15 years one-stop China custom CNC machining parts factory

Home / Product / Aluminum Parts /

As your aluminum CNC machining manufacturer, we have 40+ aluminum alloy materials, 100 CNC machining equipment, and 12 quality inspection processes. can provide you with a solution tailored to your specific needs.

Product Specification:

China CNC Machining Diy Knuckle Roller Fidget Skill Toy Manufacturer Factory

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

|

When it comes to crafting custom CNC machined knuckle roller fidget devices, precision, durability, and tactile satisfaction are essential. Here's a breakdown of the services involved in creating these engaging and functional items: |

Custom CNC Knuckle Roller Fidget Prototyping Machining

100 CNC machining equipment provide you with prototype manufacturing, evaluation, design and testing. We can complete CNC machining and delivery of Knuckle Roller Fidget prototype parts according to your specific requirements within 1 day. |

|

|

|

|

||

Custom CNC Knuckle Roller Fidget Surface Treatment |

Custom CNC Knuckle Roller Fidget Material |

||

|

We can provide a variety of surface treatment services for your CNC machined Knuckle Roller Fidget project: polishing, anodizing, powder coating, laser engraving, custom graphics, etc. 12 quality inspection processes ensure that your CNC machined parts have a yield rate of 98%. |

Our own material library can provide you with different series of materials such as aluminum, stainless steel, red copper, brass, titanium and plastic, with material testing reports attached. There are professional CNC machining Knuckle Roller Fidget project engineers to choose the right material for you. |

| The combination of prototyping, precise CNC machining, surface treatment options, material selection, and customization services ensures that your custom CNC machined knuckle roller fidget is not only functional but also visually appealing and tailored to your unique needs. |

|

|

|

||

|

|

|||

|

|

|

||

|

|

|

||

|

Surface treatments for custom CNC machined knuckle roller fidgets are essential to not only protect the material but also enhance the aesthetics and functionality of these tactile devices. Here are some common surface treatments and their advantages: |

|

1. Anodizing CNC Machining Knuckle Roller Fidget

Characteristics: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum fidgets. It's available in various colors, allowing for customization.

|

|

|

2. Polishing CNC Machining Knuckle Roller Fidget

Characteristics: Polishing involves mechanically smoothing and shining the surface of the fidget, resulting in a mirror-like, glossy finish.

|

|

|

|

3. Powder Coating CNC Machining Knuckle Roller Fidget

Characteristics: Powder coating is a dry finishing process where a fine powder is electrostatically sprayed onto the fidget's surface. It's then cured to create a protective and decorative layer.

|

|

|

|

4. Laser Engraving CNC Machining Knuckle Roller Fidget

Characteristics: Laser engraving adds intricate designs, patterns, or branding to the fidget's surface using a high-powered laser beam.

|

|

|

|

5. Custom Graphics CNC Machining Knuckle Roller Fidget

Characteristics: Custom graphics involve adding designs, logos, or artwork to the fidget's surface using techniques like screen printing or decals.

|

|

|

|

The choice of surface treatment should align with your preferences and the intended use of your knuckle roller fidget. Whether you prioritize durability, aesthetics, or a combination of both, these surface treatments can enhance the overall look and feel of your custom CNC machined knuckle roller fidget, making it both visually appealing and enjoyable to use. |

| The choice of material for custom CNC machined knuckle roller fidgets is essential to achieve the right balance of weight, durability, and aesthetics. Here are some common materials used for crafting these engaging devices: |

|

|

Custom CNC Machining Aluminum Knuckle Roller Fidget

Characteristics: Aluminum is a popular choice for knuckle roller fidgets due to its lightweight nature, durability, and corrosion resistance. It offers an excellent balance between weight and functionality.

More Details>> |

|

|

|

Custom CNC Machining Stainless Steel Knuckle Roller Fidget

Characteristics: Stainless steel is known for its exceptional corrosion resistance, strength, and durability. Knuckle roller fidgets made from stainless steel have a substantial weight.

More Details>> |

|

|

|

Custom CNC Machining Titanium Knuckle Roller Fidget

Characteristics: Titanium is renowned for its strength-to-weight ratio, corrosion resistance, and biocompatibility. It's a premium material choice.

More Details>> |

|

|

|

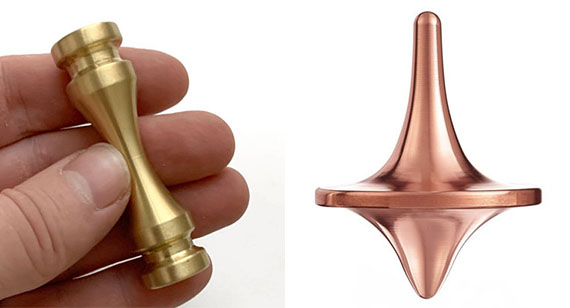

Custom CNC Machining Brass / Copper Knuckle Roller Fidget

Characteristics: Brass and copper are heavier materials known for their unique aesthetics. They develop a natural patina over time, giving the fidget a distinctive character.

More Details>> |

|

| The choice of material should align with your preferences for weight, appearance, and durability. Aluminum is a versatile and popular choice for everyday use due to its balance of characteristics. Stainless steel provides a heavier, robust option, while brass or copper adds a touch of elegance with their evolving patina. Titanium and exotic materials cater to those seeking premium options. |

| The manufacturing process for custom CNC machined knuckle roller fidgets involves several precise steps to create these engaging and functional devices. Here's an overview of the key stages in crafting these tactile wonders: |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Material Selection

Material Selection: The process begins with careful material selection. Common materials for knuckle roller fidgets include aluminum, stainless steel, brass, copper, titanium, or even exotic materials like carbon fiber. The choice of material impacts weight, durability, and aesthetics. |

|

2. Design and Prototyping

Design and Prototyping: Create detailed CAD designs to define the shape, dimensions and characteristics of the knuckle roller. Prototyping is the creation of samples or prototypes of CNC knuckle rollers to evaluate design, ergonomics and functionality before proceeding to series production. It allows adjustments to be made to get the best final product. |

|

3. CNC Machining

CNC Machining: CNC machining is the heart of the manufacturing process. CNC machines precisely cut and shape the chosen material according to the CAD designs. This step ensures the CNC knuckle roller's design is exact and its components are uniform. |

|

4. Surface Treatment

Surface Treatment: Surface treatments are applied to enhance both functionality and aesthetics. These treatments can include anodizing for corrosion resistance, polishing for a glossy finish, powder coating for durability, laser engraving for customization, or other specialized finishes. |

|

5. Quality Control

Quality Control: Rigorous quality control checks are conducted throughout the manufacturing process. Dimensional accuracy, surface finish, and overall quality are carefully assessed to meet industry standards and your specific requirements. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

6. Customization

Customization options allow you to choose the size, weight, color, and surface finish of the knuckle roller fidget to match your brand or personal preferences. Graphics, logos, or patterns can be added for branding purposes. |

|

7. Packaging and Delivery

The finished knuckle roller fidgets are meticulously packaged to prevent damage during shipping. They are then promptly delivered to your location, ready to provide an engaging and satisfying tactile experience. |

|

The precision and consistency offered by CNC machining guarantee that each knuckle roller fidget is produced with tight tolerances and uniform quality. This results in reliable, durable, and visually appealing fidgets that cater to your unique needs. The manufacturing process is tailored to ensure your custom CNC machined knuckle roller fidget offers both functional enjoyment and aesthetic appeal.. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your machining requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Machining Knuckle Roller Fidget FAQs

| Here are answers to some frequently asked questions about custom CNC machined knuckle roller fidgets: |

|

1. What is a knuckle roller fidget?

A knuckle roller fidget is a hand-held device designed for tactile enjoyment and stress relief. It typically consists of one or more cylindrical or spherical components that can be rolled and manipulated with the fingers.

Knuckle roller fidgets are designed to roll smoothly in your hand, allowing you to perform tricks and patterns with your fingers. They provide a satisfying tactile experience and can help relieve stress and anxiety.

Knuckle roller fidgets are commonly made from materials like aluminum, stainless steel, brass, copper, titanium, or even exotic materials like carbon fiber. The choice of material affects the fidget's weight, durability, and aesthetics.

Yes, many manufacturers offer customization options for knuckle roller fidgets. You can choose the size, weight, color, and surface finish to match your preferences or brand. Graphics, logos, or patterns can also be added for personalization or branding.

Yes, knuckle roller fidgets are designed to provide a calming and stress-relieving experience. Rolling and manipulating the fidget can help reduce anxiety and improve focus.

Knuckle roller fidgets can be suitable for older children and teenagers, but they should be used under adult supervision, especially if the fidget contains small parts that could be a choking hazard.

Knuckle roller fidgets typically require minimal maintenance. Keeping them clean and free from dirt or debris ensures they roll smoothly. Some materials, like brass or copper, may develop a patina over time, which can add to their character.

Yes, knuckle roller fidgets are discreet and can be used in professional settings like offices or meetings to help improve focus and reduce stress. They are often quieter and less distracting than some other fidget devices.

Yes, there are various tricks and techniques that enthusiasts and users develop for knuckle roller fidgets. These can range from basic rolling and flipping to more intricate maneuvers. Many online communities and tutorials offer guidance on these tricks.

11. Are knuckle roller fidgets collectible items?

|

| We hope these CNC Machining knuckle roller fidget FAQs answer your questions. If you have more questions or require further assistance, please feel free to contact our dedicated customer support team. We're here to help you create the perfect custom CNC Machining knuckle roller fidget for your vehicle. |

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.