15 years one-stop China custom CNC machining parts factory

1202 |

Published by VMT at Jan 18 2025 | Reading Time:About 4 minutes

1202 |

Published by VMT at Jan 18 2025 | Reading Time:About 4 minutes

Problem

Are you stuck deciding between brass vs. aluminum for your custom CNC machining project? Perhaps you’ve heard that brass CNC machining parts bring elegance and robustness, while aluminum CNC machining parts are prized for being lightweight and versatile. This dilemma can be nerve-wracking—pick the wrong metal, and you risk wasting money, facing performance issues, or missing project deadlines. Whether you’re creating decorative plaques, electronic components, or specialized parts in a CNC machining factory, the wrong choice could compromise both function and aesthetics.

Agitation

Worse yet, conflicting information abounds. Some sources tout the merits of brass—its warm color, corrosion resistance, and unique acoustic qualities—leading you to believe it’s superior in every way. Others highlight aluminum’s featherweight advantage, corrosion resistance, and cost benefits, making brass seem outdated and expensive. Which is true? How do you even begin to weigh complex factors like mechanical properties, manufacturability, or cost-efficiency without risking the integrity of your CNC prototype machining or large-scale production runs?

Solution

Relax. This comprehensive comparison of brass vs. aluminum will help you confidently determine the ideal metal for your next project. From chemical compositions and mechanical traits to surface finishes and application case studies, we’ll walk you through every aspect you need to know. By the end, you’ll understand both metals’ pros and cons, how they differ in cost, environmental impact, and how they behave during machining. Equipped with these insights, you’ll be ready to engage with CNC machining services or a CNC machining factory and make a well-informed, cost-effective decision—ensuring your final product checks every box from performance to aesthetics.

Choose brass for visual appeal and corrosion resistance; pick aluminum for lightweight durability and affordability.

Still unsure which metal best aligns with your project goals? Keep reading. We’ll delve deeper into each material’s composition, properties, advantages, and potential pitfalls. Whether you need large production runs or specialized prototypes, an in-depth understanding of brass and aluminum will enable you to collaborate more effectively with your CNC machining factory or custom CNC machining partner. Let’s begin by exploring the foundational attributes of each metal and why they’re so commonly used across countless industries.

Brass vs. Aluminum: Comprehensive Comparison

Brass vs. aluminum represents a classic debate in manufacturing. Both are non-ferrous metals, each offering distinct benefits like corrosion resistance, malleability, and a variety of surface finishes. Yet they differ in key ways—chemical makeup, mechanical properties, cost, and typical uses. Before you settle on brass CNC machining parts or aluminum CNC machining parts, it’s crucial to understand these differences. This overview sets the stage for the detailed sections ahead, ensuring you have the knowledge to pick the right material for your specific design, budget, and performance requirements.

What Is Brass?

Brass is an alloy primarily composed of copper and zinc. Small amounts of other elements—such as lead, tin, or aluminum—are sometimes added to tweak mechanical and aesthetic qualities. Known for its gold-like color and excellent machinability, brass has a long history of use in musical instruments, decorative elements, and marine fittings. Its corrosion resistance stems largely from the copper content, while zinc helps bolster overall strength. Because of this, brass is favored in applications ranging from plumbing to ornamental hardware. In a CNC machining factory setting, brass often proves straightforward to cut and shape, which can reduce production times and tooling costs.

What Is Aluminum?

Aluminum is a lightweight metal derived from bauxite ore. Known for its low density and high strength-to-weight ratio, aluminum excels in applications where weight reduction is paramount—think aerospace, automotive, and consumer electronics. Depending on the alloy series (e.g., 2xxx, 6xxx, 7xxx), aluminum’s characteristics can shift, allowing for greater tensile strength, improved corrosion resistance, or enhanced machinability. Aluminum’s natural oxide layer provides an excellent shield against rust. From CNC prototype machining to mass production, aluminum CNC machining parts remain cost-effective, easy to handle, and adaptable across a spectrum of industries.

Before diving into their properties, it helps to distinguish the varying types of brass and aluminum. Each metal category comprises multiple subtypes, each formulated for specific performance attributes—from corrosion resistance to tensile strength. Whether you’re sourcing brass rods for decorative fixtures or aluminum sheets for airplane wings, picking the right subtype ensures successful outcomes in your custom CNC machining project.

