15 years one-stop China custom CNC machining parts factory

32 |

Published by VMT at Nov 06 2025 | Reading Time:About 7 minutes

32 |

Published by VMT at Nov 06 2025 | Reading Time:About 7 minutes

When designing lightweight and durable metal components, you may find aluminum metal stamping both appealing and confusing. The problem is that without understanding the process, material selection, and tooling considerations, you can face higher costs and part failures. The good news? By learning the basics of aluminum stamping, you can create stronger, more cost-effective parts that meet your project goals.

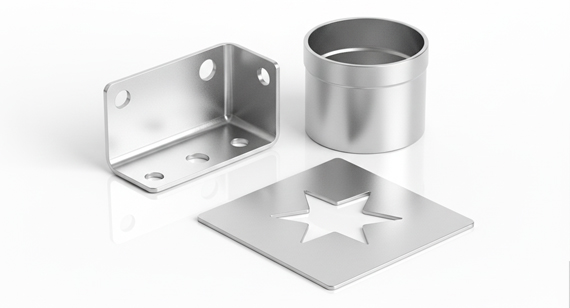

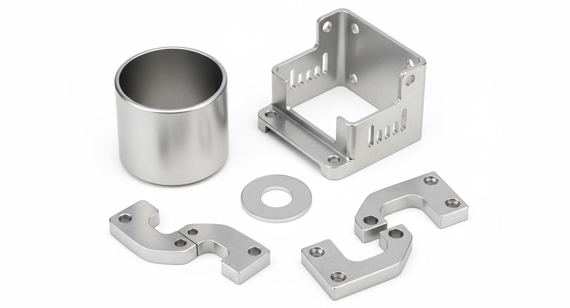

Aluminum metal stamping is a manufacturing process that shapes aluminum sheets into precise parts using dies and presses. It includes operations such as punching, blanking, bending, and drawing. This process offers lightweight, corrosion-resistant, and cost-effective components ideal for automotive, aerospace, and electronic applications.

Now that you understand what aluminum stamping is, let’s explore how the process works and what makes it different from other metal forming methods. By learning each stamping step, you’ll know exactly how your stamped aluminum parts are made and what to expect when working with professional metal stamping services like VMT.

When you need complex aluminum parts with precise shapes, you might wonder how they’re produced so accurately. The challenge is that without understanding the stamping process, you can’t design your parts efficiently. Learning how aluminum stamping works helps you make better design choices and communicate clearly with your CNC machining factory or metal stamping services provider.

The aluminum stamping process uses high-pressure machines and dies to form aluminum sheets into desired shapes. It involves steps like punching, blanking, bending, and drawing. Each step serves a specific function to create durable and lightweight stamped aluminum parts for industrial and consumer applications.

You now know that aluminum stamping is more than just pressing metal — it’s a carefully controlled sequence of operations. Next, let’s break down the main processes, including punching, blanking, bending, and drawing, to help you see how each step contributes to creating custom aluminum stamped components.

Punching

Punching is one of the most common steps in the aluminum stamping process. It uses a punch and die to create holes or cutouts in the aluminum sheet. During punching, the punch applies high pressure to force the aluminum into the die opening, removing unwanted material cleanly and efficiently.

This process is ideal for making ventilation holes, mounting slots, and electrical openings in aluminum stamped components. It delivers high repeatability and precision, making it perfect for large production runs in industries like automotive, electronics, and lighting.

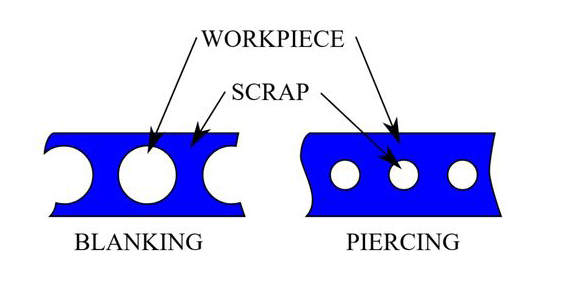

Blanking

Blanking is the process of cutting a flat piece, called a blank, from a larger aluminum sheet. This blank becomes the starting material for further stamping or forming operations. The blanking die defines the outer contour of the part, ensuring consistent dimensions and a clean edge.

This step is critical because it determines the final part’s size and shape accuracy. In aluminum metal stamping, high-quality blanking minimizes material waste and improves downstream efficiency during forming and bending.

