15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 08 22

2022 08 22 According to personal experience for many years, CNC machining of aluminum alloy cavity, the thinnest side wall height of 10MM can be at least 0.2, 20MM high and the thinnest can be 0.3, 30MM high and the thinnest can be 0.4 The bottom thickness should be determined according to the bottom area How much the thinnest can be done, 300MM can be 0.2, 600MM can be 0.3

66

66

Read more

Read more

VMT

VMT  2022 08 20

2022 08 20 CNC turning is a kind of machine tool that is widely used. It can select dozens of tools from the programs preset by the CNC system to CNC turn parts, not only can be controlled by the coordinate system) Accurate cutting or other CNC machining positions

66

66

Read more

Read more

VMT

VMT  2022 08 19

2022 08 19 In the process of CNC machining parts of aluminum shell, sometimes due to improper handling or other reasons, the surface of CNC machining parts of aluminum shell often appears unsmooth.

66

66

Read more

Read more

VMT

VMT  2022 08 19

2022 08 19 The production and processing process of the CNC machining factory is an important document to guide the manufacturing. It plays a great role in ensuring the CNC machining quality of the parts and meeting the requirements specified in the design drawings.

66

66

Read more

Read more

VMT

VMT  2022 08 18

2022 08 18 The accuracy of CNC machined parts depends on many factors, including part design, tool selection, toolpath programming, how fixtures are held, and more.

66

66

Read more

Read more

VMT

VMT  2022 08 18

2022 08 18 CNC index-controlled machine tools are programmed and operated by CNC machining language, generally G code. The CNC machining G code language informs the CNC machine tool which Cartesian coordinates to use for the machining CNC blade, and controls the CNC blade's cutting speed and spindle bearing speed ratio, as well as its special tool changer, coolant and other functions.

66

66

Read more

Read more

VMT

VMT  2022 08 17

2022 08 17 Many of the products we use in our daily lives are stainless steel. This stainless steel material is forged by stamping, laser and other methods, and sand holes, burrs, etc. occur in the later stage of the process. Therefore, many companies choose to process stainless steel etching through etching processes.

66

66

Read more

Read more

VMT

VMT  2022 08 17

2022 08 17 These are our two most popular types of stainless steel today. But what's the difference? Below, we break down history, JIS SUS304, the product types and applications of these two very different materials to help you decide which stainless steel is best for your project.

66

66

Read more

Read more

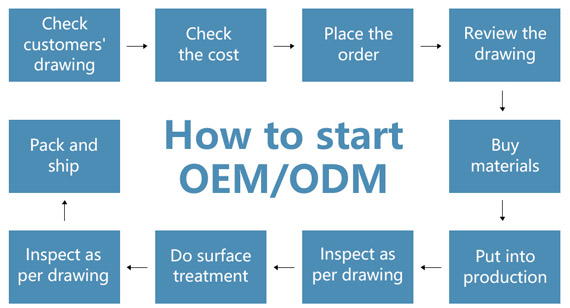

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!