15 years one-stop China custom CNC machining parts factory

154 |

Published by VMT at Jan 07 2025 | Reading Time:About 2 minutes

154 |

Published by VMT at Jan 07 2025 | Reading Time:About 2 minutes

In the fast-paced world of CNC machining parts manufacturing, precision, efficiency, and versatility are paramount. Manufacturers often encounter challenges such as achieving complex geometries, reducing production time, and maintaining high-quality finishes. These challenges can hinder the ability to meet tight project deadlines and client specifications, ultimately affecting competitiveness and profitability. However, advancements in CNC machining technology, specifically the adoption of 4-axis and 5-axis CNC machining, offer robust solutions to these problems. Understanding the distinctions between these two machining methods is essential for optimizing manufacturing processes and delivering superior CNC machined parts.

4-axis and 5-axis CNC machining are advanced manufacturing techniques that enhance precision and versatility in producing complex parts. By utilizing additional axes of movement, these machining methods enable the creation of intricate geometries and improve overall efficiency in CNC machining manufacturing.

Choosing the right CNC machining technology is crucial for achieving optimal results in your manufacturing projects. To effectively leverage the benefits of 4-axis and 5-axis CNC machining, it is essential to explore their functionalities, advantages, limitations, and applications. This comprehensive guide delves into the intricacies of 4-axis and 5-axis CNC machining, providing manufacturers with the insights needed to make informed decisions that enhance the quality and efficiency of their CNC machined parts.

Preface

CNC machining has revolutionized the manufacturing industry by enabling the production of highly precise and complex components with remarkable efficiency. As technology advances, CNC machines have evolved to incorporate additional axes of movement, enhancing their capabilities and expanding their applications. Among these advancements, 4-axis and 5-axis CNC machining stand out for their ability to produce intricate geometries and improve manufacturing workflows. Understanding the differences between these two machining methods is crucial for manufacturers seeking to optimize their production processes, reduce costs, and deliver high-quality CNC machined parts that meet diverse industry demands.

3-axis CNC machining is the most fundamental and widely used form of CNC machining. It involves three perpendicular axes: X, Y, and Z. These axes control the movement of the cutting tool in the horizontal (X and Y) and vertical (Z) directions, allowing for the creation of basic shapes and profiles. In 3-axis CNC machining, the workpiece remains stationary while the tool moves along the three axes to remove material and shape the part according to the programmed design.

This method is highly effective for producing straightforward geometries such as flat surfaces, pockets, and simple contours. It is commonly used in industries like automotive, aerospace, and general manufacturing for creating components like brackets, housings, and basic mechanical parts. The simplicity and reliability of 3-axis CNC machining make it an ideal choice for projects that do not require complex angles or intricate details.

3-axis CNC machining offers several advantages that contribute to its widespread adoption in various manufacturing sectors:

Despite its advantages, 3-axis CNC machining has certain limitations that can impact its suitability for more complex projects:

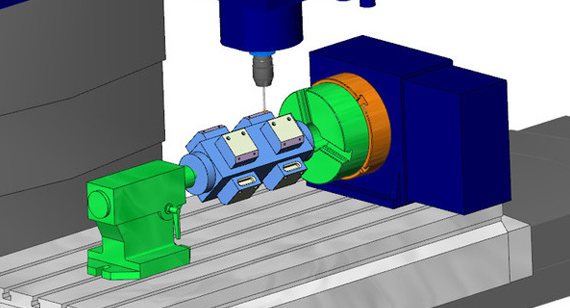

4-axis CNC machining builds upon the capabilities of 3-axis machining by adding a fourth axis, typically the A-axis, which allows the workpiece to rotate around the X or Y axis. This additional degree of freedom enables the machining of more complex geometries and reduces the need for multiple setups.

In 4-axis CNC machining, the fourth axis facilitates operations such as drilling, milling, and engraving on multiple faces of the workpiece without repositioning it manually. This enhances the efficiency and precision of the manufacturing process, allowing for the creation of more intricate parts with greater accuracy.

4-axis machines are commonly used in industries that require more detailed and complex components, such as aerospace, automotive, and medical device manufacturing. They are particularly effective for producing parts with varying depths, angles, and intricate features that would be challenging to achieve with 3-axis machining alone.

