15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 11 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Jan 11 2026 | Reading Time:About 2 minutes

5086 aluminum finds extensive applications in ship hulls, armor plates, offshore structures, pressure vessels, and storage tanks. Recognized for its exceptional durability and corrosion resistance, it performs reliably even in harsh environments such as seawater and salt spray. The alloy also offers excellent weldability and can achieve enhanced strength through cold working, making it a versatile choice for a wide range of engineering applications. Read on to explore more details that make 5086 aluminum a trusted material.

Part of the 5000 series of aluminum alloys, 5086 features magnesium (≈3.5–4.5%) as its main alloying element, with smaller amounts of manganese and chromium, resulting in a high-strength, corrosion-resistant, marine-grade alloy. It combines moderate-to-high strength, good formability, corrosion-resistance and lightweight properties, making it ideal for complex engineered structures exposed to harsh marine or corrosive environments.

Unlike heat-treatable aluminum alloys, its strength comes primarily from cold working (strain hardening), allowing it to retain most of its mechanical properties after welding. These characteristics make 5086 aluminum an excellent material for welded structures that require both strength and high corrosion resistance such as such as offshore structural frame or other marine welded aluminum assemblies.

The main alloying elements of grade 5086 aluminum are magnesium (3.5–4.5%), which provides the primary strengthening and enhances corrosion resistance, and manganese (0.2–0.7%), which improves both corrosion resistance and formability. Below table shows its typical chemical composition:

Table 1: Chemical Composition of 5086 Aluminum (Typical Ranges, wt%)

| Element | Typical Composition (wt%) |

| Aluminum (Al) | Remainder |

| Magnesium (Mg) | 3.5 – 4.5 |

| Manganese (Mn) | 0.2 – 0.7 |

| Chromium (Cr) | 0.05 – 0.25 |

| Silicon (Si) | ≤ 0.4 |

| Iron (Fe) | ≤ 0.5 |

| Titanium (Ti) | ≤ 0.15 |

| Zinc (Zn) | ≤ 0.25 |

| Copper (Cu) | ≤ 0.1 |

| Other elements, each | ≤ 0.05 |

| Other elements, total | ≤ 0.15 |

5086 aluminum is available in multiple temper conditions, and its properties—especially strength—vary significantly with temper. In fact, the strength difference between the annealed (O) condition and strain-hardened tempers (such as H116 or H131) can exceed 2×, even though the alloy composition remains the same. The table below shows typical, industry-accepted values for the most widely used marine temper, AA 5086-H116:

Table 2: Physical and Mechanical Properties of AA 5086-H116 Aluminum

| Property | Typical Value | Unit | Notes |

| Density | ~2.66–2.70 | g/cm³ | Lightweight structural alloy |

| Ultimate Tensile Strength | ~290–300 | MPa | Indicates maximum load before fracture |

| Yield Strength (0.2% offset) | ~207–215 | MPa | Primary design strength value |

| Elongation at Break | ~10–12 | % | Good ductility for a marine structural alloy |

| Brinell Hardness | ~78–81 | HB | Moderate hardness |

| Young’s Modulus | ~68–71 | GPa | Elastic stiffness |

| Thermal Conductivity | ~125–130 | W/m·K | Useful for thermal and welding considerations |

From the above table, you can find that AA 5086-H116 marine-grade aluminum alloy offers a balance of strength and ductility. With excellent corrosion resistance in seawater and good weldability, it’s ideal for boat hulls and marine structural parts. Its density and decent thermal conductivity making it lightweight and practical for structural applications.

And about general properties of AA 5086 aluminum, key characteristics include:

1.Moderate-to-High Strength, Increasing with Strain Hardening

5086 aluminum has moderate-to-high strength and is not heat-treatable. Its strength is obtained primarily through strain hardening (cold work), which means its mechanical strength increases with the degree of cold working (AA 5086-O < AA 5086-H32 < AA 5086-H116 <AA 5086-H131):

2.Excellent Corrosion Resistance, Especially in Seawater

5086 belongs to the 5xxx series aluminum-magnesium alloys, with a relatively high magnesium content of approximately 3.5–4.5 wt%. This composition provides exceptional resistance to seawater, salt spray, and marine atmospheres.

Compared with many other aluminum alloys such as 6061 or 5052, 5086 offers superior long-term corrosion performance in marine environments. This is why 5086 is widely used in ship hulls and decks, offshore platforms and other marine structural components exposed to saltwater.

3.Excellent Weldability with Good Strength Retention

5086 aluminum offers excellent weldability because its strength comes from cold work and dissolved magnesium, not from heat-treated precipitates that are sensitive to welding(non-heat-treatable aluminum-magnesium alloy system). Unlike heat-treatable alloys such as 6xxx or 7xxx series, its welding does not cause significant softening in the heat-affected zone, so it can retain most of its mechanical strength after welding.

5086 aluminum alloy is frequently used for welded joints in ship structures, decks, ladders, and yacht hulls. It’s compatible with MIG, TIG, and SMAW welding processes, and common filler metals are ER5356 and ER5183.

4.Excellent Formability , Especially in the Annealed (O) Condition

In the AA 5086-O (annealed) temper, the alloy exhibits very high ductility and excellent formability, making it well-suited for a wide range of cold-forming processes. Common Cold-Forming Processes for 5086-O include cold bending, roll forming, deep drawing, stretch forming, and press forming.

As the level of strain hardening increases (e.g., H32 → H116), strength increases while formability decreases. However, even in higher-strength tempers, 5086 still maintains reasonable workability compared with many other structural aluminum alloys.

