15 years one-stop China custom CNC machining parts factory

6 |

Published by VMT at Nov 15 2025 | Reading Time:About 4 minutes

6 |

Published by VMT at Nov 15 2025 | Reading Time:About 4 minutes

If you're unsure whether CNC milling or laser cutting fits your project, you're not alone. Many people struggle because the machining process directly affects cost, tolerance, finish, and production speed. The good news? Once you understand the basics of each method, choosing the right one becomes simple and stress-free.

To choose between CNC milling and laser cutting, compare your material type, required precision, part geometry, and production speed. CNC milling is best for thick materials and complex 3D shapes, while laser cutting is ideal for fast, clean 2D cutting. Choose the process that aligns with your tolerance needs, budget, and design requirements.

Now that you understand how to approach your choice, let’s break down each process so you can decide confidently and avoid unnecessary machining expenses.

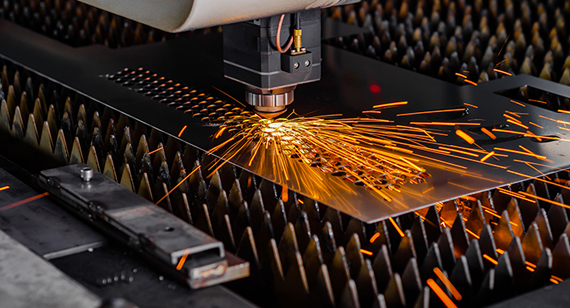

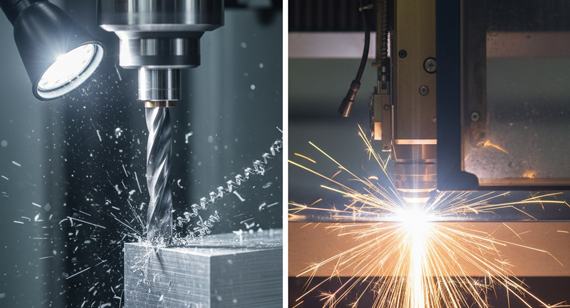

CNC milling is a machining process where a rotating cutting tool removes material from a solid block to create precise shapes. You use it when you need accurate 3D parts, tight tolerances, or detailed features that laser cutting cannot achieve. This milling process is fully automated through CNC programming, ensuring consistent quality for CNC milled parts and CNC machined parts.

Commonly Used Materials for CNC Milling:

Metal Materials

You can machine many metal materials using CNC milling, including aluminum, steel, stainless steel, brass, copper, and titanium. These metals offer strength, durability, and consistent cutting performance, making them ideal for precision milling and CNC machining services.

Plastic Materials

CNC milling also works well with plastics such as ABS, POM (Delrin), Nylon, PMMA (Acrylic), PC (Polycarbonate), and PEEK. These materials are lightweight, easy to machine, and great for prototypes or parts that require chemical or electrical insulation.

CNC Milling Materials Table

Metal Materials for CNC Milling

| Material |

Machinability Level |

Key Advantages |

Typical Applications |

| Aluminum (6061, 7075) |

Easy | Lightweight, low cost, good strength | Enclosures, brackets, prototypes |

| Stainless Steel (304, 316) |

Moderate | Corrosion-resistant, strong | Food equipment, medical parts |

| Carbon Steel (1018, 1045) |

Moderate | Strong, affordable | Structural parts, tooling |

| Brass |

Easy | Excellent precision, smooth finish | Connectors, valves, decorative parts |

| Copper |

Hard | Conductive, corrosion-resistant | Electrical parts, heat sinks |

| Titanium |

Difficult | High strength-to-weight ratio | Aerospace, medical implants |

Plastic Materials for CNC Milling

| Material |

Machinability Level |

Key Advantages |

Typical Applications |

| ABS |

Easy | Tough, inexpensive | Housings, prototypes |

| POM (Delrin) |

Easy | High stiffness, low friction | Gears, bearings |

| Nylon |

Moderate | Strong, flexible | Bushings, spacers |

| PMMA (Acrylic) |

Easy | Highly transparent | Displays, light guides |

| PC (Polycarbonate) |

Moderate | Strong, impact-resistant | Safety covers, mechanical parts |

| PEEK |

Difficult | High-performance, heat-resistant | Aerospace, medical devices |

The cost of CNC milling depends on several factors, including your material choice, part complexity, production volume, and finishing requirements. Because CNC milling is a subtractive process, more cutting time and more tool movements generally mean higher machining fees. Understanding these cost drivers helps you plan your budget and avoid unexpected charges from CNC milling services or CNC machining factories.

