15 years one-stop China custom CNC machining parts factory

288 |

Published by VMT at Apr 24 2025 | Reading Time:About 6 minutes

288 |

Published by VMT at Apr 24 2025 | Reading Time:About 6 minutes

When manufacturing precision components, surface finish and geometric accuracy are critical—but achieving both can be challenging, especially when working with complex external contours or grooves. Many machinists struggle to find a milling method that delivers clean side finishes without excessive tool wear or time-consuming setup. That’s where side milling comes in. This specialized CNC milling technique is designed to tackle those exact issues. By focusing on the sides of a workpiece, side milling creates smooth, accurate surfaces that are ideal for slots, chamfers, and profiles. In this guide, you’ll learn everything you need to know about side milling—from how it works to the tools involved, its advantages, and when to use it. Whether you’re managing large-scale CNC machining services or prototyping a single custom part, side milling can be the solution to your manufacturing challenges.

Side milling is a CNC machining technique used to cut the vertical or angled sides of a workpiece with the side of the milling cutter. It delivers precise edge finishes and is ideal for slots, grooves, and profiles. It’s essential for CNC machined parts that require detailed surface definition or complex geometries on their vertical planes.

To fully understand the value of side milling in modern CNC milling operations, it’s important to explore how the process works, what makes it different from other types of milling, and why it’s used across so many industries. Let’s start by breaking down the fundamentals of side milling and how it operates within the broader scope of CNC machining.

Side milling is one of the most effective techniques used in CNC machining to process the vertical or angled sides of a component. It is distinct from other milling methods like face milling, which primarily targets the top surface. In side milling, the cutting action is performed using the side of a rotating cutter, which removes material along the outer edges or sides of the workpiece. This makes it a perfect choice for creating slots, contours, shoulders, and intricate profiles that require high dimensional accuracy and clean side finishes.

Side milling is particularly useful in CNC prototype machining where precision and consistency are vital, even in small production runs. The process is compatible with a wide variety of materials—from aluminum and stainless steel to plastics and exotic alloys—making it a flexible method within CNC machining services. With the right tooling and setup, side milling allows manufacturers to achieve high-performance results in less time, ensuring both quality and efficiency.

What Is Side Milling?

Side milling is a CNC milling operation in which the cutting is performed by the side edge of the milling cutter rather than its face. This method enables the machine to remove material from the sides of the workpiece, forming vertical or angled edges. The cutter used for this process typically features helical or straight teeth positioned along its cylindrical body, allowing it to slice through material horizontally as the spindle rotates.

Side milling is typically conducted on vertical or horizontal milling machines, and is commonly used in the production of CNC machined parts that require detailed side features, such as grooves, keyways, or steps. In multi-axis CNC machining, side milling can be programmed to follow complex 3D paths, further enhancing its versatility.

The success of side milling depends on key parameters like feed rate, spindle speed, depth of cut, and tool geometry. When optimized correctly, side milling can produce smooth finishes, maintain tight tolerances, and minimize post-machining operations like grinding or polishing.

How Does Side Milling Work?

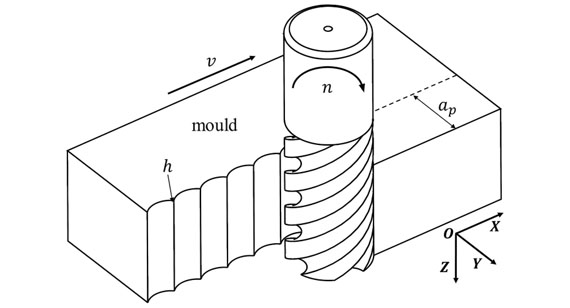

In a side milling operation, the cutter rotates as it moves along the side of the workpiece. This simultaneous rotation and horizontal movement allow the tool’s edges to engage the workpiece material and shear it off in a controlled manner. Depending on the setup, the cutter can engage the material from the side, the top, or both, making it suitable for both roughing and finishing operations.

A common setup involves securing the workpiece firmly to the machine table using a vise or fixture. The CNC controller guides the milling cutter along a predefined toolpath that corresponds to the desired geometry. Variables such as cutting direction (climb vs. conventional milling), tool path overlap, and cutter entry/exit strategies all play a role in the surface finish and machining efficiency.

