15 years one-stop China custom CNC machining parts factory

806 |

Published by VMT at Aug 18 2024

806 |

Published by VMT at Aug 18 2024

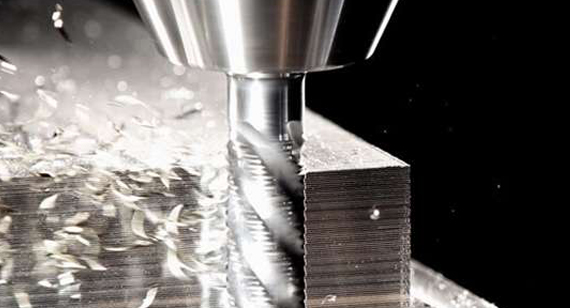

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

Roughing is the initial stage in the machining process, primarily aimed at quickly removing a significant amount of material from the workpiece to bring it closer to its final shape. This stage typically employs larger cutting depths and feed rates to boost machining efficiency. Precision and surface quality are not the main concerns during roughing; instead, the focus is on reducing the material bulk to prepare for the finishing stage.

Finishing is the advanced stage in machining, designed to enhance the dimensional accuracy, surface finish, and overall performance of the workpiece. During this stage, the cutting depth and feed rate are significantly reduced, while cutting speed is relatively high, ensuring a high-quality machined surface. Finishing not only focuses on the geometric dimensions of the part but also on surface roughness, tolerance control, and aesthetics to meet design specifications and application requirements.

Roughing and finishing both contribute to improving the performance of parts in various aspects, including hardness, adhesion, weldability, electrical conductivity, smoothness, corrosion resistance, and wear resistance. Roughing sets the foundation by quickly removing material and easing the load for subsequent operations, while finishing refines the surface and dimensional accuracy, enhancing the overall performance and lifespan of the part.

Roughing in CNC machining offers several benefits, including rapid material removal, extended tool life, laying the groundwork for finishing, increased efficiency, and simplifying complex cuts.

Rapid Material Removal: Roughing employs large cutting depths and feed rates to remove substantial material quickly, significantly boosting machining efficiency.

Extended Tool Life: Although roughing subjects the tools to greater cutting forces, the right choice of cutting parameters and tool materials can effectively prolong tool life.

Foundation for Finishing: Roughing provides a solid base for finishing, ensuring that the latter can proceed smoothly, improving accuracy and surface quality.

Increased Efficiency: Rapid material removal reduces machining time, increases production efficiency, and lowers production costs.

Simplifying Complex Cuts: For complex-shaped workpieces, roughing can create a basic outline, reducing the difficulty of subsequent finishing operations.

Finishing plays a crucial role in enhancing part quality, including high dimensional accuracy, improved aesthetics, increased durability, better surface quality, and extended product life.

High Dimensional Accuracy: Finishing ensures that the dimensional accuracy of the part meets design requirements through precise control of cutting parameters and tool paths.

Improved Aesthetics: The surface of finished parts is smooth, with no noticeable tool marks or burrs, enhancing the part's appearance.

Increased Durability: High-precision machined surfaces reduce friction and wear, improving the part's durability and lifespan.

Better Surface Quality: Finishing significantly reduces surface roughness, improving the surface quality to meet specific application needs.

Extended Product Life: By enhancing the overall performance and longevity of the part, finishing helps reduce the frequency of product replacement and maintenance costs.

Roughing and finishing differ significantly in purpose, material removal rate, feed rate and depth of cut, surface roughness/finish, dimensional accuracy and tolerance, tool type, and coolant usage.

Purpose:

Roughing: Quickly removes excess material from the workpiece to create a shape close to the final form.

Finishing: Enhances the dimensional accuracy, surface finish, and overall performance of the workpiece to meet design requirements.

Material Removal Rate:

Roughing: High material removal rate, rapidly reducing workpiece bulk.

Finishing: Low material removal rate, with precise control over the amount of material removed.

Feed Rate and Depth of Cut:

Roughing: Uses larger feed rates and depths of cut to boost efficiency.

Finishing: Significantly lower feed rates and depths of cut to ensure machining accuracy and surface quality.

Surface Roughness/Finish:

Roughing: Higher surface roughness, lower surface quality.

Finishing: Significantly reduced surface roughness, higher surface finish.

Dimensional Accuracy and Tolerance:

Roughing: Dimensional accuracy and tolerance control are relatively loose.

Finishing: Strict dimensional accuracy and tolerance control to meet design requirements.

Tool Type:

Roughing: Typically uses robust roughing tools that can withstand high cutting forces and wear.

Finishing: Uses finer, sharper tools to ensure surface quality and dimensional accuracy.

