15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

105 |

Published by VMT at Jan 05 2024

105 |

Published by VMT at Jan 05 2024

1. Introduction

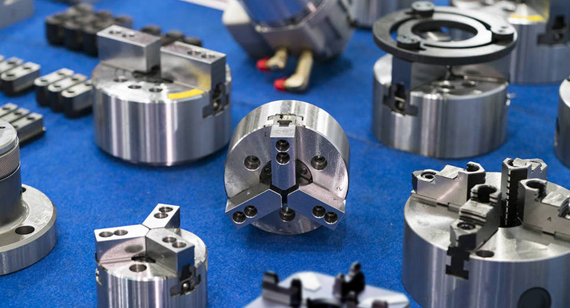

Efficient assembly processes are crucial in CNC machining factories for ensuring both production efficiency and product quality. However, issues such as slow assembly efficiency and challenges in screw tightening can arise, impacting production efficiency and potentially leading to part scrapping and increased production costs. This article delves into the analysis of these issues and proposes corresponding solutions to enhance the assembly efficiency and quality of CNC-machined parts.

2. Problem Overview

In CNC machining factories, the assembly process involves combining various machined parts according to design specifications. However, real-world production may encounter issues such as low assembly efficiency and challenges in smooth screw tightening. These problems can cause production delays, increase costs, and adversely affect product quality and customer satisfaction.

3. Analysis of Causes

Equipment Factors: The precision and stability of CNC machining equipment are critical for the assembly process. Equipment malfunctions or aging may lead to decreased machining precision, affecting assembly efficiency and the smooth tightening of screws.

Process Factors: The rationality of CNC machining processes directly influences assembly efficiency. If machining processes are not optimized, it may result in dimensional deviations and surface roughness issues, increasing assembly difficulty and time.

Fixture Design: Fixtures play a crucial role in securing and positioning parts. Poorly designed or improperly used fixtures may cause instability in part positioning during assembly, increasing the difficulty and time required for screw tightening.

Operator Skills: The skill level of operators significantly influences assembly efficiency and quality. Insufficient skills or non-compliance with procedures may result in low assembly efficiency and challenging screw tightening.

Material Management: Effective material management is crucial for the assembly process. Untimely material supply, disorganized material placement, or substandard material quality may lead to low assembly efficiency and challenging screw tightening.

4. Solutions

Equipment Maintenance and Updates: Regular maintenance of CNC machining equipment is essential to ensure its proper functioning. Aging or severely faulty equipment should be promptly updated or repaired to maintain machining precision and stability.

Process Optimization: Optimize and improve CNC machining processes based on product characteristics and assembly requirements. Measures such as improving machining precision and surface finish can reduce assembly difficulty and time.

Fixture Improvement: Enhance fixtures to improve positioning precision and stability. Additionally, reinforce the proper use and management of fixtures, ensuring operators correctly utilize them during assembly.

Operator Training: Strengthen training and skill assessment for operators to elevate their skill levels and adherence to assembly procedures. Regular training and practical exercises help operators master assembly techniques and screw tightening methods.

Material Management Optimization: Establish a robust material management system to ensure timely supply, orderly placement, and standardized quality of materials. Introducing advanced material management systems and technologies enhances efficiency and accuracy.

5. Implementation and Monitoring

In implementing the above solutions, establish a monitoring mechanism to ensure effective implementation and continuous improvement. Specific measures include:

Develop a detailed implementation plan and schedule, specifying responsible individuals and implementation steps.

Establish regular inspection and evaluation mechanisms to promptly identify and address issues during the implementation process.

Strengthen communication and collaboration with relevant departments and personnel to ensure effective implementation and support for improvement measures.

Continuously track and evaluate the improved assembly efficiency and smoothness of screw tightening to ensure the effectiveness and sustainability of improvement measures.

6. Conclusion

By conducting a comprehensive analysis of the causes behind slow assembly efficiency and challenging screw tightening in CNC-machined parts, solutions were identified covering equipment, processes, fixtures, operator skills, and material management. Through the adoption of corresponding solutions and the implementation of monitoring measures, CNC machining factories can effectively enhance the assembly efficiency and quality of CNC machined parts, reduce production costs and scrap rates, ultimately improving their competitiveness and market position.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!