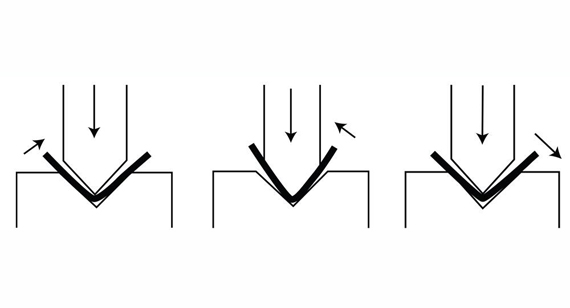

Bending

Bending involves deforming aluminum sheets along a straight axis to achieve the desired angle or curvature. The material is pressed between a punch and die to form a precise bend without breaking or cracking the surface. It’s commonly used for brackets, frames, and enclosures in custom metal stamping.

Because aluminum has excellent ductility, it bends easily—but excessive force or tight radii can lead to cracking or springback. Proper tooling and pressure control help achieve accurate and repeatable bends.

Drawing

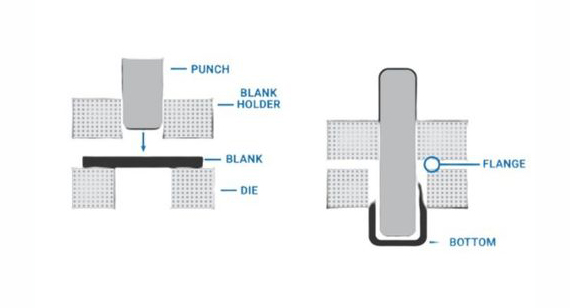

Drawing, or deep drawing, is used to transform flat aluminum blanks into hollow shapes like cups, cans, or housings. During drawing, the blank is pulled into a die cavity by a punch, stretching and forming the metal into a three-dimensional shape. This process is widely used in aluminum alloy stamping for aerospace, automotive, and packaging components.

The key to successful drawing is controlling material flow. Lubrication, die design, and aluminum grade selection all play major roles in preventing tearing and wrinkling during forming.

Aluminum stamping is preferred for its combination of strength, light weight, and versatility. Compared with other metals, aluminum is easier to form, resists corrosion naturally, and maintains excellent dimensional stability. This makes it ideal for producing stamped aluminum parts across industries such as automotive, aerospace, electronics, and lighting.

In CNC metal stamping, aluminum offers a unique advantage: it reduces part weight without compromising strength. This helps manufacturers meet performance and energy efficiency goals, especially in vehicles and aircraft. In addition, aluminum’s nonmagnetic and conductive properties make it perfect for electrical and electronic applications.

Another benefit is cost efficiency. Aluminum sheets can be stamped in high volumes using progressive or transfer dies, resulting in consistent quality and lower labor costs. Combined with CNC machining services, aluminum stamping allows tight tolerances and smooth finishes that meet demanding industrial standards.

Selecting the right aluminum alloy is one of the most important steps in the metal stamping process. Each alloy series offers unique properties such as strength, corrosion resistance, and formability. Understanding these differences helps you choose the most suitable material for your aluminum stamped components, ensuring efficiency and cost control during production.

When working with metal stamping services or a CNC machining factory, knowing the characteristics of each aluminum series can help you specify materials more precisely. This ensures your project meets both performance and budget requirements.

Aluminum Alloy Grades and Main Alloy Elements

| Alloy Series |

Main Alloying Elements |

General Characteristics |

| 1xxx Series |

99% pure aluminum | Excellent corrosion resistance, high ductility, and electrical conductivity; low strength. |

| 2xxx Series |

Copper (Cu) | High strength and hardness; lower corrosion resistance; often used in aerospace parts. |

| 3xxx Series |

Manganese (Mn) | Good formability and corrosion resistance; suitable for deep drawing and sheet applications. |

| 4xxx Series |

Silicon (Si) | Improved wear resistance and low melting point; often used for welding or brazing applications. |

| 5xxx Series |

Magnesium (Mg) | Excellent corrosion resistance and weldability; ideal for marine and automotive components. |

| 6xxx Series |

Magnesium (Mg) and Silicon (Si) | Balanced strength, corrosion resistance, and machinability; commonly used for structural parts. |

| 7xxx Series |

Zinc (Zn) | Very high strength; used in aerospace and high-stress applications; moderate corrosion resistance. |

| 8xxx Series |

Iron (Fe) and Lithium (Li) | Specialized alloys for high strength and lightweight properties in advanced applications. |

What Does “XXX” Represent? What Do the Other Letters Represent?

Aluminum alloys are identified by a four-digit numerical system that provides information about their composition and processing state. Understanding this system helps you select the right material for your aluminum stamping process or CNC machined aluminum parts.

The first digit indicates the major alloying element, such as copper, magnesium, or silicon. This defines the alloy family (for example, 1xxx, 5xxx, or 6xxx).

The second digit shows modifications to the original alloy. A zero means it’s the original composition, while other numbers indicate slight variations.

