15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

197 |

Published by VMT at Dec 11 2021

197 |

Published by VMT at Dec 11 2021

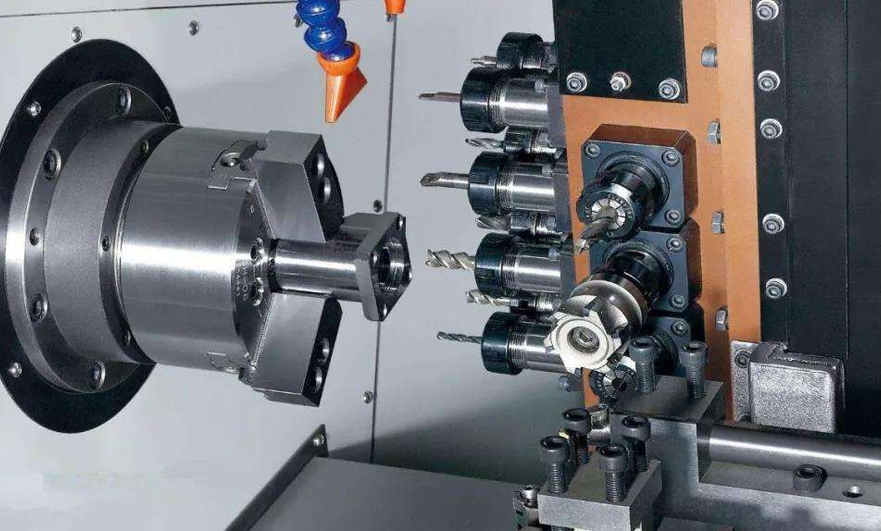

Turning and milling combined machining is currently one of the most popular machining technologies in the field of mechanical CNC machining. It is an advanced CNC machining and manufacturing technology. Turning and milling combined machining refers to the realization of multiple different CNC machining processes on one machine tool. Turning and milling combined machining is the most widely used and most difficult is CNC turning and milling. The turning-milling compound machining center is equivalent to a combination of a CNC lathe and a machining center.

At present, most of the CNC turning and milling machining is done in the turning center. Generally speaking, the CNC turning center only uses electric tools to change the turret of the CNC lathe into a turret, and the main shaft adds the function of the C axis. Due to the limitation of the turret structure and size, the power head is low and the speed is not fast, so it is impossible to install larger tools. Such a turning center is mainly based on CNC turning, and the CNC milling and drilling functions only play a role in auxiliary machining.

Due to the high cost of the electric tool post, the cost of the CNC turning center remains high. The domestic price is generally above 100,000, and the import price is above 200,000. Ordinary users cannot afford it. Most economical turning-milling composite machining materials are XZC axis, and a rotating C axis is added to the chuck to realize the basic CNC milling function.

Turning and milling combined machining is the realization of several different CNC machining processes on one machine tool. It has been widely used worldwide. The turning-milling compound machining center is actually equivalent to the combination of a CNC lathe and a CNC machining center.

Compared with other conventional machining, it has some unparalleled advantages of CNC turning. Let us share with you below:

First of all, it reduces the number of clamping times and improves the accuracy of CNC machining parts. Reduce the number of clamping times to avoid the accumulation of errors caused by positioning reference conversion. At the same time, most of the current machining equipment for turning and milling has an online detection function, which can realize the on-site detection and precision control of key data in the CNC machining and manufacturing process. Thereby improving the accuracy of CNC machining parts;

The high-strength integrated bed design improves the gravity numerical control processing capacity of difficult-to-cut materials. The machine is equipped with an automatic feeding device. Automatic feeding makes it possible for a single machine to operate on a continuous and basic line.

1. The CNC turning and milling machining center adopts high-precision inner spindle;

2. Free mobile operation panel to improve CNC machining efficiency;

3. The main batch production of various types of small parts and high-speed CNC machining of complex parts, diversified processing;

4. Especially, slim and complicated processes can be handled at the same time. It can be equipped with an automatic feeding device to improve the efficiency of CNC machining;

5. Material details: cutting, copper, iron, aluminum alloy, stainless steel, Teflon and other materials.

Secondly, the machine occupancy is reduced and the cost of CNC machining.

The compact and beautiful design improves the way of space utilization. Turning and milling combined machining is more convenient, easy to maintain and repair. Maximize customer satisfaction. Although the unit price of this equipment is relatively high. However, we will reduce the related CNC machining costs in other ways. For example, the manufacturing process chain is shortened, the equipment required for CNC machining of parts is reduced, the fixtures and tools are reduced, the workshop area is reduced, and the equipment maintenance cost is reduced.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!