15 years one-stop China custom CNC machining parts factory

520 |

Published by VMT at Jun 12 2025 | Reading Time:About 10 minutes

520 |

Published by VMT at Jun 12 2025 | Reading Time:About 10 minutes

When manufacturing metal CNC parts—especially aluminum—engineers often face a tough challenge: how to make parts more corrosion-resistant, wear-resistant, and durable without compromising precision or appearance. Harsh environments, oxidation, and friction can degrade raw metal surfaces quickly, leading to failures, aesthetic damage, or costly replacements.

This is where anodizing comes in. Anodizing is a powerful surface treatment that enhances the performance and aesthetics of metal parts by forming a tough, corrosion-resistant oxide layer. Whether you're in aerospace, automotive, electronics, or medical devices, understanding anodizing is critical for achieving longer-lasting and more reliable results in your CNC machining projects.

Anodizing is an electrochemical process that enhances metal surfaces—especially aluminum—by forming a protective oxide layer. This improves corrosion resistance, wear resistance, durability, and aesthetics. It’s widely used for anodized CNC machining parts in industries such as aerospace, medical, and automotive. Aluminum anodizing is the most common due to its excellent compatibility and performance.

To fully leverage the benefits of anodizing in your CNC machining projects, it's essential to understand how it works, its different types, what materials can be anodized, and how it compares with other surface finishing methods. In this comprehensive guide, we’ll break down the anodizing process, explore its industrial applications, and explain why anodizing remains a cornerstone surface treatment in professional CNC machining services and factories.

Anodizing is an electrochemical surface treatment process primarily used to increase the thickness of the natural oxide layer on metals. This oxide layer improves corrosion resistance, enhances wear resistance, and allows the metal surface to absorb dyes for coloring. The process is most commonly applied to aluminum, making aluminum anodizing a standard in many industries, including aerospace, automotive, electronics, and medical device manufacturing.

In simple terms, anodizing turns a metal part into the anode (positive electrode) of an electrolytic cell. When an electric current is passed through an acid electrolyte bath, oxygen ions are released from the electrolyte and combine with the metal atoms at the surface of the part. This forms a uniform and dense aluminum oxide or metal oxide layer that is much harder and more corrosion-resistant than the bare metal.

Unlike paint or plating, anodizing doesn’t coat the surface—it modifies it. The anodized layer is part of the metal, meaning it won’t peel or flake. In fact, half of the anodized thickness penetrates the surface and the other half builds up on top. This makes anodized CNC machining parts ideal for high-precision applications, as the dimensional impact is predictable and controlled.

Because of its durability, visual appeal, and environmental friendliness, anodizing is widely used by CNC machining services and CNC machining factories worldwide. Whether for functional protection or decorative finishes, anodizing offers a versatile and robust solution that significantly improves the lifecycle and performance of metal components.

The primary purpose of anodizing is to enhance the surface properties of metal parts, particularly aluminum, by creating a durable, corrosion-resistant, and aesthetically versatile oxide layer. This process is essential in applications where metal components are exposed to harsh environments, friction, or the need for specific visual or functional characteristics.

1. Corrosion Resistance

Anodizing significantly improves the corrosion resistance of aluminum and other suitable metals. The oxide layer created during the process acts as a barrier against moisture, air, salt, and other corrosive substances. This is especially valuable in marine, aerospace, and industrial settings, where unprotected aluminum would degrade rapidly.

2. Wear and Scratch Resistance

The anodized surface is harder than bare metal. For aluminum, the anodized layer can approach the hardness of sapphire, making it highly resistant to wear, abrasion, and scratches. This durability is crucial for components in anodized CNC machining parts used in high-contact or high-friction environments.

3. Electrical Insulation

Anodized surfaces are non-conductive, providing natural electrical insulation. This makes anodizing ideal for components in electrical and electronic assemblies that require surface insulation without adding bulk or complexity.

4. Improved Aesthetics and Color Options

Anodizing allows aluminum and other metals to be dyed in a wide variety of colors. The porous nature of the anodic layer enables excellent dye absorption, allowing for decorative finishes that are both vibrant and fade-resistant. This is especially popular in consumer electronics, architecture, and luxury goods.

5. Surface Preparation for Coatings or Adhesives

Anodized layers improve adhesion for paints, primers, and other coatings. In some industrial applications, anodizing is used as a pretreatment step to ensure better bonding and performance of applied surface finishes.

6. Increased Lifespan and Performance

Ultimately, the purpose of anodizing is to extend the life and performance of metal components. By enhancing hardness, corrosion resistance, and aesthetic appeal, anodizing makes parts more reliable and maintenance-free over the long term.

Because of these benefits, CNC machining services and CNC machining factories commonly incorporate aluminum anodizing into their finishing operations—offering clients not just precision, but also protection and performance tailored to demanding environments.

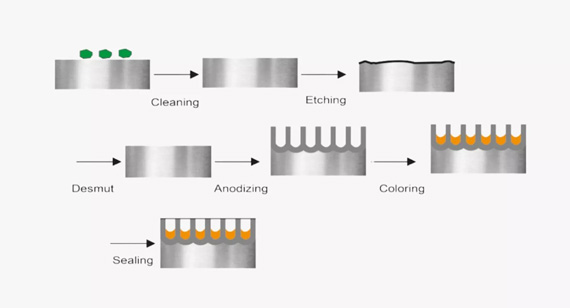

Anodizing is a carefully controlled electrochemical process that transforms the surface of a metal—primarily aluminum—into a durable, corrosion-resistant, and non-conductive oxide layer. This process is widely used in CNC machining services to enhance the quality and performance of anodized CNC machining parts, especially for industries where durability and aesthetics are crucial.

1. Surface Preparation

The anodizing process begins with thorough surface cleaning. The metal part—typically aluminum—is cleaned to remove any dirt, grease, or oxide layers using alkaline or acidic solutions. In CNC machining factories, this step is crucial to ensure the final finish is uniform and free of blemishes. Sometimes mechanical polishing or bead blasting is used beforehand for specific textures.

2. Electrolytic Setup

Once cleaned, the part is submerged in an electrolytic bath, usually consisting of sulfuric acid (Type II and Type III anodizing) or chromic acid (Type I). The aluminum part acts as the anode (positively charged), while a cathode (usually made of lead, stainless steel, or aluminum) is also placed in the bath. This setup is connected to a DC power supply.

3. Electrochemical Reaction

When the current is applied, oxygen ions from the electrolyte bond with the aluminum surface, forming aluminum oxide. This oxide layer is not applied like paint or plating—it grows from the metal itself, integrating into its structure. The result is a hard, porous, and highly adherent coating. This layer's thickness and properties depend on the voltage, current density, temperature, and time.

