15 years one-stop China custom CNC machining parts factory

21 |

Published by VMT at Nov 07 2025 | Reading Time:About 3 minutes

21 |

Published by VMT at Nov 07 2025 | Reading Time:About 3 minutes

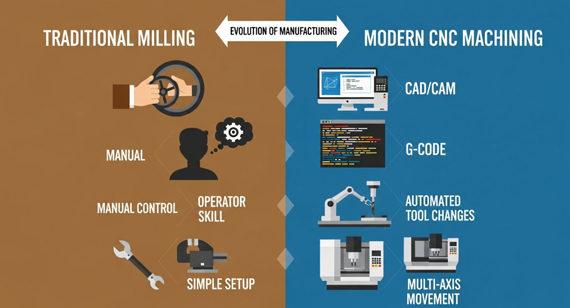

CNC machining and milling are distinct processes often confused. While milling is a subtractive method, CNC machining encompasses automated control, offering superior precision, complexity, and repeatability compared to a traditional milling machine. Understanding these CNC machining differences is crucial for project success.

Are you grappling with the often-confused terms CNC machining and milling, wondering which is truly right for your next precision component? Youre not alone. The subtle yet critical differences between these two manufacturing powerhouses can significantly impact your projects cost, quality, and speed.

At VMT CNC machining parts services factory, we understand these nuances intimately. As experienced engineers, our goal is to cut through the confusion and equip you with the clarity you need to make optimal decisions for your projects, leveraging our deep expertise in CNC manufacturing. This guide will provide a definitive comparison, highlighting why choosing the right process, be it computer numerical control services or traditional methods, is paramount.

The terms CNC machining and milling are frequently used interchangeably, leading to widespread misunderstanding. However, from an engineering perspective, theres a fundamental distinction that impacts design, production, and cost. Its about more than just the cutting tool; its about the control system and capabilities.

In our experience at VMT, clarifying this difference early in a project is vital. Incorrect assumptions about CNC machining differences can lead to significant delays, budget overruns, and ultimately, parts that do not meet specifications. Our expertise ensures you avoid these pitfalls.

Why understanding this distinction matters

Understanding the core CNC machining differences is paramount for project success. The choice between computer numerical control services and traditional milling directly influences several critical factors. These include the achievable part precision, the complexity of geometries, the overall production timeline, and the total cost.

For product designers and procurement managers, this knowledge translates directly into optimized designs and more cost-effective manufacturing decisions. It allows for better communication with CNC machining services providers and more predictable project outcomes.

Common misconceptions about machining

A common misconception is that milling vs CNC is a choice between two entirely different manufacturing methods. In reality, milling is a specific type of machining process, while CNC (Computer Numerical Control) refers to the automated control system that can be applied to many different machining operations, including milling. So, CNC milling is a highly automated form of milling.

Another prevalent mistake is underestimating the capabilities of modern CNC machining. Many believe its only for mass production, overlooking its incredible versatility for prototyping complex CNC machining parts or small batch runs with extreme precision.

Traditional milling, often referred to as conventional or manual milling, is a subtractive manufacturing process. It uses rotating multi-point cutting tools to remove material from a workpiece. The key characteristic of a milling machine in this context is its manual operation.

This method has been a cornerstone of manufacturing for decades, proving indispensable for specific tasks. It relies heavily on the direct interaction and skill of a human operator to control the machines movements.

Manual control and operator skill

In traditional milling, the machinist directly controls the machines axes (X, Y, Z) via handwheels or levers. This manual milling machine operation demands significant operator skill, experience, and precision. The quality of the finished CNC machining parts is highly dependent on the individuals expertise.

Operators must have an intimate understanding of tooling, material properties, and feeds and speeds to achieve desired results. This hands-on approach offers immediate feedback and allows for on-the-fly adjustments.

Typical applications for milling

Traditional milling shines in applications where simplicity and direct human control are advantageous. It is often chosen for low-volume production, one-off prototypes, or repair work where the setup time for automated systems would be excessive. These milling vs CNC scenarios often involve less complex geometries.

