15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

901 |

Published by VMT at Aug 20 2024

901 |

Published by VMT at Aug 20 2024

Tolerance stack-up is a critical concept in CNC machining and manufacturing, involving the cumulative effect of dimensional tolerances across multiple components during product design and assembly. During the assembly process, the dimensional tolerances of individual parts can impact the final product's dimensions and performance. Tolerance stack-up analysis aims to predict these cumulative effects using scientific methods to ensure that the product operates within design specifications. This article delves into the definition of tolerance stack-up, analysis methods, and best practices to help CNC machining professionals better understand and apply this crucial concept.

Tolerance stack-up, also known as tolerance accumulation, refers to the cumulative effect of the tolerances of individual components in a product during the manufacturing and assembly process. Due to various uncontrollable factors in manufacturing, such as material properties, equipment precision, and operator skill, the actual dimensions of parts often deviate from the design dimensions. Tolerance defines the acceptable range of these deviations as per design standards. When multiple parts are assembled together, these deviations accumulate, affecting the final product's dimensions and performance. The goal of tolerance stack-up analysis is to assess this cumulative effect to ensure the product meets design requirements.

Imagine an assembly consisting of three parts: A, B, and C, which must fit together precisely to ensure the system functions correctly. There is a gap requirement between parts A and B, and a corresponding fit requirement between parts B and C. If each part is within its individual tolerance range, the accumulated tolerance stack-up during assembly could cause the gap to exceed the design requirement, leading to assembly failure. Therefore, tolerance stack-up analysis is necessary during the design phase to ensure that all parts' tolerances remain within acceptable limits when assembled.

Tolerance stack-up analysis can be broadly categorized into two types: worst-case tolerance analysis and statistical tolerance analysis (including RSS—Root Sum Square).

Worst-Case Tolerance Analysis

Worst-case tolerance analysis is a conservative method that assumes all parts' dimensions are simultaneously at their tolerance limits (either maximum or minimum) to calculate the potential maximum or minimum deviation after assembly. This method is ideal for high-reliability applications where failure is not an option, such as in aerospace or medical devices. However, it can be overly conservative, leading to increased design costs and manufacturing difficulty.

Example of Worst-Case Tolerance Analysis:

Consider three parts A, B, and C, with dimensions of 10±0.1, 20±0.2, and 30±0.3 mm, respectively. In worst-case analysis, if part A is at its minimum (9.9 mm), part B at its maximum (20.2 mm), and part C at its minimum (29.7 mm), the total assembly dimension would be 9.9 + 20.2 + 29.7 = 60.8 mm. However, if all parts are at their nominal dimensions, the total would be 10 + 20 + 30 = 60 mm, closer to the design target.

Statistical Tolerance Analysis / RSS – Root Sum Square

Statistical tolerance analysis uses statistical methods to evaluate the tolerance stack-up effect more realistically. The RSS method, for instance, predicts the total deviation after assembly by calculating the square root of the sum of the squares of individual deviations. This method assumes that deviations follow a normal distribution or similar, providing a more reasonable prediction. Compared to worst-case analysis, statistical tolerance analysis can reduce manufacturing costs and difficulty while maintaining product quality.

Example of RSS Tolerance Analysis:

Using the same parts A, B, and C, with standard deviations of 0.05, 0.1, and 0.15 mm, respectively, the total deviation can be calculated using the RSS formula: √((0.05^2) + (0.1^2) + (0.15^2)) ≈ 0.18 mm. This result is significantly smaller than the worst-case scenario, better reflecting the actual situation.

Adopting best practices in tolerance stack-up during CNC machining can significantly improve product quality and production efficiency. Key recommendations include:

Avoid Large Part Tolerances:

While larger tolerances can reduce manufacturing difficulty and cost, they increase the risk of assembly deviation. Set tolerances based on actual needs and manufacturing capabilities.