4. Optional Coloring

After anodizing, the porous oxide layer can absorb dyes. This is where color anodizing comes into play. The part can be immersed in various dyes for custom aesthetic finishes—like black, gold, red, or blue. Alternatively, electrolytic coloring can be used for metallic hues.

5. Sealing the Pores

To lock in the color and further protect the surface, the part undergoes a sealing process. This typically involves immersing the anodized part in hot deionized water, nickel acetate solution, or other sealing chemicals. Sealing closes the pores in the oxide layer, improving corrosion resistance and preventing dye fading.

Finally, the part is dried and inspected for uniformity, color consistency, and thickness. In high-precision applications—like aerospace, medical, or electronics—anodizing quality is critical, so CNC machining factories often include quality control steps using tools like eddy current thickness gauges or visual comparison standards.

Three Common Processes for Sealing Pores in Anodizing

Once the anodizing process creates a porous aluminum oxide layer, sealing those pores is critical to locking in dyes, improving corrosion resistance, and enhancing the part’s longevity. Without sealing, the open pores in the anodized layer can trap contaminants or allow for rapid degradation, especially in aggressive environments. In CNC machining services, this sealing step ensures that anodized CNC machining parts meet durability and aesthetic standards. Below are three commonly used methods to seal the anodic pores:

1. Hot Deionized (DI) Water Sealing

Hot DI water sealing is the most traditional and widely used method. In this process, the anodized part is immersed in boiling deionized water (typically 95–100°C) for 15 to 30 minutes, depending on the thickness of the anodized layer.

How it works:

The hot water reacts with the porous aluminum oxide to form hydrated aluminum oxide (boehmite), which swells and fills the pores. This chemical transformation creates a tightly closed surface.

Advantages:

Considerations:

2. Medium Temperature Sealing

Medium temperature sealing is a more energy-efficient alternative and usually involves nickel acetate or other additives at temperatures around 60–80°C. This method can seal parts faster while maintaining good quality.

How it works:

The nickel ions enter the pores and assist in their closure while also slightly coloring the part, often giving it a grayish or greenish hue, depending on the solution chemistry.

Advantages:

Considerations:

3. Cold or Room Temperature Sealing

Cold sealing is a chemical sealing process that works at room temperature (20–30°C), making it the most energy-efficient option. This method often uses fluorozirconic acid or nickel-fluoride compounds to achieve pore closure.

How it works:

The sealing agents chemically react with the anodized layer, forming compounds that block the pores without the need for thermal expansion.

Advantages:

Considerations:

In conclusion, choosing the right sealing process depends on your application, environmental requirements, and operational constraints. Whether you're manufacturing anodized CNC machining parts for aerospace, medical, or consumer electronics, proper sealing ensures performance and reliability.

| Sealing Method |

Process |

Bath/Solution |

Result |

| Cold Sealing |

Immersion of parts in solution containing nickel-fluoride at room temperature |

Nickel-fluoride(NiF₂) |

A sealed layer of fluoro-aluminate |

| Mid-Temperature Sealing |

Immersion in a solution of metal salts (60-80°C). |

Nickel acetate, magnesium salts, cobalt salts |

Seals pores with metal salts |

| Ho Sealing |

Immersion in near-boiling deionized water (95-100°C) |

Deionized water |

Pores swell and close, forming a dense layer |

Anodizing is a highly controlled electrochemical process designed to transform the surface properties of metals—especially aluminum—by enhancing corrosion resistance, wear durability, and aesthetic flexibility. In CNC machining services, anodizing is a critical post-processing step for improving the performance of aluminum and titanium CNC machining parts. Below is a breakdown of the step-by-step process of anodizing, from preparation to oxide layer formation.

1. Turns the Part into a Positively Charged Anode

The metal part, usually aluminum, is connected to the positive terminal of a DC power source, making it the anode in the electrolytic cell. This is where the name "anodizing" originates.

2. Turns the Metal Plate into a Negatively Charged Cathode

A cathode (often made of lead, stainless steel, or aluminum) is connected to the negative terminal of the power source and placed in the anodizing tank. This sets up the circuit necessary for electrochemical reactions.

3. Immerses Both in an Acidic Electrolyte Solution

The anode and cathode are submerged in a specially formulated acidic solution, typically sulfuric acid for Type II anodizing. This solution serves as the medium for the flow of ions and the anodizing reaction.

4. Applies Voltage

Once the circuit is complete, a direct current (DC) voltage—usually between 15 to 21 volts—is applied. This current initiates a reaction that begins to oxidize the aluminum surface.

5. Removes Aluminum Ions from the Part, Creating Pores

The applied voltage causes aluminum atoms at the surface to lose electrons and dissolve into the solution as aluminum ions. This creates microscopic pores in the oxide layer that forms on the surface.

6. Attracts Oxygen Ions to the Part Surface

At the same time, oxygen ions (O²⁻) from the electrolyte are drawn to the positively charged part, where they react with the exposed aluminum at the base of the pores.

7. The Reaction Forms a Hard, Corrosion-Resistant Aluminum Oxide Layer

This chemical reaction results in the growth of a dense, structured layer of aluminum oxide (Al₂O₃). This layer is highly corrosion-resistant, non-conductive, and can be further customized through dyeing and sealing.

Each of these steps is tightly controlled to ensure the quality and consistency of anodized CNC machining parts. The outcome is a durable, functional, and often aesthetically enhanced surface—ideal for applications across aerospace, electronics, medical, and industrial products manufactured by CNC machining factories.

Anodizing is primarily associated with aluminum, but this versatile surface treatment process can be applied to several other metals as well. In CNC machining services, selecting the right metal for anodizing ensures optimal performance, durability, and appearance of the final part. The suitability of a material for anodizing depends on its ability to form a stable oxide layer when exposed to an electrolytic environment. Below are the materials commonly used in anodized CNC machining parts, especially in high-precision applications delivered by modern CNC machining factories.

Aluminum is the most widely anodized material due to its natural affinity for forming a durable oxide layer. Through aluminum anodizing, the surface becomes harder, more corrosion-resistant, and capable of holding vibrant colors. Common applications include aerospace components, consumer electronics housings, automotive parts, and medical equipment. The process is cost-effective and highly customizable, making it ideal for both functional and decorative purposes.

Magnesium

Magnesium can be anodized to improve corrosion resistance and surface hardness, but it requires special handling due to its reactivity. Anodized magnesium is used in lightweight structures like UAVs, bicycles, and electronics casings. The coating formed is generally thicker and more porous than that of aluminum, and it often serves as a good base for painting or sealing.

Titanium

Titanium responds well to anodizing, forming a thin oxide layer that enhances corrosion resistance and allows for vibrant color effects through interference rather than pigments. Anodized titanium parts are widely used in medical implants, aerospace fasteners, sports equipment, and luxury goods like watches and eyeglass frames. The biocompatibility of titanium further boosts its value in healthcare applications.

