15 years one-stop China custom CNC machining parts factory

69 |

Published by VMT at Nov 10 2025 | Reading Time:About 2 minutes

69 |

Published by VMT at Nov 10 2025 | Reading Time:About 2 minutes

Brass, an alloy with remarkable machinability, is widely used across industries. You cannot leave it, whether you’re in the areas of shipbuilding, electronics and telecommunications, vehicle manufacturing, or architectural decoration. This article will guide you through the composition, types, properties, and applications of this remarkable alloy—brass.

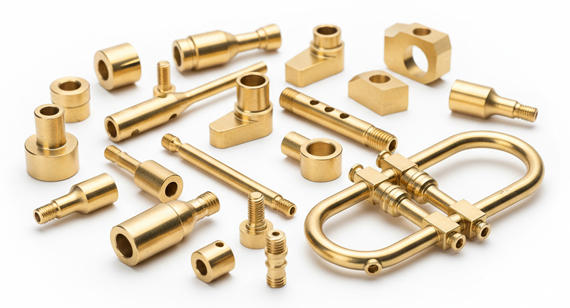

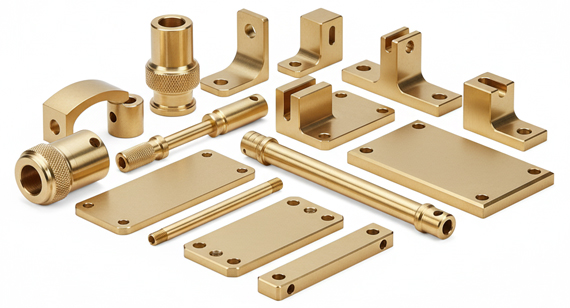

Brass is an alloy primarily composed of copper and zinc, valued for its attractive golden appearance, excellent corrosion resistance, and outstanding machinability. The proportion of copper and zinc can be adjusted to produce different types of brass, each with specific mechanical and chemical properties suited for various applications. Known for its strength, durability, and smooth surface finish, brass is widely used in industries such as electronics, plumbing, architecture, and CNC machining. Its versatility allows manufacturers to create high-precision brass CNC machined parts that combine functionality with aesthetic appeal. With reliable CNC machining services from professional CNC machining factories, brass can be turned, milled, or drilled into complex shapes that meet strict engineering requirements, making it a preferred material for both functional and decorative components.

Brass existed around 3,000 BC when copper and zinc elements combined in nature. Later, around 1,000 BC, workers found brass to be attractive and easy to process, so brass coins, decorations, etc., emerged.

For now, brass is available in different types according to the percentage of copper, zinc, and other trace metal elements. I’ll show you the specific proportions of metals in brass.

The metallographic structure of brass is classified into three types: alpha single-phase, alpha-beta two-phase, and beta single-phase (simplified as brass α, brass α-β,brassβ).

Table 1: brass α, brass α-β, and brassβ

|

Brass |

Copper to Zinc Ratio |

Composition |

|

brass α |

(55-65%): (35-45%) |

Higher copper |

|

brass α-β |

(55-60%): (40-45%) |

In the middle |

|

Brass β |

15%: 85% |

Higher zinc |

Brass is mainly composed of copper and zinc elements, and the proportions of copper to zinc affect the properties of brass.

Facts of Brass α

Zinc of brass α can be under percentage of 37%, which leads to brass α owns the properties of high ductility and corrosion resistance.

Therefore, if you want to use brass with high ductility and corrosion resistance, consider brass α. It’s a suitable material for your tube manufacturing, such as the brass tee fitting.

Higher contains of copper make the color of brass α slightly rosy and full of luster after polishing. You’ll consider uses of brass α for architectural decorating.

Facts of Brass α-β

Zinc of brass α-β is a little more than brass α, making the brass α-β relatively cheaper than brass α. But brass α-β still possesses relatively good ductility and corrosion resistance due to the difference is slight.

Good properties like brass α, but economical, that’s what you find the replacement of tube manufacturing and others.

Facts of Brass β

Zinc of brass β is the highest, leading to the limits of less corrosion resistance. But it has good properties of abrasion resistance and high hardness. Also, it is suitable for heat treatment and die casting due to its low melting point.

You can think of brass β uses of die-cast parts, such as fasteners, which are suitable and the most economical.

Chemical Composition of brass includes not only the copper and zinc elements, but also other trace metal elements ( including aluminum, tin, manganese, iron, silicon, etc). Facts about brass are closely connected to the metal elements composed of.

Table 2: Types of Brass Classified by the Chemical Composition

|

Types |

Elements |

Traits |

|

Brass 215 (Spring Brass) |

Cu:99% , Zn:1% Trace amount: O, Fe, Pb, S, P

|

High electrical conductivity, high thermal conductivity |

|

Brass 230 (Commercial Bronze) |

Cu:70-75%, Zn:25-30% Trace amount: Fe, Pb, Al, S, P, Ni |

Moderate strength, corrosion resistance |

|

Brass 260 (Standard Brass Alloy) |

Cu:70% , Zn:30% Trace amount: O, Fe, Pb, Al, S, P, Ni |

Standard brass alloy, widely used |

|

Brass 270 (Yellow Brass) |

Cu:70-80%, Zn:20-30% Trace amount: O, Fe, Pb, Al, S, P, Ni |

Machinability, corrosion resistance |

|

Brass 280 (Muntz Metal) |

Cu:60% , Zn:40% Trace amount: O, Fe, Pb, Al, S, P, Ni |

Moderate strength |

|

Brass 385 (Architectural Brass) |

Cu:60-65% ,Zn:35-40%, Pb:1.5% Other trace amount |

Moderate corrosion resistance and wear resistance |

|

Brass 443 (Admiralty Brass) |

Cu:60-65% ,Zn:35-40%, Al:2-3%,Pb:0.5% ,Mn:0.5% Other trace amount |

Good corrosion resistance, wear resistance |

|

Brass 464 (Marine Grade) |

Cu:59% , Zn:40%, Tin:1% Other trace amount |

High corrosion resistance, seawater resistance |

Worth noting:

