15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 09 16

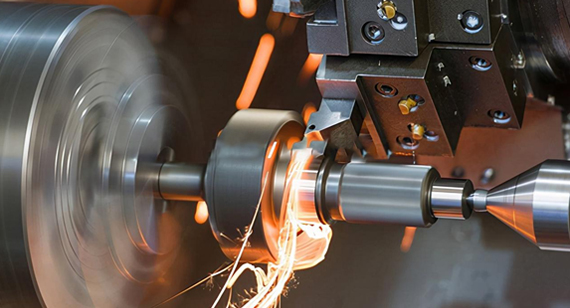

2022 09 16 When we use CNC machining, we often find that the outer circle of CNC machining parts has a taper phenomenon, which makes the diameters at both ends of the workpiece size inconsistent, which exceeds the tolerance range. So, what is the reason for the taper of the outer circle of CNC machined parts? How can we solve the problem of the taper of the outer circle of CNC machined parts?

66

66

Read more

Read more

VMT

VMT  2022 09 15

2022 09 15 Turning, milling, planing, grinding, drilling, boring, the highest precision of these machines and the tolerance levels achievable by various CNC machining methods are here.

66

66

Read more

Read more

VMT

VMT  2022 09 15

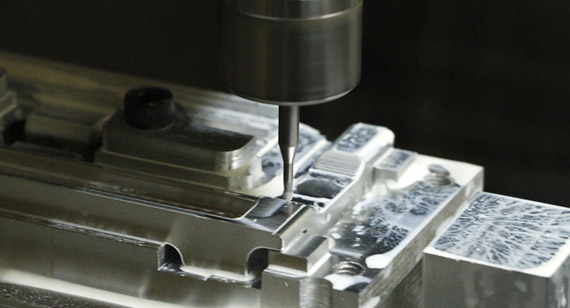

2022 09 15 CNC (Computer Numerical Control) machining is a widely used technique in the manufacturing industry for creating precise components. Within CNC machining, there are two distinct processes: rough CNC machining and fine CNC machining. While both processes contribute to the final outcome, they differ in their objectives and techniques. In this article, we will explore and explain the differences between rough CNC machining and fine CNC machining.

66

66

Read more

Read more

VMT

VMT  2022 09 14

2022 09 14 What to do if there are too many burrs when milling aluminum parts with CNC machining? Burrs will not only reduce the machining accuracy of CNC machined aluminum parts, thereby affecting the performance of the parts, but also increase the cost of CNC machining.

66

66

Read more

Read more

VMT

VMT  2022 09 14

2022 09 14 The operation technology of CNC machining is deepened and embodied in practice. If you really encounter a problem, think about how to solve it, and then exercise yourself in actual operation. Very simple questions have to be done once to understand the real meaning.

66

66

Read more

Read more

VMT

VMT  2022 09 13

2022 09 13 We control the CNC machining quality from five key links, namely the design link of the CNC machining scheme, the programming link, the simulation inspection link, the application link of the CNC machining quality control methods and tools, and the establishment of the CNC machining technical team. The following five key aspects of the in-depth study.

66

66

Read more

Read more

VMT

VMT  2022 09 13

2022 09 13 Mildew phenomenon of aluminum die-casting CNC machining parts: mainly due to the lack of moisture-proof treatment, yellowing phenomenon: the concentration of mold release agent during oxidation of cutting fluid and die-casting.

66

66

Read more

Read more

VMT

VMT  2022 09 13

2022 09 13 The metal cutting process is often accompanied by the formation of burrs. The existence of burrs not only reduces the precision and surface quality of CNC machined parts, but also affects the performance of products, and sometimes even causes accidents.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!