Niobium

Niobium anodizing is less common but favored in the production of colorful jewelry and scientific equipment. The anodizing process creates bright, interference-based colors without using dyes. It also improves corrosion resistance and aesthetic appeal.

Tantalum

Tantalum is anodized mainly in the electronics industry, particularly for manufacturing capacitors. The anodized oxide layer acts as an excellent dielectric material, making tantalum ideal for high-performance, miniaturized electronics.

Zinc

Although more challenging, zinc can be anodized for added corrosion resistance and decorative finishes. It is often used in smaller mechanical components, fasteners, and hardware items. Anodized zinc is not as durable as aluminum or titanium but still useful in specific niche applications.

Each of these materials has its own anodizing characteristics, making them suitable for a range of applications. Selecting the right material depends on the desired performance, aesthetics, and environmental conditions, all of which are expertly managed by CNC machining services focused on producing high-quality anodized CNC machining parts.

Here is a clear and professional comparison table of materials that can be anodized, tailored for CNC machining applications:

| Material |

Anodizing Suitability |

Benefits of Anodizing |

Typical Applications |

| Aluminum |

Excellent | Corrosion resistance, wear resistance, colorability, improved surface hardness | Aerospace, electronics, automotive, medical, consumer products |

| Magnesium |

Good (with special handling) | Lightweight protection, corrosion resistance, good base for coatings | UAVs, bicycle frames, electronic housings |

| Titanium |

Excellent | Biocompatibility, corrosion resistance, vivid color effects (interference colors) | Medical implants, aerospace fasteners, sports and luxury goods |

| Niobium |

Good | Interference coloring, corrosion resistance, hypoallergenic | Jewelry, scientific instruments |

| Tantalum |

Good | Excellent dielectric properties, corrosion resistance | Capacitors, high-performance electronics |

| Zinc |

Moderate | Decorative finishing, corrosion protection | Mechanical parts, fasteners, decorative hardware |

This table helps users, engineers, and procurement professionals at CNC machining factories understand which materials are best suited for anodizing, especially when selecting metals for anodized CNC machining parts within CNC machining services.

Anodizing aluminum is a precise electrochemical process that enhances the metal’s surface properties—making it more durable, corrosion-resistant, and visually appealing. This process is widely used in CNC machining services to improve the performance and aesthetics of aluminum CNC parts, particularly in industries like aerospace, electronics, medical, and consumer products.

Step-by-Step Process of Aluminum Anodizing

Surface Preparation

The aluminum part is first thoroughly cleaned and degreased to remove any oils, oxides, or contaminants. This step may involve chemical etching or mechanical polishing to create a uniform surface. A clean surface ensures a consistent anodized finish and strong adhesion of the oxide layer.

Electrolytic Setup

The part is then placed in an anodizing tank filled with an electrolyte—typically a sulfuric acid solution. The aluminum piece is connected to the positive terminal of a power supply (anode), while a cathode (often made of lead or stainless steel) is connected to the negative terminal.

Anodizing Reaction

When electrical current passes through the solution, oxygen ions from the electrolyte combine with the aluminum atoms on the surface. This controlled oxidation process forms a porous layer of aluminum oxide, which is much harder and more corrosion-resistant than raw aluminum.

Coloring (Optional)

If color is desired, dyes or metal salts can be introduced into the pores of the anodized layer. This allows for a range of vibrant and metallic finishes. Dyeing is common in decorative applications such as electronics housings or consumer products.

Sealing the Pores

The anodized layer contains microscopic pores that must be sealed to maximize corrosion resistance and lock in any applied dyes. Sealing methods include hot deionized water sealing, mid-temperature sealing with chemical additives, or cold sealing with nickel salts. This step crystallizes the oxide layer and protects the part from environmental damage.

Key Benefits in CNC Machining

Aluminum anodizing is a core value-added service offered by many CNC machining factories, particularly when functional or visual enhancement is required. It’s a vital process for turning high-performance aluminum parts into long-lasting, precision-finished components across various industries.

In CNC machining services, achieving consistent and high-quality anodized CNC machining parts depends heavily on how well the anodizing process is controlled and maintained. While anodizing may appear straightforward, the underlying technology involves several precise parameters and procedures that CNC machining factories must rigorously manage. Below are key technological considerations that influence the quality, durability, and appearance of aluminum anodizing and other metal finishes.

Anodizing Tank Setup

Proper tank setup is the foundation of effective anodizing. The anodizing tank must be constructed from chemically resistant materials like polypropylene or lead-lined steel, and must be sized to accommodate the largest parts processed. Critical factors include:

A well-set tank setup reduces defects like uneven thickness, burning, or incomplete coverage.

Controls of Acidic Solutions

Most anodizing processes, particularly Type II and Type III, use sulfuric acid as the main electrolyte. The chemical balance and purity of the solution must be strictly controlled:

Improper solution control can lead to inconsistent oxide layers, poor dye absorption, or excessive etching.

Managing Anodized Layer and Thickness

The thickness of the anodized aluminum oxide layer directly affects corrosion resistance, wear resistance, and dimensional stability. To manage this:

For CNC machining applications, the typical oxide layer ranges from 5–25 microns for decorative parts to over 50 microns for industrial or hard-anodized components.

Anodizing Tank Maintenance

Routine maintenance ensures long-term stability and performance of the anodizing process. Key activities include:

Neglecting maintenance can lead to variable results, contamination, and even costly equipment failure—problems that CNC machining factories must avoid to maintain high standards.

By strictly managing these technological aspects, anodizing facilities can ensure the production of consistent, high-quality anodized CNC machining parts. These practices are essential to deliver premium CNC machining services across industries like aerospace, automotive, medical, and consumer electronics.

Anodizing isn't a one-size-fits-all process. Various types of anodizing methods are developed to meet different functional and aesthetic requirements for anodized CNC machining parts. Choosing the correct type is essential in achieving optimal performance, durability, and finish — particularly in demanding sectors such as aerospace, medical, or electronics manufacturing. Below is an in-depth look at the most widely used anodizing types in CNC machining services and their specific uses.

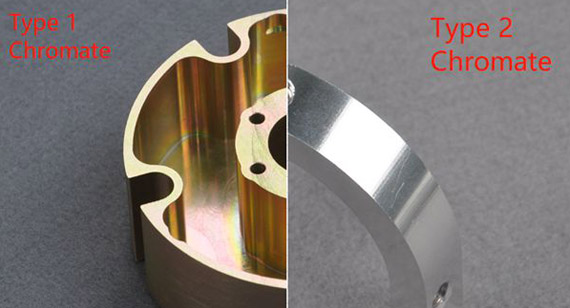

Type I – Chromic Acid Anodizing

When is it used?

