15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 10 06

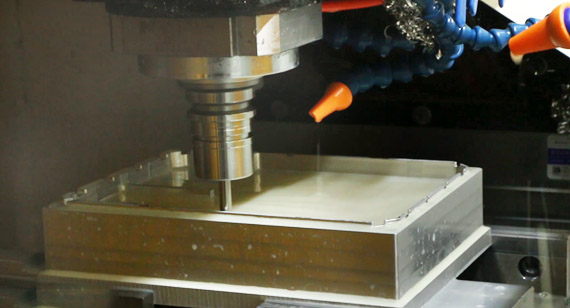

2022 10 06 The main factors for the deformation of the communication cavity during the CNC machining process are the shape complexity, aspect ratio and wall thickness of the cavity; the rigidity and stability of the material.

66

66

Read more

Read more

VMT

VMT  2022 10 05

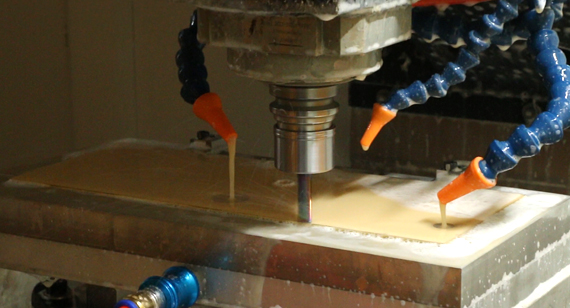

2022 10 05 Precision CNC machining has become a pillar of the manufacturing industry. More and more CNC machining manufacturers are adopting this form of machining in their operations. Although many CNC machining masters are accustomed to this form of CNC machining, not all of them know the logic behind it.

66

66

Read more

Read more

VMT

VMT  2022 10 05

2022 10 05 From metal materials to plastics, CNC precision machining products can be used in many kinds of materials. Each material has its own different characteristics, suitable for different kinds of CNC parts machining products.

66

66

Read more

Read more

VMT

VMT  2022 09 27

2022 09 27 In metal CNC machining, surface roughness defects seriously affect the quality of metal CNC machining, and the mechanism of surface roughness defects and the methods of eliminating roughness defects in various aspects are worthy of our in-depth study and continuous improvement.

66

66

Read more

Read more

VMT

VMT  2022 09 26

2022 09 26 What does the acceptance of precision CNC machining parts include? Specifically, including acceptance requirements and acceptance procedures, etc., today we will introduce the content of the two parts of acceptance requirements and acceptance procedures, as follows.

66

66

Read more

Read more

VMT

VMT  2022 09 26

2022 09 26 CNC machining is a kind of lathe developed on the basis of ordinary lathes. Compared with ordinary lathes, it is widely used in mechanical parts due to its strong adaptability, high CNC machining accuracy, high CNC machining efficiency and reduced labor intensity. in production.

66

66

Read more

Read more

VMT

VMT  2022 09 23

2022 09 23 CNC turning accuracy refers to the degree of conformity between the actual geometric parameters of the workpiece surface after machining and the expected geometric parameters, and the higher the degree of conformity, the higher the CNC machining accuracy.

66

66

Read more

Read more

VMT

VMT  2022 09 23

2022 09 23 In order to avoid the above-mentioned collision, the operator should give full play to the functions of the five senses when operating the machine tool. Observe the machine for abnormal movement, sparks, noise, rattling, vibration, and burnt smell. If any abnormal situation is found, the program should be stopped immediately, and the machine tool can continue to work after the machine tool problem is solved.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!