15 years one-stop China custom CNC machining parts factory

263 |

Published by VMT at Oct 22 2024

263 |

Published by VMT at Oct 22 2024

In the realm of manufacturing, anodized aluminum stands out for its unique blend of functionality and aesthetics. This specialized finish transforms raw aluminum into a material that is not only visually appealing but also highly durable and resistant to corrosion. Anodizing enhances the properties of aluminum, making it an ideal choice for a wide range of applications, from aerospace components to consumer electronics. As an expert in CNC machined parts manufacturing, understanding anodized aluminum is essential for delivering quality products that meet the demands of various industries. This article will provide an in-depth exploration of anodized aluminum, its processes, benefits, limitations, and applications, ensuring that you have all the knowledge you need to leverage this remarkable material in your projects.

Anodized aluminum refers to aluminum that has undergone an electrochemical process called anodizing, which thickens its natural oxide layer. This process enhances the surface properties of aluminum, making it more resistant to wear, corrosion, and damage while also allowing for dyeing to achieve various colors. The result is a finish that is not only functional but also visually striking, providing a sleek and modern appearance that is sought after in many industries.

Anodizing is particularly beneficial because it allows aluminum to maintain its lightweight properties while gaining additional strength and durability. This makes anodized aluminum an excellent choice for applications that require both structural integrity and a refined aesthetic. Whether used in automotive parts, architectural features, or consumer electronics, anodized aluminum delivers a combination of performance and beauty that is hard to match.

The primary purpose of anodizing aluminum is to enhance its surface properties and overall performance. This process offers several benefits, including:

Corrosion Resistance: Anodizing creates a protective oxide layer that shields the underlying aluminum from environmental elements, preventing corrosion and degradation over time.

Enhanced Durability: The anodized layer is harder than the raw aluminum surface, which improves wear resistance and extends the lifespan of the components.

Aesthetic Appeal: Anodizing allows for the addition of color through dyeing, giving manufacturers the ability to produce visually attractive products that align with branding and design preferences.

Improved Adhesion: The porous structure of the anodized layer allows for better adhesion of paints and adhesives, making it ideal for various finishing processes.

Electrical Insulation: The anodized layer provides electrical insulation, making anodized aluminum suitable for applications where electrical conductivity must be minimized.

Thermal Resistance: Anodized aluminum can withstand higher temperatures, making it suitable for applications exposed to heat.

By enhancing these properties, anodizing significantly increases the utility and versatility of aluminum, making it an invaluable process in manufacturing.

The anodizing process involves several key steps, each contributing to the creation of a durable and attractive finish. The process typically employs sulfuric acid as an electrolyte in a controlled environment to achieve the desired results.

To successfully anodize aluminum, specific materials and equipment are required. Understanding these components is crucial for ensuring a successful anodizing process.

Here Are the Materials You Need:

Sulfuric Acid: This is the primary electrolyte used in the anodizing process. It reacts with aluminum to form the anodized layer.

Distilled Water: Used to dilute sulfuric acid and for rinsing aluminum parts before and after anodizing to prevent contamination.

Several Jars (Containers): These are required to hold liquids during the anodizing process, including sulfuric acid and rinsing solutions.

Cathode: A conductive material that acts as a negative electrode during the anodizing process, often made from lead or stainless steel.

Aluminum Wire: This is used to connect the aluminum workpieces to the power supply, allowing for the flow of electricity during anodizing.

Degreaser: Essential for cleaning the aluminum surface before anodizing to remove oils, dirt, and contaminants.

Alkali Solution: Used in the pretreatment phase to etch and prepare the aluminum surface for anodizing.

Acid Neutralizer: This is used to neutralize any residual acid after the anodizing process, ensuring safe handling and disposal.

Power Supply: A reliable source of electricity is required to facilitate the anodizing process by applying a direct current to the aluminum workpieces.

Dye (if you want colored parts): Various dyes can be used to color the anodized layer, providing aesthetic appeal to the finished product.

What Are the Optional Items?

While the above materials are essential for anodizing, several optional items can enhance the process and results.