The last two digits (xx) identify the specific alloy within that series, distinguishing one grade from another.

For example:

After the four digits, you may see a letter, such as F, O, H, or T. These letters describe the temper, meaning how the metal was treated or strengthened after forming. Each temper affects the alloy’s hardness, strength, and ductility, which directly impact stamping performance and part durability.

What Do F (Original), O (Annealed), and H (Strain Hardening) Represent?

Aluminum alloys can be treated in different ways after production to achieve specific mechanical properties. These treatments are identified by temper designations such as F, O, and H. Knowing what each represents helps you select the best option for your aluminum metal stamping project and avoid unnecessary material or tooling issues.

F (As Fabricated or Original Temper)

The F temper indicates the aluminum is in its as-fabricated condition, meaning it hasn’t undergone any special heat treatment or strain hardening. This state offers moderate strength and is often used when no further mechanical properties are required.

It’s suitable for general forming or machining operations where dimensional precision is more important than strength.

O (Annealed Temper)

The O temper refers to aluminum that has been annealed, or heat-treated to its softest and most ductile condition. This improves formability and makes the alloy ideal for deep drawing, bending, or forming operations.

O temper is widely used in aluminum stamping processes requiring complex shapes without cracking.

H (Strain-Hardened Temper)

The H temper is produced by cold working (rolling, drawing, or bending) to increase strength through strain hardening. This process enhances hardness and yield strength but reduces ductility.

The H temper is perfect for stamped aluminum parts that need higher strength or stiffness, such as automotive brackets or enclosures.

H1, H2, H3, and H4 Tempers

The “H” designation in aluminum alloys represents strain hardening, but the numbers that follow (H1, H2, H3, and H4) specify the exact type of hardening and treatment applied. Understanding these helps you select the best condition for your aluminum stamping process or CNC machined aluminum parts, depending on the balance you need between strength and formability.

H1 – Strain Hardened Only

H1 tempers are strengthened only by cold working (no heat treatment). This type retains maximum strength from strain hardening and offers limited ductility.

It’s often used when high strength is required, and forming is minimal—ideal for aluminum stamped components like panels or brackets that don’t need extensive shaping.

H2 – Strain Hardened and Partially Annealed

H2 tempers are strain hardened and then partially annealed to reduce some of the hardness and restore ductility. This makes them more workable than H1 while maintaining good strength.

It’s a balanced choice for applications that need both strength and formability, such as covers or shallow drawn parts.

H3 – Strain Hardened and Stabilized

H3 tempers are strain hardened and then thermally stabilized to maintain mechanical properties over time. This treatment prevents unwanted changes in strength or hardness during use, especially under heat or vibration.

H3 is commonly applied to magnesium-based aluminum alloys (5xxx series) used in marine and automotive environments.

H4 – Strain Hardened and Lacquered or Painted

H4 tempers are strain hardened, then coated (painted or lacquered). The coating process involves mild heating, which slightly affects hardness.

This temper is used when appearance and corrosion resistance are critical, such as in decorative panels or consumer products.

The T temper indicates that the aluminum alloy has been heat-treated to increase strength and hardness. Unlike strain hardening (H temper), heat treatment changes the alloy’s internal structure through controlled heating and cooling. This process improves performance for aluminum stamped parts that must handle high stress or temperature.

T3 – Solution Heat-Treated, Cold Worked, and Naturally Aged

T3 alloys are first solution heat-treated, then cold worked (to add strength), and finally naturally aged at room temperature.

This temper provides a good balance of strength and ductility, making it suitable for CNC metal stamping and moderate forming operations.

T4 – Solution Heat-Treated and Naturally Aged

T4 alloys are solution heat-treated and then naturally aged without cold working.

They offer excellent formability and good strength, making them easy to stamp or bend before final assembly.

T5 – Cooled from High Temperature and Artificially Aged

T5 alloys are cooled from a high-temperature shaping process (like extrusion) and then artificially aged to reach desired strength.

This temper is stable and maintains good mechanical properties, often used in structural and automotive aluminum alloy stamping.

T6 – Solution Heat-Treated and Artificially Aged

T6 is the most common heat-treated temper. It provides maximum strength by combining solution heat treatment with artificial aging.

T6 alloys are widely used in aerospace, automotive, and industrial CNC machined aluminum parts because they hold shape under heavy loads.

T7 – Solution Heat-Treated and Overaged

T7 alloys are solution heat-treated and overaged to enhance dimensional stability and corrosion resistance.

This temper sacrifices some strength for better resistance to stress corrosion and distortion over time.

