15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 12 2026 | Reading Time:About 3 minutes

0 |

Published by VMT at Jan 12 2026 | Reading Time:About 3 minutes

CNC machining technology plays an indispensable role in the production of modern high-precision engine components. It transforms raw materials into high-quality engine parts with stable dimensional accuracy and complex geometries. Especially for custom applications, CNC offers advantages in speed, efficiency, precision, and cost. This guide will provide you with a comprehensive overview of the main CNC machining processes, engine part types, typical materials, as well as key benefits and challenges, giving you a complete overview.

CNC-machining is a subtractive manufacturing process that uses machining tools like a cut to remove material from a whole bulk material into the shape you want. The movement direction and angle of these tools is controlled by designed computer programmed instructions. And complex and precise parts are created through multiple CNC machining processes like milling, turning, drilling, etc., that we will detailly discuss in the next section.

For CNC engine components, there are diversified precision machining processes to complete the parts manufacturing.

You may through the flows of rough machining (milling, turning); hole machining (drilling, boring) to precision hole formation and positioning; post-machining of finishing (grinding, honing, lapping); and other special machining (EDM) if complex geometries needed. You can achieve high precision, dimensional accuracy of engine components by properly combining these processes:

Through CNC Milling, materials are removed by rotating cutting tools. The multi-axis CNC milling machine is equipped with rotating cutting tools to cut the material into the shape you want; feed and tool movement are controlled by the designed programs. You can accurate planes, contours, and cavities with controllable surface roughness and dimensions through this milling process, and engine components such as cylinder heads and exhaust manifolds mainly go through milling.

You can cut cylindrical or shaft components by securing them on a lathe, where a workpiece is cut along the axial or radial direction to form the desired diameter and contour. Through CNC turning, you will achieve high dimensional accuracy, concentricity, and surface finish of cylindrical engine components such as pistons, crankshaft journals, or camshafts.

You can create precise holes in engine components through this process. By rotating and feeding drill bits, the through holes or blind holes can be accurately machined. You can apply the CNC drilling process to engine parts such as coolant passages, oil galleries, and mounting holes for bolts.

CNC Boring

CNC Boring is used to enlarge or refine existing holes. You can use a single-point cutting tool inside the hole to produce complex bore shapes such as stepped or tapered holes.

Boring ensures precise hole diameters and high concentricity, which is critical for bearing, piston, and other key component assembly. It is commonly applied to parts like cylinder bores, main bearing bores, and connecting rod bores.

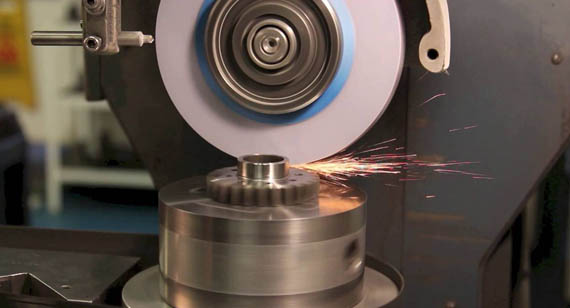

Through CNC grinding, surface material of engine parts is gradually removed by the grinding force. Usually, you can achieve high-precision dimensions and a smooth surface by using an abrasive wheel. Grinding is suitable for high-precision surfaces such as crankshaft journals, camshaft lobes, and valve seats.

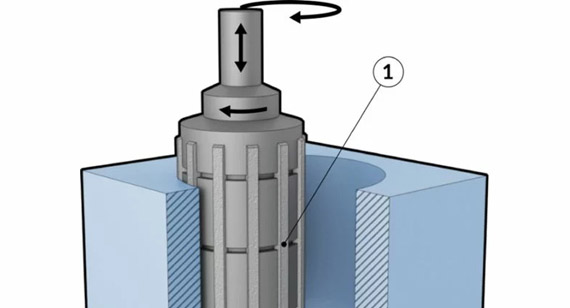

Honing is usually using the grinding stone to achieve surface cross network of the hole by the hole surface reciprocating motion, and this process is done after drilling or boring.

You can apply honing to cylinder bore, hydraulic cylinder and precision bearing bore manufacturing. The friction of these engine parts can be reduced by honing, and the sealing and lubrication performance can be improved.

CNC Lapping

You can achieve nano-scale flatness and surface finish for your engine components by CNC lapping. This process is that the abrasive slurry being used to perform light cutting on the workpiece surface, and the effects of lapping you will see is high dimensional accuracy, high surface smooth, excellent sealing.

For critical sealing surfaces such as piston crowns, cylinder head mating surfaces, and valve seats, lapping is often applied.

Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) is used for complex parts that cannot be machined with conventional cutting tools. Material is removed by generating controlled electrical discharges between an electrode and the workpiece, forming intricate cavities or contours. You can apply this process to engine assemblies of turbine blades, fuel injector nozzles, and other complex internal cavities.

CNC machining plays a vital role in modern engine manufacturing, especially for parts that require high dimensional accuracy, complex geometries, and consistent quality. Below is a classification of engine parts by name and their compatibility with CNC machining and other manufacturing processes.

