15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

159 |

Published by VMT at Sep 23 2021

159 |

Published by VMT at Sep 23 2021

One of the most common mistakes in the design of CNC machined parts:

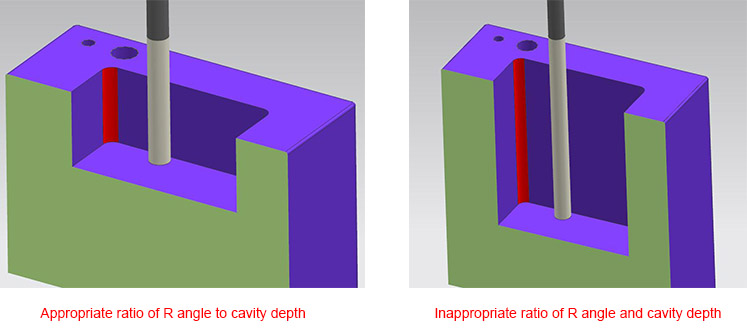

The ratio of the R angle at the corner to the cavity depth is inappropriate. This ratio is relative to CNC machining. The cavity depth is not more than 10 times the R angle. For example, if the R angle is 2MM, the cavity depth is the largest No more than 20MM, the side walls of the parts made with this ratio are very smooth, there will be no steps in the corners, the processing size is high, and the processing efficiency is high.

On the contrary, if the R angle is 2MM and the cavity depth is 60MM, which exceeds the golden machining ratio, then this part is not suitable for CNC machining, because the tool has to be installed very long, the cutting amount will be smaller, and the feed will be slower. The processing time becomes longer, the cost becomes higher, and the processed sidewall will have serious knife marks, and the processing accuracy will be very low. We can compare the following pictures to make an intuitive understanding.

The second most common mistake in the design of CNC machining parts:

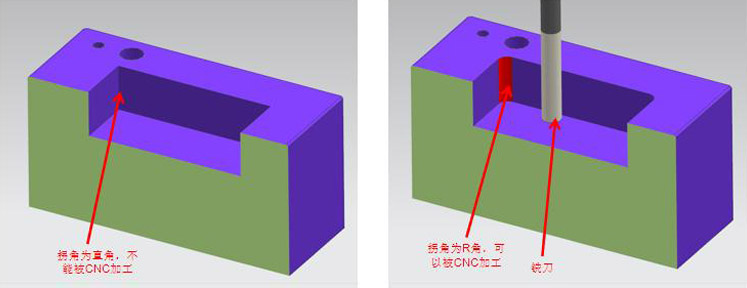

The corners of the cavity are set to right angles, which causes the structure of CNC machined parts to be unable to be manufactured by CNC. As we know, CNC tools are all cylindrical, and it cannot be machined with a right angle structure. Therefore, the corners of the cavity must be designed to be suitable R angles before the parts can be processed by CNC. We can make an intuitive understanding through the comparison of the following pictures.

The third most common mistake in CNC machining parts design:

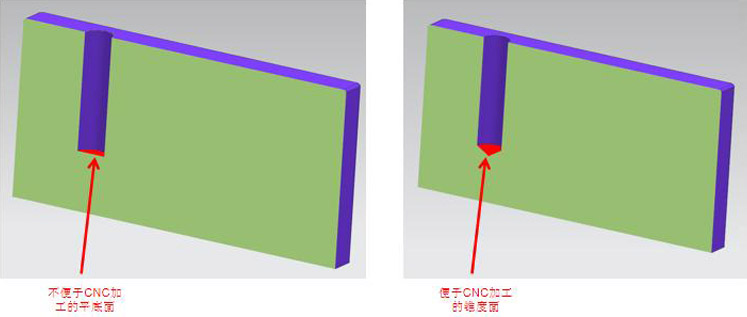

The bottom of the blind hole is designed to be flat. If it is not absolutely necessary, the blind hole should not be designed as a flat-bottomed hole, because it will be more difficult for processing, especially when the hole is very deep, it is more difficult to CNC machining, which will increase a lot of cost. . Therefore, making the bottom of the hole into a tapered surface is the most convenient for CNC machining. We can compare the following pictures for an intuitive understanding.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!