15 years one-stop China custom CNC machining parts factory

3 |

Published by VMT at Dec 25 2025 | Reading Time:About 2 minutes

3 |

Published by VMT at Dec 25 2025 | Reading Time:About 2 minutes

Materials capable of adapting to various environments and applications are a convenient go-to for manufacturers, 1055 steel is certainly one such example. Thanks to its excellent performance, cost-effectiveness and ease of supply, 1055 steel has well-performed among many manufacturers for making outdoor tools like knives, mechanical parts, and automotive structural components, etc. Here’s what you should know about it: 1055 steel’s composition, properties, manufacturing processes, equivalents, formats and applications, and pros and cons.

Meet the medium carbon steel (about 0.50%~0.60% carbon content) that has outstanding toughness, impact resistance and reliable heat treatment response. And you can find it does all of the pros at an affordable price. Because of its non-alloy steel, 1055 steel has a simple structure and composition and its performance can be enhanced by heat treatment. For 1055 steel’s chemical composition, they are:

Composition and structure contribute to 1055 carbon steel relative high hardness. Hardness together with unique impact resistance of medium carbon steel make 1055 steel well-suited for making products like axes, machetes, impact tools or structural components,etc.

The physical and mechanical properties of 1055 steel are outlined in Table 1 below:

Table 1 :Physical and Mechanical Properties of 1055 Steel

| Property | Value |

| Density | 7.85 g/cm³ |

| Ultimate Tensile Strength (UTS) | ≈ 660 MPa |

| Yield Strength (YS) | ≈ 560 MPa |

| Elongation | ≈ 10% |

| Brinell Hardness (HB) | ≈ 197 HB |

| Elastic Modulus ( E) | 190–210 GPa |

Properties of 1055 Steel Table Credit: azom

1055 steel’s yield strength and hardness contribute to its reliability if the product is subjected to high load impacts such as bending, hammering, and cutting. And its 10% of elongation ensures good toughness while its elastic modulus gives 1055 steel’s overall stiffness. All of the properties prevent 1055 steel’s products from excessive vibration and elastic deformation when machining.

If you want to heat treat 1055 steel well, there’s a necessity to watch out steps of annealing, quenching, and tempering. 1055 steel’s annealing should keep furnace cooling at 750–780°C to reduce its hardness,and improve the machinability. Subsequent quenching of 1055steel should keep water or oil quenching at 820–870°C to increase hardness up to approximately 55 HRC. And then 1055 steel is tempered ( 200–350°C) to reduce brittleness caused by quenching and improve overall toughness of the product. Proper heat treatment of 1055 steel will finally promote a good balance between hardness and toughness.

In CNC machining manufacturing, 1055 steel shows medium to high machining difficulty. With a carbon content of approximately 0.50–0.60%, it is harder to machine than 1045 steel but easier than 1060 and 1095 steel. The higher carbon level increases strength and hardness, which can lead to faster tool wear if cutting conditions are not well controlled.

Carbide cutting tools are strongly recommended, along with adequate coolant to reduce heat during machining. For the best machining performance and surface finish, 1055 steel should be processed in the annealed condition. Machining after hardening heat treatment becomes significantly more difficult.

Welding 1055 steel requires special attention due to its medium-carbon composition. This material is proned to to harden in the heat-affected zone, which increases the risk of cracking.

To reduce this risk, preheating to 150–300°C is typically required before welding. After welding, post-weld tempering is recommended to relieve internal stress and reduce hardness. Controlled heating and cooling are essential to achieve reliable weld quality and prevent weld-related defects.

During forming, 1055 steel is prone to work hardening, especially in cold working conditions. This behavior increases forming forces and limits deformation.

For this reason, hot forming is generally preferred, with typical forming temperatures of 900–1100°C to ensure good plasticity. When full hot forming is not required, warm forming at 600–750°C offers a practical alternative. This temperature range helps reduce forming loads while allowing better control of oxidation and dimensional accuracy. Proper temperature selection plays a key role in achieving stable forming results.

1055 steel has good polishability and can achieve high-quality surface finishes. However, it is a plain carbon steel and lacks inherent corrosion resistance. Without protection, it is susceptible to rust in humid or corrosive environments.

To improve durability, protective surface treatments such as oil coatings, black oxide treatment, or protective coatings are commonly applied. The chosen surface treatment should match the service environment and application requirements.

You’ll find AISI 1055 steel available in a variety of forms in the markets. Common available formats include:

Bars of Round,Square, and Flat

These are the most common forms of 1055 steel, suitable for machining such as turning, milling, and forgin.Diameters and specifications range from small bars to large bars.

Coils

These are more flexible forms and can be cut or formed into sheets or strips. You can use them for continuous stamping, bending, or forming operations.

Cold-Rolled Sheet

Cold-rolled sheets usually have a smooth surface and can be made to achieve good dimensional accuracy. The thickness of them basically range from 0.5-3mm. You can use them for making stamped parts, thin-walled components, and knife blanks,etc.

Hot-Rolled Plate

These have good toughness and are suitable for welding. You can further heat treat them into the parts you want. They are ideal for making medium and large parts thanks to their wide range of thickness.

Forgings (Bars & Blocks)

Forged 1055 steel has higher density and better mechanical properties. They are ideal for parts that need good impact resistance,such as heavy-duty components, axes, knives, and structural parts.

