15 years one-stop China custom CNC machining parts factory

1 |

Published by VMT at Jan 05 2026 | Reading Time:About 3 minutes

1 |

Published by VMT at Jan 05 2026 | Reading Time:About 3 minutes

In many actual manufacturing projects, structural components represent one of the largest categories of material demand, and they often require high strength to carry loads or provide mechanical support. However, for another category of applications—such as electronic enclosures and decorative parts—formability, corrosion resistance, and surface quality are far more important than strength.

1050 aluminum is designed specifically for these requirements, offering a more efficient and cost-effective solution.

This article focuses on the properties of 1050 aluminum, its manufacturing processes, common supply forms, and typical applications, helping you gain a clear understanding of this material. Read on to better determine whether 1050 aluminum is suitable for your project.

Within the aluminum family, 1050 aluminum is one of the most widely used high-purity grades (1XXX series, ≥99.5% aluminum), best known for its excellent formability, corrosion resistance, and overall workability. You may also see this alloy referred to as 1050A aluminum, which is simply the European standard designation (EN AW-1050A) for the same high-purity material.

Outstanding ductility allows 1050 aluminum to be easily stretched, stamped, bent, and extruded into complex shapes. Its high purity enables the formation of a natural oxide layer on the surface, providing reliable corrosion resistance. Combined with its good electrical and thermal conductivity, 1050 aluminum is a reliable choice for chemical equipment, heat exchangers, and electrical components. 1050 aluminum also responds well to anodizing, producing a uniform, highly reflective, and visually appealing surface. This makes it well suited for decorative and functional applications such as cookware and lighting reflectors.

However, 1050 aluminum has one clear limitation: its relatively low mechanical strength. Thus, aluminum alloys such as 6061, 5052, or 7075 are typically preferred in applications where higher strength is required.

1050 aluminum is a high-purity aluminum alloy (≥99.5% Al). Its typical chemical composition is shown below:

Table 1: Chemical Composition of 1050 Aluminum

| Element | Content (%) | Description |

| Aluminum (Al) | ≥99.5 | Base element |

| Silicon (Si) | ≤0.25 | Trace impurity |

| Iron (Fe) | ≤0.40 | Trace impurity |

| Copper (Cu) | ≤0.05 | Low content, minimal effect on mechanical properties |

| Manganese (Mn) | ≤0.03 | Trace amount, slightly improves strength |

| Magnesium (Mg) | ≤0.03 | Trace amount, minor influence on hardness |

| Chromium (Cr) | ≤0.03 | Trace amount, contributes to stability |

| Nickel (Ni) | ≤0.03 | Trace impurity |

| Other elements | ≤0.15 | Total impurities |

(notes: value of table 1, 2, and 3 credit from azom)

1050 aluminum exhibits the following key chemical characteristics:

A naturally formed aluminum oxide (Al₂O₃) layer protects the surface of 1050 aluminum, allowing long-term use of 1050 aluminum in humid, marine, and chemical environments with minimal corrosion.

It shows good resistance to most acids, alkalis, and salt solutions, ensuring reliable performance across a wide range of industrial conditions.

After processing or welding, the oxide layer remains even and stable, making 1050 aluminum well suited for subsequent surface treatments such as anodizing, painting, or coating.

What Are Physical Properties of 1050 Aluminum?

1050 aluminum offers physical properties such as low density, high ductility, and good thermal and electrical conductivity. These properties make it well suited for lightweight designs as well as thermal and electrical applications such as heat sinks, conductive components, and lightweight structural parts. Physical properties of 1050 aluminum are outlined in Table 2 below:

