15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 29 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Jan 29 2026 | Reading Time:About 2 minutes

You may have heard of the most versatile aluminum alloy 6061-T6, manufactured structural parts from automotive parts, industrial equipment to different kinds of hardware. It surely has high strength, and an affordable price due to its universal supply. However, there must be some other uses that it cannot meet really high strength. This is what this article will discuss— 7075-T6 aluminum —also known as "aircraft grade aluminum," stands as one of the highest strong alloy. It offers a strength-to-weight ratio that rivals many steels, making it a considered option for aerospace, defense, and high-stress industrial applications. But what’s about its characteristics and limitation? Is there any better alternative material for 7075-T6? What about its machining? This guide explores everything you need to know about material 7075 T6 aluminum.

7075-T6 is not a naturally occurring raw material; rather, it is a high-strength state achieved by applying a specific heat treatment (T6) to 7075 aluminum alloy. Understanding this material requires a distinction between 7075 aluminum alloy and its "temper."

7075 belongs to the Aluminum-Zinc-Magnesium-Copper series (7xxx series). Its designed firstly for aircraft uses and its primary alloying element is Zinc (Zn: 5.1%–6.1%), supplemented by small amounts of Magnesium (Mg: 2.1%–2.9%) and Copper (Cu: 1.2%–2.0%). According to the Aluminum Association (AA) standards, 7075 is categorized as a "heat-treatable alloy." This means its mechanical properties can be altered by its heat treatment process.

T6 Heat Treatment State (The Tempering Process)

"T" stands for Thermal Treatment. The numbers following the "T" represent different process combinations (such as solution treatment, quenching, and artificial aging), which can alter the mechanical properties, stress-corrosion resistance, and toughness of the 7075 alloy. The suffix "T6" represents the specific heat treatment regimen that grants 7075 its peak performance:

Key Characteristics of Aluminum Alloy 7075 t6

Once 7075 enters the T6 state, it exhibits the following key highlights and limitations:

Mechanical properties can be altered by 7075 aluminum alloy’s heat treatment process; This means that although the 7075-T6 aluminum alloy is prone to stress corrosion cracking and has poor weldability, it may be in the different in its other tempers. Below is a comparison of 7075-T6 and other tempers showing the properties differences:

Table 1: Comparing 7075-T6 with Other Tempers

| Temper | Tensile Strength | SCC Resistance | Dimensional Stability | Best Use Case |

| 7075-T6 | Highest (~570 MPa) | Poor | Moderate | Maximum static load in dry environments. |

| 7075-T651 | High (~570 MPa) | Moderate | Excellent | Best for CNC Machining for its excellent dimensional stability |

| 7075-T73 | Lower (~500 MPa) | Excellent | Good | High-pressure aerospace parts in corrosive environments. |

| 7075-T76 | Medium (~530 MPa) | Good | Good | Applications requiring exfoliation corrosion resistance. |

| 7075-O | Lowest (~280 MPa) | N/A | Low | Annealed state for extreme cold forming/bending. |

7075-T6 aluminum is suitable if you are only pursuing maximum static load in dry environments. If you are planning to manufacture complex parts, always specify aluminum alloy 7075-T651. This temper includes a controlled stretching process that relieves internal residual stresses. Without this, a standard aluminum alloy 7075-T6 block may warp or "spring" during heavy milling.

In high-humidity environments, 7075-T6 aluminum alloy is prone to sudden failure via Stress Corrosion Cracking. 7075-T73's "over-aging" process sacrifices about 15% strength but provides a massive leap in safety and durability.

If the high cost or specific limitations of 7075-T6 (like poor weldability or susceptible to stress-corrosion cracking) are hurdles, consider these alternative materials:

Aluminum Alloy 6061-T6: The Multipurpose Industrial Standard

The 6061-T6 vs. 7075-T6 debate is common in the structural parts manufacturing for 6061 is considered the "utility grade" of aluminum alloys due to its balanced performance; while 7075-T6 has much better strength but hard to be machined.

Aluminum Alloy 7050-T7451: The Heavy-Section Solution for Aircraft

When comparing 7050-T7451 vs. 7075-T6, the 7050-T7451 alloy is the preferred choice for thick-section aerospace applications.

Aluminum Alloy 2024-T3: The Fatigue-Resistant Alternative

In the evaluation of 2024-T3 vs. 7075-T6, the selection depends on the primary loading type—specifically, whether the component is subjected to tension versus compression.

