15 years one-stop China custom CNC machining parts factory

32 |

Published by VMT at Nov 07 2025 | Reading Time:About 4 minutes

32 |

Published by VMT at Nov 07 2025 | Reading Time:About 4 minutes

CNC machining vs. casting is pivotal. CNC offers precision for complex parts; casting suits high-volume, simpler designs. Both are key in precision manufacturing.

Choosing between CNC machining and casting isn't just a technical decision—it's a strategic one that impacts your product's performance, budget, and market entry. Are you confident you're making the right choice? This definitive guide cuts through the noise to provide clarity.

At VMT CNC machining parts services factory, we understand the critical trade-offs involved. Our unparalleled technical expertise in precision manufacturing empowers you to select the optimal method with confidence. We aim to ensure superior quality and cost-efficiency for your most critical projects.

This guide will meticulously compare these fundamental manufacturing processes, offering insights derived from our hands-on experience as a source manufacturer. We aim to equip you with the knowledge to make informed decisions for your precision manufacturing needs.

Understanding the core principles of CNC machining vs. casting is the first step in making an informed manufacturing decision. While both processes produce metal components, their underlying methodologies and applications differ significantly. Our expertise as a CNC machining factory informs this distinction.

Computer Numerical Control (CNC) machining is a subtractive manufacturing process that utilizes computerized controls to guide and manipulate machine tools. These tools remove material from a raw workpiece to create a desired part geometry. It is the cornerstone of modern precision manufacturing.

This process involves loading a digitally designed 3D model (CAD file) into a CNC machine. The machine then follows precise G-code instructions to cut, drill, bore, or mill the material. This ensures extremely high accuracy and repeatability, producing complex CNC machining parts.

Casting is an additive manufacturing process where molten material is poured into a mold cavity that has the inverse shape of the desired part. After the material solidifies, the mold is broken or opened to retrieve the finished casting. It's one of the oldest manufacturing methods.

Common casting methods include sand casting, investment casting (lost-wax casting), die casting, and permanent mold casting. Each method is suited for different materials, volumes, and levels of precision, yielding various types of casting parts.

Fundamental Process Differences

The primary distinction lies in their approach to material shaping. CNC machining removes material, starting with a solid block and subtracting volume. This method achieves high precision and complex features.

Conversely, casting adds material, forming a part from a liquid state into a specific shape. This process is generally more efficient for creating near-net-shape components. It is especially useful for parts with internal cavities or intricate forms.

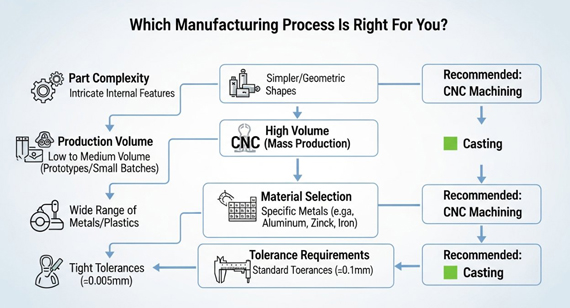

Choosing the right process demands a thorough evaluation of several critical factors. In our experience, overlooking any of these can lead to significant cost overruns or compromised part performance. We guide our clients through these trade-offs daily.

Part Complexity & Design Freedom

CNC machining offers unparalleled design freedom, allowing for intricate geometries, sharp internal corners, and undercuts without requiring draft angles. It excels at producing complex CNC machining parts with high fidelity to the CAD model. Designers have immense flexibility to optimize for function and performance.

Casting, by its nature, has design limitations. It typically requires draft angles to allow for easy part ejection from the mold, and sharp internal corners can be challenging. Complex features might necessitate multi-part molds, increasing tooling costs and complexity for casting parts.

Material Selection & Properties

CNC machining is compatible with a vast array of materials, including various metals like aluminum, steel, titanium, brass, and plastics. The machining process preserves the original material properties, often enhancing them through work hardening, ensuring superior structural integrity.