5086 is considered a sister alloy of 5083 aluminum, and they have similar properties such as density and basic elastic modulus. But they may differ in:

When selecting a material, you should carefully assess which alloy best meets your project’s requirements for service conditions, strength, formability, and corrosion resistance. Below is a more specific table comparing 5086 vs 5083 aluminum:

Table 3: Comparison of Aluminum Alloy 5086 vs 5083

| Item | 5083 Aluminum | 5086 Aluminum |

| Composition – Mg | ~4.0–4.9 % | ~3.5–4.5 % |

| Composition – Mn | ~0.4–1.0 % | ~0.2–0.7 % |

| Density (g/cm³) | ~2.7 | ~2.7 |

| Brinell Hardness | 75–110 | 65–100 |

| Young’s Modulus (GPa) | 68 | 68 |

| Elongation at Break | ~1.1–17 % | ~1.7–20 % |

| Fatigue Strength (MPa) | ~93–190 | ~88–180 |

| Ultimate Tensile Strength (MPa) | ~290–390 | ~270–390 |

| Yield (Proof) Strength (MPa) | ~110–340 | ~110–320 |

| Thermal Conductivity (W/m·K) | ~120 | ~130 |

Advantages of excellent corrosion resistance, good weldability, and stable mechanical performance after welding make grade 5086 aluminum a widespread uses in marine and industrial applications. Common applications of 5086 aluminum include:

1. Marine and Offshore Structures

AA 5086 is one of the most widely used aluminum alloys in marine environments due to its outstanding resistance to seawater corrosion. It can be used as both the main load-bearing material and welded joints. AA 5086 aluminum’s typical uses for marine and offshore structures include:

2. Vehicle and Transportation Equipment

In transportation, 5086 is primarily selected for corrosion resistance and weldability, especially in large welded assemblies, including:

3.Automotive Components (Limited Use)

Here, AA 5086 is applied to non-primary structural components:

4.Industrial and Process Equipment

5086 aluminum is well suited for large industrial structures operating in corrosive or low-temperature environments. Common examples include:

These components are typically made from formed plates and assembled through welding, with 5086 acting as the structural base material.

4. Defense and Protective Structures

5086 aluminum, mainly the 5086-H131 aluminum are used in lightweight protective and armor applications, such as:

In engineering and military documentation, 5086-H131 is the specified temper for armor applications due to its higher strength, and balance of good ductility yet impact resistance; While 5086-O (annealed), H32/H34 are insufficient in strength, and H111 is intended for forming rather than protection.

In conclusion, 5086 aluminum combines corrosion resistance, weldability, and solid performance, making it a go-to choice for shipbuilding, armor, offshore, and industrial applications. The versatility and proven stability of 5086 aluminum in harsh environments make it a trusted option for designers and manufacturers. But if you're seeking a more informed material choice, it's necessary to evaluate more details of this alloy compared with others.

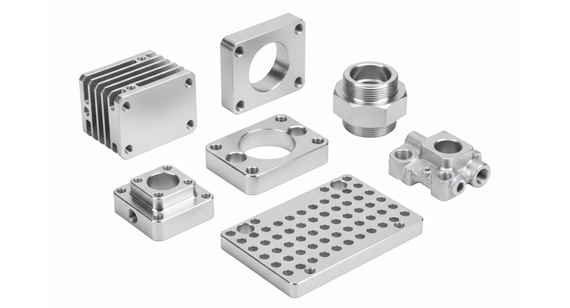

Client Challenge:

An American automotive supplier needed a batch of high-precision 5086 aluminum components for marine equipment. Due to the high strength and corrosion resistance of 5086 aluminum, machining presented challenges such as tool built-up, work hardening, and surface roughness. The parts had complex geometries, uneven wall thicknesses, and tight tolerances, making it difficult for conventional machining methods to consistently meet the required dimensional accuracy and surface quality.

VMT Solution:

To address the machining challenges of 5086 aluminum, VMT implemented the following strategies:

Results:

By optimizing machining parameters and strictly controlling the process, the delivered 5086 aluminum components met all dimensional and surface quality requirements. Assembly proceeded smoothly, and the client was highly satisfied with the machining precision, surface finish, and material performance, successfully deploying the components in marine equipment.

Q1: Aluminum 5086 vs 6061: which should you choose?

Choose 5086 aluminum when corrosion resistance and weldability in marine or harsh environments are critical, and choose 6061 aluminum when higher strength, heat treatability, and better machinability are required for structural or precision components.

Q2: What are the main price factors of 5086 aluminum?

The price of 5086 aluminum is mainly influenced by raw aluminum prices, magnesium content, product form and thickness, temper condition, order quantity, and compliance with specific standards or certifications.

Q3: What is the difference between aluminum 5052 and 5086?

Compared with 5052, 5086 aluminum offers higher strength and better performance in severe marine environments, while 5052 provides better formability and is more suitable for lighter-duty applications.

Q4: Is 5086 aluminum better than 5083 aluminum?

5086 is not strictly better than 5083; 5083 offers higher strength, while 5086 provides slightly better formability and weldability, making the choice dependent on strength requirements and fabrication needs.

Q5: Is 5086 aluminum bendable?

Yes, 5086 aluminum has good bendability, especially in softer tempers, and can be cold-formed into complex shapes while maintaining structural integrity.

Q6: What are the common forms of 5086 aluminum?

5086 aluminum is commonly supplied as plate, sheet, coil, pipe, round bar, rod, strip, square tube, rectangular tube, and angle bar, supporting a wide range of fabrication and welded structural applications.