Type I chromic acid anodizing is typically used when minimal dimensional change is required, such as in aerospace applications or precision CNC machining factories where tight tolerances must be maintained. It produces thinner, softer oxide coatings compared to other types, making it ideal for parts that undergo further assembly or need to remain lightweight.

Advantages:

Applications:

Common in the aerospace sector, this method is used for internal aircraft components, tight-tolerance housings, fasteners, and connectors that require protective coatings without affecting part geometry. It's also applicable in military-grade components where stealth and corrosion resistance matter more than decorative color.

In the broader context of aluminum anodizing, Type I offers a low-impact solution for functional protection, making it a staple in CNC machining services that cater to precision-dependent industries. Continue reading to explore Type II, Type III, and specialized coatings like alodine and phosphoric acid anodizing, each offering unique benefits for different materials and uses.

Type II – Sulfuric Acid Anodizing

When to use?

Type II anodizing, also known as sulfuric acid anodizing, is the most commonly used method for aluminum anodizing. It is suitable for a wide range of anodized CNC machining parts, particularly when both decorative finish and enhanced surface properties are desired. Type II is typically selected for components in the aerospace, automotive, consumer electronics, and architectural industries. If you need moderate durability, excellent dye absorption, and low dimensional impact, Type II is the preferred option in most CNC machining services.

Advantages:

Applications:

You’ll often find Type II anodizing used on aluminum parts for smartphones, tablets, laptops, camera equipment, bicycle components, aerospace fittings, and medical instruments. It’s a versatile and cost-effective choice when you need both performance and aesthetics — including vibrant color options through dyeing.

If you’re looking for a strong balance between protective performance, color finish, and cost, Type II anodizing is a cornerstone process in the world of CNC machining services. For even more extreme applications, consider exploring Type III (hard anodizing), which we’ll cover next.

Type III – Hard Anodizing

When to use?

Type III anodizing, often called hard anodizing, is used when superior surface durability and protection are critical. This process is ideal for parts subjected to extreme wear, abrasion, or corrosive environments. It is commonly applied in aerospace, military, industrial machinery, automotive components, and heavy-duty equipment. If your project demands a highly wear-resistant, thick anodized layer while maintaining dimensional stability, Type III anodizing is the go-to choice in CNC machining services and CNC machining factories.

Advantages:

Applications:

Type III anodizing is essential for parts like hydraulic pistons, wear plates, gears, firearm components, valve bodies, and other heavy-use CNC machined parts. Its tough surface makes it invaluable in industries where safety, durability, and precision are non-negotiable.

For CNC machining factories and services focusing on anodized CNC machining parts that require both strength and longevity, Type III anodizing delivers a combination of hardness and corrosion protection unmatched by other finishing methods.

If you want to explore anodizing processes tailored for specific industrial or aesthetic needs, don’t miss the next section on Chemical Film/Alodine and Phosphoric Acid Anodizing, which offer unique benefits for certain applications.

Chemical Film / Alodine

When to use?

Chemical film, also known as Alodine or chromate conversion coating, is ideal when you need basic corrosion resistance without altering part dimensions. It is widely used in aerospace, electronics, and military industries where electrical conductivity and minimal coating thickness are required. Alodine is especially suitable for parts that won’t be exposed to harsh environments or need further painting or bonding.

Advantages:

Phosphoric Acid Anodizing

When to use?

Phosphoric acid anodizing is often used as a surface preparation method for bonding. It creates a micro-porous layer that significantly enhances adhesive bonding strength, especially in aerospace applications. It’s typically applied to aluminum parts that need to be glued or sealed, and it forms part of Boeing’s and Airbus’s standard bonding procedures.

Advantages:

For CNC machining services working with parts that require strong adhesive bonding or conductive surfaces, both Alodine and phosphoric acid anodizing offer essential finishing options beyond traditional anodizing. Choosing the right treatment depends on functionality, cost-efficiency, and industry specifications.

Continue reading to explore the appearance and color options of anodized finishes and how they align with your design and product goals.

Here is a detailed comparison table summarizing the types and uses of anodizing processes, including key characteristics and applications:

| Anodizing Type |

Thickness |

Color Adaptability |

Electrolyte Used |

When to Use |

Key Advantages |

Typical Applications |

| Type I (Chromic Acid) |

0.00002”- 0.0001” |

Limited color options (typically grey or dark grey) |

Chromic acid |

When minimal dimensional change is required; parts with tight tolerances |

- Corrosion protection - Non-conductive - Increased dielectric strength - Accepts greater buckling |

Aerospace parts, precision components, military hardware |

| Type II (Sulfuric Acid) |

0.0001 “-0.001” |

Almost any color can be achieved through dyeing |

Sulfuric acid |

Standard anodizing for general-purpose aluminum parts |

- Corrosion resistance - Wear resistance - Increased hardness - Thin coating ideal for CNC machining parts |

Consumer electronics, automotive trim, architectural finishes |

| Type III (Hard Anodizing) |

0.0005″ to 0.006″ |

Limited to darker shades (grey to black) |

Sulfuric acid (cold, high current) |

When high wear resistance and surface hardness are critical |

- Wear-resistant surface - High hardness (60–70 HRC) - Corrosion protection - Long-lasting coating |

Industrial machinery, aerospace fasteners, engine components |

| Chemical Film / Alodine |

(< 0.0001”). |

Limited, more of a surface preparation |

Chromate solution |

When electrical conductivity and minimal build-up are required |

- Maintains conductivity - No dimensional change - Paint/primer adhesion - Economical |

Electrical enclosures, aircraft components, low-wear surfaces |

| Phosphoric Acid Anodizing |

(< 0.0001”). |

Limited, more of a surface preparation |

Phosphoric acid |

When high-strength adhesive bonding is needed |

- Improved bond strength - Creates porous oxide layer - Enhances adhesive durability |

Aerospace structures, bonded joints, fuselage components |

This table helps you select the most suitable anodizing method based on your part’s function, CNC machining tolerances, and industry requirements. For more guidance on how anodizing affects surface characteristics or color options, continue exploring the next sections of this article.