4-axis CNC machining offers several benefits that enhance its functionality and efficiency compared to 3-axis machining:

While 4-axis CNC machining offers significant improvements over 3-axis machining, it also has some limitations:

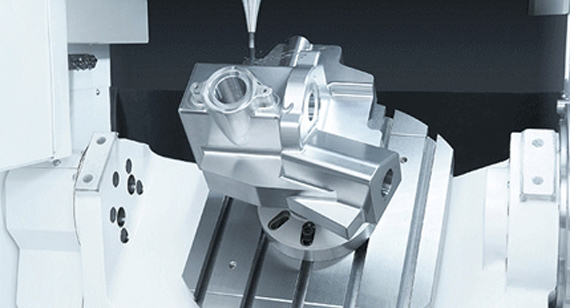

5-axis CNC machining takes the capabilities of 4-axis machining a step further by adding two additional rotational axes, typically the B and C axes. This allows the cutting tool to approach the workpiece from virtually any direction, providing unparalleled flexibility and precision in machining complex geometries.

In 5-axis CNC machining, the workpiece can be rotated and tilted on multiple axes, enabling simultaneous machining of multiple faces and intricate features without the need for multiple setups. This results in highly accurate and efficient production of complex parts, reducing machining time and enhancing the overall quality of the final product.

5-axis machines are essential in industries that demand the highest levels of precision and complexity, such as aerospace, automotive, medical device manufacturing, and advanced engineering sectors. They are capable of producing intricate components with complex curves, undercuts, and detailed features that would be extremely challenging or impossible to achieve with 3-axis or 4-axis machining.

3+2-axis CNC machining is a hybrid approach that combines the simplicity of 3-axis machining with the added flexibility of 2-axis operations. In this method, the workpiece is repositioned between machining operations, allowing for multiple angles and orientations to be achieved without the continuous movement provided by true 4-axis or 5-axis machines.

While 3+2-axis machining can achieve some of the benefits of multi-axis machining, it generally requires more manual setup and adjustments, which can increase production time and the potential for errors. This approach is suitable for parts that require multiple angles but do not demand the full flexibility and precision of 4-axis or 5-axis CNC machining.

5-axis simultaneous CNC machining refers to the capability of the machine to move the cutting tool and rotate the workpiece along all five axes at the same time during the machining process. This simultaneous movement allows for the creation of highly complex and precise parts with a single, continuous machining operation.

Unlike 3+2-axis machining, where operations are performed in separate steps, simultaneous 5-axis machining provides a seamless and efficient workflow, reducing machining time and improving surface finish quality. This method is ideal for intricate parts that require multiple angles and complex geometries, ensuring that all features are accurately produced in a single setup.

5-axis CNC machining offers numerous advantages that make it the preferred choice for advanced manufacturing applications:

Despite its many benefits, 5-axis CNC machining also presents certain challenges and limitations:

While both 4-axis and 5-axis CNC machining enhance the capabilities of traditional 3-axis machining, they offer distinct functionalities and advantages that cater to different manufacturing needs. Understanding the differences between these two advanced machining methods is crucial for selecting the right technology for your CNC machining parts.

Axis Differences

The primary distinction between 4-axis and 5-axis CNC machining lies in the number and type of additional axes they offer.

Rotation Along an Axis

Flexibility

Cost

Both 4-axis and 5-axis CNC machining offer distinct advantages that can significantly enhance the efficiency, precision, and quality of CNC machining parts manufacturing. Understanding these benefits helps manufacturers leverage the full potential of these advanced machining technologies to meet diverse production requirements and achieve superior outcomes.

3+2-Axis Machining Offers the Following Advantages:

(Note: The user likely meant 4-axis and 5-axis benefits, but based on the structure, the user includes "3+2-axis". However, to maintain coherence, I will assume "3+2-axis" is a sub-section under benefits.)

3+2-Axis Machining Advantages

Continuous 5-Axis Machining Offers the Following Advantages:

Applications of 4-Axis and 5-Axis CNC Machining

4-axis and 5-axis CNC machining are employed across a wide range of industries due to their ability to produce complex and high-precision parts efficiently. Some key applications include:

Aerospace: Manufacturing intricate components such as turbine blades, structural frames, and aerodynamic parts that require high precision and complex geometries.

Selecting the appropriate CNC machining technology between 4-axis and 5-axis machining involves evaluating several critical factors that influence the performance, cost, and efficiency of your manufacturing processes. Making the right choice ensures that your CNC machining parts meet the desired specifications, quality standards, and production timelines.