Acid Bath Agitator: This device helps maintain consistent temperature and concentration in the anodizing bath, leading to more uniform results.

Scotch-Brite Pads: Useful for cleaning parts before anodizing, these pads help remove contaminants and improve surface quality.

Ping Pong Balls: When placed in the tank, they help prevent acid fumes from escaping, ensuring a safer working environment.

Inexpensive Teapot: Useful for heating the dye, ensuring optimal dye absorption during the coloring process.

Aquarium Heater: This can be used to regulate the temperature of the dye bath, which is crucial for achieving consistent colors.

Cooking Thermometer: Essential for monitoring and adjusting the temperature of both the anodizing and dye baths, ensuring optimal conditions.

Proper surface preparation is critical for achieving high-quality anodized finishes. Here are some tips to ensure effective preparation:

Cleaning: Thoroughly clean the aluminum parts using a degreaser to remove oils, dirt, and residues. This step is crucial to prevent contaminants from interfering with the anodizing process.

Etching: Use an alkali solution to etch the surface of the aluminum. This step helps create a rough surface that improves the adhesion of the anodized layer.

Rinsing: After cleaning and etching, rinse the aluminum parts in distilled water to remove any residual chemicals, ensuring a clean surface for anodizing.

Drying: Allow the parts to dry completely before placing them in the anodizing bath. Moisture can adversely affect the anodizing process.

By following these preparation tips, manufacturers can ensure a clean, well-prepared surface that maximizes the effectiveness of the anodizing process.

To further understand the process of anodizing aluminum parts, here are the four main steps involved:

Step 1: Pretreatment

The pretreatment phase is essential for preparing the aluminum surface for anodizing.

Cleaning

Begin by thoroughly cleaning the aluminum parts with a degreaser to eliminate oils and contaminants. Rinse the parts with distilled water and allow them to dry completely.

Etching

Next, use an alkali solution to etch the aluminum surface. This step improves surface roughness, enhancing the adhesion of the anodized layer. After etching, rinse the parts again to remove any remaining solution.

Step 2: Anodizing

In this step, the prepared aluminum parts are submerged in the anodizing bath containing sulfuric acid. Connect the aluminum workpieces to the positive terminal of the power supply, and the cathode to the negative terminal. As electricity flows through the solution, an electrochemical reaction occurs, forming a thick anodized layer on the surface of the aluminum. The anodizing process typically lasts between 30 minutes to several hours, depending on the desired thickness of the anodized layer.

Step 3: Coloring

If colored anodizing is desired, the next step involves dyeing the anodized aluminum. After anodizing, the parts are rinsed and submerged in a dye bath. The porous structure of the anodized layer allows the dye to penetrate, resulting in vibrant colors. The dyeing process duration can vary based on the type of dye used and the desired color intensity.

Step 4: Sealing

Finally, seal the anodized and dyed aluminum parts to enhance durability and corrosion resistance. Sealing can be achieved by boiling the parts in distilled water or using a sealing solution. This step closes the pores of the anodized layer, locking in the dye and providing a protective barrier.

By following these steps, manufacturers can achieve high-quality anodized aluminum parts with enhanced properties and aesthetic appeal.

There are several anodizing processes available, each suited for different applications and desired properties. Understanding these types is crucial for selecting the appropriate process for specific needs.

Type I: Chromic Acid Anodizing

Chromic acid anodizing is often used for aerospace applications due to its ability to provide a thin and lightweight anodized layer. This process offers excellent corrosion resistance and is less abrasive than other methods. However, it does not provide the same level of thickness or durability as other anodizing types.

Type II: Sulfuric Acid Anodizing

This is the most common anodizing method, creating a thicker oxide layer that enhances wear and corrosion resistance. Sulfuric acid anodizing is widely used in various industries and allows for dyeing, making it a popular choice for decorative applications.

Type III: Hard Anodizing (Hard Anodizing)

Hard anodizing produces a significantly thicker and harder anodized layer, making it ideal for high-wear applications such as industrial machinery and military equipment. This process results in exceptional hardness, wear resistance, and thermal stability, but the anodized surface may have a dull appearance compared to other methods.