Coolant Usage:

Roughing: While coolant is also important in roughing, its primary purpose is to reduce tool wear and workpiece thermal deformation due to the high cutting speed and material removal.

Finishing: Coolant plays a more crucial role in finishing, helping to reduce cutting temperatures, flush away chips, and minimize friction and heat build-up in the cutting zone, ensuring the quality of the machined surface.

| Roughing | Finishing |

| High feed rate | Low feed rate |

| High cutting depth | Low cutting depth |

| Higher material removal rate | Lesser stock removal rate |

| Poor surface quality | Good surface finish |

| Low dimensional accuracy | High dimensional accuracy |

| Poor adherence to tight tolerance levels | Good adherence to close tolerance levels |

| Larger chip load on the cutter | Lesser chip load on the cutter |

| Higher production efficiency | Lower production efficiency |

Roughing requires special attention to factors such as material type, tool selection, machining parameters, machine type and control software, heat and coolant, and workpiece clamping.

Material Type: Understand the physical and chemical properties of the workpiece material to choose suitable cutting methods and tool materials.

Tool Selection: Choose the right type and specification of tools based on the machining material and requirements, ensuring the tool's strength and wear resistance.

Machining Parameters: Set cutting speed, feed rate, and depth of cut appropriately to balance machining efficiency and tool life.

Machine Type and Control Software: Use machines and control software suitable for roughing to ensure machine stability and machining accuracy.

Heat and Coolant: Monitor heat generation and coolant usage during machining, adjusting cutting parameters and cooling methods as necessary.

Workpiece Clamping: Ensure the workpiece is securely clamped during machining to prevent errors due to movement or vibration.

The finishing stage requires greater attention to factors such as dimensional accuracy, part application, post-processing, and cost.

Dimensional Accuracy: Strictly control the dimensional accuracy during machining to ensure the part meets design specifications.

Part Application: Understand the specific application environment and requirements of the part to take appropriate measures during machining to meet performance needs.

Post-Processing: Perform appropriate post-processing on machined parts, such as deburring, cleaning, and surface treatment, to improve surface quality and overall performance.

Cost: While pursuing high accuracy and quality, reasonably control machining costs to avoid unnecessary waste.

VMT CNC Machining Factory offers one-stop CNC machining services, including design consultation, material selection, roughing, finishing, and final inspection. With advanced CNC equipment and experienced technicians, we provide high-quality custom CNC machining services to meet diverse customer needs. Whether for simple part machining or complex component manufacturing, we can fulfill various customer requirements.

Roughing and finishing are indispensable stages in CNC machining, together determining the final quality and performance of a part. By appropriately sequencing operations and choosing suitable machining methods, manufacturing efficiency and product quality can be significantly improved. Attention to details and considerations during machining is also essential to ensuring successful outcomes. VMT CNC machining services are committed to providing professional, efficient, and reliable CNC machining solutions, helping customers stand out in a competitive market.

Why is Material Removal Rate (MRR) Crucial in CNC Roughing?

Material Removal Rate is a key indicator of roughing efficiency. A high MRR means that a large amount of material can be removed quickly, reducing machining time and increasing production efficiency. In CNC roughing, it is crucial to set cutting parameters appropriately to achieve a high MRR.

How Does CNC Roughing Affect Machine Life?

CNC roughing generates significant cutting forces and vibrations, placing high demands on machine rigidity and stability. If the machine is poorly designed or inadequately maintained, prolonged roughing operations can lead to accelerated wear, reduced precision, and shortened machine life. Therefore, machine selection should consider its capacity to handle roughing, and proper maintenance is essential.

What Are Common Challenges in CNC Roughing?

Common challenges in CNC roughing include rapid tool wear, significant workpiece thermal deformation, and chip handling difficulties. To address these challenges, select appropriate tools, optimize cutting parameters, and enhance coolant and chip removal to reduce cutting forces and heat accumulation, improving machining stability and efficiency.

What is the Difference Between Rough Turning and Finish Turning?

Rough turning and finish turning are two distinct stages in turning operations. Rough turning primarily aims to quickly remove excess material and shape the workpiece roughly, while finish turning further improves dimensional accuracy and surface quality. They differ significantly in cutting parameters, tool selection, and machining goals.

What Are the Three Types of Finishing?

Finishing typically includes three types: grinding, polishing, and lapping. Grinding involves cutting the workpiece surface with an abrasive tool; polishing smooths the surface using a polishing tool and compound; lapping involves fine processing with a lapping tool and compound to achieve higher surface quality. These methods have unique features and applications, and the appropriate finishing method can be chosen based on specific needs.