When done right, side milling can significantly reduce the number of machining passes needed, helping to streamline workflows for both prototype and production parts. The key lies in using the correct combination of tool material, cutter type, machine rigidity, and software programming—making it a true testament to the precision capabilities of modern CNC machining.

Side milling requires a combination of specialized tools and precision equipment to achieve high-quality results, especially in CNC machining environments. The selection of the right tools directly impacts the performance, surface finish, and dimensional accuracy of CNC machined parts. To ensure efficient side milling, every component of the machining system—from the cutting tool to the machine itself—must work in harmony.

Milling Cutters

The most critical tool in side milling is the milling cutter. Side milling typically uses slab mills, side and face mills, or staggered tooth cutters, depending on the complexity and requirements of the job. These cutters are designed with cutting edges along the circumference and sides, allowing them to perform lateral cuts into the workpiece. The number of teeth, tooth geometry, helix angle, and coating of the tool (such as TiN, TiAlN) are chosen based on the material being machined and the desired finish.

CNC Milling Machines

A high-precision CNC milling machine is essential for effective side milling. Vertical and horizontal milling machines are both capable of performing side milling, but horizontal machines are often preferred for deep cuts and aggressive material removal. Multi-axis CNC machines (3-axis, 4-axis, or even 5-axis) enhance versatility by enabling the tool to approach the workpiece from different angles, which is particularly useful in complex CNC prototype machining.

Workholding Fixtures

Workpiece stability is crucial in side milling to prevent vibration, movement, or dimensional errors. Precision vises, custom fixtures, or modular clamping systems are used to secure the workpiece firmly during cutting. For large or irregularly shaped parts, custom jigs may be designed to maintain alignment and accuracy throughout the operation.

Tool Holders and Spindles

Tool rigidity and alignment are equally important. High-precision tool holders (such as collet chucks or hydraulic chucks) ensure that the cutter remains stable under cutting forces. The spindle system of the CNC machine must offer sufficient torque, speed range, and rigidity to support the chosen cutter and material.

Coolant and Chip Management

Side milling generates significant heat and chips, especially in high-speed CNC machining services. Therefore, coolant systems—such as flood coolant, mist, or through-tool cooling—are used to control temperature and prolong tool life. Chip conveyors or vacuum systems are also necessary to evacuate debris and prevent chip recutting, which can damage the surface finish.

By investing in the right tools and equipment, side milling operations can achieve exceptional quality and efficiency. Whether producing high-precision stainless steel parts or rapid CNC prototypes, a well-equipped shop floor is the foundation of successful side milling.

Side milling is a unique machining technique that offers specific advantages and applications compared to other milling methods. Understanding its key differences helps manufacturers choose the right process for the desired result, particularly when producing precision CNC machined parts or prototypes.

Cutting Orientation

The most noticeable difference is in the direction of material removal. Side milling involves the cutter removing material from the side of the workpiece using the peripheral teeth of the milling tool. In contrast, face milling removes material from the top surface of the workpiece using the face (bottom) of the cutter. Meanwhile, end milling combines both approaches, using the tool’s end and sides to create pockets, slots, or contours.

Tool Geometry and Application

Side milling cutters are often thicker and have more aggressive cutting profiles compared to face or end mills. They are specifically designed to handle lateral loads and provide deep, clean cuts along the sides of workpieces. These tools are especially useful when producing grooves, slots, and side profiles, making them ideal in both CNC milling and traditional setups.

Face milling tools, on the other hand, are optimized for creating smooth, flat surfaces, while end mills offer versatility for detailed 3D contouring, hole drilling, and pocketing.

Suitability for CNC Machining

In CNC machining services, side milling is frequently chosen when precision edge profiles or deep channels are required. It delivers excellent dimensional control and repeatability, especially for stainless steel CNC machined parts. With multi-axis CNC milling machines, side milling can be automated and optimized for complex geometries, unlike traditional side milling setups that may lack consistency and efficiency.

Surface Finish and Feature Complexity

Side milling often produces a better finish on vertical walls compared to face or end milling, especially when using staggered tooth cutters that reduce chatter and chip load. For applications requiring tight tolerances or fine details—such as in aerospace or medical CNC prototype machining—side milling becomes the go-to method.

In summary, side milling stands apart from face and end milling due to its cutting direction, tool configuration, and application focus. It’s an essential part of the CNC machining toolkit, especially when precision side features are required on high-performance parts.

