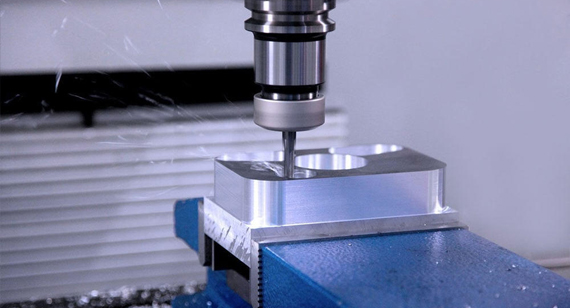

15 years one-stop China custom CNC machining parts factory

4 |

Published by VMT at Dec 26 2025 | Reading Time:About 2 minutes

4 |

Published by VMT at Dec 26 2025 | Reading Time:About 2 minutes

Across construction, manufacturing, and industrial applications, aluminum alloys are widely used due to their lightweight, corrosion resistance, and ease of fabrication. If you are looking for an aluminum alloy that is both corrosion-resistant and easy to work with for roofing, exterior cladding, or lightweight structural components, 3105 aluminum must be an ideal choice. As a representative of the aluminum-manganese series, 3105 aluminum offers excellent formability, good corrosion resistance, and a balance of lightweight with moderate strength, making it a preferred choice for engineers and manufacturers.This article will provide a comprehensive overview of 3105 aluminum’s properties, benifits and applications, and compare it with 5052 and 1100 aluminum to help you determine whether it is suitable for your project.

3105 aluminum belongs to the aluminum–manganese alloy series and is primarily composed of aluminum with small additions of manganese and magnesium. This alloy stands out for its excellent corrosion resistance and good formability, allowing it to maintain stable performance in long-term outdoor environments. Applications such as roofing, exterior wall panels, gutters, and pre-painted aluminum coils are among the most common uses of 3105 aluminum alloy.

One thing you should notice is that 3105 aluminium has moderate strength and is not suitable for high-load or heavy structural applications. If higher strength is required, aluminum alloy 5052(higher strength along with good corrosion resistance) is typically more suggested. It is also worth noting that 3105 aluminum has good machinability. But its strength is mainly enhanced through cold working processes such as rolling and bending, as it cannot be strengthened by heat treatment.

3105 aluminum alloy belongs to the aluminum-manganese (Al-Mn) series and is primarily composed of approximately 98% aluminum. It is a typical wrought alloy, with manganese (Mn) added to increase strength without sacrificing ductility, and magnesium (Mg) added to enhance work-hardening capability. Chemical composition of 3105 aluminum includes:

Table 1: Chemical Composition of 3105 Aluminum Alloy

| Element | Content (%) |

| Aluminum (Al) | Remainder (~98%) |

| Manganese (Mn) | 0.30 – 0.80 |

| Magnesium (Mg) | 0.20 – 0.80 |

| Iron (Fe) | ≤ 0.70 |

| Silicon (Si) | ≤ 0.60 |

| Copper (Cu) | ≤ 0.30 |

| Chromium (Cr) | ≤ 0.20 |

| Zinc (Zn) | ≤ 0.40 |

| Titanium (Ti) | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

3105 aluminum alloy exhibits excellent chemical stability and corrosion resistance, allowing it to maintain long-term performance across a variety of environments. Its chemical properties include:

3105 aluminum alloy performs reliably in a variety of environments such as humid air, lightly polluted industrial areas, coastal regions. Its surface naturally forms a dense oxide layer that effectively blocks oxygen and moisture, extending the service life of aluminum products.

3105 aluminum exhibits stable oxidation resistance. When exposed to air, a transparent aluminum oxide (Al₂O₃) layer forms on the surface. This natural protective layer prevents further oxidation, ensuring long-term material stability under normal operating conditions and reducing maintenance requirements.

3105 aluminum tolerates most weak acids and general acidic environments, making it suitable for long-term use. However, strong acids (e.g., nitric acid, sulfuric acid) or strong bases (e.g., sodium hydroxide) can damage the protective oxide layer and reduce corrosion resistance. Therefore, protective measures should be considered in design and manufacturing based on environmental conditions.

3105 aluminum can undergo anodizing to form a thicker and harder oxide layer, significantly enhancing corrosion and wear resistance while improving surface gloss and aesthetics. This makes it ideal for high-demand building and industrial applications or appearance requirements.