CNC milling costs can vary widely because every part requires different materials, precision levels, and machining time. When you understand the cost factors, you can design smarter, reduce waste, and avoid unnecessary expenses when working with CNC milling services or a CNC machining factory.

Material Type

Material choice has a major impact on CNC milling pricing. Aluminum is generally the most affordable, while tougher materials like stainless steel, copper, or titanium raise tool wear and cutting time, increasing overall cost.

Design Complexity

The more detailed or complex your part is, the longer the milling operation takes. Deep pockets, thin walls, tight corners, or 3D features require slower speeds and more tool changes, which increases cost.

Production Volume

Low volumes have higher unit prices because programming and setup costs are spread across fewer parts. Higher quantities reduce the cost per piece, making CNC milling more cost-effective for batch production.

Machining Time

Machining time is one of the biggest cost drivers. Hard materials, complex geometry, and slow cutting speeds add to the time required to mill your CNC machined parts.

Labor Costs

Labor includes programming, setup, inspection, and post-processing. Complex parts that require multiple fixtures or manual finishing will cost more.

Tolerances and Precision

Tighter tolerances require slower feeds, special tools, and more inspections, all of which increase cost. Only specify high precision where it is functionally necessary.

Finishes like anodizing, polishing, bead blasting, powder coating, or passivation add to the final cost. These additional steps also increase lead time.

Tools

Specialized or custom tools increase milling costs. Hard materials wear tools faster, requiring tool replacements that add to the total project cost.

Laser cutting is a non-contact machining process that uses a high-energy laser beam to cut materials with speed and precision. You use this method when you need clean edges, fine details, or fast production for flat 2D shapes. The laser cutting process is widely used in CNC cutting, laser fabrication, and precision laser cutting for both prototypes and mass production.

Commonly Used Materials for Laser Cutting

Metal Materials

Laser cutting works well with many metals, including stainless steel, carbon steel, aluminum, brass, and copper. These materials cut cleanly and quickly, making them ideal for parts that require smooth edges and fast production.

Plastic Materials

Plastics such as acrylic (PMMA), polycarbonate (PC), PETG, ABS, and some types of nylon can be laser-cut with excellent edge quality. Acrylic is especially popular because it produces crystal-clear, flame-polished edges.

Laser Cutting Materials Table

Metal Materials for Laser Cutting

| Material |

Laser Cutting Quality |

Key Advantages |

Typical Applications |

| Stainless Steel |

Excellent | Smooth edges, corrosion-resistant | Enclosures, brackets, kitchenware |

| Carbon Steel |

Excellent | Fast cutting, low cost | Structural parts, signage |

| Aluminum |

Good | Lightweight, clean edges | Panels, frames, prototypes |

| Brass |

Moderate | Decorative finish, good detail | Decorative parts, fixtures |

| Copper |

Moderate | Conductive, reflective | Electrical components, bus bars |

Plastic Materials for Laser Cutting

| Material |

Laser Cutting Quality |

Key Advantages |

Typical Applications |

| Acrylic (PMMA) |

Excellent | Clear, flame-polished edges | Displays, signs, lenses |

| Polycarbonate (PC) |

Fair | Impact-resistant | Covers, mechanical parts |

| PETG |

Good | Flexible, smooth edges | Packaging, protective panels |

| ABS |

Fair | Tough, durable | Housings, prototypes |

| Nylon |

Moderate | Strong, flexible | Gaskets, wear parts |

The cost of laser cutting depends on material type, thickness, cutting speed, laser power, and design complexity. Because the laser cutting process is fast and efficient, simple 2D shapes usually cost less than CNC milling. However, thicker metals, detailed patterns, and high-power settings can increase the overall price when working with a CNC machining factory or laser fabrication service.