Casting is limited to materials that can be melted and poured, typically metals and some plastics. The cooling process can influence the material's microstructure, potentially leading to varied mechanical properties compared to a wrought or machined equivalent. Specific alloys are formulated for optimal castability.

Here's a comparison of typical material compatibility:

Table: Material Suitability Comparison

| Factor |

CNC Machining |

Casting |

| Metals |

Aluminum, Stainless Steel, Titanium, Brass, Copper | Aluminum alloys, Cast Iron, Steel alloys, Zinc alloys |

| Plastics |

ABS, PC, Nylon, POM, PEEK | Thermosetting resins (e.g., phenolics), some thermoplastics |

| Material Integrity |

Preserves/enhances original properties | Microstructure can vary with cooling, potential for porosity |

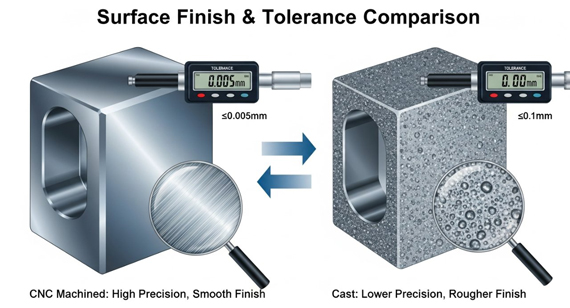

Surface Finish & Precision Tolerances

One of the defining advantages of CNC machining is its ability to achieve exceptionally tight tolerances and superior surface finishes. Our CNC machining services consistently produce parts with tolerances often as tight as +/- 0.005mm (0.0002 inches) and surface finishes down to Ra 0.8 µm. This precision is crucial for critical mating surfaces and high-performance applications.

Casting typically yields rougher surface finishes and broader dimensional tolerances. While secondary operations like grinding or machining can improve these, the initial cast part will have limitations. For general-purpose casting parts, tolerances might be +/- 0.5mm (0.02 inches) or more.

Table: Precision & Surface Finish Comparison

| Factor |

CNC Machining |

Casting |

| Typical Tolerance |

Range+/- 0.005mm to +/- 0.025mm | +/- 0.2mm to +/- 1mm (or larger for some processes) |

| Surface Finish(Ra) |

0.8 µm to 3.2 µm (can be finer with polishing) | 3.2 µm to 12.5 µm (rougher) |

| Critical Features |

Excellent for tight fits, sealing surfaces, intricate details | Requires secondary operations for high precision |

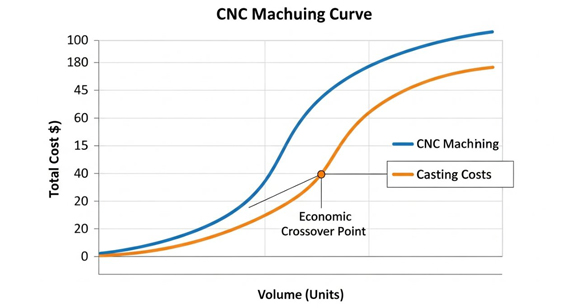

Production Volume & Tooling Costs

This is often the pivotal factor in the CNC machining vs. casting debate. CNC machining typically has low to no upfront tooling costs. Program changes are software-based, making it ideal for low-volume production, rapid prototyping, and custom, one-off CNC machining parts. Unit costs remain relatively stable regardless of volume, making cnc machining services cost-effective for smaller batches.

Casting, especially processes like die casting or investment casting, involves significant upfront tooling costs for molds or dies. These tools are expensive to design and manufacture. However, once tooling is established, the unit cost for each casting part becomes very low, making it highly economical for high-volume production runs.

Table: Cost & Volume Considerations

| Factor |

CNC Machining |

Casting |

| Tooling Cost |

Low to none (fixture design) | High (molds, dies, patterns) |

| Unit Cost |

Higher for high volumes, consistent for low volumes | Low for high volumes, impractical for low volumes |

| Optimal Volume |

Low to medium volume, prototypes, custom parts | High volume, mass production |

Lead Time & Time to Market

For prototypes and low-volume production, CNC machining offers significantly faster lead times. We can often produce complex CNC machining parts in days or weeks, allowing for rapid design iteration and quicker market entry. Our cnc machining factory is optimized for agile production.