3105 Aluminum Alloy features low density and lightweight characteristics, along with good thermal and electrical conductivity. You can check the below physical properties of 3105 aluminum in table 2:

Table 2: Physical Properties of 3105 Aluminum Alloy

| Property | Value | Unit | Description |

| Density | ~2.7 – 2.8 | g/cm³ | Similar to typical aluminum alloys (lightweight material) |

| Melting Range | ~640 – 660 | °C | Onset and completion of melting |

| Specific Heat Capacity | ~900 | J/kg·K | Thermal capacity, comparable to other aluminum alloys |

| Thermal Conductivity | ~130 – 190 | W/m·K | Good heat transfer capability (slightly lower than pure aluminum) |

| Coefficient of Thermal Expansion | ~23 – 24 | µm/m·K | Thermal expansion behavior similar to most aluminum alloys |

| Electrical Conductivity | ~44 % IACS (volume) | % IACS | Alloying elements reduce conductivity compared to pure aluminum |

Physical and the Following Mechanical Data Credit: Makeitfrom 3105 (also AlMn0.5Mg0.5 / EN AW-3105 / AA 3105 / A93105 / N31)Aluminum

You can find out the typical value range of 3105 aluminum mechanical properties as follows:

Table 3: Mechanical Properties of 3105 Aluminum Alloy

| Property | Typical Range | Unit |

| Young’s Modulus | ~69 | GPa |

| Poisson’s Ratio | ~0.33 | — |

| Shear Modulus | ~26 | GPa |

| Ultimate Tensile Strength (UTS) | 120 – 240 | MPa |

| Yield Strength (0.2% offset) | 46 – 220 | MPa |

| Elongation at Break | 1.1 – 20 | % |

| Brinell Hardness | 29 – 67 | HB |

| Fatigue Strength | 39 – 95 | MPa |

3105 aluminum alloy is available in multiple tempers, such as the annealed (soft) condition with lower strength and higher ductility, and strain-hardened tempers with higher strength and lower elongation. The specific mechanical property values vary with temper, degree of cold work, and material thickness.

Overall:

3105 aluminum is widely used in construction and manufacturing due to the following benefits:

3105 aluminum remains stable in long-term outdoor conditions. Even in humid, lightly polluted, or coastal environments, it maintains structural integrity and appearance, resisting oxidation and corrosion.

The alloy offers strong resistance to most atmospheric and mild chemical environments while providing sufficient mechanical strength for structural support, achieving a balance between protection and load-bearing capability.

3105 aluminum is easy to roll, bend, stamp, or otherwise cold-form, making it suitable for exterior panels, roofing sheets, and complex industrial components.

Compatible with conventional welding methods, including TIG, MIG, and spot welding. Welded parts retain excellent performance, facilitating the assembly of complex structures.

While not a high-conductivity aluminum, 3105 provides sufficient conductivity for lightweight electrical applications in construction and industrial components.

The alloy is easy to machine, drill, and cut, and it can also be coated, painted, or anodized, offering high manufacturing flexibility.

Smooth surface with good texture, easily painted or anodized, combining functionality with visual appeal for building facades and decorative components.

Moderate material cost and low maintenance make 3105 aluminum a practical and economical choice for construction and industrial manufacturing.

Coated or anodized 3105 aluminum resists UV exposure, wind, and rain, providing long service life. Additionally, aluminum is recyclable, supporting environmentally sustainable applications.

So many benefits of 3105 aluminum give it widespread uses including:

3105 aluminum finds applications in light-duty trailers, vehicle panels, cargo boxes, and non-structural automotive components. Its lightweight and corrosion-resistant properties help reduce maintenance requirements in vehicle manufacturing.

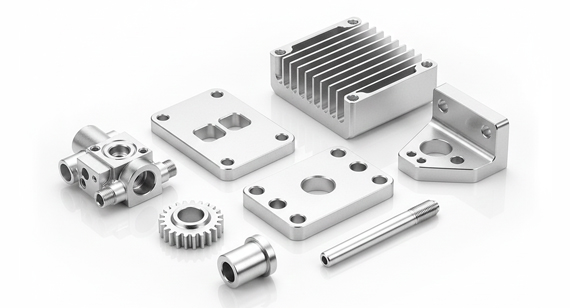

In industrial applications, 3105 aluminum is commonly used in coated or pre-painted rolled sheets and lightweight structural components such as brackets, housings, and frames. Its moderate strength and chemical stability make it a reliable choice for parts requiring durability without excessive weight.