W (Solution Heat Treatment)

“W” temper, or solution heat treatment, is a process used to dissolve soluble elements (like magnesium or silicon) into a solid solution within aluminum alloys. The metal is heated to a specific temperature, held long enough for alloying elements to dissolve, and then rapidly quenched (usually in water). This locks the alloying elements in place, resulting in a soft but workable material that can later be aged (naturally or artificially) to increase strength.

In simple terms, W temper is the freshly heat-treated condition right after quenching — soft, ductile, and ready for further hardening.

Aluminum is one of the most widely used materials in metal stamping because it is lightweight, corrosion-resistant, and easy to form. Different aluminum grades offer varying levels of strength, ductility, and surface finish. Choosing the right alloy depends on the product’s requirements — such as strength, corrosion resistance, or forming performance. Below is an overview of common aluminum grades used in metal stamping and their main characteristics.

| Aluminum Alloy |

Main Characteristics |

| 1100 Aluminum Alloy |

Commercially pure aluminum with excellent corrosion resistance and workability. Soft and ductile, ideal for deep drawing and intricate stamping operations. Not heat-treatable. |

| 3003 Aluminum Alloy |

Aluminum-manganese alloy with higher strength than 1100. Excellent corrosion resistance, good formability, and weldability. Commonly used in stamped parts for food and chemical equipment. |

| 5052 Aluminum Alloy |

Aluminum-magnesium alloy known for its excellent corrosion resistance, especially in marine environments. Higher strength and better fatigue resistance than 3003. Suitable for both stamping and bending. |

| 6065 Aluminum Alloy |

Offers a balance between strength and formability. Can be heat-treated to improve hardness and durability. Often used in applications requiring structural performance. (Note: Often compared to 6061 or 6063 in similar uses.) |

| 7075 Aluminum Alloy |

High-strength aluminum-zinc alloy used for demanding applications. Excellent mechanical properties but limited formability. Common in aerospace and military stamped parts. |

| 8006 Aluminum Alloy |

Aluminum-iron-manganese alloy mainly used for foil and packaging stamping. Offers good strength, thermal resistance, and excellent formability for thin stamped products. |

Stamped aluminum parts are widely used across industries such as automotive, electronics, and aerospace because they combine strength, light weight, and excellent manufacturability. Aluminum’s natural properties make it ideal for stamping processes, allowing precise shapes with consistent performance and minimal waste. Below are the key advantages of stamped aluminum components.

| Advantage |

Description |

| Excellent Surface Finish |

Aluminum provides a clean, smooth surface that can be polished, anodized, or painted easily, enhancing appearance and corrosion protection. |

| High Strength-to-Weight Ratio |

Aluminum offers impressive mechanical strength while being significantly lighter than steel, making it ideal for reducing component weight without sacrificing durability. |

| Excellent Thermal Conductivity |

Aluminum efficiently transfers heat, making it perfect for stamped parts used in heat exchangers, housings, and electronic devices. |

| Good Electrical Conductivity |

Its natural conductivity makes aluminum suitable for stamped electrical connectors, busbars, and circuit components. |

| Low Temperature Resistance |

Aluminum retains its ductility and toughness at low temperatures, performing well in cold environments. |

| Excellent Corrosion Resistance |

The natural oxide layer on aluminum protects it from rust and corrosion, extending the life of stamped parts. |

| Good Formability and Ductility |

Aluminum can be easily stamped, drawn, or bent without cracking, allowing the production of complex shapes. |

| High Recyclability |

Aluminum can be recycled repeatedly without losing its properties, reducing material costs and environmental impact. |

Aluminum stamping involves forming flat aluminum sheets into desired shapes through various stamping methods. These processes use specialized dies and high-tonnage presses to cut, bend, or draw the metal precisely. Understanding the different stamping process types and technologies helps manufacturers choose the best method for achieving specific part geometries, tolerances, and production volumes.

| Process Type / Technology |

Description |

| Blanking |

Cuts flat aluminum sheets into specific shapes or “blanks” that serve as the starting point for further forming operations. It ensures precise dimensions and minimal material waste. |

| Bending |

Involves deforming aluminum sheets along a straight line to create angles or curves. It’s commonly used for brackets, enclosures, and structural parts. |

| Drawing (Deep Drawing) |

Stretches aluminum sheet metal into a three-dimensional shape, such as cups, cans, or housings, without thinning or tearing. |

| Piercing |

Creates holes or cutouts in aluminum sheets using a punch and die, essential for parts that require fastening or assembly. |

| Coining |

Uses high pressure to form fine surface details or embossed features, producing high-precision parts with smooth finishes. |

| Embossing |

Raises or indents specific areas of aluminum sheets for decorative or functional purposes, improving stiffness and aesthetics. |

| Progressive Die Stamping |

Combines multiple stamping operations (blanking, bending, piercing, etc.) in one continuous process, ideal for high-volume production with tight tolerances. |

| Transfer Stamping |

Moves aluminum blanks from one die station to another using mechanical transfer systems, suitable for large or complex parts. |

| Fine Blanking |

A precision stamping method that produces parts with very clean edges and minimal burrs, often used for functional or aesthetic components. |

| Hydroforming |

Uses high-pressure hydraulic fluid to form aluminum sheets into complex shapes with smooth surfaces and consistent wall thickness. |

