offer a range of materials, including stainless steel, aluminum, and specialized alloys, each chosen for its unique properties, ensuring the longevity and robustness of your access control system shell. |

|

|

|

||

|

|

|||

|

|

|

|

Welcome to the realm of custom CNC machining for face recognition door access control system shells, where surface treatments are pivotal in both elevating the visual appeal and ensuring the functionality of your security component. We offer a range of surface treatments tailored to your specific requirements. Here's a closer look at our surface treatment options: |

|

1. Anodizing: Elevating Durability

One of the most popular choices for surface treatment is anodizing. This process involves creating a protective oxide layer on the surface of aluminum housings. It not only enhances the housing's durability but also provides excellent corrosion resistance, crucial for outdoor installations. |

|

|

2. Powder Coating: A Burst of Colors and Protection

Powder coating offers a wide spectrum of color options and finishes. The process entails applying a dry powder to the housing's surface electrostatically. Once cured, it results in a smooth and vibrant finish, ideal for adding a touch of personalization while protecting the housing. |

|

|

|

3. Polishing: Achieving a Mirror Finish

For those aiming for a high-end and reflective appearance, polishing is the way to go. CNC-machined housings can be meticulously polished to achieve a mirror-like finish, adding a touch of sophistication to the overall design. |

|

|

|

4.Paint and Graphics: Branding and Customization

Custom paint and graphics application offer a canvas for branding and customization. Company logos, color schemes, and unique designs can be applied, reinforcing brand identity and making the housing stand out. |

|

|

|

5. Hard Coating Anodizing: Ultimate Protection

When utmost protection is required, hard coatings come into play. Options like anodized hard coat or PVD coatings provide exceptional resistance against wear and tear. These coatings are particularly valuable for installations in harsh environments. |

|

|

|

6. Hydrographics: Uniqueness Redefined

Hydrographics, also known as water transfer printing, enables the application of intricate patterns and designs to the housing's surface. This method allows for truly unique and eye-catching appearances that can set your access control system apart. |

|

|

|

7. Laser Engraving: Precision Personalization

Laser engraving is an option for adding precise and intricate designs or text to the housing's surface. It's an excellent choice for labeling or branding purposes. |

|

|

| In conclusion, the choice of surface treatment for CNC-machined housings for face recognition access control systems is pivotal. Whether you prioritize durability, aesthetics, or branding, there is a surface treatment method that aligns with your goals. By tailoring the treatment to your specific needs, you can ensure that your access control system not only functions flawlessly but also leaves a lasting impression. |

| When it comes to custom CNC machining for face recognition door access control system shells, we offer a range of material options to cater to your specific needs and preferences. Here are some of the materials we can work with: |

|

|

Stainless Steel Face Recognition Door Access Control System Shell

Strength: Stainless steel is known for its exceptional strength and durability.

More Details>> |

|

|

|

Aluminum Face Recognition Door Access Control System Shell

Lightweight: Aluminum is a lightweight option without compromising on strength. Durability: Despite its lightweight nature, aluminum is durable and resistant to corrosion, making it a reliable choice for protecting the components of your access control system.

More Details>> |

|

|

|

Brass Face Recognition Door Access Control System Shell

Classic Appearance: Brass exudes a classic and elegant appearance with its warm, golden tones.

More Details>> |

|

|

|

Titanium Face Recognition Door Access Control System Shell

Lightweight Strength: Titanium is lightweight yet exceptionally strong.

More Details>> |

|

|

|

Custom Face Recognition Door Access Control System Shell(Specialized Alloys: Tailored Solutions)

Customization Opportunities: Specialized alloys can be tailored to meet your exact specifications, ensuring that the access control system shell aligns perfectly with your project's needs.

More Details>> |

|

|

|

Polymer or Plastic Face Recognition Door Access Control System Shell

For cost-effective options, polymer or plastic materials are available.

More Details>> |

|

| Ultimately, the best material choice will depend on your specific needs, budget, and design preferences. Our team can provide further guidance based on your project requirements to ensure you select the most suitable material for your face recognition door access control system shell. |

| When it comes to manufacturing face recognition door access control system shells, precision and customization are paramount. CNC machining is the go-to method for creating these specialized enclosures. Let's dive into the manufacturing process, highlighting key steps and considerations while incorporating the essential keywords throughout. |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The process begins with meticulous design and CAD (Computer-Aided Design) modeling. Engineers create detailed 3D models of the face recognition door access control system shell, ensuring it meets the specific requirements of the project. |

|

2. Material Selection

Material Selection: Choosing the right material is crucial. Typically, materials like aluminum, stainless steel, or plastic are used for CNC machining these shells. The selection depends on factors such as durability, weight, and environmental conditions. |

|

3. CNC Machining

CNC Machining: The heart of the manufacturing process is CNC machining. Computer Numerical Control (CNC) machines precisely carve out the shell from the chosen material. CNC machining offers unparalleled accuracy, enabling the creation of intricate designs and precise dimensions. |

|

4. Surface Treatment

Surface Treatment: To enhance both aesthetics and functionality, the enclosures are available in a variety of finishes: anodized, powder coated, polished, custom paint and graphics, hardcoat, and more are ideal options. |

|

5. Quality Control

Quality Control: Thorough quality control is essential to ensure that each face recognition door access control system shell meets the highest standards. Precise measurements, durability tests, and visual inspections are performed to guarantee the shell's functionality and appearance. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

6. Assembly and Testing

Depending on the project requirements, the shell may need to be integrated with various components of the access control system. This includes mounting for cameras, sensors, and wiring pathways. |

|

7. Packaging and Delivery

The final step involves careful packaging to protect the shell during transit. It's then delivered to the installation site, ready for seamless integration into the access control system. |

|

In conclusion, the manufacturing process for face recognition door access control system shells is a precise and highly customizable endeavor. CNC machining, with its precision and versatility, plays a central role in creating these specialized enclosures. By selecting the right materials and surface treatments, and adhering to strict quality control standards, manufacturers can ensure that these shells not only provide robust protection for the access control system but also contribute to the overall aesthetics and functionality. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Machining Face Recognition Door Access Control System Shell FAQs

| Certainly! Here are some common FAQs (Frequently Asked Questions) related to custom CNC machining for Face Recognition Door Access Control System Shells: |

|

1. What materials are commonly used for CNC machining Face Recognition Door Access Control System Shells?

Common materials include aluminum, stainless steel, and various plastics. The choice depends on factors such as durability, weight, and environmental conditions.

CNC machining stands for Computer Numerical Control machining, a precise method that uses computer-controlled tools to create complex designs. It's preferred for its accuracy and versatility, allowing for intricate shell designs.

Yes, customization is a key advantage of CNC machining. You can apply custom paint, graphics, and even branding to the shells to align them with your specific needs.

Yes, you can opt for surface treatments like anodizing, powder coating, or hard coatings to enhance the shells' resistance to environmental factors, making them suitable for outdoor installations.

Quality control measures include precise measurements, durability tests, and visual inspections to ensure that the shells meet the highest standards in terms of functionality and appearance.

Yes, the shells can be designed to accommodate components like cameras, sensors, and wiring pathways, allowing for seamless integration into the access control system.

Lead times can vary depending on the complexity of the design and the quantity required. It's advisable to consult with the manufacturer for specific lead time estimates.

Minimum order quantities may vary among manufacturers. It's best to inquire with the manufacturer about their specific requirements.

To receive a quote, you can contact the CNC machining provider directly through their website or customer service channels. They will typically require detailed information about your project specifications.

Provide detailed design specifications and collaborate closely with the manufacturer to ensure the shells are tailored to your access control system's unique needs.

|

| We hope these FAQs answer your questions. If you have more questions or need further assistance, please do not hesitate to contact our dedicated customer support team. We are here to help you create the perfect custom CNC machined face recognition access control system enclosure for your vehicle. |

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.