Table 2: Physical Properties of 1050 Aluminum

| Property | Value | Description |

| Density | 2.71 g/cm³ | Lightweight material |

| Melting Point | 645–650 °C | Suitable for thermal forming and welding |

| Boiling Point | 2470 °C | High-temperature stability |

| Latent Heat of Fusion | 397 kJ/kg | Thermal energy storage capacity |

| Thermal Conductivity | 230 W/m·K | Excellent heat transfer |

| Electrical Conductivity | 59% IACS | Good electrical conductivity |

| Specific Heat Capacity | 0.897 J/g·K | Moderate heat capacity |

| Coefficient of Thermal Expansion | 23.6 µm/m·K | Good dimensional stability under temperature changes |

| Crystal Structure | FCC(Face-Centered Cubic) | High ductility and formability |

| Magnetic Properties | Non-magnetic | Suitable for electronic applications |

The key physical properties of 1050 aluminum include:

With a density of approximately 2.7 g/cm³, 1050 aluminum is ideal for lightweight designs in automotive, aerospace, and architectural applications.

Aluminium alloy 1050 efficiently transfers heat, making it commonly used in heat sinks, heat exchangers, and HVAC components.

With electrical conductivity close to 60% IACS(meaning it conducts about 60% as well as pure annealed copper), 1050 aluminium is widely used in cable sheathing, busbars, and electrical components.

1050 aluminum exhibits good reflectivity to both visible and infrared light. This physical property allows 1050 aluminium alloy to achieve a bright and uniform reflective appearance after polishing or basic surface finishing, making it well suited for applications such as lighting reflectors and architectural decorative components.

1050 aluminum has relatively low strength but excellent ductility and machinability, making it ideal for light-load structures, thin sheets, stamping, and forming applications. The mechanical properties of aluminum 1050 in H14 temper(cold-worked, half-hard condition) are shown in the following:

Table 3: Mechanical Properties of 1050 Aluminum

| Property | Value | Description |

| Tensile Strength | 90 MPa | Can be improved slightly with work hardening |

| Yield Strength | 35 MPa | Low strength, suitable for light-load applications |

| Elongation | 35% | High ductility, easy to form |

| Elastic Modulus | 69 GPa | Moderate stiffness |

| Brinell Hardness | 25 HB | Soft material, easy to machine |

| Fatigue Strength | — | Varies with thickness and temper |

The mechanical properties of 1050 aluminum can be summarized as follows:

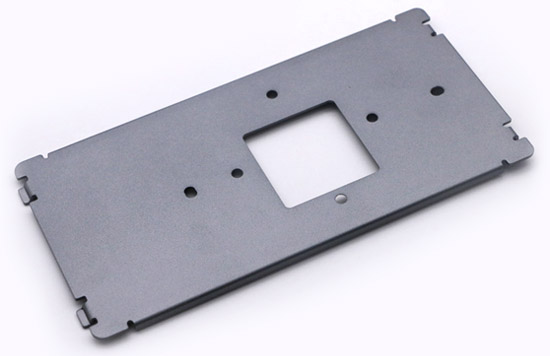

1050 aluminum has relatively low mechanical strength, which makes it unsuitable for high-stress or load-bearing components. Rather, it is ideal for non-structural or light-load parts, such as decorative panels, electronic enclosures, etc.

Thanks to its excellent ductility and plasticity, 1050 aluminum can be easily bent, stretched, or formed into complex shapes without cracking. This allows manufacturers to create intricate parts through stamping, deep drawing, bending, and extrusion.

Aluminum 1050’s softness and low hardness enable precise machining with CNC, stamping, extrusion, and bending processes. This property allows for the production of detailed and intricate components, including custom enclosures and light structural elements.

1050 aluminum is compatible with MIG, TIG, and spot welding, producing reliable weld joints. As a result, it is widely used in equipment housings, lightweight frames, and other fabricated components that require stable assembly.

1050 aluminum performs well under light-load and moderate cyclic conditions with its fatigue resistance. This durability makes it suitable for non-critical parts that experience repeated use or minor vibrations, such as control panels or decorative assemblies.

What Are the Manufacturing Processes of the Alloy?