Laser cutting costs vary based on material, thickness, laser type, and design complexity. Understanding these factors helps you plan your budget more accurately and avoid unexpected charges from laser cutting services or CNC machining factories.

Material Type

Different materials respond differently to laser cutting. Carbon steel is affordable and cuts quickly, while stainless steel and aluminum generally cost more due to slower speeds and higher gas usage.

Thickness

Thicker materials require more laser power, slower cutting speeds, and more gas pressure. This increases overall cutting time and cost.

Strength

Stronger materials such as stainless steel require more energy to cut, which increases both power consumption and total machine time.

Reflectivity

Highly reflective metals like aluminum, brass, and copper are harder to cut because they reflect laser energy. This requires higher power settings and increases machining costs.

Laser Power

Higher laser power cuts faster but consumes more energy. Lower power is cheaper but slower. Your material and thickness determine the power needed.

Laser Type

CO₂ lasers handle plastics and organic materials well, while fiber lasers work better for metals. Fiber lasers usually offer higher efficiency and lower operating costs.

Machine Size

Larger laser cutters have higher operating and maintenance costs. Cutting very large sheets may cost more due to machine size and setup time.

Power Consumption

Laser cutting machines consume significant electricity, especially at high power levels. Longer cutting time means higher power costs.

Cutting Speed

Faster cutting reduces cost, while slower cutting increases it. Speed depends on material type, thickness, and power settings.

Design Complexity

More intricate shapes, corners, holes, and patterns increase cut length and time, raising total cost.

Gas Usage

Laser cutting uses gases like oxygen, nitrogen, or air. High-pressure nitrogen cutting produces cleaner edges but costs more.

Labor Costs

Labor includes programming, setup, material handling, and inspection. Complex designs or multiple setups increase labor fees.

Post-processing

Extra steps such as deburring, polishing, bending, or surface treatment add to the final price.

When deciding between CNC milling and laser cutting, understanding their key differences helps you choose the right process for your part. Factors like precision, speed, material type, and cost all vary between the two methods, and knowing these distinctions can save time and money.

Process Comparison Table

| Factor |

CNC Milling |

Laser Cutting |

Notes / Tip |

| Process |

Subtractive machining using rotating cutting tools | Non-contact cutting with high-energy laser | Milling shapes 3D geometry; laser excels at 2D cuts |

| Tolerances & Precision |

High precision (±0.01 mm typical) | Good precision (±0.05 mm typical) | Use milling for very tight tolerances |

| Production Speed & Efficiency |

Slower for complex parts | Faster for simple 2D cuts | Laser is ideal for high-volume sheet cutting |

| Material Thickness |

Works well on thick and thin materials | Best for thin to medium sheets | Milling is better for thick metals |

| Material Type |

Metals, plastics, composites | Metals and plastics; some reflective materials harder | Milling handles tougher materials better |

| Surface Finish & Quality |

Excellent with proper tooling and feed | Smooth edges, minimal mechanical stress | Milling may require finishing; laser cuts often need no deburring |

| Cost-Effectiveness |

Higher for low-volume, complex parts | Lower for flat 2D parts | Laser is faster, but milling adds value for 3D or high-strength parts |

| Setup Time |

Longer due to fixturing and tool selection | Shorter; mostly programming | Laser cutting reduces setup for simple designs |

Both CNC milling and laser cutting offer unique advantages, but each also has limitations. Knowing these pros and cons helps you select the right process for your project, whether you prioritize speed, precision, or material versatility.

CNC Milling and Laser Cutting: Advantages

CNC milling and laser cutting excel in different areas. CNC milling is strong for 3D shapes and precise tolerances, while laser cutting shines with fast, clean 2D cuts. Understanding these advantages allows you to use each process efficiently.

Advantages of CNC Milling

Tip: Use CNC milling for parts that need detailed 3D features or high-strength materials to maximize quality and durability.

Advantages of Laser Cutting

Tip: Laser cutting is best for flat designs where speed and edge quality are critical—avoid it for thick or complex 3D parts.

CNC Milling and Laser Cutting: Disadvantages

While CNC milling and laser cutting are both powerful machining processes, each has limitations. Knowing the disadvantages helps you avoid costly mistakes and choose the best process for your part.