Here’s a detailed table summarizing anodizing and its characteristics, including descriptions and visual appearances of different anodizing types:

| Type of Anodizing |

Description |

Appearance |

| Transparent Anodizing |

A clear, natural oxide layer formed on aluminum without dyes; often used to enhance corrosion resistance while preserving the metal’s natural look. | Silvery, matte to slightly glossy finish; showcases natural grain or finish of the underlying aluminum. |

| Dyed Anodizing |

The porous oxide layer is dyed with organic or metallic pigments before sealing; used for aesthetics and part identification. | Available in a wide range of colors—black, red, blue, gold, green, purple, etc.—depending on dye type. |

| Hard Anodizing |

A thick, dense oxide layer formed under low-temperature and high-current conditions; offers superior wear and corrosion resistance. | Dark gray to black color (even without dyes); rougher and more industrial in appearance. |

| Gloss Anodizing |

A polished surface is anodized to retain a mirror-like or high-luster finish; requires pre-polishing or chemical brightening before anodizing. | Bright, mirror-like surface with a reflective metallic sheen. |

| Brushed Anodizing |

Surface is mechanically brushed before anodizing, creating fine lines or directional texture under the anodized layer. | Satin or matte finish with visible brushed lines; often used in electronics and decorative applications. |

These variations in anodizing allow manufacturers and CNC machining factories to balance functionality with visual appeal, especially in consumer electronics, aerospace, and medical industries.

Here's a structured table summarizing how different anodizing colors are achieved using dye impregnation or electrolytic coloring techniques:

| Color |

Dye Impregnation |

Electrolytic Coloring |

| Clear/Natural |

no dye needed |

natural oxide color |

| Black |

Immersion in black dye |

High current density with various salts |

| Gold |

Immersion in yellow dye |

Metal salts (Nickel) |

| Red |

Immersion in red dye |

N/A |

| Blue |

Immersion in blue dye | N/A |

| Green |

Immersion in green dye |

N/A |

| Bronze | N/A |

Metal salts (Tin/Nickel) |

| Purple |

Immersion in purple dye |

N/A |

| Custom Colors |

Blending of specific dyes |

N/A |

Explanation:

These techniques help CNC machining factories and anodizing service providers offer tailored finishes for products in industries like aerospace, electronics, and consumer goods.

Here’s a structured overview of the pros of anodizing, designed for clarity and easy reference:

Anodizing: Pros Overview

| Advantage |

Description |

| Corrosion Resistance |

The anodized layer protects aluminum and other metals from moisture, air, and chemicals, making it ideal for marine, aerospace, and industrial environments. |

| Enhanced Surface Finish |

Anodizing smoothens the metal surface, offering a clean, professional look suitable for both aesthetic and functional applications. |

| Increased Conductivity |

While the anodized layer itself is non-conductive, it can be selectively applied, allowing controlled conductivity where needed in electronic parts. |

| Durability and Longevity |

Anodized surfaces resist wear, chipping, and flaking better than paint or plating, ensuring parts remain intact over long-term use. |

| Easy to Care |

Anodized surfaces are easy to clean, resistant to fingerprints, and require minimal maintenance—ideal for consumer electronics and appliances. |

| UV Stable |

Anodized finishes resist fading and damage from UV exposure better than traditional coatings, making them suitable for outdoor products. |

| Protecting Base Metal |

The process converts the metal surface into a tough, bonded oxide layer that prevents further corrosion or oxidation. |

| Various Colors |

Through dyeing or electrolytic coloring, a wide range of custom colors can be achieved—great for branding and design. |

| Cost |

While there is an upfront cost, the long-term value from increased lifespan and reduced maintenance makes anodizing cost-effective. |

| Safety and Health | Anodized layers are chemically stable and non-toxic, suitable for medical devices, food-grade equipment, and consumer products. |

This structured view is crucial for companies evaluating anodized CNC machining parts. For more guidance on how anodizing fits into your product design, explore our full range of CNC machining services at VMT.

Here is a structured table outlining the disadvantages of anodizing, written clearly and professionally to help readers make informed decisions:

Anodizing: Cons Overview

| Disadvantage |

Description |

| Limited Material Compatibility |

Anodizing is mainly effective on specific grades of aluminum. It is not suitable for metals like stainless steel that are highly resistant to chemicals like mortar, salt, and chlorine, limiting its versatility in multi-material designs. |

| Color Inconsistency |

Since anodizing alters the base metal rather than applying a surface coating, achieving color uniformity is challenging—especially with low-grade alloys. High-grade materials may reach up to 95% consistency, but color mismatches between batches are still common. |

| Not Ideal for Marine-Grade Stainless Steels |

Stainless steels used in harsh environments (such as marine-grade) cannot be anodized effectively, restricting the process’s use in industries that demand high corrosion resistance across various metals. |

| Batch-to-Batch Variability |

Unlike electroplating, anodizing results can vary noticeably between production runs, making it harder to ensure visual and dimensional consistency for large product series or replacements. |

| High Cost for Small Runs |

Anodizing is cost-prohibitive for low-volume orders due to expensive setup, equipment, and the need for premium-grade materials. This makes it less economical for prototyping or custom one-off components. |

For industries seeking precise, repeatable finishes—such as aerospace, robotics, or medical—these limitations must be weighed carefully. If your application demands tight visual or dimensional tolerance, consider discussing your needs with a trusted CNC machining factory offering both anodizing and alternative surface treatments.

Anodizing is widely applied in industries that require a combination of corrosion resistance, aesthetic finish, electrical insulation, and durability. Because of its ability to enhance surface performance without altering core mechanical properties, anodizing is especially popular for aluminum CNC machining parts. The process is particularly valued by CNC machining services and CNC machining factories aiming to meet the demanding standards of sectors such as aerospace, automotive, medical, and consumer electronics.

Anodized Aluminum Applications

Aluminum anodizing is the most common form of anodizing due to the metal’s natural oxide formation tendency. The following are typical applications:

Anodized aluminum is used for skin panels, structural components, fasteners, and interior cabin elements. These parts benefit from high strength-to-weight ratios, excellent corrosion resistance, and good bonding surfaces for paint or adhesives.

Aluminum parts like wheel covers, fuel tank caps, engine casings, and interior trim are often anodized to improve weather durability and add aesthetic appeal. This surface treatment resists wear from road salt, heat, and UV exposure.

Smartphones, laptops, and tablets frequently use anodized aluminum housings. The coating provides a sleek finish while resisting fingerprints and scratches, contributing to both style and longevity.

From cookware to door hardware and appliances, anodized finishes offer decorative options with enhanced durability and cleanability.

Precision frames, mounts, and housings are anodized to reduce glare, avoid light reflection, and provide electrical insulation.

Lightweight anodized components in robotic arms and sensors deliver long-lasting performance in dynamic environments, especially where wear and electrical insulation are critical.

Parts like medical device housings, scalpel handles, and sterilization tray handles are anodized to ensure biocompatibility, repeated sterilization, and a clean, corrosion-resistant surface.

If you need anodized CNC machining parts tailored to high-performance applications, choosing the right CNC machining factory that understands industry requirements and anodizing technology is essential. You can also explore more about how aluminum is anodized or compare anodizing vs. powder coating for the best finish solution.