Casting processes generally involve longer lead times, primarily due to the time required for mold design, manufacturing, and initial sample validation. Once the tooling is approved, production can be fast, but the initial setup phase is extensive. This can delay market entry for new casting parts.

Post-Processing Requirements

CNC machined parts often require minimal post-processing beyond deburring or minor surface treatments. The precision of the primary machining operation frequently delivers the final required specifications directly. This streamline enhances the efficiency of precision manufacturing.

Casting parts often necessitate extensive post-processing. This can include trimming flash, removing risers and gates, grinding, sandblasting, heat treating, and sometimes even secondary CNC machining to achieve tighter tolerances or finer surface finishes. These additional steps add cost and time.

Structural Integrity & Material Strength

CNC machining preserves the grain structure of the original material, often enhancing it through the cold working effects of cutting. This typically results in parts with superior and consistent mechanical properties, including higher tensile strength and fatigue resistance. This is critical for demanding precision manufacturing applications.

Casting involves melting and solidifying metal, which can result in a granular microstructure that differs from wrought materials. While improvements have been made, issues like porosity, shrinkage, and inconsistent grain structure can occur, potentially affecting the material's structural integrity and strength for casting parts.

In our role as a leading CNC machining factory, we regularly leverage these core advantages to deliver exceptional value to our clients. For many advanced engineering applications, CNC machining stands out as the optimal choice. It embodies the essence of precision manufacturing.

Unmatched Precision & Details

CNC machining provides absolute control over tool paths and material removal, resulting in components with incredibly tight tolerances and repeatable accuracy. This capability is essential for critical aerospace, medical, and defense CNC machining parts. Our CNC machining services guarantee this level of detail.

This precision extends to intricate details, sharp edges, and complex internal features that would be impossible or impractical to achieve through casting. The digital blueprint is translated directly into physical form with exceptional fidelity.

Rapid Prototyping & Low Volumes

Without the need for expensive and time-consuming molds, CNC machining is ideal for rapid prototyping and producing low-volume batches. Design iterations can be quickly implemented by simply updating the CAD model and machine programming. This flexibility accelerates product development.

This agility allows engineers to test and refine designs with actual functional parts much faster than with casting. For startups and R&D projects, this ability to quickly iterate on CNC machining parts is a tremendous advantage, reducing time-to-market.

Superior Material Integrity

The subtractive nature of CNC machining ensures that the inherent strength and microstructure of the original material are maintained or even improved. There are no concerns about voids, inclusions, or grain boundary issues often associated with the solidification process in casting.

This preservation of material integrity is vital for parts subjected to high stresses, extreme temperatures, or critical safety requirements. Components produced by CNC machining services offer predictable and reliable performance.

Complex Geometries & Customization

Modern multi-axis CNC machines can produce highly complex, organic, and free-form geometries that are challenging for traditional casting. This empowers designers to create parts optimized purely for performance, without manufacturing constraints limiting their vision.

From custom medical implants to specialized aerospace components, CNC machining parts can be fully customized to meet unique specifications. Our CNC machining factory thrives on turning highly complex designs into tangible, high-performance realities.

While our core expertise lies in precision manufacturing via CNC, we recognize the distinct advantages of casting for specific applications. Understanding these scenarios is crucial for holistic manufacturing strategy. Casting remains a powerful tool for certain types of casting parts.

High Volume & Cost Efficiency

For extremely high-volume production where tooling costs can be amortized over hundreds of thousands or millions of units, casting becomes incredibly cost-effective. The low per-unit cost makes it the dominant choice for mass-produced casting parts.

Automotive components, consumer goods, and industrial equipment often leverage casting for its ability to produce large quantities rapidly once the initial setup is complete. This scalability is a key differentiator when comparing cnc machining vs casting.