In CNC milling and traditional machining, the type of side milling cutter you choose directly impacts machining quality, surface finish, and productivity. Understanding the various types of side milling helps manufacturers and machinists select the best tool for specific applications—especially when dealing with complex CNC machined parts or prototypes.

Normal Milling Cutters

Normal side milling cutters are typically straight-tooth or helical-tooth disc-shaped tools used for cutting grooves or finishing the sides of workpieces. These cutters are mounted on horizontal spindles and are ideal for general-purpose machining. They are commonly used in CNC machining services for producing precise slots, shoulders, and external features with straight, vertical profiles.

These cutters offer high rigidity and stability, making them suitable for cutting through tough materials like stainless steel. For industries requiring CNC prototype machining with consistent edge quality—such as aerospace or industrial manufacturing—normal side milling cutters are a reliable choice.

Staggered Tooth Milling Cutters

Staggered tooth side milling cutters are designed for more efficient chip removal and smoother cutting action. The teeth are arranged in an alternating pattern, which reduces cutting force and vibration, especially in deep or aggressive cuts. This configuration also helps improve surface finish and extend tool life, which is particularly beneficial when machining hardened materials or large-volume runs.

Because staggered tooth cutters create less heat and distribute the load evenly, they’re often used in high-precision CNC machining applications where thermal expansion or tool deflection could impact the final result. These cutters are excellent for machining aluminum, titanium, and various grades of stainless steel CNC machined parts, providing cleaner edges and superior dimensional control.

Achieving high-quality results in side milling, especially in CNC machining environments, depends on a variety of interrelated factors. These factors affect surface finish, dimensional accuracy, tool life, and overall efficiency. Whether you're working on high-precision CNC machined parts or quick-turn CNC prototype machining, understanding and controlling these elements is essential for optimal performance.

Feed Rate and Depth of Cut

The feed rate (how fast the tool moves across the workpiece) and the depth of cut (how deep the tool penetrates) play a major role in side milling quality. Too high of a feed rate can cause tool chatter, poor surface finish, or even breakage. Too shallow of a cut, on the other hand, may increase machining time and wear the tool inefficiently. Finding the right balance ensures smoother finishes and longer tool life, especially in high-volume CNC machining services.

Tool Design: Number of Teeth, Chip Formation, and Helix Angle

The number of teeth on the cutter impacts how efficiently chips are removed. More teeth can improve surface finish, while fewer teeth reduce load and heat in tough materials. The chip formation—how material is sheared and removed—must be optimized to avoid built-up edges and material drag. The helix angle of the cutter influences cutting smoothness: higher angles reduce cutting forces and improve finish, while lower angles are better for harder materials.

Cutting Tool Material

Tool material determines how long the cutter lasts and how well it withstands heat and wear. Common choices include high-speed steel (HSS) and carbide. For hard metals like stainless steel, carbide is preferred in CNC milling operations for its durability and resistance to thermal deformation.

Machine Spindle Accuracy and Alignment

Precision begins with the machine itself. If the spindle is misaligned, even the best tools and settings will produce subpar results. Proper spindle alignment and rigidity are crucial for consistent milling depth and edge accuracy—especially when working with CNC machining parts that require tight tolerances.

Tool Hardness and Workpiece Material

Tool hardness must exceed that of the workpiece to maintain cutting effectiveness. Materials like stainless steel, aluminum, or titanium require different hardness levels and tool coatings. The hardness and machinability of the workpiece material also determine how aggressive the milling parameters can be.

Tool Speed and Movement

The spindle speed (RPM) and the toolpath strategy affect how the cutter engages with the material. Improper speeds may cause overheating or tool deflection. With CNC machining, this is controlled via programming, making it easier to optimize and reproduce consistently across batches.

Operator Skill and Training

Even with advanced CNC machining services, the machinist’s expertise still matters. A well-trained operator can interpret machine feedback, make real-time adjustments, and prevent problems before they impact production. Proper training ensures safety, maximizes equipment life, and guarantees consistent part quality.

In the world of CNC milling, selecting the right milling technique is crucial for achieving precise dimensions, surface finishes, and production efficiency. Among the most common methods are side milling, flat milling, and end milling—each with unique characteristics and best-use scenarios. Understanding their differences helps manufacturers choose the most suitable technique for specific applications, whether producing detailed CNC machined parts or prototypes through CNC prototype machining.