Types of Brass

The distinction between brass vs. aluminum goes beyond surface-level features. Chemical composition, physical traits, and mechanical performance all play roles in determining which metal is better suited for your application. Let’s dissect these core areas to give you a fuller picture of how brass CNC machining parts and aluminum CNC machining parts stack up.

Brass vs. Aluminum: Chemical Composition

Brass:

Aluminum:

Brass vs. Aluminum: Physical Properties

Density:

Melting Point:

Thermal Conductivity:

Brass vs. Aluminum: Mechanical Properties

Tensile Strength:

Hardness:

Ductility and Formability:

No metal is a one-size-fits-all solution. Both brass and aluminum excel in some scenarios but may underperform in others. In this section, we’ll delve deeper into the benefits and drawbacks each metal offers, shedding light on why you might pick one over the other in your custom CNC machining projects.

Advantages of Brass

Brass has long been celebrated for its distinctive appearance and workable nature. Let’s break down the traits that make brass an appealing choice for various industries, from decorative arts to mechanical systems.

Durability

Thanks to the interplay of copper and zinc, brass alloys exhibit considerable durability. They resist cracking under stress and can tolerate moderate mechanical loads. This resilience keeps brass components functional over long service cycles, especially in moderate-load applications like gears or fittings.

Corrosion Resistance

Brass does not rust in the same way ferrous metals do. Its corrosion resistance is significantly better than many steels, making brass suitable for marine hardware, plumbing fixtures, and even certain electrical connectors. Some brasses also have added aluminum or arsenic to further enhance corrosion resistance in brackish or chlorinated water conditions.

Aesthetic Appeal

A classic reason to choose brass is its iconic golden hue, which brings warmth and elegance. In decorative pieces such as plaques, medallions, or nameplates, brass stands out for its premium look. Moreover, it can be polished to a mirror-like sheen or allowed to develop a patina for a more vintage appeal.

Disadvantages of Brass

While brass excels in looks and moderate mechanical performance, it comes with certain trade-offs you should consider.

Staining

Brass may tarnish or stain over time, especially when exposed to moisture or certain chemicals. Though some users find the resulting patina charming, it could be a downside in applications requiring a pristine, long-lasting finish without regular maintenance.

Cost

The copper content in brass can drive up material costs, making brass more expensive than aluminum or some steels. If your project involves large volumes, the cost can add up quickly, especially if you need thick sections or specialized brass grades.

Ductility

Although brasses are generally workable, high-zinc brasses can be less ductile and more prone to cracking when cold-worked. In CNC machining services, some brass variants machine wonderfully, but forming processes might demand caution if the zinc content is very high.

Low Thermal Conductivity (Compared to Copper or Aluminum)

Brass conducts heat reasonably well but not as effectively as pure copper or aluminum. If heat dissipation is a primary concern—such as in heat exchangers or electronic enclosures—other metals might be more suitable.

Advantages of Aluminum

Aluminum’s status as a manufacturing heavyweight (ironically, it’s light in density) stems from a remarkable blend of strength, corrosion resistance, and processing ease. Here’s a closer look at what makes aluminum CNC machining parts so widespread in modern industries.

Excellent Strength-to-Weight Ratio

Compared to heavier metals like brass or steel, aluminum can achieve comparable strength at a fraction of the weight. This advantage is critical in aerospace, automotive, and sports equipment, where shedding mass directly improves performance, fuel efficiency, or user comfort.

Corrosion Resistance

Aluminum forms a natural oxide layer that protects it from further oxidation, making it inherently corrosion-resistant. Certain anodizing or coating processes can push this resistance even further, ensuring longevity in harsh environments like coastal regions.

Electrical Conductivity

While not as conductive as copper, aluminum is still an excellent conductor of electricity. It’s often used in electrical wiring, bus bars, and enclosure systems where weight reduction is crucial. For custom CNC machining, aluminum’s electrical properties make it an attractive material for both prototypes and large-volume production of electronic components.

Disadvantages of Aluminum

Despite its many merits, aluminum isn’t the perfect solution for every scenario. Below are some common limitations worth noting.

