15 years one-stop China custom CNC machining parts factory

28 |

Published by VMT at Nov 06 2025 | Reading Time:About 3 minutes

28 |

Published by VMT at Nov 06 2025 | Reading Time:About 3 minutes

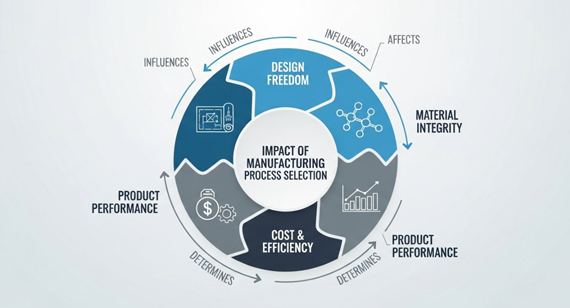

Choosing between CNC machining vs welding dictates product performance. CNC excels in precision and complexity; welding offers robust joining. Optimal machining process selection hinges on design, volume, and material integrity.

Are you risking product failure or budget overruns by making an uninformed manufacturing process choice? The decision between CNC machining and welding is more critical than you think – it impacts everything from part performance to your bottom line.

Beyond surface-level understanding, engineering success demands a deep dive into these fundamental processes. This guide from our cnc machining factory will unravel the key differences, helping you confidently navigate the complexities and make an informed choice.

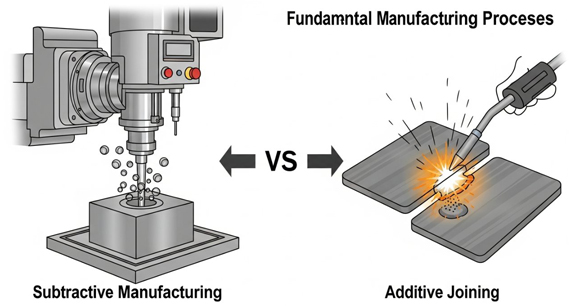

Selecting the appropriate manufacturing method is not merely a technical step; it's a strategic decision. The choice between subtractive (like CNC machining) and additive (like welding) processes profoundly shapes your product. This impacts its functionality, longevity, and even its market viability.

Impact on Design & Performance

The manufacturing process directly dictates what your design can achieve. Factors like geometric complexity, dimensional accuracy, and surface finish are intrinsically tied to the chosen method. For instance, high-precision CNC machining parts often allow for tighter tolerances and more intricate features.

Component performance, stress distribution, and material integrity are also significantly affected. Welding introduces heat-affected zones and residual stresses, which can alter mechanical properties. CNC machining, conversely, works with the base material's inherent properties, offering a consistent internal structure.

Cost Implications & Production Efficiency

Manufacturing costs extend beyond raw material and direct labor. Setup times, tooling expenses, material waste, and post-processing requirements all contribute to the final price per part. Understanding these elements is crucial for cost-effective production.

Production efficiency relates to lead times, scalability, and repeatability. Some processes are ideal for prototyping and low-volume runs, while others excel in high-volume, continuous production scenarios. The machining process selection directly influences these operational metrics.

Understanding Project Criticality

Every project has unique demands regarding reliability, safety, and operational environment. For critical applications, such as aerospace or medical devices, the chosen manufacturing process must deliver uncompromising quality and traceability. For less demanding applications, cost might become the overriding factor.

The level of criticality guides decisions on material selection, quality control measures, and acceptable risk. This influences whether the inherent strengths of CNC machining services or welding are more aligned with your project’s ultimate success.

Computer Numerical Control (CNC) machining is a subtractive manufacturing process that uses programmed computer software to control the movement of machine tools. Material is precisely removed from a solid block, or workpiece, to create the desired final geometry.

Core Principles & Capabilities

At its core, CNC machining utilizes cutting tools to shape material. The process involves designing the part using CAD (Computer-Aided Design) software, then generating toolpaths with CAM (Computer-Aided Manufacturing) software. This code guides multi-axis machines, from 3-axis mills to complex 5-axis machines, with extreme precision.

Our cnc machining factory specializes in complex geometries and tight tolerances that are often unachievable with other methods. This capability makes it indispensable for industries where exact specifications are paramount.

Advantages for Precision Parts

CNC machining offers unparalleled dimensional accuracy and repeatability. We can consistently achieve tolerances down to ±0.005mm or tighter, depending on material and geometry. This precision is critical for parts requiring exact fits, such as mating components or those integrated into complex assemblies.

The controlled environment and automated processes minimize human error, ensuring consistent quality across large batches. This makes it ideal for producing high-quality cnc machining parts that meet stringent industry standards.