Side Milling

Side milling involves cutting along the side of a workpiece using the side edges of the milling cutter. It is ideal for machining vertical surfaces, slots, steps, and grooves. The cutter’s axis is parallel to the surface being machined. Side milling is commonly used in CNC machining services when there’s a need to shape external features or remove material from the sides of a part with high accuracy. It offers great versatility in texture, finish, and dimensional control.

Flat milling, often referred to as face milling, uses the cutting edges on the periphery and the face of the tool to machine large, flat surfaces. The cutter axis is perpendicular to the workpiece surface, making this method ideal for creating flat surfaces, preparing rough stock, or achieving excellent surface finishes. It is generally faster than side milling when working on large surface areas but is limited to horizontal machining.

End milling combines both axial and radial cutting and is widely used in CNC machining for profiling, contouring, slotting, and drilling applications. The tool resembles a drill bit with cutting edges at the tip and along the sides. End milling is especially useful for detailed features and complex 3D shapes. It can cut in any direction, making it extremely versatile, especially in CNC prototype machining.

Key Differences

What Are the Factors That Affect Milling Quality?

Achieving high-quality results in CNC milling, especially for precision components like CNC machined parts, depends on more than just the machine or material. Several key factors influence the quality of the milling outcome—ranging from the design of the cutting tool to the operator's skill level. In side milling, where dimensional accuracy and surface finish are critical, understanding and controlling these factors is essential.

Cutting Tool Speeds

The speed at which the cutting tool rotates—known as spindle speed—directly affects the surface finish, tool life, and heat generation during CNC machining. If the tool spins too fast, it can overheat and wear prematurely. Too slow, and the cut might be inefficient or rough. Optimizing cutting speeds based on material type and cutter geometry is essential for maintaining consistent quality.

Feed Rates

Feed rate refers to how fast the tool moves across the workpiece. In side milling, if the feed rate is too high, it may cause tool deflection, chatter, and poor surface finish. If it's too slow, it can lead to unnecessary heat buildup and reduced productivity. Fine-tuning feed rates ensures clean, efficient cutting and longer tool life—critical in both high-volume runs and CNC prototype machining.

Operator Experience

Even with the best machines and tools, operator skill plays a vital role in quality output. A trained operator understands how to fine-tune machine settings, adjust for tool wear, and troubleshoot issues during the milling process. Their experience in detecting early signs of tool failure or misalignment can save time and materials, ensuring the consistent output of CNC machining services.

Tool Design

The geometry, number of teeth, coating, and helix angle of the milling cutter all impact the milling result. For example, staggered tooth cutters reduce vibration in side milling, improving finish and prolonging tool life. Proper chip evacuation design also affects whether the tool can maintain a clean cutting path—especially important in materials like aluminum or stainless steel.

Conclusion

When combining these factors—optimized cutting speeds and feed rates, high-quality tool design, and experienced operation—CNC machining becomes a precision-driven process capable of delivering repeatable, top-quality results. These principles apply across all CNC milling operations, but especially in side milling, where clean edges and precise slot dimensions are essential.

Side milling is a core technique within CNC machining, used for shaping, trimming, and refining the vertical edges of a workpiece. Its precision, versatility, and surface finish make it ideal across various industries. Whether in CNC prototype machining or mass production of CNC machined parts, side milling plays a crucial role in modern manufacturing. Here's how it's commonly applied across different types of operations.

Flat Machining

One of the primary uses of side milling is in creating flat surfaces parallel to the cutter axis. This application is especially important when parts require high dimensional accuracy on the sides—ensuring perfect fit during assembly. With the help of CNC milling, flat side machining becomes highly consistent, making it ideal for aerospace frames, automotive brackets, and precision tooling components.

Grooving

Groove creation is another powerful application of side milling. Whether you're cutting keyways, T-slots, or other intricate grooves, side milling offers clean, sharp results. Grooving is especially vital in the production of parts that need locking features or need to mate with other components. CNC control ensures that grooves are cut to tight tolerances, even on hard materials like titanium or stainless steel.