Brass 215 is a high-purity brass alloy containing 99% copper. Brass 215, used for precision manufacturing such as circuits, thermal sensors, is the best choice for you.

Brass 260 is a standard brass alloy, widely used in common parts and structures.

Brass 443 and Brass 464 with better corrosion resistance than Brass 385. So if you’re focused on hull plating or fittings, use Brass 443 or Brass 464.

Properties of brass can be characterized in two respects: mechanical and chemical properties.

Mechanical Properties

Strength

The benefit of brass with high strength is that the brass can be manufactured into high-strength components. Like Brass 215 (Spring Brass), with high tensile strength, is the best material for manufacturing springs.

Ductility

Brass with high ductility is suitable for cold working. Like Brass 270 (Yellow Brass), with excellent cold workability, is widely used in all industries with processing methods of cold rolling, cold drawing, and stamping.

Hot workability

Brass with good hot workability is suitable for thermoforming and casting processing. Like Brass 230 (Commercial Bronze) and Brass 270 (Yellow Brass) are suitable to be manufactured into parts with ways of forging, extrusion, and die casting.

Hardness

Brass with high hardness is suitable being use in demanding environments. Like brass 464 (Marine Grade) is suitable for the wear requirement in a marine environment.

Toughness

Brass with high toughness can be used in environments requiring high corrosion resistance. Brass 443 (Admiralty Brass) and Brass 464 (Marine Grade) are two good ones.

Chemical Properties

Corrosion Resistance

Brass, holding high corrosion resistance, is good for tube or hull building. Brass 443 (Admiralty Brass) and Brass 464 (Marine Grade) are two good ones.

Oxidation Resistance

Brass surfaces can form a stable copper oxide layer, making them suitable for decorations.

Acid resistance

Brass can withstand environments with low acid concentrations.For example, brass can be used for parts in food processing equipment that come into contact with vinegar.

Additionally, brass possesses antibacterial properties and a low coefficient of friction, making it suitable for surface contact parts and sliding components.

As you have learnt about the structure, types, and Properties of brass, here I will list common application areas of brass.

Musical Instruments

Brass is applied for musical Instruments, especially for crafting brass wind instruments. Due to the good ductility and antibacterial properties of brass, brass instruments such as trumpet, cornet, flugelhorn, or the instrumental parts are manufactured (Brass 270). Brass with a hot-worked process is used for manufacturing wind instruments, while brass with a cold-worked process is used for manufacturing hard parts of instruments.

Architectural Industry

Brass is widely used in the architectural field. Brass with a bright, lustrous finish makes it ideal for architectural decoration. Door handles, locks, valves, and other components in the construction sector are often crafted from brass.

Electronics and Telecommunications

Brass, whether hot-worked or cold-worked, is widely used in the electronics industry. Brass die-castings and CNC-machined brass parts, such as fasteners, are commonly found in the market. Brass 215, with its excellent electrical conductivity, is suitable for manufacturing precision components, such as parts in circuit boards.

Brass is used for certain machining of automobile parts, including bearing bushings, valve seats, bearings, bearing tubes, gears, and cooling system parts. For instance, Brass 215, with its high thermal conductivity, serves as a suitable material for radiator tubes used in engine cooling systems. Other automobile parts utilize appropriate brass grades based on specific part requirements, such as ductility or hardness specifications.

Brass alloys come in many types. You need to fully understand the properties of brass grades to select the suitable material before starting your project. How can the specific performance requirements of your CNC-machined brass parts project be acheived?

VMT here is a professional CNC Machining Brass Parts factory, specializing in providing CNC high-precision machining of customized brass parts for various industries. With advanced CNC machining equipment and a strict quality control system, as well as surface finishes, VMT provides you with reliable CNC machining services, ensuring that every brass part meets precise dimensional and surface finish requirements. If you need professional advice on selecting materials for customized brass parts, welcome to contact us. We are available 24/7.

No. Brass rarely contains iron and does not rust. But brass can oxidize over time, causing its color to darken. Applying a coating can delay this oxidation process.

What color is brass?

Brass typically exhibits a gold-like yellow color, but if the copper element is higher, it tends to be a slight red.

What’s the melting point of brass?

The melting point of brass ranges from 900°C to 940°C, depending on the ratio of copper to zinc.

What is brassware?

Common brassware includes kitchen items such as frying pans, shower fixtures like faucets, lighting fixtures like chandeliers and wall lamps, as well as hardware fittings and industrial components.

No. Brass is mainly made up of copper and zinc, belongs to a non-magnetic material.

Is brass conductive?

Yes. Brass 215 (Spring Brass) is highly conductive.

How to tell the difference between copper and brass?

Copper is typically reddish or orange, while brass is gold-like yellow or yellowish-brown.