Material Versatility & Finishes

A vast array of materials can be CNC machined, including various metals (aluminum, steel, titanium, brass), plastics (Delrin, PEEK, ABS), and composites. The process allows for excellent surface finishes, from rough milled surfaces to mirror-like polishes, often eliminating the need for extensive post-processing.

Achievable surface roughness values can range from Ra 3.2 µm (general machining) down to Ra 0.8 µm or finer (precision finishing). This versatility in materials and finishes extends the application range of cnc machining services significantly.

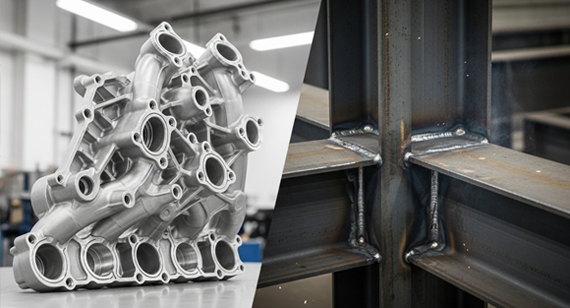

Common Applications

CNC machining is a cornerstone in industries demanding high precision and complex forms. This includes aerospace components (e.g., turbine blades, structural brackets), medical implants (e.g., bone plates, surgical instruments), automotive engine parts, and intricate electronics housings.

It's also widely used for prototyping, creating functional models with production-grade materials and finishes. This allows for rigorous testing before committing to large-scale manufacturing.

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by causing coalescence. This is typically achieved by melting the workpieces and adding a filler material to form a molten pool that cools to become a strong joint.

Core Principles & Methods

The fundamental principle of welding is to create a metallurgical bond between two or more parts. Heat is applied, often from an electric arc, flame, or laser, to melt the edges of the parts. A filler material, compatible with the base metals, is then added to strengthen the joint.

Various welding methods exist, including TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), arc welding, laser welding, and resistance welding. Each method has specific applications, advantages, and limitations regarding material type, thickness, and joint strength.

Strengths in Joining & Repair

Welding excels at permanently joining discrete components, creating robust and structural assemblies. It's often the most practical method for large structures, assemblies with varying thicknesses, or when joining pre-fabricated sections.

It is also an invaluable process for repair and maintenance. Damaged or worn components can often be restored through welding, extending their lifespan and reducing replacement costs. This is particularly useful for heavy machinery and industrial equipment.

Material Joining & Structural Integrity

Welding can join a wide range of similar and dissimilar metals. However, the heat input during welding can affect the material's microstructure, potentially creating a heat-affected zone (HAZ) with altered mechanical properties. This is a critical consideration for structural integrity.

Proper weld design, material selection, and post-weld heat treatment are essential to mitigate these effects and ensure the joint meets the required strength and durability. Careful process control is paramount for reliable structural components.

Typical Use Cases

Welding is foundational in industries like construction (structural beams, bridges), shipbuilding (hulls, superstructures), automotive manufacturing (chassis, exhaust systems), and pipelines. It's also prevalent in heavy fabrication for industrial equipment, tanks, and pressure vessels.

When creating large, integrated structures where the primary goal is robust connection rather than absolute dimensional precision across the entire assembly, welding is frequently the preferred choice.

Understanding the core distinctions between CNC machining vs welding is essential for effective machining process selection. These differences span how material is handled, the precision achievable, and the impact on final part characteristics.

Material Removal vs. Material Addition

CNC machining is a subtractive process. It starts with a larger block of material and removes excess using cutting tools to achieve the desired shape. This method results in material waste in the form of chips, but it precisely defines internal and external features from a single, homogenous piece.

Welding, conversely, is an additive joining process. It fuses two or more separate pieces of material, often with the addition of filler material. It creates a bond rather than shaping a monolithic component, inherently involving heat and localized material changes.

Table: Process Fundamentals

| Feature |

CNC Machining |

Welding |

| Process Type |

Subtractive (Material Removal) | Additive (Material Joining) |

| Starting Material |

Solid block/stock | Multiple separate components |

| Primary Action |

Cutting, grinding, drilling | Fusing, melting, bonding |

| Material Waste |

Chips, swarf | Filler material, grinding waste |

Precision, Tolerance, & Surface Finish

CNC machining offers superior precision and tighter tolerances, typically achieving dimensional accuracies down to microns. The machine's rigidity and programmed control allow for extremely fine feature creation and excellent repeatability. Surface finishes can be highly refined, often ready for immediate use.

Welding, while capable of creating strong joints, generally has looser tolerances and rougher surface finishes. The heat input and material distortion make achieving micron-level precision across a welded assembly challenging. Post-weld grinding and finishing are often required.