Table 1: CNC Engine Part Types – Manufacturing Compatibility Table

| Engine Part Name | CNC Machining Compatibility | Typical Manufacturing Process | Notes |

| Cylinder Head | High | CNC machining / Casting + CNC | Combustion chambers and valve seats require high precision |

| Connecting Rod | High | CNC machining / Forging + CNC | Precision and weight consistency are critical |

| Intake Manifold | High | CNC machining / Casting + CNC | Common in performance and custom engines |

| Oil Pan | High | CNC machining | Popular in racing and custom applications |

| Valve Train Components | High | CNC machining | Includes rocker arms and cam supports |

| Engine Brackets & Mounts | High | CNC machining | Structural but non-combustion parts |

| Engine Block | Medium | Casting + CNC post-machining | CNC used for cylinder bores and bearing surfaces |

| Crankshaft | Medium | Forging + CNC machining | CNC used for journals and precision features |

| Camshaft | Medium | Casting or forging + CNC | Lobe profiles require accurate CNC machining |

| Pistons | Medium | Forging + CNC machining | CNC used mainly for finishing |

| Flywheel | Medium | Casting or forging + CNC | CNC used for balance and mounting surfaces |

| Exhaust Manifold | Medium | Casting + CNC | CNC mainly for flange surfaces |

| Turbocharger Housing | Medium | Casting + CNC | CNC used for sealing and mounting surfaces |

| Piston Rings | Low | Rolling + grinding | CNC not used for part formation |

| Gaskets / Head Gasket | Low | Stamping / Layer bonding | CNC only used for tooling |

| Spark Plugs | Low | Multi-process assembly | Not suitable for CNC machining |

| Fuel Injectors | Low | Precision forming + assembly | CNC rarely used for final components |

Engine Parts by Fully CNC-Machined

High-compatibility means those can be fully CNC-machined engine parts. These engine parts benefit most from CNC machining due to their structural complexity and functional precision requirements. And they can acheive tight tolerances, flexible design changes, and excellent surface finish through CNC machining.

Engine Parts by CNC Post-Machining

While CNC machining is essential for many engine components, it is often used alongside casting or forging to achieve the best balance of precision, strength, and cost.

Medium compatibility relies on CNC machining mainly for post-processing after casting or forging. For these engine parts, CNC machining is mainly used for finishing operations, such as boring, milling, surface flattening, and tolerance control, rather than for primary shaping.

Engine Parts That Typically Not CNC-Machined

These engine parts rely on manufacturing processes where CNC machining is not suitable or not economical. CNC may still be used to produce tooling or molds, but not the final component itself.

For choosing the proper materials for CNC engine components, it is essential to consider the materials’ properties such as weight, strength, durability (fatigue resistance), and corrosion resistance. The intended usage environment of the engine assemblies that you will design, or manufacture must align with the material properties, and cost considerations should also be taken into account. You can find the popular materials and their key properties in below table:

Table 2: Typical Materials for CNC Engine Parts

| Category | Material | Key Characteristics | Typical Applications |

| Aluminum Alloys | 6061 Aluminum | Lightweight, good strength and machinability, corrosion-resistant, cost-effective | Engine brackets, housings, mounting flanges, intake components, structural parts |

| 7075 Aluminum | Strength comparable to steel, excellent fatigue resistance, higher cost, moderate corrosion resistance | High-load brackets, racing connecting rods, small high-strength structural components | |

| Cast Aluminum (A356, 319) | Suitable for complex geometries, good thermal conductivity, lightweight, low mass-production cost | Engine blocks (casting + CNC post-machining), cylinder heads, housing components | |

| Ferrous Metals (Steel & Cast Iron) | Gray Cast Iron (GCI) | Excellent wear resistance and vibration damping, good thermal stability, low cost | Engine blocks and cylinder liners (casting + CNC finishing) |

| Compacted Graphite Iron (CGI) | Higher strength and stiffness than gray iron, superior fatigue resistance, suitable for high-stress applications | High-load diesel engine blocks | |

| Alloy Steel (4140, 4340, 8620) | High strength, toughness, and fatigue resistance; ideal for cyclic loading | Crankshafts, connecting rods, gears, drive shafts | |

| Carbon Steel (AISI 1045) | Good strength and wear resistance, good machinability, cost-effective | Shafts, gears, crankshaft components, transmission parts | |

| Other Materials | Titanium Alloy (Ti-6Al-4V) | Exceptional strength-to-weight ratio, corrosion and heat resistance; high material and machining cost | High-performance engine shafts, wear-resistant and lightweight structural components |

| Engineering Plastics (Nylon, Delrin) | Lightweight, low friction, good wear resistance and vibration damping; non-load-bearing | Bushings, guides, insulators, low-load auxiliary engine components |

Understanding the benefits and challenges can help you make a smarter choice for whether designing or manufacturing CNC engine parts:

Benefits

You can produce your engine parts with even ±0.01 mm accuracy through CNC machining, ensuring smoother engine operation, reduced vibration, and extended component lifespan. These make you more confidently manufacture high-performance engines in the market.

