15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 07 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Jan 07 2026 | Reading Time:About 2 minutes

High precision and quality of drone parts directly determine the overall quality of drones. From racing and aerial photography to industrial inspection, logistics, and agriculture, drone parts require specific properties, such as high stiffness, lightweight design, aesthetic appearance, or corrosion resistance. All of these can be effectively achieved through one of the most advantageous manufacturing methods—CNC machining, enabling the production of well-suited CNC drone parts. This guide explores CNC drone parts, including the definition of CNC, their types, materials, advantages, and applications, providing valuable insights for enthusiasts, engineers, and manufacturers.

CNC drone parts are drone components manufactured using computer-controlled machining processes—the CNC. CNC machining is a subtractive manufacturing process in which a computer controls the movement of different cutting tools inside a lathe or milling machine. Following a programmed path, the cutting tools remove material from a solid block until the needed shape is achieved. The CNC manufacturing process for drone parts generally follows these steps:

The manufacturing process starts with design. Engineers create a 3D CAD model of the drone part that defines its geometry, dimensions, hole locations, and assembly interfaces. At this stage, the design is optimized for structural layout and outlook requirements and ensures the part can be accurately produced by CNC machining.

After the design is completed, the designed part model is imported into CAM software for setting up the machine’s operating path. The CAM system generates CNC instructions that control how the machine tools move during machining. These instructions define tool paths, machining sequences, and cutting parameters required to produce the part correctly.

Machining (Milling, Drilling, Cutting)

Next, the CNC machine begins machining the part from a solid block of material by following the programmed paths. Milling operations remove material to form the part’s outer shape and complex surfaces, while drilling operations create precise holes for fasteners or assembly. Additional cutting operations are performed to trim excess material and shape detailed edges or small features of the part.

For complex drone parts, machining can be completed in a single setup using 5-axis CNC machines, which allow multiple tool angles and enable accurate machining of complex geometries with fewer repositioning steps.

Post-Processing

Once machining is completed, the part moves to post-processing, including surface finishing and inspection. Surface treatments such as polishing, anodizing, or coating are applied to improve appearance, durability, and corrosion resistance. Inspection is then performed to verify dimensional accuracy and overall quality, ensuring the finished drone part meets design and performance requirements.

Drone components serve distinct functional purposes, including structural parts (frames, arms), propulsion and electronic system parts (motor mounts, propeller hubs), and payload components (gimbals, sensor housings). Below are common drone part types suitable for CNC machining:

Drone Frames

The frame is the structural backbone of a drone. CNC machining ensures precise dimensions and a strong yet lightweight structure. Frames are typically CNC-cut from carbon fiber or machined from aluminum, providing rigidity and stable support for batteries, flight controllers, and sensors.

Arms

Drone arms connect the motors to the frame. CNC-machined arms are designed to optimize weight distribution, and minimize vibration of the drone. Advanced designs of CNC-machined arms include reinforced joints or hollow structures to balance strength and weight.

Motor Mounts

Motor mounts stabilize the motors and directly affect flight efficiency and propeller longevity. Precision CNC machining ensures perfect alignment and minimal vibration, improving thrust transfer. Many mounts are made from aluminum alloys, providing rigidity and helping dissipate heat. Some designs also incorporate vibration-dampening features to protect sensitive components.

Propellers and Hubs

CNC-machined propeller hubs and adapters ensure balanced rotation and reduce vibration. Precision machining is especially important for high-speed drones, where even minor imbalance affects stability. Well-designed hubs also contribute to energy efficiency, lower noise, and overall flight reliability.

Gimbals and Camera Mounts

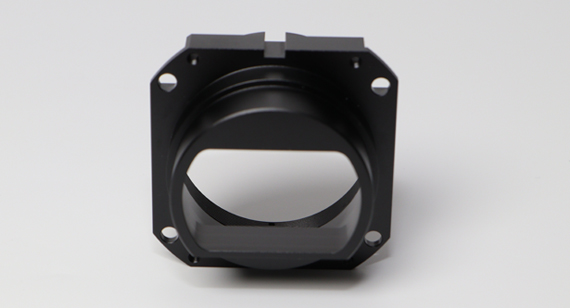

Gimbals and camera mounts ensure stability for aerial photography and surveying applications. CNC machining provides precise dimensions and rigid structures, minimizing vibration transfer. Precision-machined assemblies stabilize and isolate cameras or sensors, ensuring smooth footage and accurate data collection. Some designs include custom housings or lens modification kits for added protection and improved cooling.