Table: Precision & Finish Comparison

| Aspect |

CNC Machining |

Welding |

| Dimensional Accuracy |

Very High (micrometer level) |

Moderate to Low (millimeter level, prone to distortion) |

| Tolerances |

Very Tight (e.g., ±0.005mm) |

Looser (e.g., ±0.5mm to ±1mm) |

| Surface Finish |

Excellent, wide range (smooth to mirror-like) |

Rough, often requires significant post-processing |

| Repeatability |

Very High, automated consistency |

Good, but more operator-dependent |

Material Compatibility & Integrity

CNC machining works with a vast array of materials, preserving their inherent properties throughout the process. Since material is only removed, the base material's internal structure and strength remain consistent throughout the part.

Welding can join many materials, including some dissimilar ones, but it introduces a heat-affected zone (HAZ) around the weld. This HAZ can alter the material's microstructure, potentially reducing strength or ductility in localized areas. Residual stresses from cooling can also be an issue.

Table: Material Impact

| Factor |

CNC Machining |

Welding |

| Material Integrity |

Preserves base material properties, uniform |

Can create Heat-Affected Zone (HAZ) with altered properties |

| Internal Stresses |

Minimal, uniform |

Potential for significant residual stresses |

| Material Compatibility |

Wide range, works with solid stock |

Wide range, can join dissimilar metals (with caveats) |

Design Freedom & Geometric Complexity

CNC machining offers exceptional design freedom for complex geometries, undercuts, internal features, and intricate contours. Multi-axis machines can create highly organic and functional shapes from a single block, minimizing the need for assembly.

Welding, while allowing for complex assemblies of simpler parts, is generally more limited in creating intricate single-piece geometries. The process is best suited for joining existing surfaces, making internal complexities or very fine features challenging or impossible to achieve through the weld itself.

Production Volume & Scalability

For high-volume production of identical, precision cnc machining parts, CNC machining is highly scalable and cost-effective per unit once initial setup and programming are complete. Automation ensures consistent quality across millions of parts.

Welding can also be automated (robotic welding) for high-volume tasks, particularly for simpler joints. However, for complex, custom assemblies, it often remains a more labor-intensive and slower process compared to the rapid material removal of a CNC machine for a single component.

Cost Factors: Setup, Material, Labor

Initial setup costs for CNC machining can be higher due to programming and tooling. However, per-part costs drop significantly with volume. Material waste can be a factor, but optimization strategies are common.

Welding setup is often simpler, but labor costs can be substantial, especially for skilled manual welding. Filler materials add to costs. The cost of post-processing (grinding, heat treatment) also needs to be factored in.

Table: Economic & Production Factors

| Factor | CNC Machining | Welding |

| Setup Cost | Higher (programming, tooling) | Lower (basic equipment) |

| Material Cost Impact | Raw block cost + waste | Material cost + filler material |

| Labor Cost | High initial programming, low per-part labor | High for skilled manual welding |

| Per-Part Cost (High Volume) | Low, highly automated | Moderate to High, can be automated but often slower |

| Scalability | Excellent | Good, especially with robotic systems |

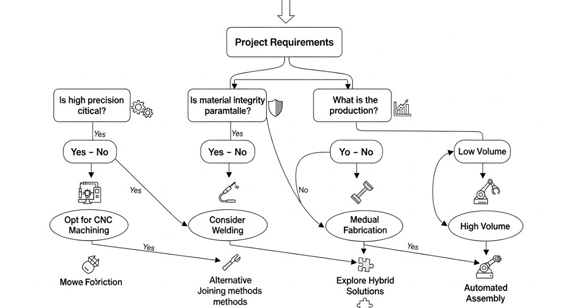

The decision between CNC machining vs welding is rarely black and white. It requires a systematic evaluation of your project's unique requirements, leveraging expert guidance to achieve optimal outcomes. This involves understanding the nuances of each process and their strategic application.

Decision Framework: A Step-by-Step Guide

A robust decision framework helps clarify the best path forward. Start by defining your part's function, environment, and lifespan. Then, consider material properties, geometric complexity, required tolerances, and surface finish. Finally, analyze production volume, budget, and lead time constraints.

This structured approach, often with input from our cnc machining services engineers, ensures all critical factors are weighed appropriately. It moves beyond a simple comparison to a tailored solution.

Prioritizing Project Requirements

Not all project requirements carry equal weight. For a medical implant, precision and material integrity are paramount, outweighing initial cost. For a large structural frame, robust joining and cost-effectiveness might take precedence over micron-level precision.

Clearly identifying your non-negotiable requirements and flexible parameters is the first step in effective machining process selection. This prioritization will guide you towards the most suitable manufacturing method.