1050 aluminum is a commercially pure alloy known for its excellent ductility and ease of processing. Unlike heat-treatable aluminum alloys, 1050 achieves its mechanical properties mainly through forming processes, rather than complex heat treatments. Manufacturing processes of 1050 aluminum alloy include:

The high ductility of 1050 aluminum allows it to be easily shaped using various forming techniques. Cold rolling and continuous casting are commonly used to produce sheets, coils, and strips. Deep drawing is ideal for manufacturing concave items such as cookware and food containers, while bending and spinning are often used for lighting reflectors, signage, and decorative components.

As a non-heat-treatable alloy, 1050 aluminum does not rely on aging to increase strength. Instead, cold working provides its primary mechanical properties. Annealing is used when necessary to relieve stresses from previous forming operations, restore ductility, and prepare the material for further processing.

1050 aluminum can be welded with almost all conventional methods, including MIG, TIG, and resistance welding. Proper surface preparation, such as removing oxides and using protective gases, ensures reliable joints. For surface finishing, anodizing is a popular option, enhancing corrosion resistance and providing a uniform, attractive appearance.

While relatively soft, 1050 aluminum machines well, making it suitable for CNC machining, milling, and turning operations. Its low hardness reduces tool wear, but sharp tools and appropriate cutting fluids are recommended to achieve high-quality surfaces and precise dimensions.

Overall, 1050 aluminum is easy to shape, weld, and machine. These qualities highlight why 1050 aluminum is favored in projects where efficient and reliable fabrication is key.

Choosing the right surface treatment allows 1050 aluminum to achieve improved appearance, and durability or others without compromising its any properties. Different surface finishes of 1050 aluminum can meet your specific requirements such as wear resistance, electrical performance, decorative appearance, or color consistency. Common surface finishes of 1050 aluminum products include:

Polishing and brushing are mechanical finishing processes used to improve the surface smoothness of 1050 aluminum or to create decorative textures. After treatment, the surface can achieve a bright, mirror-like finish or a fine brushed appearance, enhancing both visual appeal and tactile quality. This type of surface treatment is well suited for aluminum products where surface aesthetics and texture are important, such as visible panels, decorative components, and signage.

Anodizing is an electrochemical process that thickens the natural oxide layer on the surface of 1050 aluminum, forming a dense and protective oxide film. This treatment increases surface hardness and wear resistance while also providing a stable base for coloring. Anodized 1050 aluminum parts are both durable and visually appealing, and can achieve either a natural metallic look or a colored finish, making anodizing ideal for electronic enclosures, architectural profiles, and decorative aluminum components.

Powder coating and spray painting create a uniform protective layer on the surface of 1050 aluminum, improving weather resistance and scratch resistance. These finishes also allow for a wide range of colors and surface textures, meeting both functional and aesthetic requirements. This surface treatment is commonly used when consistent appearance, color customization, or additional surface protection is needed.

Electroplating involves depositing a thin metallic layer—such as nickel or chromium—onto the surface of 1050 aluminum. This process enhances surface hardness, wear resistance, and decorative quality. Depending on the plating material, electroplating can also improve electrical conductivity or produce a high-gloss, mirror-like finish. It is typically used for functional metal parts, electrical contact components, and decorative aluminum products that require enhanced surface performance.

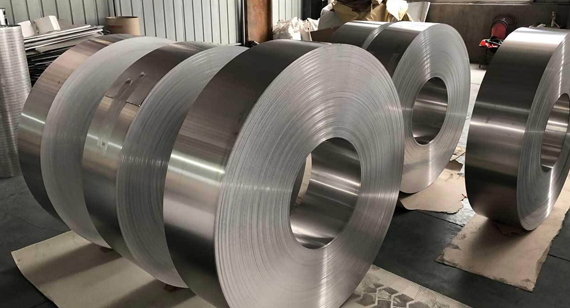

You’ll find 1050 aluminum widely available from metal suppliers in a broad range of forms. They are primarily produced through rolling and extrusion processes and supplied in commonly tempers of O (annealed/soft) and H14 (half-hard, strain-hardened). Common formats of 1050 aluminum include:

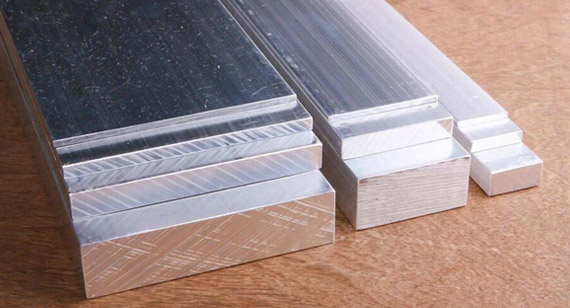

Sheets are one of the most common forms of 1050 aluminum. 1050 aluminum sheets are typically used for general sheet metal work, food-industry containers, and decorative applications.