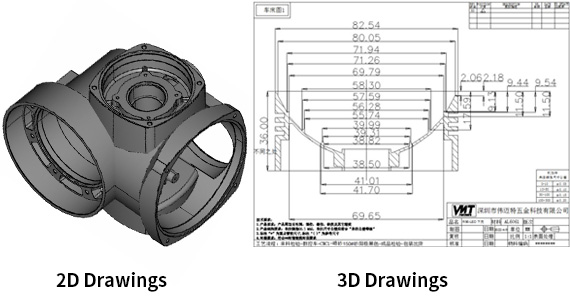

Keep Drawings Clean:

Clear, concise drawings with well-defined tolerances and dimensions minimize misunderstandings and errors, improving manufacturing efficiency and quality.

Evaluate Tolerance Sensitivity:

Focus on critical parts and dimensions during tolerance stack-up analysis. Consider how different tolerance combinations impact the final product performance.

Understand Manufacturing Challenges:

Be aware of the limitations and capabilities of the manufacturing process, such as material deformation, machining precision, and equipment stability. Collaborate with the manufacturing team to accurately set tolerance ranges and optimize product design.

Consider Post-Manufacturing Part Quality:

Account for quality changes after manufacturing, such as those from heat treatment, surface finishing, or wear over time. Include these factors in tolerance stack-up analysis to ensure long-term product compliance with design requirements.

Tolerance Stack-Up Tools

Various tolerance stack-up analysis tools have emerged with the development of computer technology. These tools use advanced algorithms and databases to quickly and accurately perform tolerance stack-up analysis, generating detailed reports and charts. Utilizing these tools can enhance analysis efficiency, reduce human error, and help engineers better understand the complexities and effects of tolerance stack-up.

General Tolerance Best Practices

In CNC machining, following established best practices for tolerance control can significantly improve product quality and production efficiency. These practices include using reasonable tolerance allocation strategies, optimizing part design to reduce tolerance accumulation, and employing advanced manufacturing processes and equipment to enhance machining precision.

Tolerance stack-up is a crucial aspect of CNC machining that cannot be overlooked. By employing sound tolerance stack-up analysis methods and best practices, professionals can predict and control assembly deviation risks, ensuring that products meet design requirements. This article has introduced the definition, analysis methods, and best practices of tolerance stack-up, highlighting its importance in improving product quality and production efficiency. We hope this information serves as a valuable resource for CNC machining professionals.

Why is tolerance stack-up so important?

Tolerance stack-up directly impacts the assembly precision and performance of a product. Excessive tolerance stack-up can lead to assembly difficulties, performance degradation, or even product failure. Therefore, it's crucial to address tolerance stack-up during the design and manufacturing process.

What are first-order and second-order tolerance stack-up?

First-order tolerance stack-up refers to the cumulative effect of tolerances between directly adjacent parts, while second-order tolerance stack-up involves more complex relationships between multiple parts and assemblies. The analysis method chosen depends on the specific situation.

What general challenges are faced in tolerance stack-up?

Challenges include accurately predicting and assessing tolerance accumulation effects, developing reasonable tolerance allocation strategies, and optimizing part design to minimize tolerance accumulation. Additionally, uncertainties and variations in the manufacturing process must be considered.

How can tolerance stack-up be avoided?

While complete avoidance is impossible, the impact of tolerance stack-up can be minimized through optimized design and manufacturing processes. This includes using more precise machining methods, optimizing part structures, and adopting advanced tolerance control techniques.

What is the purpose of tolerance in design?

Tolerance in design allows for deviations in manufacturing processes while ensuring that the final product still meets its functional requirements. It balances product quality with manufacturing costs, ensuring economic feasibility.

What are the formulas for tolerance stack-up?

The formulas depend on the analysis method used. In worst-case analysis, total deviation is calculated by directly adding or subtracting the extreme tolerance values of each part. In statistical tolerance analysis, such as RSS, the total deviation is predicted by calculating the square root of the sum of the squares of individual deviations. These formulas are derived from statistical and probabilistic principles.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!