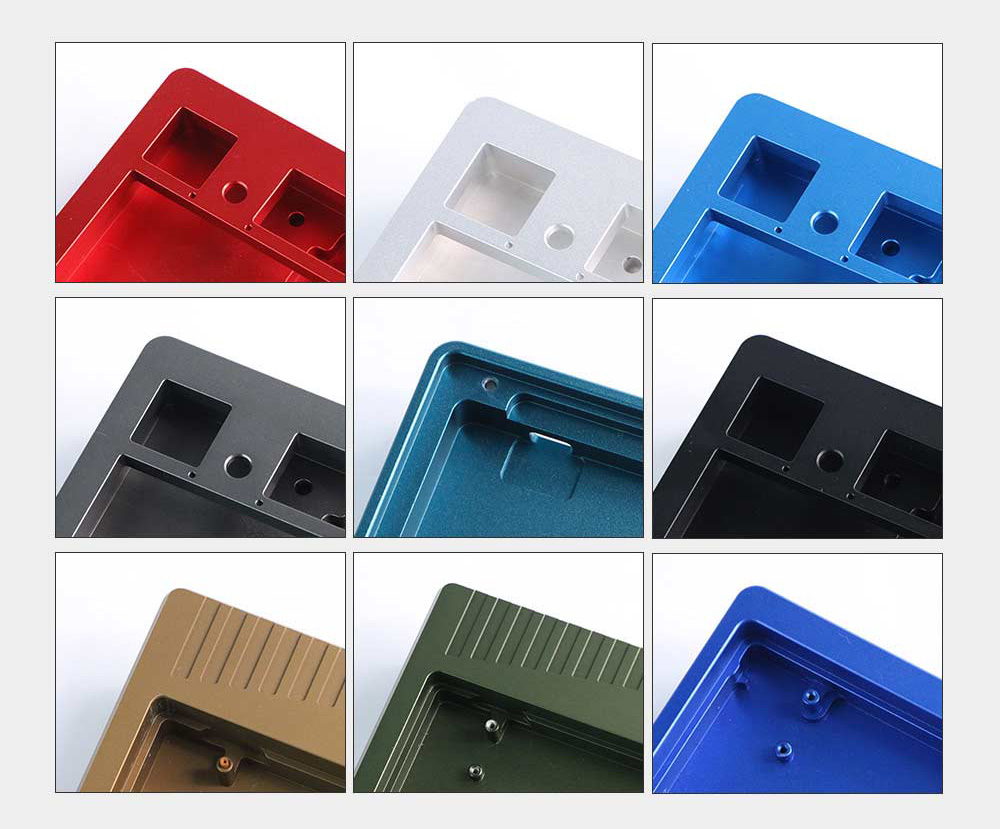

Anodized aluminum offers a diverse palette of colors that enhance its aesthetic appeal. The coloring process allows for various shades, from subtle to vibrant hues.

Clear/Silver:

This color maintains the natural metallic appearance of aluminum while providing the benefits of anodizing. It is often used in applications where a classic and sleek look is desired.

Black:

Black anodized aluminum offers a sophisticated and modern appearance. It is popular in architectural applications, consumer products, and electronics, providing a sleek finish that is both functional and stylish.

Gold, Blue, Red, Green, etc.:

Anodizing allows for a wide range of colors, including gold, blue, red, green, and many others. These colors are achieved through the dyeing process, enabling manufacturers to create visually striking products that align with branding and design requirements.

The ability to anodize aluminum in various colors enhances its versatility and appeal. Manufacturers can choose from a wide spectrum of shades to meet specific design needs, ensuring that anodized aluminum components stand out in the marketplace.

Choosing the right anodizing process depends on various factors, including the intended application, desired properties, and aesthetic requirements. For applications requiring high corrosion resistance and a lightweight finish, chromic acid anodizing may be ideal. In contrast, sulfuric acid anodizing is well-suited for general applications where durability and aesthetics are essential. Hard anodizing is recommended for components that experience heavy wear and require maximum hardness. Understanding these factors is crucial for selecting the appropriate anodizing method for specific needs.