Aluminum Alloy 5083: The Marine Grade for High Strength Parts

When comparing 5083 aluminum vs. 7075-T6, the requirement for corrosion resistance in high-strength structural components is the deciding factor.

While 6061, 5083, and 7050 offer spec ific performance advantages or cost-efficiencies in their respective fields, 7075-T6 remains irreplaceable in engineering design under the following conditions:

1. High-Strength Requirements for Thin-Section Components (< 1 inch)

In applications where the material thickness is less than 1 inch and maximum strength is required, 7075-T6 typically offers superior static strength. In these thin-section scenarios, there is no technical necessity to pay the premium for the specialized crack-resistant properties found in 7050, which are specifically engineered for heavy-gauge sections.

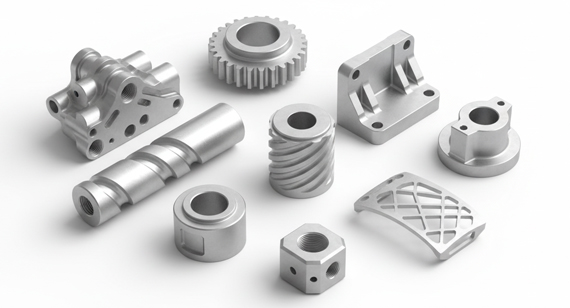

2. Requirements for Extreme Hardness, Impact, and Wear Resistance

7075-T6 is the ideal choice for applications requiring resistance to indentation, abrasion, or high-impact loads, provided that high-level corrosion resistance is not a primary concern.

It is exceptionally suited for components such as precision gears, worm wheels, molds (such as plastic injection molds), and firearm lower receivers (e.g., AR-15 specifications). In these applications, alternatives like 6061 or 5083 would fail prematurely due to rapid wear or structural deformation caused by their lower material hardness.

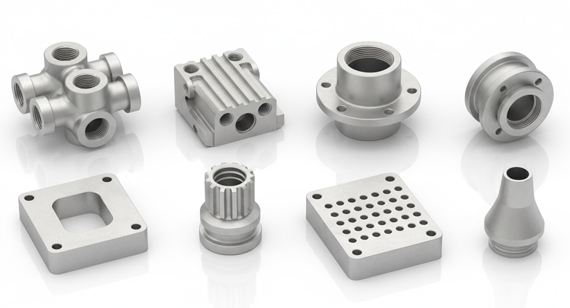

7075-T6 aluminum alloy is widely used in the following applications due to its steel-like strength and excellent strength-to-weight ratio:

7075-T6 aluminum alloy is highly suitable for CNC machining(cutting, drilling, milling 7075-T6 through computer-controlled machines). It has good dimensional stability, which helps it maintain its shape and meet tight tolerances without warping. Because it is hard and less ductile, it produces brittle chips that break easily. This allows 7075-T6 parts to achieve a very smooth surface finish. While it is harder than 6061-T6 and slightly more difficult to machine, it still has good machinability for complex milling and turning.

When machining 7075-T6, tool selection and process control are key. Here are some recommendations:

A high-performance racing engineering team contacted VMT to produce a batch of precision spur gears for a power transmission system. The client specified 7075-T6 aluminum alloy to achieve maximum strength. However, the complex tooth profile and the internal residual stresses inherent in 7075-T6 presented a risk of dimensional deviation during machining.

Our Solution:

The Result:

1.Is 7075-T6 aluminum weldable?

No, it is generally considered non-weldable by conventional methods (MIG/TIG) as it is prone to "hot cracking." Mechanical fastening or specialized friction stir welding are preferred.

2.What is the difference between 6061t6 aluminum vs 7075 t6?

7075-T6 is nearly 80% stronger than 6061-T6 but costs more and is less corrosion-resistant. Use 7075 for high-performance structural parts and 6061 for general-purpose applications.

3.Does 7075-T6 aluminum alloy need anodizing?

Yes. Due to its high zinc and copper content, it is susceptible to corrosion. Hard Anodizing is highly recommended to protect the surface.

4.Why is my 7075-T6 part warping after CNC machining?

You are likely using standard T6. Switch to 7075-T651, which is stress-relieved via stretching, to ensure dimensional stability.

5.How hard is aluminum alloy 7075-T6?

It has a Rockell B hardness of about 87 (150 Brinell). It is significantly harder than most other aluminum alloys.

6.Can 7075-T6 aluminum alloy be used for engine parts?

It is excellent for structural engine mounts or spacers but check the operating temperature. Aluminum 7075 begins to lose strength significantly at temperatures above 100°C (212°F).