Examples include creating simple slots, flat surfaces, or basic pockets on CNC machining parts. Its also suitable for educational purposes or workshops with limited budgets for advanced CNC manufacturing equipment.

Limitations of conventional milling

While valuable, conventional milling has inherent limitations compared to CNC machining. Achieving high levels of precision and repeatability across multiple parts can be challenging due to human variability. Complex geometries are difficult, if not impossible, to produce manually.

Surface finish can also be inconsistent, and production speeds are significantly slower. These factors highlight why the milling machine vs CNC distinction is crucial when precision and volume are priorities.

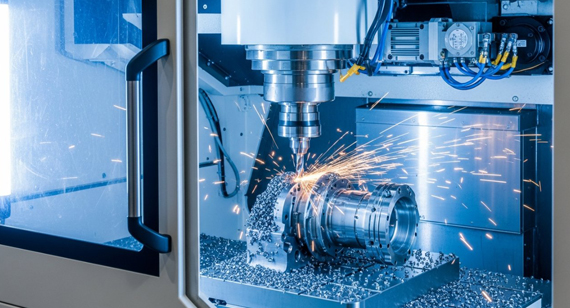

Modern CNC machining represents a paradigm shift in manufacturing, driven by automation and computational power. It is not merely an evolution of the milling machine; its a fundamentally different approach to controlling machine tools. CNC machining services utilize computer programs to dictate every tool movement.

At our cnc machining factory, we leverage this technology to deliver exceptional precision and efficiency. CNC stands for Computer Numerical Control, meaning a computer system directs the machine.

The role of automation and G-code

The core of CNC machining lies in its automation, controlled by G-code. G-code is a specialized programming language that instructs the machines movements, tool selections, speeds, and feeds. This eliminates manual intervention during the cutting process.

This level of automation ensures consistent, repeatable results across thousands of CNC machining parts. Its a cornerstone of reliable CNC manufacturing and CNC milling services in modern industry.

Multi-axis capabilities and complexity

A significant advantage of CNC machining is its capability for multi-axis operations. While traditional milling typically operates on 3 axes (X, Y, Z), modern CNC machining can involve 4, 5, or even more axes simultaneously. This enables the creation of incredibly complex, contoured CNC machining parts in a single setup.

This expanded geometric freedom allows engineers to design intricate components previously deemed impossible or too costly to manufacture. Its a key factor in distinguishing CNC machining vs milling for advanced applications.

The power of CAD/CAM integration

CNC machining seamlessly integrates with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. Designs created in CAD are translated into machine-readable G-code by CAM software. This digital workflow streamlines the entire production process.

This integration minimizes human error, accelerates design iterations, and ensures that the final CNC machining parts precisely match the digital model. It is the foundation of precision milling and efficient CNC manufacturing.

When comparing CNC machining vs milling, the differences extend far beyond just manual versus automated. These distinctions impact every facet of a project, from design to final inspection. Understanding these variations is crucial for making informed choices.

At VMT, we meticulously analyze these factors to recommend the optimal process for your specific CNC machining parts needs. Our expertise in CNC machining differences ensures you get the best fit.

Automation level and human intervention

The most apparent CNC machining differences lie in automation. CNC machining operates with minimal human intervention once programmed, allowing operators to oversee multiple machines. Traditional milling requires constant human control and attention.

This difference impacts labor costs, consistency, and overall production efficiency, particularly for CNC milling services.