When CNC Machining Excels

CNC machining is the preferred choice when:

When Welding is the Better Fit

Welding is often the superior choice when:

Hybrid Approaches & Considerations

In many modern applications, a hybrid approach proves most effective. Some components may be best suited for precision CNC machining parts, while others are efficiently joined through welding. An assembly might consist of CNC machined elements welded together.

For example, a precision-machined housing might have mounting brackets welded onto it. Understanding how to integrate both processes optimizes performance and cost. Our deep technical expertise allows us to recommend such integrated solutions.

As a leading cnc machining factory, our mission extends beyond mere manufacturing. We serve as a trusted technical partner, guiding our clients through complex decisions like choosing machining or welding. Our commitment is to deliver high-quality parts that meet and exceed expectations.

Our Expertise in Precision CNC Machining

In our experience, true precision comes from a combination of advanced technology, skilled engineers, and rigorous quality control. We operate state-of-the-art multi-axis CNC machines and employ seasoned machinists who deeply understand material science and toolpath optimization. This expertise ensures every cnc machining part meets the most stringent specifications.

We pride ourselves on our ability to tackle challenging projects, delivering complex geometries and ultra-tight tolerances consistently. Our team provides comprehensive cnc machining services, from design for manufacturability (DFM) analysis to final inspection.

Transparent Pricing & Project Consultation

A common issue we see is a lack of clarity in manufacturing costs. We believe in complete transparency. Our project consultation process includes detailed cost breakdowns and open discussions about material choices, production methods, and potential optimizations. This ensures you understand the true value of our cnc machining services.

We offer free technical consultations to help you weigh the pros and cons of different processes for your specific application. This unbiased guidance is crucial for making informed decisions.

The Source Manufacturer Advantage

As a source manufacturer, we directly control every aspect of the production process. This means tighter quality control, faster lead times, and ultimately, more competitive and transparent pricing for our cnc machining parts. You're working directly with the team that designs and produces your components, cutting out intermediaries.

This direct relationship fosters better communication and responsiveness, allowing for quick adjustments and consistent quality throughout your project lifecycle. Our clients benefit from this seamless, integrated approach.

Ensuring Your Project Success

Our goal is your project's success. By leveraging our deep technical expertise and comprehensive cnc machining services, we ensure that the machining process selection aligns perfectly with your performance, quality, and budget requirements. We don't just make parts; we engineer solutions.

We follow strict quality management systems, often compliant with industry standards like ISO 9001, to guarantee the reliability and traceability of every component we produce. Trustworthiness is built into our every operation.

The decision between CNC machining vs welding is foundational for your project's success. By understanding their key differences, advantages, and limitations, you can confidently choose the optimal path.

Your Next Step for Project Success

Don't leave your project's success to chance. Contact our expert engineers today for a free, no-obligation project consultation and transparent quote. Leverage our deep technical expertise and source manufacturer advantage to ensure you choose the absolute best process for your high-quality parts.

How does CNC machining differ from welding?

CNC machining is a subtractive process that removes material from a solid block to form a part, relying on precise computer control. Welding is an additive process that joins multiple components by melting and fusing them, often with filler material.

When should I choose CNC machining for my parts?

You should choose CNC machining when your project demands high precision, tight tolerances, complex geometries, and superior surface finishes. It's ideal for producing robust, high-quality cnc machining parts from a single piece of material.

What are the main benefits of welding?

Welding excels at creating strong, permanent bonds between separate components, making it suitable for large structural assemblies. It is also effective for joining dissimilar metals and for repair applications.

Can both processes be used in one project?

Yes, a hybrid approach using both CNC machining and welding is very common. Precision components can be CNC machined, then joined together or integrated into larger structures via welding. This combines the strengths of both methods.

How does each process impact material integrity?

CNC machining preserves the base material's inherent properties, creating a uniform internal structure. Welding introduces a heat-affected zone (HAZ) that can alter material microstructure and mechanical properties, potentially creating residual stresses.

What is the cost difference between CNC welding?

Generally, CNC machining has higher initial setup costs but lower per-part costs for high-volume, complex parts due to automation. Welding often has lower setup but higher labor costs for skilled manual work and can be slower for intricate assemblies.

What design factors favor CNC machining?

Designs requiring intricate internal features, complex curvatures, undercuts, and very fine details that must be integral to a single piece are best suited for CNC machining. It offers extensive geometric freedom.

Why is machining process selection important?

The correct machining process selection critically impacts part performance, dimensional accuracy, structural integrity, and overall project cost and lead time. An informed choice prevents reworks, ensures quality, and optimizes budget.