Anodized aluminum offers a range of benefits that make it a preferred choice across various industries. Here are some of the key advantages of using anodized aluminum parts.

Aesthetics

The anodizing process enhances the visual appeal of aluminum parts, providing a sleek and modern finish. The ability to color anodized aluminum allows manufacturers to create products that align with branding and design preferences.

Enhanced Durability and Longevity

Anodized aluminum exhibits improved durability and resistance to wear and corrosion. The thick anodized layer protects the underlying aluminum from environmental factors, extending the lifespan of components.

Easy to Maintain

Anodized surfaces are easy to clean and maintain. The smooth finish prevents dirt and grime from accumulating, making regular cleaning straightforward and hassle-free.

Color Stability

The coloring process used in anodizing results in stable and long-lasting colors. Unlike paints or coatings that may fade over time, anodized colors remain vibrant and consistent, ensuring the aesthetic quality of products is maintained.

Economical

While the initial cost of anodizing may be higher than standard finishes, the long-term benefits, such as reduced maintenance and replacement costs, make anodized aluminum a cost-effective choice.

Has Better Insulation Properties

Anodized aluminum provides improved insulation properties, making it suitable for applications where thermal or electrical insulation is required.

Thermal Insulation

The anodized layer acts as an effective thermal barrier, reducing heat transfer and making anodized aluminum suitable for applications exposed to varying temperatures.

Environmentally Friendly

Anodizing is an environmentally friendly process, as it does not involve harmful chemicals and generates minimal waste. Additionally, the longevity of anodized aluminum reduces the need for replacements, contributing to sustainability efforts.

While anodized aluminum offers numerous benefits, it also has certain limitations that manufacturers should consider.

Limited to Aluminum and Aluminum Alloys

Anodizing is primarily applicable to aluminum and its alloys, limiting its use in other materials. Manufacturers must ensure that the components to be anodized are suitable for this process.

Changes in Aluminum Alloys Can Affect Color

The color achieved during anodizing can vary based on the specific aluminum alloy used. Changes in alloy composition may lead to inconsistencies in color, requiring careful selection of materials to achieve desired results.

Dimensional Changes

The anodizing process can cause dimensional changes in aluminum parts. Manufacturers must account for this factor when designing components, as anodizing may alter tolerances and specifications.

Hard Anodizing Can Affect Surface Finish

While hard anodizing provides exceptional durability, it may result in a dull surface finish that some applications may find undesirable. Manufacturers must weigh the benefits of hardness against the potential impact on aesthetics.

Anodizing Layer Can Be Damaged

While the anodized layer is durable, it can be damaged by harsh chemicals, abrasion, or impact. Care must be taken during handling and cleaning to maintain the integrity of the anodized surface.

Not Suitable for Large Parts

Anodizing may not be feasible for large parts due to limitations in equipment and bath sizes. Manufacturers should consider the size of components before opting for anodizing as a finishing method.

Designing aluminum components for anodizing involves several important considerations to ensure optimal results. Here are some tips to guide the design process.

Dimensional Considerations

Designers should account for potential dimensional changes during the anodizing process. Tolerances should be adjusted to ensure that finished parts meet specifications after anodizing.

Hardness Requirements

Consider the hardness requirements of the finished component. If high wear resistance is essential, selecting the appropriate anodizing type (e.g., hard anodizing) is crucial.

Color Matching

When specifying colors for anodized aluminum parts, it is essential to consider how the anodizing process can affect the final color. Manufacturers should work closely with dye suppliers to ensure accurate color matching.

Compound Coatings

In some applications, compound coatings may be required for enhanced performance. Designers should evaluate the compatibility of anodizing with other coating processes to achieve the desired results.

Conductivity

Anodized aluminum provides electrical insulation, which may be desirable in some applications. However, designers should consider the impact of anodizing on electrical conductivity when designing components for specific functions.

Consider Alloys

Different aluminum alloys may respond differently to the anodizing process. Designers should select appropriate alloys that achieve the desired performance and aesthetic results.