Contouring

For parts with irregular or curved profiles, contouring with side milling cutters is an effective strategy. The CNC machine moves along programmed paths, allowing for detailed contour machining while maintaining edge quality. This application is widely used in mold making, medical devices, and architectural components requiring decorative or aerodynamic shapes.

Surface Finishing

Side milling is commonly used to refine surface finishes on vertical walls or edges. With the correct feed rate and cutter geometry, manufacturers can achieve near-polished finishes that reduce the need for secondary grinding or polishing. This is particularly valuable in industries like electronics or optical parts, where surface quality is non-negotiable.

Profiling and Chamfering

In precision CNC machining services, profiling the outer edges of a workpiece or adding a chamfer can be done efficiently through side milling. It improves aesthetics, removes sharp edges, and prepares parts for coating or assembly. Chamfers also prevent damage during handling—critical in aerospace and medical applications.

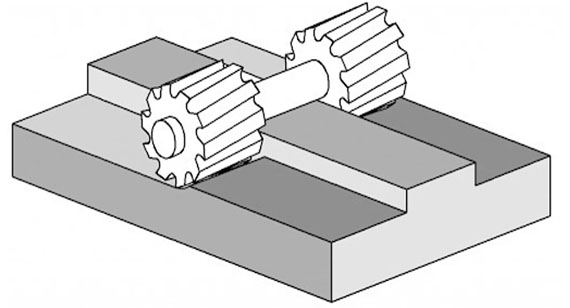

Stride Milling

Stride or straddle milling uses two side milling cutters spaced apart on the same arbor. It’s a time-saving method to machine both sides of a workpiece in one pass, offering symmetrical accuracy and improved productivity. This is especially useful in industrial applications where identical side features are required.

Side milling offers numerous benefits in CNC machining, but it also comes with some challenges. Understanding both the advantages and disadvantages is crucial when deciding whether side milling is the best option for your project.

Advantages of Side Milling

Disadvantages of Side Milling

Side milling, while versatile and highly efficient, does come with its own set of challenges. Understanding these difficulties and knowing how to overcome them is crucial for ensuring a smooth and successful milling process. Let's explore some of the common challenges and solutions.

1. Poor or Inconsistent Chip Evacuation

One of the most significant challenges in side milling is poor or inconsistent chip removal. When chips are not evacuated efficiently, they can interfere with the cutting tool, causing overheating, premature wear, and even damage to the workpiece. The accumulation of chips in the cutting area also reduces the overall efficiency of the operation, increasing the chances of poor surface finish and reduced accuracy.

2. Excessive Vibration or Chatter

Vibration, or chatter, occurs when the tool and workpiece resonate with one another, causing unwanted oscillations that can affect the quality of the milling process. In side milling, vibration can result in a poor surface finish, dimensional inaccuracies, and even premature tool failure. Larger workpieces or those with lower rigidity are especially prone to this issue.

3. Premature or Rapid Tool Wear

Tool wear is inevitable during milling, but in side milling, the constant pressure exerted on the tool can cause it to wear out faster than in other processes. High cutting speeds, hard materials, and improper tool material selection can lead to rapid tool degradation, resulting in poor-quality parts and increased downtime due to frequent tool changes.

4. Tool Breakage

In some cases, side milling can lead to tool breakage, especially when excessive cutting forces or inadequate tool support are applied. Tool breakage not only disrupts the machining process but can also result in scrap parts and expensive downtime.

5. Workpiece Deformation

Deformation occurs when the material being milled undergoes changes in shape due to the forces applied during machining. Thin or soft workpieces are particularly susceptible to bending or warping during side milling, especially when high cutting forces are used or the material is not supported correctly.

By being aware of these challenges and implementing these solutions, you can significantly improve the efficiency and quality of your side milling operations. Ensuring that the milling process is well-organized and optimized will help you achieve the best results while minimizing defects and tool wear.

Safety is paramount in any machining operation, including side milling. The complexity of the process and the high-speed nature of the equipment involved require careful attention to detail and adherence to safety protocols. By following proper safety measures, you can minimize the risk of accidents, protect your equipment, and ensure a safe working environment for operators.

1. Wear Personal Protective Equipment (PPE)

One of the fundamental safety measures in side milling is the use of personal protective equipment (PPE). PPE serves as a protective barrier between the operator and the hazards associated with milling operations, including flying debris, sharp edges, and excessive noise.