Limited Heat Resistance

Aluminum’s relatively low melting point (around 660°C) means it can’t maintain structural integrity under high-temperature environments. If your component faces extreme heat—like engine cylinders or industrial furnaces—aluminum may deform or lose mechanical properties.

Surface Fragility

Although you can anodize or coat aluminum for better wear resistance, the metal itself is prone to scratching or denting. High-traffic or high-wear parts may require robust finishing solutions or alternative metals if surface durability is a priority.

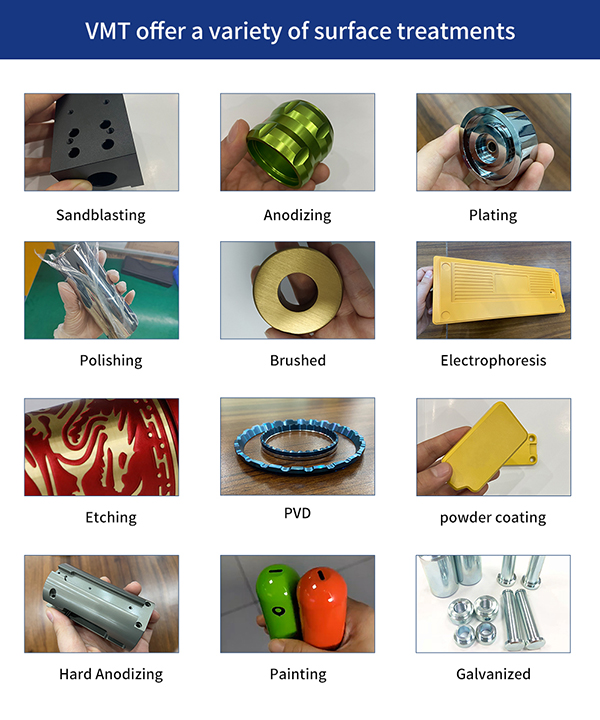

Surface finishing can dramatically affect your part’s aesthetics, corrosion resistance, and wear life. Different metals accept different treatments, so understanding which finishes apply to brass vs. aluminum is crucial in achieving the best outcome for your custom CNC machining project.

What Surface Finishes Can Be Done on Brass Parts?

What Surface Finishes Can Be Done on Aluminum Parts?

Surface finish options, mechanical properties, and cost all converge when picking between brass vs. aluminum for a specific application. Below, we’ll explore typical uses for both metals, helping you see real-world scenarios where each metal genuinely excels.

Applications of Brass

Brass parts are everywhere—from household items to heavy industrial components. The metal’s distinctive color, moderate strength, and reliability make it a go-to choice across various niches.

Brass is commonly used in electrical terminals, connectors, and switches. Its decent conductivity, combined with corrosion resistance, ensures consistent, reliable connections over time. Leaded brass, in particular, can be machined easily into precise fittings.

Pipes and Fittings

In plumbing applications, brass has long been favored for valves, pipe fittings, and faucets because it resists corrosion, is non-magnetic, and doesn’t contaminate water with rust. Marine-grade brasses also stand up well in saltwater environments.

Decorative and Functional Products

Brass’s aesthetic merits shine in doorknobs, drawer pulls, and musical instruments. Many artisans and architects leverage the metal’s golden hue for statement pieces, both inside and outside buildings.

Coins, Plaques, Medals, Metal Cards, Labels, Nameplates

Its resistance to wear and tarnish makes brass a durable option for coins, medals, or nameplates that must hold up under frequent handling. The metal’s easy engravability also lends itself to precise lettering or intricate logo designs.

Is Brass the Right Choice for You?

If you value a warm, classic look, moderate mechanical strength, and reliable corrosion resistance, brass could be your go-to option. When teaming up with CNC machining services, you’ll find that brass’s good machinability translates into shorter production times for intricate parts. However, factor in potential tarnishing and higher raw material costs if your design includes large volumes or thick sections. If aesthetics and moderate durability trump weight minimization, brass might be the ideal solution.

Aluminum Applications

Aluminum shines (sometimes literally) in modern engineering for good reason: it’s lightweight, strong, and relatively affordable when purchased in large quantities. Let’s dig into some common aluminum use cases.

