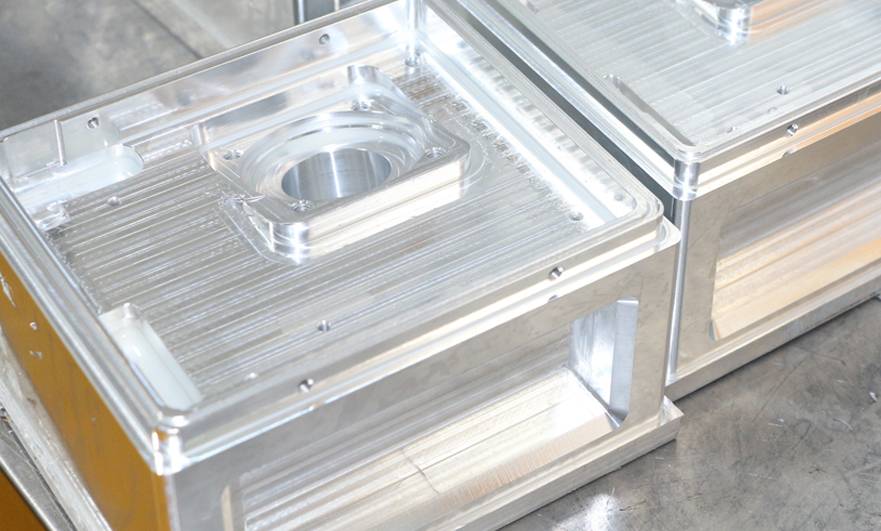

15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

233 |

Published by VMT at Jun 07 2022

233 |

Published by VMT at Jun 07 2022

1. Reserve an appropriate amount of CNC machining allowance

In order to ensure that the appearance and size of the CNC machined parts reach the standard value, there is usually a semi-finishing tool path before the polishing tool under the condition, so the allowance after the semi-finishing is preferably guaranteed to be 0.03mm Between ~0.15mm.

2. Reduce programming cutting tolerance

Because each programming software is different, the dialog box will also change, but the cutting tolerance is an indispensable parameter in programming, and the tolerance of CNC machining parts also directly affects the metal CNC machining. The precision and appearance of the product.

3. Optimize (optimize) the overlap of advancing and retreating knives

After optimizing the procedure, although there will be overlapping traces at the advance and retreat of the knife, the embossing and cutting marks can be eliminated. CNC machining has high production efficiency in the case of multi-variety and small batch production, which can reduce the time for production preparation, machine tool adjustment and CNC machining parts process inspection, and the cutting time is reduced due to the use of the optimal cutting amount.

4. Online detection (check and test) pick-up peak (peak)

The size and appearance of CNC machined parts can be improved. CNC numerical control machine tool processing solves the problem of complex, precise, small batch, and multi-variety parts processing. It is a flexible and high-efficiency automatic machine tool, which represents the development direction of modern machine tool control technology and is a typical mechatronics. product. It has been widely used in modern industry, greatly improving the production efficiency of CNC machining.

5. Select (xuanze) advance and retreat knife

Increase the advancing and retreating tool line, no matter it is advancing or retreating, it does not contact the workpiece, so that the processing surface is smoother.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!