15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 08 10

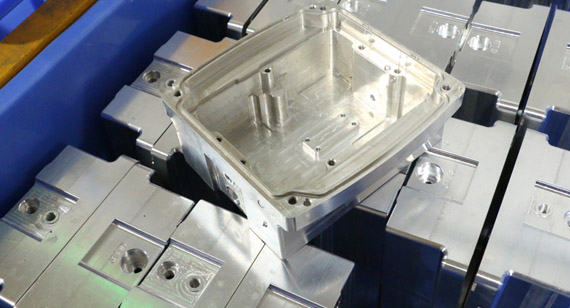

2022 08 10 CNC aluminum machining parts have good mechanical properties, small proportion of material, good corrosion resistance and excellent craftsmanship. They are often used in universal structural parts and frame parts, which can not only meet the requirements of mechanical strength and accuracy, but also Effectively reduce the weight of the equipment, so it is widely used in complex parts.

66

66

Read more

Read more

VMT

VMT  2022 08 09

2022 08 09 The above are the top ten things to pay attention to for aluminum CNC machining parts and five common CNC machining methods for aluminum CNC machining parts. VMT believes that everyone has an understanding of the relevant knowledge of aluminum CNC machining.

66

66

Read more

Read more

VMT

VMT  2022 08 08

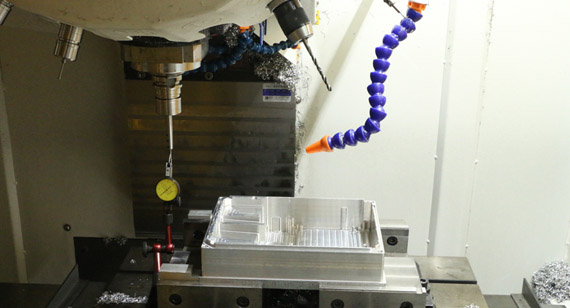

2022 08 08 The principle of aluminum CNC machining is to use the automatic control system to install digital program flow commands to control the automatic start and stop of CNC machine tool bearings.

66

66

Read more

Read more

VMT

VMT  2022 08 06

2022 08 06 What are the CNC machining materials you know? Do you know the advantages of each material? What material is suitable for CNC machining what parts? Come check it out!

66

66

Read more

Read more

VMT

VMT  2022 08 05

2022 08 05 There are several common processes for CNC prototyping machining: CNC machining, 3D printing, silicone molding, sheet metal processing, low pressure perfusion, etc. Today we will briefly describe the steps and advantages of CNC prototyping machining.

66

66

Read more

Read more

VMT

VMT  2022 08 04

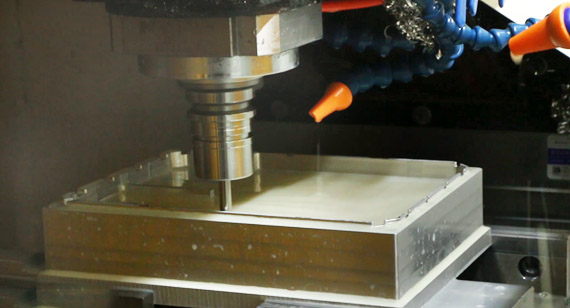

2022 08 04 CNC prototype machining and manufacturing is a method of prototype proofing by using CNC machines to cut off excess materials through subtractive manufacturing. CNC machining speed is fast, cost is low, and the processing materials have the requirements of high strength, high temperature resistance, high toughness, transparency, etc.

66

66

Read more

Read more

VMT

VMT  2022 08 03

2022 08 03 Due to its many advantages, cnc prototype machining has always been the mainstream processing method of modern prototype processing. It is not only suitable for various fields, but also allows customers to achieve the best results for verification purposes.

66

66

Read more

Read more

VMT

VMT  2022 08 02

2022 08 02 Which one is more suitable for CNC machining or 3D printing? Next, VMTCNC machining manufacturer will popularize this knowledge for everyone. Which method is better for CNC prototype machining parts proofing? 3D printing or CNC machining.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!