Disadvantages of CNC Milling

CNC milling is versatile and precise, but it comes with certain drawbacks that can affect production speed and cost.

Slower Production Speed: CNC milling takes longer for complex or large-volume parts because of multiple tool paths and setups. Compared to laser cutting, milling can be slower, especially for simple 2D shapes.

Initial Cost: CNC milling machines and tooling are expensive. The setup cost, including programming and fixturing, adds to the initial investment for small orders.

Disadvantages of Laser Cutting

Laser cutting is fast and precise for many applications, but it also has limitations that affect material choice and part quality.

Material Thickness Limitations: Laser cutting works best with thin to medium-thickness sheets. Thick metals require higher power or multiple passes, increasing cost and reducing efficiency.

Heat-Affected Zone (HAZ): Laser cutting generates heat that can affect edges, causing discoloration or minor warping in some metals and plastics.

Table: CNC Milling vs. Laser Cutting: Advantages and Disadvantages

| Process |

Advantages |

Disadvantages |

Notes / Tips |

| CNC Milling |

- High precision and tight tolerances - Works with metals, plastics, composites, and tough materials - Durable parts suitable for structural applications - Handles complex 3D geometries |

- Slower production for simple or high-volume parts - High initial setup cost and tool investment - Tool wear over time |

Best for parts requiring 3D shapes, high strength, or tight tolerances. Reduce costs by consolidating parts in one setup. |

| Laser Cutting |

- Fast cutting for thin to medium sheets - Fine detail and intricate patterns - Non-contact processing reduces deformation and tool wear - Minimal post-processing for clean edges |

- Limited to thinner materials - Heat-affected zone (HAZ) may affect edges - Reflective metals (copper, brass) harder to cut - Cannot easily produce 3D features |

Ideal for high-volume 2D flat parts with clean edges. Avoid thick materials and overly complex 3D designs. |

Choosing the right machining process depends on your part’s material, geometry, tolerance, and production requirements. Knowing when to use CNC milling or laser cutting helps you optimize cost, speed, and quality.

When to Choose CNC Milling

Tip: CNC milling is ideal for parts with multiple surfaces, holes, and 3D features that cannot be cut with a laser.

When to Choose Laser Cutting

Tip: Use laser cutting for high-volume, simple, or decorative flat parts to save time and reduce costs.

Choosing between CNC milling and laser cutting depends on your project’s material, geometry, precision requirements, and production volume. CNC milling excels in producing complex 3D parts with tight tolerances and durable materials, while laser cutting is ideal for fast, precise 2D cuts on thin to medium sheets. By understanding each process’s advantages, limitations, and cost factors, you can select the method that optimizes efficiency, quality, and budget for your CNC machined parts or laser-fabricated components.

1. What is better, CNC or laser?

It depends on your project. CNC milling is better for 3D parts, thick metals, and tight tolerances. Laser cutting is ideal for fast, precise 2D cuts on thin to medium sheets. Choosing the right process depends on material, geometry, production volume, and budget.

2. Can laser CNC cut wood?

Yes, laser cutting can precisely cut and engrave wood. Thin sheets or plywood are easiest to cut, while thicker wood may require multiple passes. Always ensure proper ventilation and safety when laser cutting wood.

3. Can a laser cutting machine cut glass?

Standard lasers cannot fully cut glass, but specialized CO₂ laser systems or water-assisted lasers can engrave or mark it. Cutting thick or brittle glass requires careful setup to avoid cracking.

4. CNC Machining vs. CNC Milling: What are the differences?

CNC machining is a broad category that includes CNC milling, CNC turning, drilling, and other processes. CNC milling specifically uses rotating cutting tools to remove material and create 3D parts.

5. CNC Turning vs. CNC Milling: What are the differences?

CNC turning rotates the workpiece while a cutting tool shapes it, making it ideal for cylindrical parts. CNC milling keeps the workpiece stationary and moves the cutting tool along multiple axes to produce 3D shapes.

6. CNC Milling vs. Traditional Machining: What are the differences?

Traditional machining relies on manual operation, which can be slower and less precise. CNC milling automates the process with computer control, producing higher precision, consistent quality, and faster production for complex parts.