Table 1: Automation and Human Intervention

| Feature |

CNC Machining |

Traditional Milling |

| Control System |

Computer Numerical Control | Manual Handwheels/Levers |

| Operator Role |

Programming, Setup, Monitoring | Direct, Constant Control |

| Intervention |

Minimal during operation | Continuous during operation |

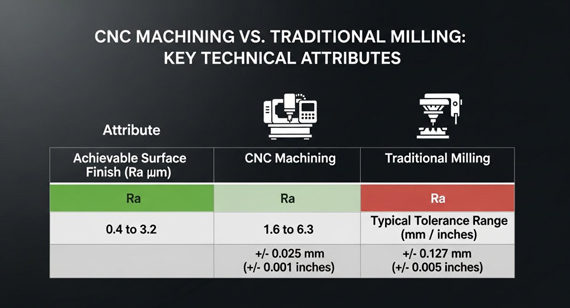

Precision, accuracy, and surface finish

CNC machining offers significantly higher precision and accuracy than traditional milling. Our cnc machining factory routinely achieves tolerances as tight as ±0.005mm (±0.0002 inches), adhering to strict industry standards like ISO 2768. Automated processes eliminate human error.

Achieving a superior surface finish (lower Ra values) is also much more consistent with CNC machining. Milling machine operations, due to manual control, typically have wider tolerances and less consistent finishes.

Table 2: Precision, Accuracy, and Surface Finish

| Attribute |

CNC Machining |

Traditional Milling |

| Typical Tolerance |

±0.005mm (±0.0002") |

±0.1mm (±0.004") |

| Repeatability |

Excellent (Automated) |

Variable (Operator-dependent) |

| Surface Finish |

Consistent, High Quality |

Variable, Moderate Quality |

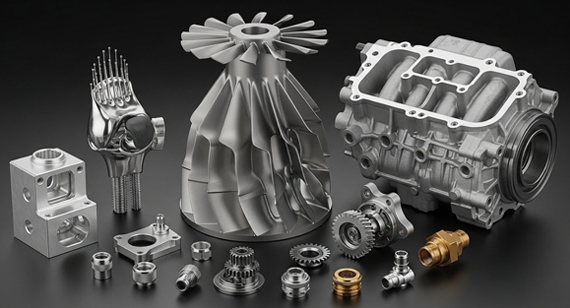

Part complexity and geometric freedom

The ability of CNC machining to utilize multi-axis movements translates directly into unparalleled geometric freedom. It can produce highly complex, organic shapes, intricate internal features, and precise contours. These CNC machining parts are often impossible to create on a conventional milling machine.

Traditional milling is largely limited to simpler 2D or 2.5D geometries. Its operations are constrained by the linear movement capabilities of its axes, making milling vs CNC a clear choice for intricate designs.

Table 3: Part Complexity and Geometric Freedom

| Aspect |

CNC Machining |

Traditional Milling |

| Geometric Freedom |

High (Multi-axis, Contours) |

Limited (2D, 2.5D) |

| Internal Features |

Complex, Intricate |

Simple, Accessible |

| Part Complexity |

Very High |

Low to Moderate |

Production volume and scalability

CNC machining excels in production volume and scalability. Once a program is proven, it can produce thousands of identical CNC machining parts efficiently. This makes it ideal for medium to high-volume manufacturing.

Conversely, a milling machine is best suited for low-volume production or one-off jobs. Scaling up with traditional milling would require a significant increase in skilled labor and machines, making it less cost-effective.

Table 4: Production Volume and Scalability

| Category |

CNC Machining |

Traditional Milling |

| Ideal Volume |

Medium to High Volume |

Low Volume, Prototypes |

| Scalability |

Easily Scalable |

Limited Scalability |

| Consistency |

Highly Consistent |

Operator Dependent |

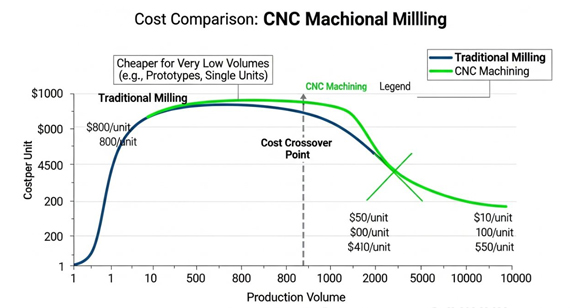

Cost considerations: Setup vs. per-part

When evaluating CNC machining vs milling from a cost perspective, its essential to consider both setup costs and per-part costs. CNC machining typically has higher initial setup costs due to programming and fixture design. However, the per-part cost drops significantly with higher volumes due to automation and speed.