3105 aluminum is widely used in construction for metal roofing, exterior wall panels, eaves, gutters, and downspouts. Its excellent corrosion resistance and durability make it ideal for long-term outdoor exposure, while its formability allows it to be easily shaped into complex architectural components.

Beyond basic roofing, 3105 aluminum is suitable for façade cladding, soffits, and ceiling panels. Its smooth surface and compatibility with coating or anodizing processes ensure both aesthetic appeal and long-term protection against the elements.

3105 aluminum is also applied in HVAC systems for ductwork, panels, and enclosures. Its corrosion resistance and ease of fabrication make it suitable for both indoor and outdoor installations.

The alloy is used for outdoor advertising signs, billboards, and wayfinding signs, benefiting from its corrosion resistance and good surface finish. In commercial kitchens, 3105 aluminum is used for equipment, cabinets, and shelving, combining hygiene, durability, and ease of cleaning.

3105 aluminum alloy and 5052 aluminum alloy both offer excellent corrosion resistance, making them suitable for outdoor or high-humidity environments. In practical engineering and construction projects, these two alloys are often considered as alternative options.

But they differ in strength, formability, or others. You will find that:

The following table compares 3105 and 5052 aluminum alloys based on key performance and typical uses.

Table 4: Comparison of 3105 Aluminum vs 5052 Aluminum

| Item | 3105 Aluminum | 5052 Aluminum |

| Tensile Strength | 145–205 MPa | 210–250 MPa(higher) |

| Corrosion Resistance | High | High |

| Weldability | Good | Medium |

| Formability | High | Medium |

| Typical Applications | Roofs, exterior walls, architectural panels, coated sheets, insulation cladding | Load-bearing parts, structural components, marine fittings, pressure vessels, automotive parts |

3105 aluminum alloy and 1100 aluminum are both non-heat-treatable alloys with good formability and weldability, commonly used in construction and light industrial applications.

But because of their differences in alloying elements, they differ in strength, corrosion resistance, etc. You will find that:

The following table compares the two alloys among key performance metrics and typical applications.

Table 5: Comparison of 3105 Aluminum vs 1100 Aluminum

| Item | 3105 Aluminum | 1100 Aluminum |

| Tensile Strength | 145–205 MPa(Higher) | 110–140 MPa |

| Corrosion Resistance | High | Medium |

| Weldability | Good | Excellent |

| Formability | High | High |

| Decorative Finish | Good, can be painted or anodized | Excellent, can be polished or anodized |

| Typical Applications | Roofs, Exterior Walls, Architectural Sheets | Decorative Panels, Reflective Materials, Light Structures |

This article provides a detailed overview of the properties and applications of 3105 aluminum, along with comparisons to common aluminum alloys 5052 and 1100. 3105 aluminum is a well-balanced, versatile aluminum–manganese alloy that combines corrosion resistance, good strength, excellent formability, and weldability, making it particularly suitable for building roofs, exterior walls, coated sheets, and lightweight structural components.

In comparison, 5052 aluminum offers higher strength and is better suited for load-bearing structural applications, while 1100 aluminum, with its exceptional machinability and weldability, is ideal for decorative and lightweight applications.

Looking for high-precision aluminum parts? We offer CNC machining services for 3105, 5052, 1100 aluminum, and other alloys—perfect for rapid prototyping or mass production.

Get your free quote and custom machining solution from VMT CNC Machining Factory now!

Q1: Can 3105 aluminum be welded?

A: Yes, 3105 aluminum has good weldability, but care should be taken to manage the heat-affected zone.

Q2: Is 3105 aluminum corrosion-resistant?

A: Yes, it offers high corrosion resistance, making it ideal for long-term outdoor applications.

Q3: Is 3105 aluminum suitable for sheet and coil processing?

A: Absolutely. It can be rolled, bent, and stamped easily.

Q4: Which is stronger, 3105 or 5052 aluminum?

A: 5052 aluminum is stronger than 3105, though 3105 has slightly better formability.

Q5: How does 3105 compare to 3003 aluminum?

A: 3105 has slightly higher strength and better corrosion resistance, while 3003 is more widely used for general forming.

Q6: How does 3105 compare to 3104 aluminum?

A: 3105 and 3104 have similar strength and corrosion resistance, but 3104 may offer slightly better work-hardening properties for forming.