Blanking Aluminum

Blanking is the process of cutting flat aluminum sheets into specific shapes called blanks. These blanks serve as the starting point for further stamping or forming operations. The process ensures consistent dimensions and minimal material waste. Blanking is commonly used for automotive panels, electronic enclosures, and structural components.

Piercing Aluminum

Piercing uses a punch and die to create holes or cutouts in aluminum sheets. This operation is essential for producing ventilation holes, mounting points, or openings for fasteners and electrical components. Piercing provides clean edges and high repeatability when performed with proper lubrication and tooling.

Coining Aluminum

Coining applies high pressure to emboss fine surface details or patterns onto aluminum sheets. This operation is often used for decorative designs, logos, or functional features requiring tight tolerances. Coining produces high-precision features with smooth surfaces.

Aluminum Deep Drawing

Deep drawing stretches flat aluminum blanks into hollow or recessed shapes such as cups, housings, or containers. The process requires high-ductility alloys like 3003 or 5052 to prevent cracking or tearing during forming. Deep drawing allows complex shapes while maintaining uniform wall thickness.

Embossing Aluminum

Embossing creates raised or recessed patterns on aluminum sheets for decorative or functional purposes. It increases part stiffness, improves aesthetics, and can add functional details such as alignment marks. Embossing is widely used in panels, housings, and trims.

Flanging Aluminum

Flanging is the process of bending the edge of an aluminum sheet at a 90-degree angle or other required angles to create a flange. This operation strengthens the edge, provides attachment points, and improves part rigidity. Flanging is commonly used for brackets, enclosures, and structural components in automotive, aerospace, and electronics industries.

1. Aluminum Progressive Die Stamping

What is Aluminum Progressive Die Stamping?

Progressive die stamping is a high-efficiency process where multiple stamping operations — such as blanking, piercing, bending, and flanging — are performed sequentially in a single die set. The aluminum sheet moves step by step through each station until the final part is complete.

Characteristics of Aluminum Progressive Die Stamping

Tip: Design parts with progressive die capabilities in mind to minimize scrap and ensure smooth material flow.

2. Aluminum Transfer Die Stamping

What is Aluminum Transfer Die Stamping?

In transfer die stamping, each aluminum blank is moved from one die station to the next using mechanical transfer systems. This allows for the stamping of larger, more complex parts that cannot be processed in a single die.

Characteristics of Aluminum Transfer Die Stamping

Tip: Ensure your CNC machining factory can handle transfer systems for heavy or intricate aluminum components.

3. Aluminum Four-Slide Stamping

What is Aluminum Four-Slide Stamping?

Four-slide stamping uses multiple horizontally and vertically moving slides to shape aluminum parts from bar stock rather than sheets. This method is effective for producing small, intricate components with complex geometries.

Characteristics of Aluminum Four-Slide Stamping

Tip: Four-slide stamping works best with smaller parts; large panels or deep-drawn components require other stamping methods.

4. Aluminum Fine Blanking

What is Aluminum Fine Blanking?

Fine blanking is a precision stamping process that produces aluminum parts with very smooth edges and tight tolerances. It uses specialized dies and higher press forces to minimize burrs and distortion.

Characteristics of Aluminum Fine Blanking

Tip: Fine blanking requires higher-quality tooling and presses, so it is slightly more expensive than standard stamping but eliminates the need for secondary finishing.

After aluminum stamping, surface treatment is often applied to improve appearance, corrosion resistance, and durability. Choosing the right surface treatment ensures your stamped aluminum components meet functional and aesthetic requirements, whether for automotive, electronics, or consumer products.

Anodizing

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum surfaces. It enhances corrosion resistance, improves wear resistance, and allows coloring for decorative purposes. Anodized aluminum maintains its finish for years and is widely used in aerospace, electronics, and architectural applications.

Electroplating

Electroplating deposits a thin layer of metal, such as nickel or chrome, onto the aluminum surface to improve corrosion resistance, hardness, or aesthetics. This process is common for functional and decorative parts, including automotive trims and electronic housings.