Traditional milling has lower setup costs, but its higher labor dependence and slower speed result in higher per-part costs, especially as volumes increase. Our cnc machining factory provides transparent pricing to help you analyze this trade-off.

Table 5: Cost Considerations

| Cost Factor |

CNC Machining |

Traditional Milling |

| Setup Cost |

Higher (Programming, Fixtures) |

Lower (Manual setup) |

| Per-Part Cost |

Decreases with Volume |

Increases with Volume |

| Overall Economy |

Cost-effective for Volume |

Cost-effective for Low Volume |

Lead time and efficiency advantages

The efficiency of CNC machining offers significant lead time advantages, especially for complex CNC machining parts. Automated tool changes, rapid traverse rates, and continuous operation reduce cycle times dramatically. This enables faster prototyping and quicker time-to-market.

Manual milling machine operations are inherently slower and more labor-intensive. Each step requires direct human input, extending production lead times, making Milling vs CNC an important lead time factor.

Table 6: Lead Time and Efficiency

| Metric |

CNC Machining |

Traditional Milling |

| Cycle Time |

Fast, Automated |

Slower, Manual |

| Production Speed |

High |

Low |

| Lead Time Impact |

Shorter |

Longer |

Material compatibility and tooling

Both CNC machining and traditional milling can work with a wide range of materials, including metals, plastics, and composites. However, CNC machining often employs more specialized and advanced tooling. These tools, combined with precise control, allow for optimal material removal rates and superior surface finishes.

Our cnc machining factory utilizes advanced tooling specific to the material and part geometry. Milling machine operations typically use standard tooling, which may limit efficiency or surface quality for certain materials.

Table 7: Material Compatibility and Tooling

| Aspect |

CNC Machining |

Traditional Milling |

| Material Range |

Wide (Metals, Plastics, Composites) |

Wide (Metals, Plastics, Composites) |

| Tooling |

Advanced, Specialized |

Standard |

| Material Removal |

Optimized, High Efficiency |

Moderate Efficiency |

The decision between CNC machining vs milling is not about one being inherently "better" than the other. Its about selecting the optimal process that best aligns with your projects specific requirements, technical demands, and budget. Our engineering team provides expert guidance.

We help clients navigate these CNC machining differences to ensure the most effective and efficient production of their CNC machining parts. This tailored approach is key to success.

Opting for CNC: High precision, complex parts

You should opt for CNC machining when your project demands high precision, tight tolerances, and intricate geometric complexity. This includes CNC milling services for aerospace components, medical devices, automotive parts, and optical systems. If your design features non-linear surfaces, multi-faceted angles, or internal features, CNC manufacturing is the ideal choice.

Furthermore, if you require consistent quality across medium to high production volumes, CNC machining offers the repeatability and efficiency to meet these demands effectively.

Choosing Milling: Simpler tasks, low volume

Traditional milling machine operations remain a viable and often more economical option for simpler tasks and very low production volumes. If your CNC machining parts have basic geometries such as flat surfaces, simple pockets, or straightforward holes, and you only need a few prototypes or one-off components, manual milling can be efficient.

Its also suitable for custom modifications or quick repair jobs where the programming time for CNC machining would outweigh the benefits.

Case study: Project A vs. Project B

Consider Project A: a client needed 500 units of an intricate medical implant with complex contours and a surface finish requiring Ra 0.8. Due to the high precision, repeatability, and volume, our recommendation was CNC machining. This ensured uniform quality and cost efficiency.

Project B involved a custom jig for internal factory use, requiring just one unit with basic slots and holes. Here, traditional milling machine operation offered the quickest and most cost-effective solution, bypassing extensive programming time. This illustrates our flexible cnc machining factory approach.