Landing Gear

Landing gear protects drones during takeoff, landing, and ground handling. CNC machining enables lightweight yet impact-resistant designs from aluminum or titanium. Complex folding or retractable joints can also be precisely manufactured for portability and reliability.

Electronic Casings

Flight controllers, ESCs, batteries, and other electronic systems require precise housings to ensure durability and performance. CNC machining produces tight-fitting enclosures that protect electronics from vibration, dust, and environmental exposure, ensuring durability and reliable performance of the drone.

Common Materials for CNC Drone Parts

The choice of material affects performance of UAV components, you may need to balance strength, weight, durability, and cost. The most commonly used materials include different metals, composites, and high-performance plastics:

Table 1: Common Materials for CNC Drone Parts

| Material | Subtype | Key Properties | Typical Applications | Notes |

| Aluminum Alloys | 6061-T6 | Lightweight, corrosion-resistant, good strength | Frames, arms, general structural components | Easy to machine, very suitable |

| 7075-T6 | Very high strength, moderate corrosion resistance | Motor mounts, landing gear, high-stress parts | Harder to machine than 6061, suitable with proper tooling | |

| Titanium Alloys | Ti-6Al-4V | Extremely strong, corrosion-resistant, heat-resistant | Critical high-load parts like rotor hubs, landing gear | Suitable but difficult, requires hard or coated tools |

| Stainless Steel | 304 / 316 | High durability, corrosion-resistant | Fasteners, gears, shafts in industrial drones | Only for small parts, heavier and slower to machine |

| Carbon Fiber Composites | N/A | Very high strength-to-weight ratio, rigid, fatigue-resistant | High-performance frames and arms, racing drones, professional aerial photography drones | CNC router-cut, dust control needed |

| Engineering Plastics | ABS | Lightweight, impact-resistant, cost-effective | Enclosures, casings, battery pads | Easy to machine |

| Nylon | Impact-resistant, lightweight | Non-structural mounts, protective parts | CNC friendly | |

| Delrin (POM) | Excellent dimensional stability, tight tolerances | Precision mounts, gimbal parts | Easy to machine, good for tight tolerances | |

| PEEK | High temperature resistance, electrical insulation, strong | Specialized electronic housings, high-stress non-structural parts | Difficult to machine, premium material |

CNC drone parts are designed to meet the specific demands of different operational environments. Each application requires tailored materials, precision tolerances, and design features to ensure optimal performance, reliability, and safety. Common applications include:

1. Precision Agriculture

Drones for crop spraying or agricultural monitoring require components that can handle heavy payloads and repeated mechanical stress. For example,

2. Infrastructure Inspection

Drones inspecting pipelines, power lines, or buildings demand precise sensor alignment and environmental protection. For example,

3. Cinematography

Professional filming drones require high precision, minimal vibration, and lightweight construction for smooth footage. For example,

4. Military Applications

Military drones demand extreme reliability, high precision, and adaptability to harsh environments. CNC machining produces UAV parts that meet these requirements:

5. Consumer and Competitive FPV

Racing drones prioritize performance, durability, and customization. CNC-machined parts help meet these demands:

When it comes to building high-performance drones, the choice of components can make all the difference. CNC machined drone parts offer a range of advantages that are hard to beat.

Precision and Structural Stability

CNC machining is controlled by computer programs, allowing for extremely high precision. An UAV component is cut from a single block of material, resulting in superior structural integrity compared to 3D-printed or injection-molded components.

Wide Material Selection

CNC can work with a variety of high-performance materials such as aluminum, titanium, steel, and engineering plastics. This flexibility allows drone designers to optimize weight, strength, and temperature resistance, enhancing both flight performance and durability.