Powder Coating / Painting

Powder coating involves applying a dry powder to the aluminum surface and curing it under heat to form a protective layer. Painted finishes can also be applied with liquid paints. Both methods provide excellent corrosion protection, vibrant colors, and a smooth finish.

Sandblasting

Sandblasting uses high-pressure abrasive particles to clean, smooth, or texture the aluminum surface. It is commonly applied before painting or anodizing to remove impurities, improve adhesion, and create a uniform finish.

Polishing

Polishing smooths aluminum surfaces to achieve a mirror-like finish. This is ideal for decorative parts, reflective surfaces, or components requiring low friction. Polished aluminum also improves the visual appeal of stamped components.

Wire Drawing

Wire drawing creates linear, textured lines on aluminum surfaces using abrasive brushes or rollers. This finish is commonly used for aesthetic purposes and to reduce glare on panels or housings. It also adds a unique decorative effect for consumer products.

Stamped aluminum parts are highly versatile and used across a wide range of industries. Their lightweight, corrosion resistance, and excellent formability make them ideal for both functional and decorative components. Understanding which industries commonly use stamped aluminum can help you choose the right materials and stamping processes for your project.

Aerospace Industry

Aluminum stamped components are widely used in aircraft for structural parts, panels, and brackets. The combination of high strength-to-weight ratio and corrosion resistance makes aluminum ideal for aerospace applications.

Automotive manufacturers rely on aluminum stamping for body panels, chassis components, heat shields, and brackets. Aluminum reduces vehicle weight, improving fuel efficiency while maintaining structural integrity.

Marine Industry

Aluminum’s excellent corrosion resistance makes stamped parts suitable for boats, ships, and offshore equipment. Components like hull panels, brackets, and fittings benefit from aluminum’s lightweight and durability.

Stamped aluminum is used for medical equipment housings, surgical trays, and lightweight structural components. Its cleanliness, corrosion resistance, and ability to be anodized make it suitable for medical environments.

Electrical and Electronic Industry

Aluminum stamped parts are common in electrical enclosures, heat sinks, connectors, and circuit housings. Aluminum’s excellent electrical and thermal conductivity enhances performance while keeping weight low.

Lighting Industry

Stamped aluminum components are used in lamp housings, reflectors, and decorative lighting panels. Aluminum provides both aesthetic appeal and functional heat dissipation.

Construction Industry

Aluminum stamped panels, trims, brackets, and structural components are used in building facades, windows, and HVAC systems. Aluminum’s corrosion resistance and low weight reduce maintenance costs.

Food and Beverage Industry

Stamped aluminum parts are widely used in food processing equipment, packaging, and containers. Aluminum’s corrosion resistance, lightweight, and recyclability make it ideal for these applications.

Aluminum Stamped Parts Applications

Different aluminum series are used in stamping based on their strength, corrosion resistance, and formability. Understanding the applications of each series helps you choose the right alloy for your stamped aluminum components.

| Aluminum Series |

Typical Applications |

| 1xxx Series (1100 Aluminum) |

Used for deep-drawn parts, decorative panels, roofing, and kitchen utensils due to its excellent corrosion resistance and formability. |

| 2xxx Series (2024 Aluminum) |

Common in aerospace structural components, brackets, and high-strength applications where high load-bearing capacity is required. |

| 3xxx Series (3003 Aluminum Alloy) |

Ideal for roofing, siding, gutters, automotive panels, and chemical equipment due to its corrosion resistance and moderate strength. |

| 4xxx Series (4045 Aluminum Alloy) |

Often used for automotive heat exchangers, chemical containers, and structural components requiring good thermal conductivity. |

| 5xxx Series (5052 Aluminum Alloys) |

Suitable for marine hardware, fuel tanks, pressure vessels, and roofing where high corrosion resistance and moderate strength are needed. |

| 6xxx Series (6061 Aluminum Alloy) |

Used in aerospace fittings, automotive frames, and structural applications requiring a balance of strength, corrosion resistance, and machinability. |

| 7xxx Series (7075 Aluminum Alloy) |

High-strength applications like aerospace components, defense equipment, and automotive parts where performance under stress is critical. |

| 8xxx Series (8006 Aluminum Alloy) |

Primarily used for aluminum foil, packaging, and food-related stamped products due to excellent formability and thermal resistance. |

Common Problems and Solutions for Aluminum Stamping Parts

Aluminum is lightweight, corrosion-resistant, and easy to form, but its unique properties can cause challenges in stamping. Understanding the conditions that trigger common issues—and how to solve them—can improve quality, reduce waste, and extend die life.

Material Deformation

Why it happens: Aluminum has high ductility, but excessive press force, uneven die surfaces, or unsupported areas can cause unwanted bending, warping, or stretching. Thin sheets are particularly prone to distortion.