1050 aluminum plates are similar to sheets but significantly thicker. They are used in applications that require greater rigidity and strength, such as structural components or machined parts, where thin sheets would not provide sufficient load-bearing capacity.

1050 aluminum is frequently supplied in coils or strips, especially for high-volume industrial processing. These coils can be slit or cut to length for stamping, forming, or continuous manufacturing operations.

Bars are available in multiple shapes and sizes and are commonly used for machining or fabrication. Typical forms include round bar, flat bar, and rod, each serving different practical purposes.

Round bars are widely used for turning operations, shafts, pins,and general machined components. Flat bars are often selected for brackets, frames, and structural elements where a rectangular profile is required. Rods are usually supplied in smaller diameters with tighter tolerances, are commonly used for precision parts, rivets, and light mechanical components.

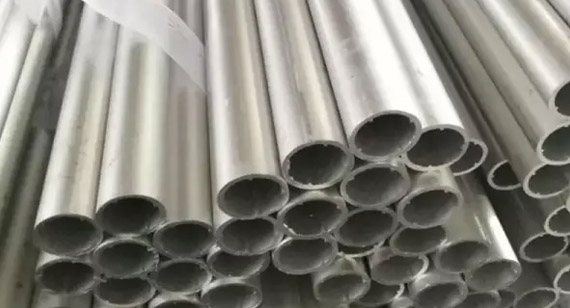

Both standard and large-diameter extruded tubes of 1050 aluminum are available. These are commonly used in chemical processing equipment, HVAC systems, and other applications that benefit from aluminum’s corrosion resistance and formability.

Wire made from 1050 aluminum is used for electrical conductors and cables, as well as for rivet stock and certain welding filler applications where high purity aluminum is required.

Thanks to its high purity and excellent light-tight and reflective properties, 1050 aluminum is also produced as thin foil. Typical uses include cryogenic insulation, laboratory and optical experiments, and other specialized applications.

Suppliers can also provide a variety of extruded profiles, such as U-sections, angles, channels, and custom shapes. These are widely used in general fabrication, light construction, and framing systems.

1050 aluminum alloy is widely used across industries such as automotive, construction, electronics, packaging, and chemical processing due to its excellent workability, corrosion resistance, high electrical and thermal conductivity, and outstanding formability. Below are the typical applications of 1050 aluminum alloy in different industries:

Thanks to its lightweight nature and good machinability, 1050 aluminum is used to manufacture lightweight body panels and components. It helps reduce overall vehicle weight, improve fuel efficiency, and maintain adequate durability of parts.

2. Construction and Decoration

1050 aluminum is easy to shape and offers high surface reflectivity, making it ideal for architectural and decorative applications. Common uses include curtain walls, doors and windows, aluminum profiles, signboards, road signs, and lamp reflectors. Its excellent corrosion resistance ensures long-term service life with minimal maintenance.

3. Electronics and Electrical Industry

The high electrical conductivity and good formability of 1050 aluminum make it highly popular in the electronics and electrical sector. Typical applications include wire and cable sheathing, electrolytic foil, conductive busbars, heat sinks, and electronic enclosures.

4. Packaging Industry

Because 1050 aluminum is non-toxic, corrosion-resistant, and easy to process, it is widely used in food, beverage, and pharmaceutical packaging. Common products include aluminum foil, beverage cans, and pharmaceutical packaging materials, ensuring product safety while remaining fully recyclable.