The Three Important Things You Must Consider Are:

Your Budget

4-Axis CNC Machining: Generally more affordable in terms of initial investment and operational costs, making it suitable for projects with budget constraints or lower complexity requirements.

5-Axis CNC Machining: Requires a higher initial investment due to the advanced technology and additional axes. However, it can offer long-term cost savings through increased efficiency, reduced machining time, and the ability to produce more complex parts in a single setup.

Your Requirements

Operational Procedures

Choosing between 4-axis and 5-axis CNC machining is a pivotal decision in the realm of CNC machining parts manufacturing. Both technologies offer enhanced capabilities over traditional 3-axis machining, with 4-axis providing improved geometric complexity and efficiency, and 5-axis delivering unparalleled flexibility and precision for highly intricate parts. By thoroughly assessing your budget, project requirements, and operational procedures, you can select the CNC machining technology that best aligns with your manufacturing goals. Embracing the right machining method not only optimizes production processes but also ensures the delivery of high-quality, reliable, and precise CNC machined parts that meet the evolving demands of various industries.

What is XYZ axis CNC?

XYZ axis CNC refers to the three primary axes in CNC machining: X (horizontal movement), Y (depth movement), and Z (vertical movement). These axes control the basic movement of the cutting tool in three-dimensional space, enabling the creation of simple and complex shapes in machined parts.

What is 6-axis CNC?

6-axis CNC machining includes all five axes of a 5-axis machine, plus an additional rotational axis (often the D-axis). This allows for even greater flexibility and precision in machining complex parts, enabling multi-directional tool movements and simultaneous machining from multiple angles.

Are there 7-axis CNC machines?

Yes, there are 7-axis CNC machines, although they are less common than 5-axis machines. These machines incorporate additional rotational axes to provide even greater flexibility and capability in machining highly intricate and complex parts, often used in specialized industries like aerospace and automotive.

What is the difference between 5-axis and 6-axis machining?

The primary difference lies in the number of axes. 5-axis machining includes two rotational axes in addition to the three linear axes, allowing the tool to approach the workpiece from virtually any direction. 6-axis machining adds another rotational axis, offering even more flexibility and precision, which is beneficial for extremely complex and detailed parts.

What is the difference between CNC axes and VMC axes?

CNC axes refer to the movement directions in any CNC machine, including milling, turning, or grinding machines. VMC (Vertical Machining Center) axes specifically pertain to vertical milling machines and typically include X, Y, and Z axes, along with additional rotational axes in multi-axis VMCs. The difference is mainly in the application and orientation of the machine’s movement.

How much does a 5-axis CNC milling machine cost?

The cost of a 5-axis CNC milling machine varies widely based on factors such as brand, size, precision, and additional features. Generally, prices can range from $100,000 to over $500,000 for high-end models equipped with advanced capabilities and high precision required for specialized industries.

How much does a 4-axis CNC machined part cost?

The cost of a 4-axis CNC machined part depends on factors such as material, complexity, volume, and machining time. Generally, prices can range from a few dollars for simple parts to several hundred dollars for highly complex and precise components. Getting a detailed quote from a CNC machining factory is recommended for accurate pricing.

How much does a 5-axis CNC machined part cost?

5-axis CNC machined parts typically cost more than 3-axis or 4-axis parts due to the increased complexity and precision involved. Prices can range from tens to thousands of dollars depending on the part’s complexity, material, volume, and required precision. For an accurate estimate, manufacturers should consult with CNC machining services to discuss specific project requirements.

What types of multi-axis CNC machines are most common?

The most common multi-axis CNC machines include 4-axis and 5-axis milling machines. These machines are widely used across various industries due to their ability to produce complex and precise parts efficiently. Additionally, some specialized applications may utilize 6-axis and 7-axis machines for even greater flexibility and capability.

What are G codes and M codes?

G codes and M codes are the programming languages used to control CNC machines. G codes instruct the machine on movement and positioning (e.g., G00 for rapid positioning, G01 for linear interpolation), while M codes manage machine operations such as coolant control and tool changes (e.g., M03 for spindle on clockwise, M05 for spindle stop).

What can a 5-axis CNC machine make?

A 5-axis CNC machine can create highly complex and intricate parts that require multi-directional machining. Examples include aerospace components like turbine blades, automotive parts with complex geometries, medical devices, intricate molds and dies, and detailed artistic sculptures. The versatility of 5-axis machines allows for the production of parts with multiple angles, curves, and intricate features that are difficult or impossible to achieve with fewer axes.