Knife Blanks

Because 1055 steel has good toughness and a moderate hardness range, many suppliers directly provide knife blanks for the production of impact knives such as axes, machetes, and tool blades.

Custom Dimensions

Suppliers typically offer cut-to-length, precision-ground, laser-cut, and forged net-shape parts to help reduce machining allowances and production time.

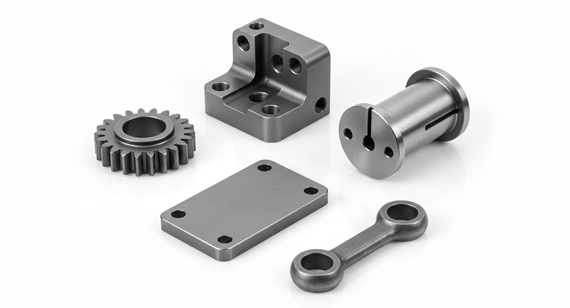

You will find carbon steel 1055 is widely applied to manufacture products that balance strength, abrasion resistance, and impact absorption, like:

1. Manufacturing

1055 carbon steel is commonly used to produce cutting tools and molds, particularly for tools that require long-lasting sharpness and durability, such as:

In the automotive sector, 1055 carbon steel is ideal for components that bear high stress and dynamic loads, including:

Its high strength and fatigue resistance make it suitable for critical automotive structural parts.

3. Aerospace Industry

Used in components requiring a high strength-to-weight ratio, such as:

These parts endure significant stress during operation, and 1055 carbon steel provides the necessary reliability.

4. Energy Sector

In the oil, gas, and other energy industries, 1055 carbon steel is used for equipment that demands high wear resistance and durability:

5. Agriculture

Widely adopted in agricultural machinery to improve durability and reduce downtime due to tool wear, such as:

6. Construction

Used in rebar and structural components, its high strength and hardness enhance the durability of buildings and infrastructure.

7. Marine Industry

In shipbuilding, 1055 carbon steel is used for high-strength, corrosion-resistant components, such as:

8. Hand & Household Tools

Used in a variety of hand tools to increase durability and lifespan, including:Hammers, chisels, pry bars and various knives.

9. Sporting Goods

Ideal for manufacturing lightweight, high-strength sports equipment, such as:

10. Fasteners

Bolts, screws, and other fasteners are often made from 1055 carbon steel to ensure secure and reliable mechanical connections.

Comparable grades of 1055 medium carbon steel vary across countries or regions, and the following grades are generally considered to the equivalent:

Table 2: Equivalents of 1055 Steel

| Standard System | Equivalent Grade | Notes |

| GB (China) | 55# / 55 | Common carbon structural steel in China, approx. 0.55% carbon content |

| AISI / SAE (USA) | 1055 | Equivalent to GB 55#, commonly used for knives, axes, and shafts |

| ASTM / UNS (USA) | G10550 | Reference for structural steel and heat-treated parts |

| JIS (Japan) | S55C | Standard carbon steel, suitable for machined parts after heat treatment |

| DIN (Germany) | 1.1203 | German standard carbon steel, used for forged or machined parts |

| EN (EU) | C55E / C55R | EN standards: C55E for forgeable steel, C55R for tempered or quenched parts |

| BS (UK) | 070M55 | British standard carbon steel, equivalent to 1055 |

| ISO (International) | C55 | International standard, approx. 0.55% carbon content |

Using 1055 steel brings various advantages to suit your projects, main advantages include:

Here’s some limitations of 1055 steel you may watch out if you’re going to use this material in your project:

1. 1055 carbon steel vs 1045 carbon steel: Which one is better?

The choice depends on your needs. 1055 carbon steel is harder, offers better edge retention, and performs more reliably under stress while 1045 carbon steel is softer, easier to work with, and more affordable.

2. 1055 carbon steel vs 1060 carbon steel: What’s the difference?

1060 steel offers higher hardness and better edge retention while 1055 steel provides greater toughness and superior impact resistance.

3. 1055 carbon steel vs 1095 carbon steel: Which performs better?

1095 steel has excellent edge retention but is more brittle; 1055 steel is tougher, less prone to chipping, and suitable for impact-oriented blades.

4. Does 1055 steel rust?

Yes. As a carbon steel, 1055 will rust without proper care. Regular cleaning and oiling are required.

5. What standards and specifications apply to 1055 steel?

Common standards include: DIN 1.1209, ASTM A29, ASTM A510, ASTM A576, ASTM A682, FED QQ-S-700 (1055), SAE J403, SAE J412, SAE J414.

6. What is the price for 1055 steel in 2025?

In 2025, 1055 steel is roughly US $450–750/ton in China, US $1,050–1,300/ton in the United States, US $1,080–1,350/ton in Europe, US $900–1,200/ton in Japan, and US $700–1,000/ton in Russia. Actual prices can vary due to different forms, order size and others.

1055 steel, as a typical medium-carbon steel, has long held a stable position in the knife manufacturing, tooling, and machinery manufacturing industries due to its high toughness, good machinability, and controllable cost. If you are looking for a material that combines strength, reliability, and economy, 1055 steel is a choice worth considering.

You can get a free quote for a variety of services that we offer at VMT CNC machining factory, including options specific to 1055 steels or other materials, like laser cutting, CNC machining, and surface finishes. VMT CNC machining factory provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs.