15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 10 19

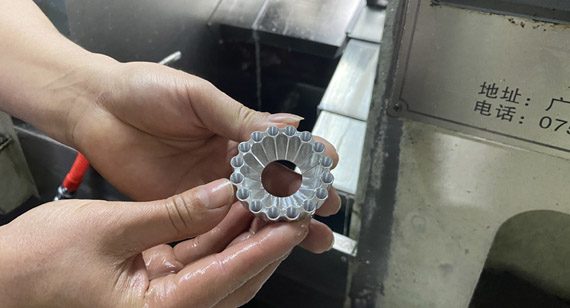

2022 10 19 In the process of high-precision CNC parts machining, we should also pay attention to the full inspection of product quality. The VMT CNC machining factory is equipped with a complete range of precision CNC machining equipment, CNC machine tools, and testing equipment.

66

66

Read more

Read more

VMT

VMT  2022 10 18

2022 10 18 The key single-piece and batch prices are different. If there is no batch machining of aluminum CNC parts, the unit price will be higher. First, you need to buy aluminum raw materials, make part blanks, write programs, and then prepare tools, arrange fixtures, set tools, find origin, transfer programs, Aluminum data parts machining, final shaving, post-machining, but also packaging and shipping.

66

66

Read more

Read more

VMT

VMT  2022 10 18

2022 10 18 The most straightforward answer: 3D printing is an additive technology, and CNC precision machining is a subtractive technology. Which one is better?

66

66

Read more

Read more

VMT

VMT  2022 10 13

2022 10 13 CNC aluminum precision parts machining is currently widely used in various fields and different industries such as intelligent robots, automobiles, medical care, new energy, semiconductors, manufacturing, aerospace and aviation.

66

66

Read more

Read more

VMT

VMT  2022 10 13

2022 10 13 CNC machining, also known as CNC machining center, is the most popular and widely adopted CNC machining method by many CNC machining manufacturers, especially some machinery and equipment manufacturing companies.

66

66

Read more

Read more

VMT

VMT  2022 10 12

2022 10 12 The advantages of precision parts machining are small batch production, which can save time cost and material cost and accelerate the time to market of products. Small batch production is inseparable from the hand model.

66

66

Read more

Read more

VMT

VMT  2022 10 12

2022 10 12 First of all, CNC machining is suitable for most precision parts CNC machining in robotics, aviation, navigation, automotive, medical, industrial and other fields. CNC machining has high precision, fast efficiency and stable quality.

66

66

Read more

Read more

VMT

VMT  2022 10 06

2022 10 06 Strength and hardness of CNC machining parts material: In CNC machining, the harder the material to be cut, the greater the cutting force required, the greater the energy consumed, the greater the heat generated, and the faster the loss of the tool.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!