Anodized Magnesium

Anodizing magnesium is a specialized surface treatment that enhances corrosion resistance and surface hardness, making this lightweight metal viable for demanding environments. While less commonly anodized than aluminum, magnesium’s low density and excellent strength-to-weight ratio make it highly valuable in aerospace, automotive, and electronic applications. Through anodizing, magnesium parts can achieve greater wear resistance and surface stability, extending their life span in both functional and aesthetic roles.

Magnesium’s natural reactivity means that anodizing requires precise control and experience. As a result, only well-equipped CNC machining factories with specific expertise in magnesium processing typically offer this service. The process creates a stable oxide layer that can be dyed for color differentiation or used to improve bonding with paints and adhesives. When integrated with high-precision CNC machining services, anodized magnesium components can deliver lightweight, high-performance solutions in technology-driven fields.

Application Examples of Anodized Magnesium:

Anodized magnesium provides a combination of lightweight performance and protection against the elements, making it ideal for high-end bicycle frames and structural parts.

Automotive and electric vehicle manufacturers use anodized magnesium for battery enclosures to reduce weight while maintaining structural integrity and safety.

In industrial tools and handheld devices, anodized magnesium ensures resistance to handling wear and corrosion while keeping parts light and ergonomic.

Magnesium’s weight advantage is crucial for unmanned aerial vehicles (UAVs), satellite modules, and aerospace parts. Anodizing ensures these components remain durable in extreme environments without adding unnecessary mass.

If your project requires anodized CNC machining parts made from magnesium, ensure your supplier offers specialized CNC machining services with experience in magnesium anodizing. For a broader view, explore our pages on aluminum anodizing, titanium anodizing, or anodizing vs. electroplating to choose the right finish for your application.

Anodized Zinc

Zinc anodizing is a less common but increasingly important surface treatment used to enhance the durability, corrosion resistance, and aesthetics of zinc and zinc alloy components. Unlike aluminum anodizing, zinc anodizing requires a more specialized process due to the metal’s different electrochemical properties. However, when properly executed, the anodizing of zinc can form a thin, decorative oxide layer that offers both protective and aesthetic benefits.

This surface treatment is especially valuable in CNC machining services for parts that demand precise dimensions, improved environmental resistance, and a refined appearance. While zinc is naturally corrosion-resistant to some extent, anodizing significantly boosts its lifespan, especially in harsh industrial or outdoor environments. Furthermore, anodized zinc parts can be dyed in various colors and sealed for long-term performance, offering a balance between function and form. Many CNC machining factories are equipped to handle small zinc components with the precision required for effective anodizing.

Application Examples of Anodized Zinc:

Anodized zinc components like screws and fasteners benefit from improved corrosion resistance and consistent torque performance, particularly in fuel systems and assemblies exposed to moisture or chemicals.

Anodized zinc helps maintain the structural reliability of essential fittings and connectors while also enhancing visual appeal, making them suitable for exposed or decorative use in buildings and infrastructure.

Zinc’s malleability and finish compatibility make it ideal for anodized decorative elements that must withstand handling and environmental exposure.

These components benefit from anodizing with enhanced wear resistance, non-conductivity, and a polished look, making them suitable for both technical and consumer-facing applications.

If you’re designing parts for consumer products, electronics, or automotive applications, anodized CNC machining parts made from zinc offer durability without compromising aesthetics. To learn more, visit our guides on aluminum anodizing, titanium anodizing, or the differences between anodizing and powder coating. Let VMT’s expert CNC machining services help you select the right surface treatment for your next project.

Anodized Titanium

Anodizing titanium is a specialized electrochemical process used to create a durable, oxide-rich surface that is both corrosion-resistant and capable of displaying a wide range of vibrant, interference-based colors—without using dyes. The unique properties of titanium make it especially suitable for anodized CNC machining parts in industries requiring lightweight strength, biocompatibility, and resistance to extreme environments.

Unlike aluminum anodizing, titanium anodizing doesn’t build a thick oxide layer; instead, it manipulates the oxide film’s thickness to refract light and produce brilliant colors. This makes it ideal not just for functional applications, but also for decorative and branding purposes. Anodized titanium parts are frequently produced using high-precision CNC machining services to ensure tight tolerances and flawless surface finishes that are ideal for anodizing.

Application Examples of Anodized Titanium:

Anodizing enhances titanium's already exceptional resistance to corrosion and fatigue, making it ideal for critical aerospace systems and assemblies exposed to high stress and fluid dynamics.

Titanium's biocompatibility and the ability to color-code implants or tools (e.g., hip replacements, dental implants, scalpel handles) through anodizing make it the material of choice in healthcare applications.

In high-performance and motorsport environments, anodized titanium parts provide excellent strength-to-weight ratios and resist thermal degradation.

Titanium’s light weight and scratch-resistant anodized colors make it ideal for luxury watches and accessories where aesthetics and durability are both critical.

Consumer products benefit from the lightweight, hypoallergenic nature of titanium, combined with anodized finishes that resist wear and add unique visual appeal.

When you need lightweight, corrosion-resistant, and colorful components, anodized titanium CNC machining parts are a superior choice. For precision-crafted titanium parts with professional surface finishing, trust VMT’s expert CNC machining services. Explore our titanium CNC machining and anodizing services to bring both performance and beauty to your designs.

Here is a clear and organized table showing what anodizing is used for and which parts benefit from it, categorized by material type:

| Material |

Application Areas |

Typical Anodized Parts |

| Aluminum |

Aerospace, Automotive, Consumer Electronics, Medical, Optical | Skin panels, structural parts, fasteners, trim, wheel covers, engine covers, device housings, surgical trays |

| Magnesium |

Aerospace, Automotive, Tools, UAVs | Bicycle frames, battery housings, hand tools, drone components |

| Titanium |

Aerospace, Medical, Automotive, Consumer Goods | Fasteners, implants, hydraulic housings, muffler parts, watch cases, eyeglass frames, bike parts |

| Zinc |

Automotive, Building, Electronics | Screws, nuts, bolts, pipe fittings, decorative hardware, lighting fixtures, tool handles |

This table helps illustrate the versatility of anodizing across various metals and industries, with a focus on parts where anodizing enhances corrosion resistance, appearance, and performance.

Anodizing is not a one-size-fits-all process—it must be carefully adjusted depending on the application, the base metal, and the desired finish. To achieve consistent, high-performance anodized CNC machining parts, CNC machining factories must control a range of processing parameters with precision. These parameters directly influence the surface characteristics of the anodized layer, which ultimately determines the performance, appearance, and functionality of the final component. Properly optimizing these factors ensures durable finishes, superior corrosion resistance, and vibrant or functional colors for CNC machining services across industries.

