15 years one-stop China custom CNC machining parts factory

716 |

Published by VMT at Oct 23 2024

716 |

Published by VMT at Oct 23 2024

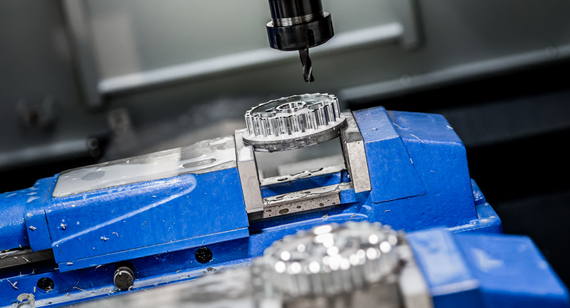

Magnesium CNC machining is a specialized process that requires a thorough understanding of both the material's properties and the best practices to ensure safe and effective machining. Magnesium, known for its lightweight and high-strength characteristics, has found applications across various industries, including aerospace, automotive, and electronics. However, its unique properties also introduce specific risks that must be managed effectively. This article aims to provide an overview of magnesium, its machinability, associated risks, and essential safety guidelines for CNC machining.

Magnesium is a chemical element with the symbol Mg and atomic number 12. It is a lightweight metal, known for being one of the least dense structural metals. Magnesium alloys are widely used in manufacturing due to their excellent mechanical properties and versatility. These alloys are primarily composed of magnesium, combined with other metals such as aluminum, zinc, and manganese to enhance their strength and durability.

Magnesium is utilized in a variety of applications, including:

Aerospace: Used in aircraft components to reduce weight and improve fuel efficiency.

Automotive: Employed in car parts, such as wheels and engine blocks, to enhance performance and reduce emissions.

Electronics: Used in casings and frames for devices, providing both protection and a lightweight design.

Sports Equipment: Found in products like bicycles and sports gear, offering strength without adding excess weight.

Yes, magnesium can be CNC machined, and it is often preferred for components where weight reduction is critical. The CNC machining process allows for precise shaping and forming of magnesium alloys, enabling manufacturers to produce complex geometries that meet specific design requirements. However, machining magnesium requires careful attention to detail and safety measures due to its flammability and the production of fine metal shavings during the process.

Machining magnesium alloys presents unique challenges. Although magnesium is relatively easy to machine compared to other metals like titanium, several factors affect its machinability:

Tool Wear: Magnesium can cause rapid wear on cutting tools due to its abrasive properties, necessitating frequent tool changes and maintenance.

Heat Generation: The machining process generates heat, which can lead to thermal distortion of the material if not managed properly.

Chip Management: The chips produced during machining can be fine and flammable, requiring effective chip management strategies to prevent fire hazards.

Overall, while magnesium alloys can be machined efficiently, the process demands knowledge of the right tools, cutting parameters, and safety precautions to achieve optimal results.

When machining magnesium alloys, the choice of cutting fluid is crucial to ensuring a safe and effective process. The right cutting fluid can help manage heat, reduce tool wear, and improve the surface finish of the machined parts.

Oil-based

Oil-based cutting fluids are generally recommended for milling magnesium alloys. These fluids provide excellent lubrication, which is vital in reducing friction between the cutting tool and the material. They also help dissipate heat, preventing thermal distortion and prolonging tool life.

Petroleum-based Cutting Fluids

Petroleum-based cutting fluids are effective for machining magnesium due to their ability to create a protective barrier that minimizes oxidation and corrosion. These fluids can significantly enhance the overall performance of the machining process.

Despite its advantages, machining magnesium poses several risks that must be managed to ensure safety and efficiency.

Fire Hazards

One of the most significant risks associated with magnesium machining is the potential for fire. Magnesium shavings and dust are highly flammable and can ignite spontaneously under certain conditions. It is crucial to implement proper chip management strategies and to have appropriate fire extinguishing equipment on hand.

Tool Wear

Magnesium can cause rapid wear on cutting tools due to its abrasive nature. Using the right tools and maintaining them in good condition is essential to mitigate this risk.

Heat

The machining process generates heat, which can lead to overheating and affect the integrity of both the tool and the material. Monitoring temperatures and employing appropriate cooling techniques is vital.

Surface Finish Distortion

Magnesium’s susceptibility to heat and stress can lead to distortion during machining. Proper setup and careful handling are necessary to maintain the desired surface finish and tolerances.

To ensure safe and effective machining of magnesium alloys, several essential tips should be followed:

Maintain Proper Tool Condition

Regularly inspect and maintain cutting tools to prevent excessive wear. Using sharp, high-quality tools can significantly improve performance and safety.

Avoid Too Small Clearance Angles

When designing tooling, avoid small clearance angles to prevent binding and excessive friction, which can lead to heat buildup and tool failure.

Make Discontinuous Chips

Aim to produce discontinuous chips rather than long, continuous ones. Discontinuous chips are easier to manage and pose less of a fire hazard.

Avoid Using Water-based Coolants

Water-based coolants can lead to corrosion and should generally be avoided when machining magnesium. Instead, opt for oil-based or petroleum-based cutting fluids.