Your brand’s engine design may ask for a batch of customized complex designs for engine components such as complex combustion chambers, cooling channels, or curved surfaces. CNC tools can create these complex shapes more cost-effective than other ways such as casting (which must need molds first) and ensure your design vision is precisely realized quickly with high repeatability (controlled by computer programmed instructions).

For you ‘ve known that CNC engine components production is controlled by computer programmed instructions and the instructions can be changed for your next new parts design quickly. That’s really flexible to shorten delivery cycles for new parts, thereby achieving a competitive edge in the market.

CNC machining can handle various materials—aluminum alloy, steel, cast iron, or titanium alloy. Your design or requirements for engine performance can be met by suitable materials choices.

Challenges

There are still some practical challenges, and you may apply appropriate strategies for your CNC engine parts.

Hard-to-machine materials, such as titanium alloys and hardened steels, are challenging to process. You might consider, while ensuring strength and durability, choosing materials that are easier to machine, such as high-strength aluminum alloys or medium carbon steels. For the CNC-machined material of the engine parts you select, it’s best to confirm with the factory in advance whether it is suitable. This can reduce the risk of extended lead times or increased costs.

During the design phase, you can evaluate the engine part design and consult the factory for suggestions on optimizing wall thickness, cavity layout, or adding reinforcements.

CNC programming requires proficiency in CAD/CAM software and G-code to ensure the machining program is executed accurately. If you want to become a high-level engineer, learning advanced software and mastering multi-axis programming and toolpath optimization is essential. Designers from the brand side should also communicate with engineers to optimize part structures and machining plans.

If you are considering building your own machining line, the initial investment in CNC equipment and labor costs is extremely high. Therefore, comparing quotes and capabilities from different factories is more practical. At the same time, you need to balance part complexity and cost and appropriately adjust the design or batch size to make the best production decisions for your engine parts.

CNC machining has become a cornerstone of modern engine manufacturing, offering precision, repeatability, and flexibility that traditional methods cannot easily match. By understanding the processes involved, the materials best suited for CNC, and the challenges you may face, you can make smarter design and production decisions for your engine components.

Client Challenge:

A high-performance automotive manufacturer required a CNC-machined aluminum engine support component made from 6061-T6 aluminum alloy, with dimensions approximately 250 mm × 120 mm × 80 mm. The part featured thin walls down to 3 mm, deep cavities, and complex curved surfaces. Tight geometric tolerances of ±0.01 mm and surface roughness of Ra 0.8 μm were required. Traditional casting or multi-step machining methods led to deformation, assembly misalignment, high material waste, and extended lead times.

VMT CNC Machining Factory Solution:

Through DFM evaluation and structural optimization, unnecessary cavities and transitions were minimized, and tool paths and fixtures were redesigned for stability. The part was machined in a single setup on a 5-axis CNC milling machine using custom vacuum fixtures. The machining workflow included rough milling, semi-finishing (contour cutting + chamfering), and precision finishing (surface finishing + CNC boring). High-performance carbide tools were used with a feed rate of 1500 mm/min and a cutting depth of 1.5 mm per pass. Throughout the process, 3D CMM inspection, SPC monitoring, and online deformation compensation ensured dimensional accuracy, flatness, and hole positioning met design requirements.

Results:

The first-piece prototype was completed in 4 days. Dimensional accuracy was maintained within ±0.010 mm, surface roughness reached Ra 0.78 μm, and material utilization improved by approximately 15%. Batch production achieved a ≥98% first-pass yield. The client successfully integrated the component into engine assembly with precise fit and reliable performance, and was highly satisfied with VMT’s precision, efficiency, and consistency, subsequently expanding their order volume.

1.Which engine parts are CNC machined?

Cylinder heads, connecting rods, intake manifolds, oil pans, and valve train components are among the most common CNC engine parts, especially in low-volume and high-performance applications.

2. How does CNC machining compare to additive manufacturing when producing engine components?

CNC machining provides higher precision, better surface finish, and material density compared to additive manufacturing (3D printing). Additive methods can create complex geometries with less material waste but may require post-processing to achieve the same strength and surface quality.

3. How does CNC machining ensure repeatability and consistency in mass production?

CNC machines operate under computer-controlled instructions, which maintain tight tolerance across multiple parts. Standardized programs, tool monitoring, and automated setups allow manufacturers to produce engine components with consistent dimensions and performance batch after batch.

4. How do advancements in CNC technology affect engine component manufacturing?

Modern multi-axis CNC machines, advanced tooling, and simulation software allow more complex shapes, tighter tolerances, and faster cycle times. These improvements enable higher-performance engine designs that were previously difficult or impossible to manufacture.

5. When should I choose CNC machining over casting or forging for engine parts?

CNC machining is ideal when high precision, tight tolerances, and intricate features are required. Casting or forging is better for initial shaping of large volumes or high-strength components, which can then be finished with CNC to meet exact specifications.

6. Can CNC machining reduce engine component weight without compromising strength?

Yes, CNC allows precise material removal to create lightweight structures such as hollowed components or optimized ribbing, which improves performance while maintaining necessary strength and stiffness.