Key Parameters in the Anodizing Process

The following are the critical parameters that CNC machining factories and surface treatment specialists must consider and control during anodizing:

Material Properties Affected by Anodizing

Adjusting the above parameters allows engineers to tailor the anodized layer’s properties for specific applications. The key material characteristics influenced include:

For CNC machining services, especially in aerospace, medical, and electronics industries, understanding and controlling these parameters is essential to deliver reliable and repeatable anodized parts with optimal performance.

Anodizing and powder coating are two popular surface finishing techniques widely used in CNC machining services to enhance the durability, appearance, and corrosion resistance of metal parts. While both processes serve the purpose of protecting and beautifying components, they differ significantly in how they are applied, the type of protection they offer, and the end results. Choosing the right finishing method depends on the part’s application, material, desired look, and environmental conditions.

Comparison Table: Anodizing vs. Powder Coating

| Criteria |

Anodizing |

Powder Coating |

| Process Type |

Electrochemical process that thickens the natural oxide layer on metal | Dry powder is electrostatically applied and then cured under heat |

| Durability |

Very durable, especially hard anodizing; integral to the surface | Highly durable external coating but may chip or scratch under impact |

| Thickness |

Thin layer (typically 0.0005"–0.003") | Thicker coating (2–5 mils or 0.002"–0.005") |

| Corrosion Resistance |

Excellent, especially with proper sealing and for aluminum | Excellent, though prolonged exposure may cause degradation in harsh environments |

| Color Options |

Limited but natural metallic tones possible; can be dyed | Wide range of bright, opaque, or metallic colors with consistent coverage |

| Surface Finish |

Metallic, matte, satin, glossy, or translucent finishes | Smooth, glossy, textured, matte, or specialty textures |

| Cost |

Typically more expensive for small batches; requires high-quality base metal | Cost-effective for large parts and batches; lower setup cost |

| Applications |

Aerospace, medical, automotive, electronics (when metal conductivity is needed) | Appliances, automotive, architectural, furniture, consumer goods |

Summary

When selecting between the two, consider your part’s function, environment, and aesthetics to achieve the best performance and appearance.

Anodizing and electroplating are two widely used surface finishing techniques in CNC machining services, each offering unique advantages for improving metal part performance. While both modify the surface of metals to enhance protection and appearance, they work on opposite principles—anodizing builds up a protective oxide layer by oxidation, whereas electroplating adds a metal layer by reduction. Understanding their differences helps manufacturers choose the best method for specific parts, environments, and performance requirements.

Comparison Table: Anodizing vs. Electroplating

| Criteria |

Anodizing |

Electroplating |

| Process Type |

Electrochemical oxidation (metal becomes the anode) | Electrochemical reduction (metal becomes the cathode) |

| Layer Characteristics |

Forms an oxide layer integral to the base metal | Deposits a metallic layer on top of the surface |

| Typical Thickness |

Thin to moderate (0.0005"–0.003") | Varies (few microns to >0.010", depending on the metal and duration) |

| Main Purpose |

Improve corrosion resistance, wear resistance, and aesthetics | Enhance appearance, conductivity, corrosion resistance, or wear resistance |

| Corrosion Resistance |

Excellent on aluminum (especially when sealed); porous layer if unsealed | Depends on plating material (e.g., nickel, chromium, gold, zinc); generally good |

| Durability |

Very hard and wear-resistant (especially hard anodizing) | Depends on coating material; can chip, peel, or wear over time |

| Surface Appearance |

Metallic, matte, satin, or glossy; maintains metallic feel | Reflective or shiny; smooth and decorative metallic surface |

| Color Options |

Limited natural shades; wide range possible through dyeing or electrolytic coloring | Wide range using different metals (e.g., gold, chrome) but limited post-dyeing |

| Environmental Effects |

Environmentally friendly (no heavy metals); low VOCs | May involve hazardous chemicals like cyanide, heavy metals; requires strict waste control |

| Common Applications |

Aerospace, electronics, medical, consumer electronics, automotive trim | Jewelry, automotive components, electronics, tools, decorative finishes |

Summary

For CNC machining services, choosing between anodizing and electroplating depends on the metal type, functional requirements, environmental exposure, and aesthetic goals.

Anodizing is an electrochemical surface treatment process that enhances the natural oxide layer on metals, most commonly aluminum. By converting the metal surface into a durable, corrosion-resistant, and often decorative oxide finish, anodizing significantly improves both the performance and appearance of metal components. This makes it a preferred finishing technique in industries like aerospace, automotive, electronics, and medical devices.

What Anodizing Does?

| Function |

Description |

| Creates a Hard Oxide Layer |

Forms a tough aluminum oxide coating that protects against abrasion and wear. |

| Improves Corrosion Resistance |

Shields metal surfaces from environmental factors like moisture, salt, and chemicals. |

| Adds Aesthetic Value |

Enables a wide range of finishes and colors through dyeing or electrolytic coloring. |

| Enhances Surface Properties |

Increases surface hardness, provides electrical insulation, and improves adhesion for paints and adhesives. |

| Maintains Dimensional Precision |

The oxide layer is thin and penetrates the surface, preserving tight tolerances. |

Why Do Anodizing?

| Reason |

Benefit |

| To Protect the Metal |

Prevents rust, corrosion, and surface degradation over time. |

| To Improve Wear Resistance |

Extends part lifespan in high-friction environments. |

| To Enhance Aesthetics |

Offers consistent finishes in various colors, ideal for branding and design. |

| To Enable Electrical Insulation |

Provides non-conductive properties suitable for electronic applications. |

| To Prepare for Coatings or Adhesives |

Creates a porous surface that holds paints and glues better. |

| To Maintain Lightweight Design |

Strengthens metal without adding significant weight—ideal for aerospace and mobile devices. |

Summary

Anodizing enhances the functionality and appearance of metals—especially aluminum—by forming a durable, corrosion-resistant oxide layer. It's a smart choice when you need a long-lasting, lightweight, and visually appealing finish without compromising dimensional accuracy or performance.

Anodizing is a valuable finishing process—but to get the best results, it's important to plan ahead. Whether you're working with CNC-machined parts, components for consumer products, or precision aerospace hardware, here are the key considerations to understand before anodizing your parts.

1. Material Compatibility

2. Alloy Type Matters

Different aluminum alloys react differently to anodizing.

Alloy composition can affect color consistency, corrosion resistance, and layer thickness.

3. Design for Anodizing

4. Tight Tolerances

Anodizing adds a thin oxide layer (typically 0.0001"–0.003").

Inform your machinist in advance so they can account for dimensional changes.

5. Surface Finish Affects Appearance

6. Color Variation Can Occur

7. Type of Anodizing

Know the differences and choose the appropriate type:

8. Post-Anodizing Requirements

Consider whether you'll need:

9. Batch Size & Cost

Summary

Before anodizing, consider the metal type, alloy grade, part design, surface prep, tolerance impact, and desired finish. Communicating with your CNC machining provider or anodizing shop early in the design phase will help ensure quality, cost-efficiency, and functional performance of your anodized parts.