Solution: Select an alloy and temper suitable for the part’s complexity. Ensure die design supports even material flow, use proper blank holding techniques, and adjust press tonnage to match sheet thickness.

How to prevent it:

Surface Defects

Why it happens: Scratches, galling, or rough surfaces often occur when dies are misaligned, the sheet has debris, or lubrication is insufficient. Alloys with lower hardness are more prone to surface marks during forming or drawing.

Solution: Maintain clean, contaminant-free sheets. Use proper lubricants and consistent application. Inspect and polish dies regularly, and ensure precise alignment during stamping operations.

How to prevent it:

Cracks and Breakage

Why it happens: Cracks occur if the material is too hard (e.g., T6 temper), the part is over-stretched during deep drawing, or corners are too sharp. Thin sections are especially vulnerable.

Solution: Choose ductile aluminum alloys such as 1100, 3003, or 5052 for deep drawing. Adjust die radii and stamping speeds, and avoid sudden high-pressure strokes that exceed material limits.

How to prevent it:

Springback

Why it happens: Aluminum has a high elastic recovery rate, so after bending or flanging, it tends to partially return to its original shape. This effect is stronger with thicker sheets and harder tempers.

Solution: Overbend parts slightly during forming to compensate for springback. Use dies with appropriate radii and consider the temper of the alloy—softer tempers reduce springback.

How to prevent it:

Poor Edge Quality (Bursts or Burrs)

Why it happens: During blanking or piercing, improper punch-to-die clearance, worn dies, or too much pressure can tear the sheet edges, leaving burrs or uneven surfaces. Harder alloys amplify the problem.

Solution: Maintain precise punch-to-die clearance for the specific alloy and thickness. Sharpen or replace dies regularly. Secondary finishing or deburring can remove remaining burrs.

How to prevent it:

Welding Issues

Why it happens: Aluminum forms a strong oxide layer quickly, which prevents proper fusion. Thin stamped parts may warp due to localized heat, and high-strength alloys may crack if improperly welded.

Solution: Pre-clean parts to remove oxide layers. Use welding methods suitable for aluminum, such as TIG or MIG with proper shielding gas. Minimize heat input to prevent warping and select compatible alloys for welding.

How to prevent it:

Aluminum Oxide Acceleration

Why it happens: Aluminum naturally forms an oxide layer that is hard and abrasive. During stamping, this can increase die wear or interfere with processes like plating or welding.

Solution: Remove oxide layers where necessary through chemical or mechanical cleaning. Use lubricants during stamping to reduce friction. For welding or coating, pre-treat the surface to ensure adhesion.

How to prevent it:

Accelerated Die Wear

Why it happens: Repeated stamping, especially with abrasive alloys or high-volume production, causes tool surfaces to wear faster. Hard aluminum alloys or deep drawing operations increase die stress.

Solution: Use hardened or coated dies (e.g., PVD or nitrided surfaces). Apply proper lubrication and perform preventive maintenance. Rotate dies in high-volume lines to extend life.

How to prevent it:

Aluminum Piercing Problems

Why it happens: Poor hole quality occurs when punch-die alignment is off, die clearance is incorrect, or punch speed is inconsistent. Thin sheets or hard alloys worsen tearing or distortion around holes.

Solution: Maintain accurate punch-to-die clearance, ensure proper press operation, and check alignment frequently. Select softer alloys for parts with fine piercing requirements.

How to prevent it:

Wear Problems in Aluminum Piercing

Why it happens: Continuous punching of aluminum, especially thicker or hard alloys, wears the die and punch faster than normal. Inconsistent lubrication increases friction and heat, further accelerating wear.

Solution: Use wear-resistant tooling materials like hardened steel or coated dies. Apply proper lubrication consistently and schedule preventive maintenance to replace worn punches or dies before they damage parts.

How to prevent it:

Pro Tip: Always match alloy selection, die design, press settings, and lubrication for each stamping operation. Small adjustments early in the process prevent most common problems, reduce scrap, and improve part quality.

VMT specializes in producing high-quality aluminum stamped components and CNC machined aluminum parts for a wide range of industries, including automotive, aerospace, electronics, and medical devices. By combining advanced metal stamping processes with precision CNC machining, VMT ensures every part meets exact specifications for functionality, durability, and appearance.

Custom Aluminum Metal Stamping

VMT provides custom metal stamping services that handle small to high-volume production runs. Their expertise covers all major aluminum stamping operations, including blanking, piercing, coining, deep drawing, embossing, and flanging. They can work with a wide range of aluminum alloys, from ductile 1100 to high-strength 7075, to create components optimized for your application.