Aerospace Components

Airplanes, spacecraft, and drones all benefit from aluminum’s high strength-to-weight ratio. Parts such as wing panels, fuselage frames, and rotor blades often incorporate aluminum alloys (e.g., 6061, 7075) to reduce weight and improve fuel efficiency.

While copper remains the gold standard for conductivity, aluminum provides a viable, lighter alternative. Overhead power lines often rely on aluminum or aluminum-copper hybrids to reduce sag and overall weight while maintaining decent conductivity.

Design, Branding, and Accessories

Aluminum’s sleek finish and anodizing options make it popular for brand identity pieces—dog tags, keychains, nameplates, and decorative signage. Companies often select it for water bottles, business cards, and promotional items due to its modern look and recyclability.

Is Aluminum the Best Choice for You?

If weight minimization, cost efficiency, or excellent corrosion resistance are top priorities, aluminum stands out. It’s also ideal if your parts will undergo frequent handling or need to dissipate heat effectively. Keep in mind that extreme heat or high-wear conditions may push you toward alternative metals. Still, for most prototypes, consumer goods, and structural components, a CNC machining factory can produce aluminum CNC machining parts quickly, accurately, and affordably.

Cost considerations often make or break a material choice. Is brass’s upscale appeal worth the higher price? Will aluminum’s cheaper per-pound cost truly offset any finishing expenses? Let’s see how brass vs. aluminum compares from a budgetary standpoint.

Price per Pound

Availability

Brass and aluminum are both widely available, but aluminum typically has a more robust global supply chain—especially in sheet, plate, bar, and extrusion forms. While brass isn’t rare, specialized grades can be pricier or harder to locate.

Manufacturing Costs

Brass can be extremely machinable, especially leaded brass, which reduces tooling wear and machine time. Aluminum also machines quickly but may require certain lubrication or finishing steps depending on the application. Overall manufacturing costs can go either way, depending on the specific grade and the complexity of your design.

Beyond raw material prices, other factors—like design optimization and waste reduction—impact overall project cost. By carefully planning each stage, you can make more informed decisions about whether brass or aluminum maximizes return on investment.

Ask yourself: Do you truly require brass’s unique aesthetic and corrosion profile, or will aluminum suffice at a lower price point? Or is there a middle ground, like a copper-alloyed aluminum that might meet halfway?

Optimizing Quantities

Bulk orders can reduce the per-unit cost for both brass and aluminum. Evaluate your production forecasts and weigh whether larger stock purchases make financial sense. This approach often benefits industries with recurring production runs.

Standard Stock Sizes

Utilizing standard rod, sheet, or extrusion sizes lowers waste. Custom extrusions may offer an ideal geometry, but they come with setup fees. Tapping into standard dimensions can streamline your CNC machining services, reducing lead times.

Material Efficiency

Design for net-shape manufacturing—use the geometry that minimizes off-cuts or scrap. While both brass and aluminum can be recycled, leftover material is still an added step in the supply chain.

A material’s machinability can profoundly influence production timelines, tooling expenses, and surface quality. Let’s dissect potential roadblocks you might encounter when machining brass vs. aluminum.

Machining Challenges

Chip Control and Evacuation

Work Hardening

Built-Up Edge

Sustainability concerns have prompted many manufacturers to question the environmental costs of different metals. Brass vs. aluminum each has distinct footprints, from initial ore extraction to end-of-life recycling.

Energy Consumption

Recyclability

Overall Durability

Material Weight

We’ve looked at mechanical traits, costs, finishes, and environmental considerations. Now let’s recap the main points that might sway your choice toward brass vs. aluminum.

Price

Applications

Part Characteristics

Forming Processes

Machining Waste

Both metals are recyclable, but aluminum’s lighter mass could yield lower shipping costs for scrap. Brass scrap, however, has higher resale value due to its copper content.

Aesthetic Requirements

Whether you choose brass or aluminum, CNC machining services can bring your designs to life. Many shops specialize in both materials, providing everything from CNC prototype machining for short runs to mass production. Communicate your specific needs—tolerances, finishes, and performance criteria—to ensure your CNC machining factory selects the right tooling, feed rates, and finishing processes. Ultimately, a partnership with an experienced manufacturer can optimize your project timeline, cost, and final product quality—regardless of your metal choice.