Use Explosion-proof Vacuum Cleaners to Collect Chips

Employ specialized vacuum cleaners designed to handle magnesium chips safely. These units are equipped to prevent the ignition of flammable materials.

Never Use Water to Extinguish Magnesium Fires

In the event of a fire involving magnesium, never use water to extinguish it, as this can exacerbate the fire. Instead, use a Class D fire extinguisher designed for metal fires.

Magnesium offers several compelling reasons for its selection in CNC machining applications:

Excellent Machining Properties

Magnesium is known for its excellent machinability, allowing for efficient production of complex shapes and designs.

Complex Geometries

CNC machining of magnesium allows for the creation of intricate geometries that are often challenging to achieve with other materials.

Recyclability

Magnesium is highly recyclable, making it an environmentally friendly option for manufacturers looking to reduce waste and promote sustainability.

CNC machining of magnesium offers numerous advantages that make it a preferred choice across various industries:

Lightweight Properties

Magnesium is one of the lightest structural metals available, making it ideal for applications where weight savings are critical.

High Strength to Weight Ratio

Magnesium boasts a high strength-to-weight ratio, providing excellent mechanical performance without the added mass.

Excellent Machining Performance

CNC machining of magnesium allows for high precision and accuracy, essential for meeting stringent tolerances in manufacturing.

Good Thermal Conductivity

Magnesium exhibits good thermal conductivity, making it suitable for applications requiring efficient heat dissipation.

Electromagnetic Interference (EMI) Shielding

Magnesium provides effective EMI shielding, making it valuable in electronic and communication applications.

Environmental Benefits

The recyclability and lightweight nature of magnesium contribute to reduced energy consumption and lower emissions throughout its lifecycle.

Versatile Finishing

CNC machined magnesium parts can be finished in various ways, allowing manufacturers to achieve specific aesthetic and functional requirements.

Selecting the right tools is crucial for effective magnesium machining. Here are some common tool types:

High-speed Steel Tools

High-speed steel (HSS) tools are often used for machining magnesium alloys due to their durability and heat resistance.

Solid Carbide Tools

Solid carbide tools offer enhanced wear resistance and can handle higher speeds, making them suitable for precision machining of magnesium.

Coated Carbide Tools

Coated carbide tools can improve tool life and performance, particularly when machining abrasive materials like magnesium.

Polycrystalline Diamond Tools

Polycrystalline diamond (PCD) tools provide excellent wear resistance and are ideal for high-precision applications involving magnesium alloys.

Several CNC machining methods are employed for processing magnesium alloys, each with its specific applications and benefits:

CNC Drilling

CNC drilling is used to create holes in magnesium components with precision and accuracy, essential for assembly and functionality.

CNC Milling

CNC milling allows for the shaping of magnesium into complex geometries, enabling manufacturers to produce intricate designs.

CNC Turning

CNC turning is ideal for creating cylindrical shapes and components from magnesium alloys, ensuring tight tolerances and smooth finishes.

Laser Cutting

Laser cutting provides a precise method for cutting magnesium sheets and components, allowing for intricate designs without excessive tooling wear.

Eavesdropping

Eavesdropping is a less common method for machining magnesium but can be applied in specific applications to achieve desired results.

At WMT, we specialize in providing high-quality magnesium alloy machined parts tailored to your specific needs. Our state-of-the-art CNC machining services ensure precision, efficiency, and safety in every project. Whether you require custom solutions or prototype machining, we are here to support your manufacturing goals.

Magnesium CNC machining offers numerous benefits, including lightweight properties, high strength, and excellent machinability. However, it also presents specific risks that must be managed through careful planning and adherence to safety guidelines. By understanding the characteristics of magnesium and following best practices, manufacturers can effectively harness its advantages while minimizing risks. As industries continue to seek lightweight and efficient materials, magnesium will play a pivotal role in advancing modern manufacturing.

Is it safe to machine magnesium?

Yes, but proper safety precautions must be taken due to its flammability and the risks associated with fine metal chips.

What are the costs associated with machining magnesium compared to other materials?

Machining magnesium can be cost-competitive with other materials, but specific factors such as tooling and safety measures may affect overall costs.

Which magnesium alloy is best for machining?

Common alloys include AZ31, AZ61, and ZK60. These alloys are well-regarded for their machinability, strength, and versatility, making them suitable for a wide range of applications.

What are the disadvantages of machining magnesium alloys?

Disadvantages include flammability, the need for special handling and tooling due to rapid tool wear, and challenges in managing fine chips and dust during the machining process.

What are the common uses of magnesium?

Magnesium is commonly used in the aerospace and automotive industries for lightweight structural components, in electronics for casings, and in various consumer goods for its durability and weight-saving benefits.

Can I weld magnesium?

Yes, magnesium can be welded, but it requires specific techniques and precautions to avoid issues such as porosity and cracking. Shielded metal arc welding and gas metal arc welding are common methods.

Is magnesium stronger than steel?

While magnesium has a high strength-to-weight ratio, it is not stronger than steel in terms of absolute tensile strength. However, its lightweight properties make it advantageous for applications where weight reduction is critical.

By following the guidelines outlined in this article and understanding the unique properties of magnesium, manufacturers can effectively leverage CNC machining for producing high-quality magnesium parts while ensuring safety and efficiency in their operations.