After stamping, VMT can perform CNC machining services to add precise features, holes, threads, or finishing touches. This combination of stamping and CNC machining allows for complex geometries, tight tolerances, and superior surface finishes on aluminum parts.

Aluminum Stamping and Surface Finishing

VMT also provides surface treatment services such as anodizing, powder coating, electroplating, polishing, and wire drawing. These treatments enhance corrosion resistance, improve aesthetics, and extend the service life of stamped aluminum components.

Engineering Support and Quality Control

VMT offers design consultation, material selection guidance, and prototyping support to ensure that your stamped aluminum parts meet functional and budget requirements. All parts undergo strict quality control, including dimensional inspection, hardness testing, and visual surface checks, to ensure reliable performance.

VMT Advantage: By integrating custom aluminum stamping with precision CNC machining and surface finishing, VMT delivers parts that are not only functional and durable but also visually appealing and production-ready for any industry.

Conclusion

Aluminum metal stamping is a versatile and efficient method for producing high-quality components across a wide range of industries. By understanding the different aluminum alloys, stamping processes, and surface treatments, you can select the right materials and techniques for your specific application.

Whether you need blanking, piercing, coining, deep drawing, embossing, flanging, or advanced processes like progressive die stamping and fine blanking, proper alloy selection, die design, and process control are key to avoiding defects and achieving precision.

Combining stamping with CNC machining and surface finishing ensures parts meet both functional and aesthetic requirements. Companies like VMT offer comprehensive custom metal stamping services and CNC machining solutions, providing expertise from material selection to final quality control.

With careful planning and professional support, you can maximize the strength, durability, and visual appeal of your stamped aluminum parts while reducing production costs, scrap, and delays. Aluminum stamping remains a reliable, cost-effective solution for creating lightweight, corrosion-resistant, and high-performance components.

These FAQs answer common questions about aluminum metal stamping, including materials, processes, equipment, and finishing options. Whether you are new to aluminum stamping or looking for professional guidance, this section provides practical insights.

1. What is Aluminum Stamping?

Aluminum stamping is a manufacturing process where aluminum sheets are shaped into parts using dies and presses. Operations can include blanking, piercing, bending, flanging, coining, embossing, and deep drawing. Stamped aluminum parts are lightweight, corrosion-resistant, and used in many industries, from automotive to electronics.

2. Is Aluminum Suitable for Stamping?

Yes. Aluminum is ideal for stamping because it is lightweight, ductile, and corrosion-resistant. Its formability allows for deep drawing and complex shapes. However, the alloy and temper must match the part design to avoid cracking, excessive springback, or deformation.

3. Is Metal Stamping Costly?

The cost depends on factors like part complexity, aluminum grade, die type, and production volume. Progressive or transfer die stamping for high-volume production reduces per-part cost, while custom low-volume stamping may be more expensive due to tooling and setup costs.

4. How Thick Can You Stamp Aluminum?

Aluminum sheets from 0.2 mm to 6 mm or more can be stamped, depending on the alloy, die, and stamping process. Thinner sheets are easier to form but may deform, while thicker sheets require higher press forces and robust tooling.

5. How to Choose Aluminum Alloys for Metal Stamping?

Choose alloys based on strength, corrosion resistance, and formability:

Consult with your stamping or CNC machining partner to select the best alloy for your part geometry and use environment.

6. Can You Anodize Stamped Aluminum Sheets?

Yes. Anodizing enhances corrosion resistance and allows decorative coloring. Ensure the alloy is compatible (most common alloys are), and the surface is properly cleaned before anodizing to achieve a consistent finish.

7. Are There Lubricants Specifically for Aluminum Stamping?

Yes. Aluminum stamping requires specialized lubricants to reduce friction, prevent galling, and protect dies. Water-based, oil-based, or dry-film lubricants can be used depending on the process and alloy. Proper lubrication improves part quality and extends die life.

8. Are There Stamping Machines Specifically for Processing Aluminum?

Most presses can handle aluminum sheets, but some machines are optimized for its lightweight properties. Progressive die presses, transfer presses, and four-slide machines are commonly used for aluminum stamping, depending on part complexity and production volume.

9. Are There Dies Specifically for Stamping Aluminum?

Yes. Dies for aluminum stamping often use hardened steel or coated surfaces to resist wear from aluminum’s abrasive oxide layer. The die design may also include features to reduce springback and improve part consistency, especially for complex bends and deep-drawn shapes.

10. What are the Best Metal Fasteners for Aluminum?

Fasteners should minimize galvanic corrosion and match the aluminum’s mechanical properties. Aluminum, stainless steel, or coated steel screws and rivets are commonly used. Avoid uncoated copper or brass in direct contact with aluminum to prevent corrosion.