15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

181 |

Published by VMT at Dec 10 2021

181 |

Published by VMT at Dec 10 2021

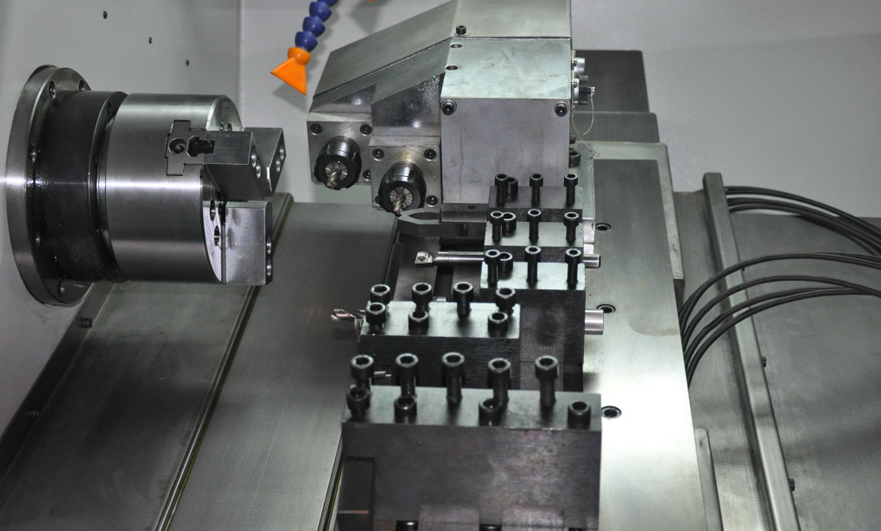

Common CNC machining processes include: CNC machining, CNC turning, CNC milling, stamping, sheet metal machining, casting, injection molding, etc.

The difference between turning and milling: CNC turning machining rotating parts, the CNC machining parts are clamped on the machine spindle through three chucks, rotating at high speed, and then using a turning tool to cut the shape of the product according to the generatrix of the slewing body. Lathes can also be used for CNC machining of inner holes, threads, drills, etc. The latter two are low-speed CNC machining.

The CNC lathe can be used for CNC machining of complex rotating body shapes. CNC milling is to fix the blank and use a high-speed rotating tool to walk on the blank to cut out the required shape and characteristics. Traditional CNC milling is mainly used to mill simple shapes/features such as profiles and grooves.

CNC milling machines can be used to process complex shapes and features. CNC milling and boring machining centers can be used for three-axis or multi-axis milling and boring, such as machining, molds, inspection tools, fixtures, thin-walled complex curved surfaces, artificial prostheses, blades, etc. When selecting the content of CNC milling, the advantages and key functions of the CNC milling machine should be fully utilized.

CNC turning or CNC milling allows machining of CNC machined parts at one time, while CNC milling is a composite machining technology that uses computer numerical control to perform a variety of tasks designed when both the tool and the CNC machined parts are rotating.

Through CNC milling and turning machining, complex curved surfaces or special-shaped CNC machining parts can be processed in the CNC milling center. The CNC milling machine can reach the surface of any CNC machining part. Most of the CNC turning and milling combined processes can be in the CNC turning center.

There are two different types of CNC turning and milling:

1. Contour machining when CNC machining parts are parallel to the tool axis

2. Perform surface machining when the CNC machined part is perpendicular to the tool axis.

Features of CNC milling

1. Shorten the manufacturing process chain of CNC machining parts and improve efficiency

2. Reduce the number of clamping times and improve the accuracy of CNC machining parts

3. Freely moving worktable and high-precision built-in spindle

4. Mainly used for large-scale production of small parts or complex CNC machining parts with high speed and diversification.

The designed CNC machining parts can be processed at one time.

5. Suitable for cutting copper, iron, aluminum, stainless steel, brass, plastic and more materials.

6. It is more accurate, faster and lower cost than one-time CNC machining

The turning and milling composite machining center is a machine tool that performs CNC turning and CNC milling through the linkage of the B axis and the C axis. It can be said that all or most of the CNC machining parts can be processed on the CNC turning and milling machines. The reason is also to name a small production line. It not only improves the accuracy and efficiency of CNC machining parts, but also saves machine space.

In the past, it was necessary to complete a part on several machines, but now it only takes one day to complete all the machining. This machine tool can also be divided into vertical milling, compound turning and horizontal turning. These machines are very common in Europe and Japan. China has just started, and its development is very slow.

The main reason is that China's machine tools are still CNC processed like previous machine tools, which greatly wastes turning and milling machine tools. At present, the main machine tool manufacturers include WFL, DMG, Mazak, Baomei, Mori Seiki, etc.

For the five-axis CNC machining center, only CNC milling can be performed, not CNC machining. Therefore, CNC machining has many limitations. The combination of turning and milling can cover the machining of the five-axis CNC machining center, but the five-axis CNC machining cannot be processed by CNC turning and milling.

The horizontal CNC machining center is a traditional machining center, which corresponds to the vertical CNC machining center. The axis of the horizontal CNC machining center is parallel to the worktable. The main machining box-type CNC machining parts can only be processed by CNC milling, not machining. It is divided into three-axis, four-axis, five-axis and other CNC machining centers. Its main feature is the large scale of CNC machining, high efficiency of CNC machining, but large area and high cost.

The CNC turning and milling machining center is a compound machine tool. At present, there are many kinds of machine tools in the world, and the turning-milling combined machining technology is the most mature and most commonly used combined machining center. You can complete all or most of the machining in one configuration to reduce secondary clamping errors and improve.

Accuracy and efficiency of Chinese CNC machining parts service. It can be said that this is a simple production line. It is undoubtedly faster and more convenient for CNC machining parts with high precision requirements or parts that must be fixed multiple times.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!