Consistency Across Parts

Because CNC machines follow exact programmed paths, every part produced is almost identical. This ensures consistent dimensions, reduces assembly errors, and increases overall flight reliability—a crucial factor for multi-rotor drones where balance is key.

Durability

CNC UAV components are typically more resistant to wear because they are machined from solid materials. They maintain their performance even in harsh conditions and can withstand impacts better than 3D-printed parts, resulting in longer-lasting, reliable components.

Customizability

Designs can be optimized using CAD or AI tools, allowing for complex geometries and lightweight structures. CNC machining makes it easy to create parts tailored for different applications—whether for racing, aerial photography, or industrial drones—while also supporting small-batch custom production.

Rapid Prototyping and Efficient Production

CNC machining supports small-batch rapid production, enabling quick iteration of designs. Prototypes can be delivered in as little as 72 hours, and the process scales efficiently to larger production runs, ensuring both speed and consistency. While extremely complex parts may take slightly longer to machine, CNC remains a highly reliable and efficient production method.

Selecting high-quality CNC drone components is crucial for performance, safety, and operational efficiency in industrial applications. Consider the following factors:

Choose materials based on the drone’s structural and operational requirements. Consider factors such as strength, weight, corrosion resistance, and thermal stability. Selecting the right material ensures that each component performs reliably under intended conditions while maintaining durability and optimal operational efficiency.

2. Component Compatibility and Standardization

Ensure that part dimensions, mounting points, and interfaces are fully compatible with your drone platform. Standardized components reduce assembly errors, facilitate maintenance, and allow for interchangeability in production environments.

3. Precision and Tolerances

CNC UAV components manufactured with tight tolerances minimize vibration, improve system accuracy, and ensure seamless integration with sensors, cameras, and gimbals. High-precision parts are essential for industrial applications such as inspection, surveying, or mapping, where performance reliability is critical.

4. Manufacturer Reliability

Partner with experienced CNC manufacturers with a proven track record in producing aerospace or industrial-grade components. Reliable suppliers maintain strict quality control, ensure material traceability, and adhere to engineering specifications, ensuring consistent component quality.

5. After-Sales Support

Choose manufacturers that provide comprehensive after-sales support, including engineering assistance, design optimization, and replacement services. Strong support reduces downtime and ensures consistent, reliable operation of drones in commercial and industrial deployments.

CNC drone parts provide unmatched precision, strength, and customizability, making them essential for modern drone manufacturing. Whether you are building drones for racing, aerial photography, or industrial applications, precision CNC components can enhance your drone’s stability, performance, and safety. By carefully selecting materials, tolerances, and reliable manufacturers, you can create drones that are not only high performing but also durable and reliable.

If you are looking for high-quality CNC components, VMT CNC Machining Factory can help you achieve your goals. With advanced CNC capabilities and strict quality control, VMT ensures that every part you order meets the highest standards of precision and durability. Visit our CNC drone parts services to explore how you can customize your drone parts and take your UAV projects to the next level. Welcome to contact us!

Q1: How do CNC parts compare to 3D printed parts?

CNC parts offer higher precision and strength, suitable for high-load or high-speed components. 3D printed parts are better for rapid prototyping or lightweight, low-stress components.

Q2: What factors affect CNC machining costs?

Material choice, part size, precision, batch quantity, and post-processing requirements all influence cost.

Q3: Which drone parts are most worth upgrading to CNC?

Frames, arms, motor mounts, camera mounts, and propeller supports typically have the greatest impact on flight performance.

Q4: How precise are CNC drone parts?

CNC drone parts are typically manufactured with tight tolerances, often within ±0.05 mm or better. High precision helps reduce vibration, improve alignment, and ensure stable integration of motors, sensors, and gimbal systems.

Q5: Are CNC drone parts suitable for custom or small-batch production?

Yes. CNC machining is well suited for custom designs and small-batch production, allowing fast design iteration while maintaining consistent quality and repeatable accuracy across parts.

Q6: How do CNC drone parts improve durability and service life?

Because CNC parts are machined from solid materials, they offer superior wear resistance and structural integrity. This makes them more reliable in long-term use and in demanding environments compared to molded or printed components.