In the debate of brass vs. aluminum, neither metal stands as an outright winner across all applications. Brass delivers a classic aesthetic, reliable corrosion resistance, and a weight that can be beneficial in certain contexts. Aluminum offers unmatched lightness, decent strength, and high versatility in cost-sensitive or high-volume scenarios. Your final decision should revolve around your budget, target environment, mechanical demands, and, of course, personal or brand-specific aesthetics. By understanding the composition, properties, finishing options, and real-world uses of brass and aluminum, you can make a confident choice for your custom CNC machining project. Whichever path you choose, both metals boast robust recycling prospects and a global supply chain, ensuring you have the resources to manufacture top-notch parts for years to come.

1. Is Brass Harder Than Steel?

Generally, most steels surpass brass in hardness and tensile strength. However, some specialized brasses can be work-hardened or alloyed to achieve comparatively high strengths. If ultimate hardness is your main concern, steel is often the better choice.

2. Which is Better, Aluminum or Brass?

It depends on your project’s needs. Brass excels in decorative appeal and moderate corrosion resistance, making it great for plumbing and aesthetic parts. Aluminum is superior in weight-sensitive and cost-critical applications due to its lighter mass and cheaper price point.

3. Brass or Aluminum Housings Are Better?

Aluminum housings are typically lighter and more affordable, often used in consumer electronics or automotive components. Brass housings provide a classy look and better wear resistance in certain conditions. Your choice hinges on performance, budget, and aesthetic demands.

4. Is Aluminum Rust-Proof?

Aluminum does not rust like iron-based metals. Instead, it forms a protective oxide layer. While not truly “rust-proof,” it’s far more corrosion-resistant than many other metals.

5. Does Brass Rust?

Brass doesn’t rust in the traditional sense (forming iron oxide). It can tarnish, which is a surface discoloration, but this process does not structurally weaken the metal like rust does to iron or steel.

6. Why Does Aluminum Turn Yellow?

Aluminum can sometimes develop a yellowish tint due to environmental factors like UV exposure, contamination, or improper anodizing processes. A protective coating or cleaning solution can help prevent or remove this discoloration.

7. Which One is a Better Conductor of Heat, Aluminum or Brass?

Aluminum generally conducts heat more effectively than brass. If heat dissipation is crucial—like in heat sinks or cooling fins—aluminum is usually the go-to metal.

8. What Metal is Better Than Brass?

“Better” is relative. In some contexts, stainless steel or bronze might outperform brass in strength or corrosion resistance. However, brass remains unbeatable in certain decorative or moderate-load applications, especially for its golden sheen and decent machinability.

9. Will Brass Corrode Aluminum?

When brass and aluminum come into direct contact with an electrolyte (e.g., water), galvanic corrosion can occur. The risk is higher if the environment is particularly corrosive. Proper insulation or coatings can mitigate this.

10. Does Brass Conduct Electricity Better Than Aluminum?

No, aluminum generally has higher electrical conductivity than brass. However, copper (the main component in brass) is even more conductive than aluminum, so the exact conductivity depends on the specific brass alloy.

11. Are Brass Heat Sinks Better Than Aluminum Heat Sinks?

Aluminum is typically preferred for heat sinks due to its superior thermal conductivity and lighter weight. Brass, though it can be used, is generally heavier and slightly less thermally conductive.

12. What Is the Best Metal for Cooling?

Copper is considered one of the best for cooling due to its high thermal conductivity. Aluminum is a close second and is more cost-effective and lightweight, which is why it’s so widely used in heat sinks.

13. Which Is More Expensive, Aluminum or Bronze?

Bronze, an alloy of copper and tin, is typically pricier than aluminum due to the higher copper content. Aluminum’s abundance and established supply chains often make it more economical for large-scale projects.

In choosing between brass vs. aluminum, remember each metal offers distinct properties, cost structures, and finishing possibilities. Whether you go with brass CNC machining parts for their aesthetic warmth or aluminum CNC machining parts for lightweight efficiency, reputable CNC machining services can help you achieve superior results in any CNC machining factory or custom CNC machining endeavor.