15 years one-stop China custom CNC machining parts factory

2 |

Published by VMT at Dec 27 2025 | Reading Time:About 2 minutes

2 |

Published by VMT at Dec 27 2025 | Reading Time:About 2 minutes

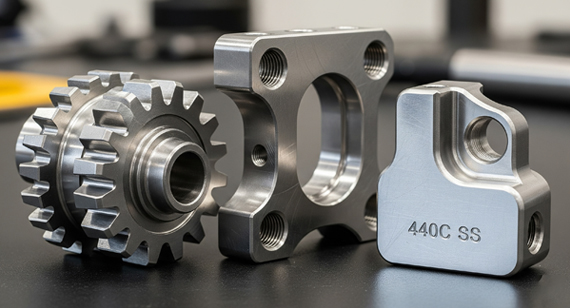

Since modern manufacturing began, the steel you choose can make a big difference in how a product performs, how it’s machined, and how it holds up over time. This is especially true in industries such as mold making and precision machining, where high-hardness steels like D2 tool steel and 440C stainless steel are frequently compared.

Both 440C and D2 steels can reach similar high hardness after heat treatment (typically 58–62 HRC), and they are widely used in wear-resistant and precision parts. But in actual use, they differ in wear resistance, corrosion resistance, machinability, and other properties. As a result, you may ask questions such as: Which is more wear-resistant, D2 or 440C? Which material is easier to machine?

To help you figure out these issues, this article will provide clear answers to help you make the optimal decision quickly. From an industrial application perspective, you can take an in-depth look at the chemical composition, mechanical properties, cost, and uses of D2 and 440C in this article. Below is the full comparison of D2 steel vs. 440C steel.

D2 is a high-carbon, high-chromium tool steel known for its outstanding wear resistance and ability to hold a sharp edge. It typically contains about 1.4–1.6% carbon and 11–13% chromium. This combination allows D2 to reach very high hardness after heat treatment (around 60–62 HRC), making it extremely resistant to abrasion and ideal for maintaining cutting edges.

Because of these qualities, D2 is widely used for industrial molds, punches, cold-work tooling, and parts that must withstand heavy wear or impact.

Even though D2 has a good amount of chromium and offers some corrosion resistance, it does not meet the requirements to be considered true stainless steel. For this reason, it is often called “semi-stainless”. It performs well in normal environments, but in long-term exposure to moisture or corrosive conditions, it will not resist rust as well as real stainless steels. If corrosion resistance is critical, you will need to apply a surface treatment or choose a different stainless-steel grade, like 304 or 316 or 440C.

440C is a high-carbon martensitic stainless steel and is one of the hardest stainless steels available. It usually contains about 1.0–1.2% carbon and around 16–18% chromium, giving it both high hardness (typically 58–60 HRC) and excellent corrosion resistance.

Thanks to this balance of hardness and corrosion resistance, 440C is commonly used in precision mechanical parts, bearings, valves, and equipment that must perform in wet or corrosive environments.

Compared with D2, 440C is tougher and easier to machine and polish, while also offering much better corrosion resistance. Because of these advantages, it is a popular choice when you need both strength and resistance to rust. But if you ask for better corrosion resistance, surface treatments such as PVD coatings can further enhance wear and corrosion resistance.

The chemical composition of D2 and 440C steel is outlined in Table 1 below:

Table 1: Chemical Composition Comparison: D2 vs 440C Steel

| Element (wt %) | D2 Tool Steel | 440C Stainless Steel |

| Carbon (C) | 1.40–1.60% | 1.00–1.20% |

| Chromium (Cr) | 11–13% | 16–18% |

| Molybdenum (Mo) | 0.70–1.20% | 0.40–0.75% |

| Vanadium (V) | 0–1.10% | Trace/very low |

| Manganese (Mn) | ≤0.60% | ≤1.00% |

| Silicon (Si) | ≤0.60% | ≤1.00% |

| Iron (Fe) | Balance | Balance |

| Others (P,S, etc.) | Trace | Trace |

Table 1 credit: makeitfrom AISI D2 and makeitfrom AISI 440C

Chemical composition of D2 and 440C can lead to their different performance. D2 steel contains a high level of carbon, which promotes the formation of hard carbides. The 11-13% chromium together with carbon allows D2 steel to reach high hardness and wear resistance. And small additions of vanadium further improve its abrasion resistance, while molybdenum increases strength and hardenability.