Choosing the right anodizing surface treatment service is essential for achieving both the functional and aesthetic goals of your project. Not all anodizing providers offer the same capabilities, quality standards, or turnaround times, so making an informed decision can help avoid costly errors and ensure long-term performance of your parts.

1. Determine Your Application Requirements

Start by identifying the core purpose of anodizing for your part:

Match your needs with a provider who specializes in the type of anodizing suited to your application (e.g., Type II for color and protection, Type III for wear resistance).

2. Evaluate Anodizing Capabilities

Check whether the service provider offers:

3. Quality Certifications and Standards

Look for anodizing services that comply with relevant industry certifications, such as:

These certifications ensure process consistency, traceability, and environmental responsibility.

4. Examine Equipment and Facility Standards

The right anodizing shop should have:

Advanced facilities are more likely to deliver consistent coating quality and repeatable results.

5. Ask About Surface Preparation Services

A proper anodized finish depends on meticulous surface preparation, including:

Make sure the provider offers or supports these pre-treatment processes to achieve your desired final appearance.

6. Review Previous Work and Customer Feedback

Look at:

Strong feedback and visual samples indicate a shop’s experience and reliability.

7. Check Turnaround Time and Scalability

Your production schedule may require:

Clarify lead times, batch capabilities, and whether they can support your growth or design changes.

8. Request Sample Parts or Trial Runs

Many reputable services will allow you to:

This is particularly important if color accuracy or tolerance compliance is critical.

9. Compare Pricing Transparently

Request quotes that include:

Avoid choosing solely based on cost—consider value, service quality, and consistency.

Summary

Choosing the right anodizing surface treatment service involves balancing technical capability, industry experience, quality certifications, and reliable customer support. By carefully assessing your needs and evaluating potential providers against these criteria, you can ensure your anodized parts meet both performance and aesthetic expectations.

Anodizing is a critical surface treatment process that enhances the durability, corrosion resistance, aesthetic appeal, and functionality of metals—especially aluminum. Whether used in aerospace, automotive, medical, electronics, or consumer products, anodizing adds value by forming a robust oxide layer that integrates with the base material instead of merely coating it. From basic protective finishes to vibrant decorative colors and high-performance coatings, anodizing processes like Type I, II, and III offer tailored solutions to meet diverse industry needs.

Understanding how anodizing works—from its electrochemical mechanism and material compatibility to pore sealing, coloring options, and surface characteristics—allows engineers, designers, and manufacturers to make informed decisions. Each anodizing method presents unique advantages, such as wear resistance, electrical insulation, or minimal dimensional change, making it essential to match the process to the intended application.

Before anodizing your parts, it’s crucial to evaluate your performance requirements, consider material constraints, and choose a service provider with the technical capabilities and quality certifications necessary to meet your expectations. By doing so, you ensure that the final anodized components not only meet aesthetic standards but also perform reliably in demanding environments.

Ultimately, anodizing is more than a surface treatment—it's a strategic enhancement that extends the life and performance of your metal parts while offering extensive design flexibility and functional benefits.

1. Why is aluminum the most commonly anodized metal?

Aluminum naturally forms a stable oxide layer that can be thickened through anodizing. It’s lightweight, widely used, and responds well to anodizing, making it ideal for protective and decorative finishes.

2. What colors can be achieved with anodizing?

A wide range of colors is possible, including black, gold, red, blue, green, purple, and custom tones. These are achieved using dye impregnation or electrolytic coloring processes.

3. Does anodizing prevent rust?

Anodizing prevents corrosion but not rust. Since aluminum doesn’t rust like iron, anodizing helps enhance its corrosion resistance, preventing oxidation and surface degradation.

4. What makes anodized aluminum corrosion resistant?

The anodized layer is made of aluminum oxide, which is hard, chemically stable, and impermeable to air and moisture—protecting the underlying metal from corrosion.

5. How to care for anodized parts?

Use mild soap and water for cleaning. Avoid abrasive cleaners or harsh chemicals. Regular gentle cleaning maintains the anodized finish and performance.

6. Why should you anodize parts?

To improve corrosion resistance, wear resistance, aesthetics, surface hardness, and coloring options without adding significant thickness to the part.

7. How is anodizing performed?

Anodizing involves making the part the anode in an electrolytic cell, immersing it in an acid bath, applying voltage, and forming a controlled oxide layer on the metal surface.

8. How can you assess the quality of anodized parts?

Quality is assessed by evaluating color consistency, thickness, adhesion, surface hardness, and corrosion resistance through standardized testing methods.

9. Why should I include fixture marks in my design?

During anodizing, parts must be held by a fixture to conduct electricity. These contact points may leave small uncoated areas, which should be accounted for in design placement.

10. Is anodizing conductive?

No. The anodized layer is non-conductive. However, this insulating property is useful in electrical and thermal applications where insulation is desired.

11. What materials can I anodize?

Common anodizable metals include aluminum, titanium, magnesium, niobium, tantalum, and zinc. Each reacts differently and is used for different applications.

12. Is anodizing expensive?

For high-volume production, anodizing is cost-effective. However, small batches or special colors can be more expensive due to setup costs and material quality requirements.

13. Does the anodized layer wear out?

Yes, but it is highly durable. The wear rate depends on the type of anodizing and environmental conditions. Type III (hardcoat) anodizing offers the highest durability.

14. What chemicals are used for anodizing?

Common electrolytes include sulfuric acid (Type II and III), chromic acid (Type I), and phosphoric acid (for bonding or surface prep). Proper handling and disposal are essential.

15. What is the difference between Type II and Type III anodizing?

Type II (sulfuric acid) produces a thinner decorative coating, while Type III (hard anodizing) forms a much thicker, more wear-resistant surface for high-performance applications.

16. Does anodizing expand?

Yes. Anodizing grows both outward and inward into the metal. About half the layer thickness penetrates the surface, and the rest adds to the part’s dimensions.

17. When does aluminum need anodizing?

When parts are exposed to wear, corrosion, UV light, or need enhanced aesthetics or electrical insulation, anodizing is a preferred treatment.

18. How long does anodizing take before fading?

Color stability depends on the dye and environment. High-quality anodizing with proper sealing can last many years before noticeable fading.

19. How long does anodizing last?

Properly anodized parts can last 10–20 years or longer, especially with good maintenance. Hard anodizing offers even longer service life in industrial applications.

20. What metals cannot be anodized?

Metals like stainless steel, carbon steel, and copper do not respond well to anodizing. Their oxide layers don’t form in the same controlled, stable way as aluminum or titanium.