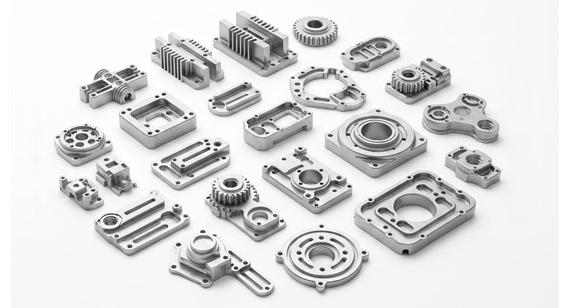

5. Industrial and Mechanical Manufacturing

In mechanical manufacturing, 1050 aluminum is commonly used for CNC-machined parts, lightweight structural components, and general sheet metal fabrication. Its softness and high ductility make stamping, bending, and extrusion processes easier, especially for complex shapes or mass production.

6. Chemical and Pharmaceutical Equipment

1050 aluminum exhibits good resistance to many chemical substances, making it suitable for the chemical and pharmaceutical industries. Typical applications include chemical processing equipment, pipelines, storage tanks, and pharmaceutical machinery, ensuring durability and operational safety.

7. Food Industry

Due to its non-toxic nature and corrosion resistance, 1050 aluminum is an ideal material for food-contact applications. It is commonly used for food containers, kitchen cookware, and food packaging materials, ensuring food safety and long service life.

8. Thermal Management Applications

With its high thermal conductivity, 1050 aluminum is well suited for thermal management components such as cooling fins, air-conditioning and refrigeration system heat exchangers, and heat-dissipation parts used in boiler manufacturing.

From this article , you’ve learnt that 1050 aluminum is a high-purity aluminum alloy that stands out for its excellent corrosion resistance, low density, high ductility, and outstanding machinability. In modern manufacturing, choosing 1050 aluminum brings clear benefits in lightweight design, environmental sustainability, and production efficiency, making it especially suitable for CNC machining, extruded profiles, and precision component manufacturing.

If you are looking for prototyping and surface finishes of high-precision metal parts, VMT CNC Machining Factory is your reliable manufacturing partner. With over 15 years of experience, we specialize in aluminum CNC machining and the production of high-precision metal parts, including custom aluminum housings, enclosures, and complex structural components. From rapid prototyping and high-precision machining to a wide range of surface finishes, we provide end-to-end solutions tailored to your exact requirements. Serving industries such as medical, electronics, and automotive, we deliver parts with tolerances as tight as ±0.01 mm—helping turn your designs into dependable, high-performance components. Contact VMT today to experience professional, efficient, and responsive support for all your aluminum projects.

Is 1050 aluminum suitable for high-load structural applications?

No, it is not ideal for high-load structures due to its relatively low mechanical strength. It is better suited for low-load applications where corrosion resistance, formability, or conductivity is more important.

Can 1050 aluminum be used for CNC machining?

Yes, 1050 aluminum is very suitable for CNC machining, especially for high-precision parts and complex geometries. Its softness and excellent machinability make it easy to cut, drill, and mill.

How recyclable is 1050 aluminum?

Aluminum is 100% recyclable without loss of properties. Recycling aluminum requires only about 5% of the energy needed to produce primary aluminum, making it both environmentally friendly and cost-effective.

Aluminum 1050 vs 5052: What’s the difference?

1050 aluminum offers higher purity, better formability, and superior electrical conductivity. In contrast, 5052 aluminum has much higher strength and better fatigue resistance, making it more suitable for structural and marine applications.

Aluminum 1050 vs 6061: Which should I choose?

1050 aluminum is ideal for applications requiring excellent corrosion resistance and formability but low strength. 6061 aluminum provides significantly higher strength and good machinability, making it better for load-bearing and structural components.

What is the difference between aluminum 1050 and 1350?

Both are high-purity aluminum alloys, but 1350 aluminum has higher electrical conductivity than 1050. As a result, 1350 is commonly used in electrical conductors, while 1050 is more widely used in general fabrication and forming applications.