Avoid Sharp Edges

Sharp edges can create weak points in anodized layers, increasing the risk of damage. Designers should avoid sharp edges and incorporate radii or fillets to enhance the durability of anodized parts.

Consider Anodizing Type

Select the appropriate anodizing type based on the intended application and performance requirements. Each type offers unique advantages and limitations that should be carefully evaluated.

Consider Final Appearance

The final appearance of anodized aluminum parts is influenced by various factors, including surface preparation and anodizing type. Designers should consider how these factors will impact the visual quality of finished components.

Anodized aluminum is used across a wide range of industries, thanks to its unique properties and benefits. Here are some of the key applications where anodized aluminum plays a vital role.

Aerospace and Defense Industry

Anodized aluminum is commonly used in aerospace applications for components such as aircraft frames, fittings, and housings. Its lightweight, durable, and corrosion-resistant properties make it ideal for demanding environments.

In the medical field, anodized aluminum is used for various equipment, including surgical instruments and medical devices. Its biocompatibility and ease of cleaning make it a preferred choice for maintaining hygiene and safety.

The automotive industry leverages anodized aluminum for parts such as trim, structural components, and engine housings. The aesthetic appeal and durability of anodized finishes enhance the overall quality and appearance of vehicles.

Anodized aluminum is widely used in consumer electronics, including smartphones, laptops, and other devices. Its lightweight properties, combined with attractive finishes, make it a popular choice for modern electronics.

Many manufacturers opt for anodized aluminum in custom parts and components due to its versatility and the ability to achieve specific designs and colors.

Architecture and Construction Industry

Anodized aluminum is used in architectural applications for facades, window frames, and structural elements. Its corrosion resistance and aesthetic versatility make it ideal for modern construction projects.

Prototyping and Product Development

Anodized aluminum is frequently used in prototyping and product development phases, allowing designers to create visually appealing and functional prototypes that accurately represent the final product.

Household Goods

Anodized aluminum is found in various household products, including cookware, appliances, and furniture. Its durability and ease of maintenance make it a preferred material for everyday items.

Hydraulic Fittings

In hydraulic applications, anodized aluminum is used for fittings and components that require corrosion resistance and reliable performance under pressure.

In conclusion, anodized aluminum is a remarkable material that combines functionality and aesthetics. The anodizing process enhances the properties of aluminum, making it more durable, corrosion-resistant, and visually appealing. By understanding the anodizing process, its benefits, limitations, and various applications, manufacturers can make informed decisions when selecting materials for their projects. Anodized aluminum plays a vital role in industries ranging from aerospace to consumer electronics, proving its versatility and reliability in meeting the diverse needs of modern manufacturing.

Can all aluminum be anodized?

Not all aluminum alloys are suitable for anodizing. Only certain aluminum alloys with a high purity level yield satisfactory anodized finishes.

Is aluminum anodizing expensive?

The cost of aluminum anodizing can vary depending on factors such as the type of anodizing, batch size, and surface preparation requirements. However, the long-term benefits often outweigh the initial costs.

Can you anodize aluminum at home?

While it is possible to anodize aluminum at home, it requires specialized equipment and chemicals. It is recommended to seek professional anodizing services for consistent and high-quality results.

What colors can you get from anodizing aluminum?

Anodized aluminum can be colored in a wide range of shades, including clear, black, gold, blue, red, green, and more. The specific colors available depend on the dyeing process used.

Can aluminum be anodized twice?

Yes, aluminum can be anodized multiple times, but it is essential to ensure proper surface preparation and treatment between anodizing cycles to achieve the desired results.

Is anodizing safe?

Anodizing is generally considered safe when proper safety precautions are followed. The chemicals used in the process should be handled with care.

Does aluminum have to be etched before anodizing?

Etching is often recommended before anodizing to improve surface quality and enhance adhesion of the anodized layer.

Are aluminum anodes and titanium anodes the same?

No, aluminum and titanium anodes are not the same. They are made from different materials and have distinct properties and applications in anodizing processes.