2. Organize Your Work Area

A cluttered or disorganized work area increases the risk of accidents. Tools, materials, and machinery should be arranged so that operators can access everything they need easily while minimizing distractions and hazards. Obstructions can interfere with the smooth operation of the milling machine and may even cause accidents when moving workpieces or tools.

3. Positively Position the Workpiece

The workpiece needs to be securely positioned and clamped to the milling machine before starting the operation. A loosely held workpiece can shift during cutting, leading to inaccuracies, tool damage, or even dangerous situations where the workpiece is thrown out of the machine.

4. Use Machine Guards and All Safety Features

Machine guards and safety features on CNC mills and traditional milling machines are designed to protect operators from moving parts and other hazards. Ensuring these safety features are in place and functioning properly is crucial for reducing risks.

5. Choose the Right Cutting Speed and Tool

Using the wrong cutting speed or tool can lead to excessive tool wear, poor machining results, and an increased risk of accidents. High cutting speeds may lead to tool breakage or workpiece deformation, while low speeds can result in inefficient cutting and excess heat buildup.

6. Know the Emergency Stop Button

Every CNC machine comes with an emergency stop (E-stop) button that allows the operator to quickly stop the machine in case of an emergency. Familiarity with this safety feature is vital for preventing accidents in the event of tool failure, machine malfunction, or unforeseen issues during milling operations.

By following these safety considerations, operators can help ensure a safe and productive working environment during side milling operations. Being proactive in maintaining safety standards will not only protect individuals but also enhance the efficiency and precision of the milling process.

When it comes to side milling, choosing the right CNC machining services provider is crucial to achieving high-quality, precise results. VMT CNC Machining stands out as a reliable partner in providing top-notch CNC side milling services for a variety of industries, including aerospace, automotive, medical, and industrial sectors.

Why Choose VMT CNC Machining Services?

VMT offers extensive experience in CNC machining, particularly in side milling operations. Our team of skilled professionals is well-equipped to handle projects that demand high precision, accuracy, and efficiency. From prototyping to large-scale production, VMT ensures that your machining needs are met with the highest quality standards.

Advanced Technology and Equipment

At VMT, we use state-of-the-art CNC machines that are specifically designed for side milling. Our equipment is equipped with advanced features that enhance precision and reduce the risk of errors, ensuring that every part we produce meets the specifications set by our clients. This cutting-edge technology allows us to handle even the most complex side milling tasks with ease.

We are committed to delivering products that meet the highest standards of quality. Our quality control processes are stringent and involve comprehensive inspections at every stage of production. From the initial design to the final product, we ensure that all components are accurately milled, durable, and ready for immediate use. Our focus on quality ensures that our clients receive reliable, long-lasting products.

Customization to Meet Specific Requirements

We understand that each project is unique, and we are committed to providing custom solutions that align with your specific requirements. Whether you need custom tooling, special materials, or a specific milling technique, our team at VMT can tailor our services to suit your needs. This flexibility ensures that you receive precisely the parts you need, without compromise.

Competitive Pricing

VMT offers competitive pricing without compromising on quality. We strive to provide our customers with the best value for their investment. By leveraging advanced technology and efficient processes, we can offer cost-effective solutions for both small and large production runs. Whether you are looking for one-off prototype parts or high-volume manufacturing, VMT ensures that you get the best pricing available in the industry.

Fast Turnaround Times

We understand the importance of meeting deadlines. VMT CNC machining services are designed to provide quick turnaround times without sacrificing quality. Our streamlined processes, coupled with our efficient scheduling system, enable us to meet tight deadlines while maintaining the precision and accuracy that our clients expect.

Expert Consultation and Support

At VMT, we don’t just provide machining services; we offer expert consultation to help guide you through the entire process. From design to final product, our experienced team is available to answer any questions and assist with any challenges you may face. Our goal is to ensure that your project runs smoothly from start to finish.

When you choose VMT for your CNC side milling needs, you are partnering with a company that is committed to delivering high-quality, efficient, and cost-effective solutions. Whether you need complex, precision parts or large-scale production runs, VMT CNC Machining has the expertise, technology, and dedication to meet your needs.

In conclusion, side milling is an essential process in CNC machining that allows for precise and efficient manufacturing of parts with complex side features. It is particularly useful in industries where high accuracy, complex shapes, and consistency are critical. With the right tools, materials, and expertise, side milling can produce high-quality parts for a wide range of applications, from aerospace to medical devices.