At VMT CNC machining parts services factory, our commitment goes beyond just manufacturing. We act as a trusted partner, providing the engineering insights necessary to navigate complex production decisions. Our deep understanding of milling vs CNC empowers your projects.

We leverage decades of experience in CNC machining services to deliver not just parts, but optimized solutions.

Source manufacturing for quality assurance

As a source cnc machining factory, we maintain complete control over our manufacturing processes, including both CNC milling and traditional methods. This direct oversight ensures unparalleled quality assurance, from material selection to final inspection. We adhere to rigorous standards like ISO 9001 and AS9100 for aerospace projects.

This commitment to quality means fewer defects, reduced lead times due to rework, and consistent performance of your CNC machining parts.

Transparent pricing for informed decisions

We believe in empowering our clients with complete clarity. Our approach to pricing is transparent, providing detailed breakdowns for both CNC machining and traditional milling options. This allows you to make truly informed decisions based on your budget and technical requirements.

There are no hidden costs or surprises, ensuring that your choice between CNC machining vs milling is financially sound and predictable.

Deep technical guidance for your project

Our engineering team offers comprehensive technical consultation to help you understand all CNC machining differences. We review your designs, material specifications, and volume requirements. We then provide expert recommendations on whether CNC machining or traditional milling is the best fit.

This deep technical guidance, refined through years of CNC manufacturing experience, ensures your project starts on the right path and achieves optimal results.

Make the Right Machining Choice Today

Navigating the choice between CNC machining vs milling doesnt have to be a complex challenge. By understanding the core CNC machining differences and partnering with an expert cnc machining factory like VMT, you can ensure your projects success. We are here to simplify your decisions.

Our team combines advanced CNC machining services with transparent communication to deliver the highest quality CNC machining parts.

Free consultation with our engineering team

Dont let manufacturing ambiguities impact your projects success. We invite you to a free, no-obligation consultation with our experienced engineering team. Well discuss your specific requirements and clarify any questions regarding Milling vs CNC.

Leverage our technical expertise to make the optimal choice for your next precision component.

Request a precise, no-obligation quote

Ready to move forward with confidence? Contact us today to receive a precise, no-obligation quote for your CNC machining parts project. We offer competitive and transparent pricing tailored to your needs.

Experience the VMT difference – a trusted source for high-quality CNC machining and expert guidance.

What is the main difference between CNC and milling?

The main difference is control. CNC machining uses computer programs for automated, precise control across various operations, including milling. Traditional milling relies on a human operators manual control of a milling machine.

Is CNC milling the same as CNC machining?

No, CNC milling is a specific type of operation performed by a CNC machine. CNC machining is a broader term encompassing all subtractive processes (milling, turning, grinding) that are controlled by a computer.

When should I choose traditional milling?

Traditional milling is best for low-volume production, one-off prototypes, or simpler geometries where the setup and programming time for CNC machining would be uneconomical. It suits jobs not requiring extreme precision.

What are the advantages of CNC machining?

CNC machining offers superior precision, accuracy, and repeatability. It can produce highly complex geometries, handles higher production volumes efficiently, and reduces lead times through automation.

Can CNC machines perform other operations?

Yes, CNC machining is versatile. Beyond CNC milling, CNC machines can perform turning, grinding, drilling, and even advanced processes like EDM or laser cutting, all under computer control.

How does cost compare between the two methods?

CNC machining has higher initial setup costs but lower per-part costs for higher volumes. Traditional milling has lower setup costs but higher per-part costs due to manual labor, especially as volume increases.

What precision can VMT achieve with CNC?

At VMT, our cnc machining factory routinely achieves tolerances as tight as ±0.005mm (±0.0002 inches) with CNC machining. We adhere to stringent industry standards like ISO and AS9100 for demanding applications.

How does VMT help clients choose the right process?

Our engineering team provides deep technical guidance. We assess your design, material, volume, and budget, then recommend the optimal process, whether its CNC machining services or traditional methods, ensuring the best outcome.