Simpler Shapes & Broader Tolerances

When part geometries are relatively simple and functional requirements allow for broader dimensional tolerances and rougher surface finishes, casting can be an efficient choice. The initial investment in tooling is justified by the lower unit cost.

Typical examples include engine blocks, large structural components, and casings where the exact dimensions of every surface are not critical. Subsequent CNC machining can be used on critical interfaces if needed.

Specialized Material Applications

Certain alloys are specifically designed for optimal castability, offering unique properties that may be difficult or expensive to achieve through other methods. For example, some high-strength superalloys are more readily processed via investment casting.

Additionally, casting can be advantageous for creating very large, monolithic casting parts that would be impossible or prohibitively expensive to machine from a solid billet. This includes very large machine frames or structural elements.

In many advanced precision manufacturing scenarios, the optimal solution is not an either/or but a strategic combination of CNC machining and casting. This hybrid approach leverages the strengths of both processes. Our CNC machining factory often provides these finishing services.

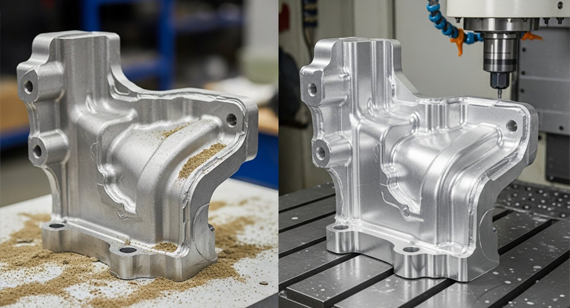

Integrating Casting with CNC Finishing

It's common practice to use casting to create a near-net-shape casting part, capturing the overall form and general features efficiently. This significantly reduces the amount of material that needs to be removed in subsequent operations.

Following the casting process, CNC machining services are then employed to machine critical features. These include tight tolerance holes, precision mating surfaces, threads, or intricate details requiring a superior surface finish. This ensures the best of both worlds.

Strategic Benefits for Complex Parts

This hybrid approach allows manufacturers to capitalize on the cost-effectiveness of casting for bulk material and complex internal structures. Simultaneously, they benefit from the precision and surface quality of CNC machining where it matters most.

For example, an engine block might be cast for its main structure and internal passages, then precision machined by our CNC machining factory on cylinder bores, mounting faces, and bearing surfaces. This reduces overall production time and cost while meeting stringent performance demands.

When it comes to your critical components, partnering with an experienced and reliable CNC machining factory is paramount. At VMT, we are more than just a vendor; we are an extension of your engineering team. We are dedicated to precision manufacturing.

Commitment to Quality & Expertise

Our team of expert engineers brings decades of hands-on experience in complex CNC machining parts production. We adhere strictly to international quality standards, including ISO 9001 and AS9100, ensuring every part meets your exact specifications. This commitment underpins our CNC machining services.

We continuously invest in the latest multi-axis CNC machinery and advanced inspection equipment. This allows us to maintain the highest levels of precision and reliability, giving you complete confidence in our precision manufacturing capabilities.

Transparent Pricing & Technical Guidance

We believe in complete transparency throughout the manufacturing process. From initial concept review to final production, you'll receive clear, detailed quotations and honest technical advice. We help you navigate the complexities of cnc machining vs casting.

Our engineers work closely with your design teams, offering DFM (Design for Manufacturability) insights to optimize your designs for cost-efficiency and superior performance. Our CNC machining services are built on a foundation of trust and collaborative problem-solving.

The decision between CNC machining vs casting is multifaceted, requiring careful consideration of your project's unique demands. There's no single "best" method; only the best fit for your specific CNC machining parts or casting parts.

Comprehensive Selection Checklist

To help our clients make this critical choice, we often use a checklist that covers various aspects. This ensures all relevant factors are weighed before committing to a manufacturing process. This structured approach to precision manufacturing minimizes risks.

Consider the following:

Making the right manufacturing choice is crucial for your project's success. At VMT CNC machining parts services factory, we are committed to providing you with the clarity and expertise needed. Our precision manufacturing capabilities are ready to serve you.