VMT CNC Machining stands as a trusted partner for businesses looking for top-tier side milling services. Our commitment to innovation, quality, and customer satisfaction ensures that your project will be handled with the utmost precision and care. With our advanced technology, skilled operators, and comprehensive quality control processes, we guarantee that you’ll receive the best possible results.

If you are looking for reliable, cost-effective, and high-quality CNC side milling services, VMT CNC Machining is your go-to choice. Contact us today to learn more about how we can help you achieve your manufacturing goals.

1. Does tool diameter determine the success of side milling?

Yes, the tool diameter plays a critical role in the success of side milling. Larger diameters are typically used for heavy cuts and high material removal rates, while smaller diameters allow for greater precision in tight spaces.

2. Can side milling be used with CNC machining?

Absolutely! Side milling is a common operation in CNC machining, and CNC machines are equipped to perform it with high accuracy and efficiency. This makes it ideal for manufacturing complex parts with precise side features.

3. How important are axial and radial depths of cut in side milling?

Both axial and radial depths of cut are crucial in side milling. Proper depths help optimize cutting efficiency, reduce tool wear, and prevent vibration or chatter. Balancing these depths ensures smoother cuts and better quality parts.

4. What is the difference between a side milling cutter and a face milling cutter?

A side milling cutter primarily cuts along the sides of the workpiece, while a face milling cutter cuts on the surface of the workpiece. Side milling cutters are designed to handle deeper cuts, whereas face milling cutters are used for flat surface finishing.

5. How to reduce tool deflection in side milling?

To reduce tool deflection in side milling, it is essential to use the correct tool design, cutting speeds, and feed rates. Additionally, ensuring the tool is rigidly secured and using shorter tools can also minimize deflection.

6. What are the three types of milling?

The three primary types of milling are face milling, end milling, and side milling. Each type has its unique applications and is used for different types of cuts and shapes in the manufacturing process.

7. What does it mean if someone is milling?

Milling refers to the process of using rotary cutters to remove material from a workpiece by advancing it against a rotating cutting tool. It is commonly used to create precise parts with a variety of shapes and features.

8. Why is milling so expensive?

Milling can be expensive due to the cost of the machinery, tools, and skilled labor required. Additionally, the precision and quality of the cuts, along with the complexity of the parts, can contribute to higher costs.

9. What is the difference between a regular milling cutter and a side milling cutter?

A regular milling cutter is used for various operations, including face milling and peripheral milling, while a side milling cutter is specifically designed to mill the sides of a workpiece, allowing for deeper cuts.

10. Can an end mill cut sideways?

Yes, an end mill can cut sideways, making it ideal for side milling operations. The cutting edges on the sides of the tool allow it to cut both horizontally and vertically, providing versatility in machining operations.

11. Which is better, down milling or reverse milling?

Down milling is generally preferred for most machining applications due to its higher efficiency and better surface finish. However, reverse milling is sometimes used for specific materials or applications where less heat generation is required.

12. What is the most common type of milling?

Face milling is one of the most common types of milling. It is used to create flat surfaces and is effective in producing smooth finishes on parts.

13. Why is it called milling?

The term "milling" comes from the fact that the process involves removing material from a workpiece using a rotating cutter, similar to how a traditional mill grinds materials.

14. What is the oldest CNC milling machine?

The oldest CNC milling machines were introduced in the 1940s and 1950s, with basic capabilities to automate the milling process. These early machines laid the foundation for the sophisticated CNC technology used today.

15. Is CNC milling difficult?

CNC milling requires skilled operators to set up and program the machines. While the process itself is not necessarily difficult, it demands precision, knowledge of tooling, and an understanding of machining parameters.

16. Why is CNC milling so expensive?

CNC milling can be expensive due to the cost of advanced machinery, precision tooling, and the highly skilled labor required to operate and program CNC machines. Additionally, complex projects with tight tolerances can increase costs.

17. What is G code?

G code is the programming language used to control CNC machines. It provides specific instructions to guide the machine's movements, speeds, and operations during the milling process.

By leveraging VMT's CNC machining services, you can ensure the highest standards of quality and precision for your side milling needs. Reach out to us today to explore how our expert team can assist with your next project.