Compared to D2 steel, 440C stainless steel has higher chromium, which gives it much better corrosion resistance. But its carbon content still allows it to achieve high hardness after heat treatment. Its molybdenum and other alloying elements also support strength and corrosion behavior.

When comparing different steel types, there are several major physical and mechanical properties you should always check. These properties include density, elastic modulus, hardness, tensile strength, yield strength, elongation, thermal conductivity, and thermal expansion. Below are the D2 vs. 440C steel comparison index on each property.

Table 2: Physical & Mechanical Properties Comparison: D2 vs 440C Steel

| Property | D2 Tool Steel | 440C Stainless Steel |

| Density | ~7.70–7.75 g/cm³ | ~7.75 g/cm³ |

| Modulus of Elasticity | ~210 GPa | ~200 GPa |

| Hardened Hardness (HRC) | 58–62 HRC | 58–60 HRC |

| Tensile Strength (hardened) | ~1,800 MPa | ~1,900–2,030 MPa |

| Yield Strength | ~1,500+ MPa | ~1,900+ MPa |

| Elongation (hardened) | ~10–12% | ~2–4% |

| Thermal Conductivity | ~20–25 W/m·K | ~24 W/m·K |

| Thermal Expansion | ~10.4–11.6 ×10⁻⁶ /°C | ~10.1–10.4 ×10⁻⁶ /°C |

Table 2 credit: azom UNS T30402 and azom UNS S44004

The two steels have very similar density, elastic modulus, thermal conductivity, and thermal expansion. This means that if you design your parts, you can treat them similarly in structural and heat-treatment calculations without worrying about major physical differences.

Both D2 and 440C can reach similar hardness after heat treatment (around 58–62 HRC). But even with comparable hardness, they don’t perform the same in real-world wear conditions. D2’s higher carbon content and its abundance of very hard chromium carbides give it noticeably stronger wear resistance and better edge retention. That’s why D2 is often the go-to choice for dies, punches, and other parts that see heavy abrasion or constant sliding contact.

440C generally shows better toughness and impact resistance. D2’s high carbide volume makes it very hard but also more brittle, meaning it can chip or crack under impact or vibration. For shock-loaded parts, 440C is usually the safer choice.

D2 is difficult to machine due to its high hardness and carbide structure, causing rapid tool wear. It is typically shaped by grinding, EDM, or pre-hard machining, which raises cost and cycle time. 440C is much easier to machine, holds tolerance better, and offers more economical machining, especially in high-volume CNC work.

440C clearly outperforms D2 in corrosion resistance. As the stainless steel, 440C keeps enough free chromium in its matrix to form a strong, stable passive layer. This layer helps prevent rust and makes 440C a great choice for humid, marine, chemical, medical, or food-grade environments.

D2 also contains chromium, but it's extremely high carbon content binds much of that chromium into hard carbides. As a result, there is far less free chromium available to build a protective passive film. That’s why D2 only offers moderate corrosion resistance and is often called a “semi-stainless” steel.

If your part is made from D2, it can develop rust spots when exposed to moisture, salt spray, or chemicals for long periods. Salt-spray testing shows this clearly: after just 72 hours, D2 develops noticeable rust, while 440C shows far less corrosion.

That said, both steels will lose performance and service life if they are used in harsh environments without proper surface treatment or maintenance.

If D2 steel or 440C steel isn’t paired with the right surface treatment, it can seriously shorten the service life of your product or component.