Free Technical Consultation Offer

Ready to optimize your manufacturing process and achieve superior part quality? Contact our engineering experts today for a free, in-depth technical consultation and transparent quote. Let our deep expertise guide your project from concept to high-quality reality.

Problem: A client in the industrial automation sector needed a new sensor housing. Their initial design called for a multi-component assembly that was traditionally manufactured using a combination of sand casting for the main body and subsequent extensive CNC machining for critical mounting features. The casting parts frequently showed inconsistencies in wall thickness and porosity, leading to high scrap rates and significant post-machining costs. The client faced delays and unreliable performance in their final product, struggling with the limitations of cnc machining vs casting trade-offs.

Our Solution: After a detailed technical consultation, our VMT engineering team proposed a complete redesign and manufacturing shift to full CNC machining for the entire sensor housing. We utilized advanced 5-axis CNC machining services to produce the complex internal geometries and external mounting points from a single billet of high-grade aluminum. Our CNC machining factory implemented specific tool path strategies to maintain optimal material integrity and achieve a superior surface finish directly from the machine.

Result: The switch to precision manufacturing via CNC machining parts yielded transformative results. The client experienced a dramatic reduction in scrap rates (over 90%) due to the elimination of casting defects and improved dimensional accuracy. The lead time for finished components was reduced by 30%, as extensive post-processing and rework were no longer necessary. The final sensor housing demonstrated enhanced structural integrity and reliability, leading to a more robust end product and a faster time-to-market. The overall project cost was significantly reduced when considering the total cost of ownership, validating the superior value of our CNC machining parts services factory.

What is the main difference between CNC and casting?

CNC machining removes material from a solid block using computer-controlled tools to create parts. Casting involves pouring molten material into a mold and letting it solidify.

CNC is a subtractive process, ideal for precision and complex geometries. Casting is an additive process, better for high volumes and simpler shapes, often for initial casting parts.

When should I choose CNC machining?

Choose CNC machining for complex CNC machining parts requiring high precision, tight tolerances, and superior surface finishes. It's also ideal for rapid prototyping and low-to-medium volume production.

It excels where material integrity is paramount, such as in aerospace or medical precision manufacturing. Our CNC machining services support these demanding applications effectively.

When is casting a better option?

Casting is generally a better option for very high-volume production runs where tooling costs can be justified. It is cost-effective for simpler casting parts with broader tolerances.

It's suitable for materials that are specifically formulated for casting, like various iron or aluminum alloys, to produce large or intricate components efficiently.

What are the cost implications of each?

CNC machining typically has lower upfront tooling costs, making it cost-effective for low volumes and prototypes. Unit costs are stable but can be higher for mass production.

Casting involves high initial tooling costs for molds. However, the per-unit cost for mass-produced casting parts can be significantly lower once tooling is amortized.

Can CNC machining achieve tighter tolerances?

Yes, CNC machining consistently achieves significantly tighter dimensional tolerances compared to casting. Our CNC machining factory can produce parts with tolerances of +/- 0.005mm or even finer.

Casting processes typically yield tolerances that are an order of magnitude larger, often requiring secondary CNC machining for critical features.

What materials are best for CNC machining?

CNC machining is compatible with a wide range of materials. These include various metals like aluminum, stainless steel, titanium, brass, and engineering plastics such as ABS, Nylon, and PEEK.

The choice depends on the specific application requirements, including strength, weight, corrosion resistance, and thermal properties for CNC machining parts.

How does material strength differ between the two?

CNC machined parts generally exhibit superior and more consistent material strength due to preserving the original material's grain structure. The machining process can even enhance properties.

Casting can introduce defects like porosity or inconsistent grain structure during solidification. This can potentially lead to lower and less predictable mechanical properties for casting parts.

Is a hybrid approach common in manufacturing?

Yes, a hybrid approach combining casting with subsequent CNC machining is very common in precision manufacturing. This strategy leverages the strengths of both processes.

Casting creates a near-net-shape part efficiently, and CNC machining services add critical precision to specific features. This optimizes cost, performance, and lead time.