15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 08 01

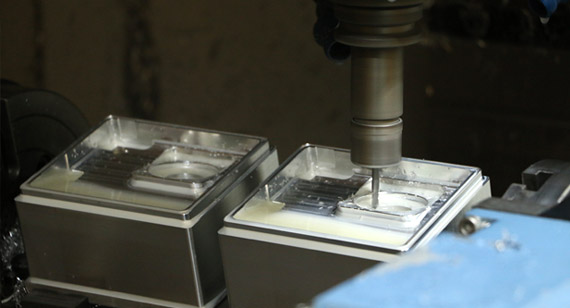

2022 08 01 CNC machining usually refers to computer numerical control precision machining, CNC machining lathes, CNC machining milling machines, CNC machining boring and milling machines, etc.

66

66

Read more

Read more

VMT

VMT  2022 07 29

2022 07 29 Industrial product prototypes often need to be CNC prototypes. CNC prototypes are the first step to verify the feasibility of products. It is the most direct and effective way to find out the defects, deficiencies, and drawbacks of designed products, so as to improve the defects in a targeted manner, eliminating the need for Expensive mold opening costs reduce R&D risks and speed up R&D efficiency.

66

66

Read more

Read more

VMT

VMT  2022 07 28

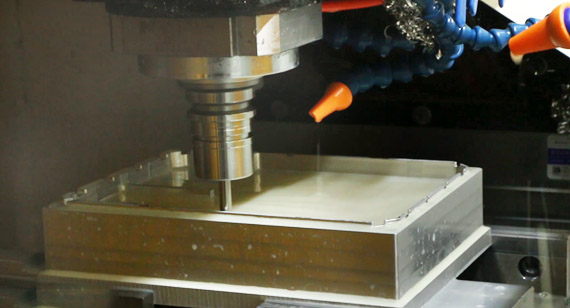

2022 07 28 In order to meet people's demand for the diversity and high quality of CNC machining parts for aluminum casings, it is necessary to summarize the process skills in the process of CNC machining parts. Based on years of CNC machining experience, VMT CNC machining parts manufacturer summarizes the CNC machining skills that should be paid attention to in CNC machining parts for aluminum case.

66

66

Read more

Read more

VMT

VMT  2022 07 27

2022 07 27 With the continuous development of the flashlight industry, more and more attention has been paid to the design of the flashlight housing and the application of materials. To make a good flashlight housing, we must first understand the purpose of the designed product, the use environment, the type of shell, the light effect, the shape, the cost, etc. Wait.

66

66

Read more

Read more

VMT

VMT  2022 07 26

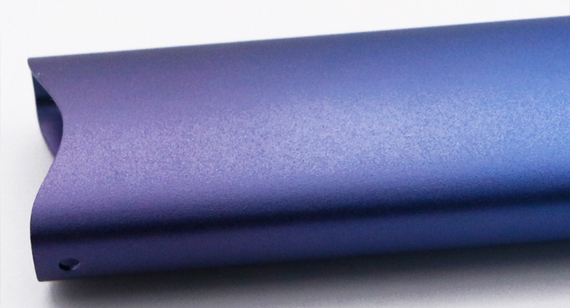

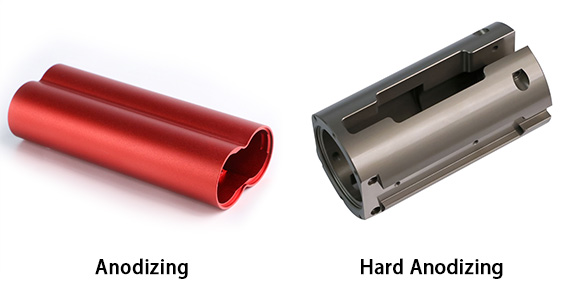

2022 07 26 Today we are happy to share some knowledge about anodizing that can be done on a range of materials, especially aluminum alloys, and makes aluminum CNC machined parts practical and beautiful.

66

66

Read more

Read more

VMT

VMT  2022 07 25

2022 07 25 CNC prototype has high machining accuracy, can accurately control product quality, and has high production efficiency. It is a CNC prototyping method commonly used by many large CNC prototyping machining factories. However, there are still differences in the machining accuracy of CNC prototypes.

66

66

Read more

Read more

VMT

VMT  2022 07 25

2022 07 25 What are the reasons for the poor accuracy of CNC machining parts? OEM CNC machining parts manufacturers answer some of the questions that often arise in actual CNC machining.

66

66

Read more

Read more

VMT

VMT  2022 07 23

2022 07 23 Aluminum alloy material is the most used material in VMTCNC machining. In order to overcome the defects of surface hardness and wear resistance of aluminum precision CNC machining parts, expand the application range and prolong the service life of aluminum alloy parts, the surface treatment technology has become aluminum alloy CNC.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!