D2 steel has large, hard carbides, which makes it great for wear resistance but noticeably harder to polish. Most D2 parts need grinding first and achieving a fine cosmetic finish takes more time and specialized abrasives like diamond. That’s why D2 is often paired with coatings such as PVD, DLC, TiN, nitriding, or even hard chrome. These treatments can help compensate for its only moderate corrosion resistance and enhance wear life in demanding industrial applications.

Stainless steel 440C, on the other hand, finishes beautifully. It can be polished to a true mirror surface with much less effort, making it ideal for parts that need both performance and clean aesthetics.

Beyond polishing, 440C responds exceptionally well to electropolishing and passivation . This can boost its already strong corrosion resistance by smoothing the surface and strengthening the passive chromium oxide layer.

Although coatings are available for both steels, 440C is preferred for applications requiring a bright, sanitary surface because it polishes readily and responds well to electropolishing and passivation. By contrast, D2 needs heavy grinding, diamond abrasives, or protective coatings to approach the same cosmetic and hygienic level.

When you look at the total cost of your products, you're not just paying for the raw steel. The machining cost and long-term service life of the parts matter just as much. You’ll need to evaluate your specific application to determine which steel delivers the lowest total cost.

In terms of raw steel price, 440C is usually the pricier option. Across typical recent market ranges, it often runs about 20%–40% higher than D2, depending on supplier and stock form. D2 steel, being widely available and produced in large volumes, tends to be the more economical raw material.

Machining and lifetime cost can shift the equation fast. D2 is hard on cutting tools and slow to machine, which pushes up machining cost. But if you're building dies, punches, wear plates, or stamping tools, D2 may still be cheaper over time because it survives abrasive service far longer than 440C.

On the other hand, if you’re making parts for food-processing equipment, medical tools, pumps, valves, marine hardware, or anything exposed to humidity or cleaning chemicals, 440C becomes the clear winner. Its corrosion resistance lets it run longer with less maintenance, making it the more economical choice in those environments, even with the higher upfront material price.

D2 shines in applications where extreme wear resistance, compressive strength, and dimensional stability matter most, you may find it is used for:

440C is selected when you need a combination of high hardness, excellent corrosion resistance, and clean or wet environment performance. It’s common in applications where hygiene, moisture, or precision machining requirements rule out tool steels like D2. You may find it is used for:

D2 tool steel and 440C stainless steel are two popular metal materials used in metal parts production. Between D2 tool steel vs 440C stainless steel, we provide you with what you need to know above.

If you’re still unsure which steel grade fits your design, VMT CNC machining factory can review your application and recommend the most cost-effective solution. Our full-service CNC machining capabilities include high-precision milling, turning, grinding, and EDM, along with controlled heat treatment and advanced surface finishing such as polishing, passivation, and PVD/DLC coatings.

From rapid prototyping to large-volume production, our engineering team ensures consistent dimensional accuracy, repeatability, and reliable performance. If you would like to learn more or request a free quotation, we’re always ready to help.

Is 440C a good steel?

Yes, 440C is a very good steel, especially when you need corrosion resistance and good hardness. It machines and polishes well and is widely used in bearings and precision parts.

Is D2 steel good?

Yes, D2 is an excellent steel for wear resistance and edge retention. It is very hard and durable, but it is not very corrosion resistant and can be difficult to machine.

NITRO-V vs D2 — which is better?

NITRO-V is generally better because it offers good corrosion resistance, toughness, and strong wear resistance. D2 still wins when maximum abrasion resistance is the only priority.

154CM vs D2 — which is better?

D2 is better for wear resistance and edge life. 154CM is better when you need corrosion resistance and toughness.

What is 440C equivalent to?

440C is equivalent to AISI 440C / UNS R41500 and is often considered EN 1.4116 / DIN X105CrMo17 and ASTM 440C. It is also close in performance to AEB-L / ATS-34, though those are not exact matches.

What is D2 equivalent to?

D2 is equivalent to AISI D2 / DIN 1.2379 / EN X153CrMoV12, and is often compared with other high-carbon, high-chromium tool steels like SKD11 / ASP23 (not exact, but similar class).