15 years one-stop China custom CNC machining parts factory

655 |

Published by VMT at Apr 09 2025 | Reading Time:About 10 minutes

655 |

Published by VMT at Apr 09 2025 | Reading Time:About 10 minutes

Choosing the right type of turning operation can be the deciding factor between an efficient, cost-effective project and one that suffers from rework, poor tolerances, and wasted materials. With the growing use of CNC turning across industries, engineers and buyers are often overwhelmed by the range of available turning techniques. From facing and taper turning to contouring, boring, and threading, each method offers unique advantages depending on the material, geometry, and functional requirements of the part. If you're unsure which approach best suits your design, you're not alone.

That’s where this guide comes in—to clarify, compare, and help you make informed decisions. Whether you're an engineer optimizing design for manufacturability or a procurement specialist seeking the most efficient CNC turning service, this article is your go-to resource for understanding the various types of turning operations, their applications, and how to choose the right one.

There are over 15 types of turning operations, including facing, taper turning, grooving, boring, and threading. Each method supports different shapes, tolerances, and materials. Choosing the correct type depends on your part’s geometry, surface finish requirements, and production volume. CNC turning services can integrate multiple operations to achieve high precision and production efficiency.

To make the best use of turning technology, it’s essential to understand how each type of operation works and what role it plays in part fabrication. Let’s begin by demystifying the basics—what is turning, how it works, and what steps are involved in the turning process from setup to final inspection.

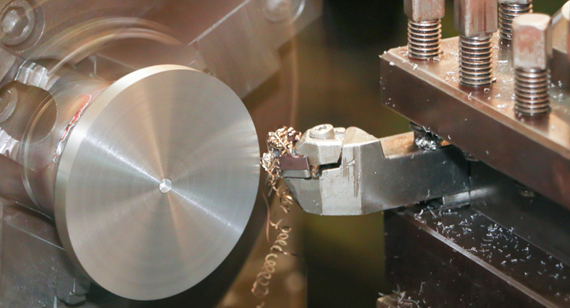

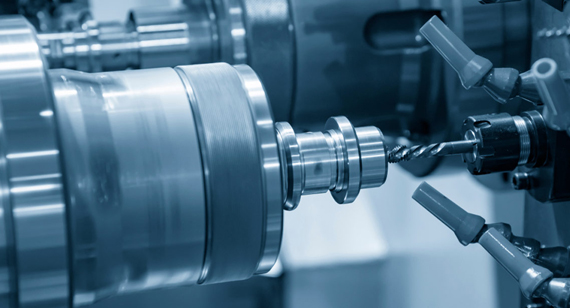

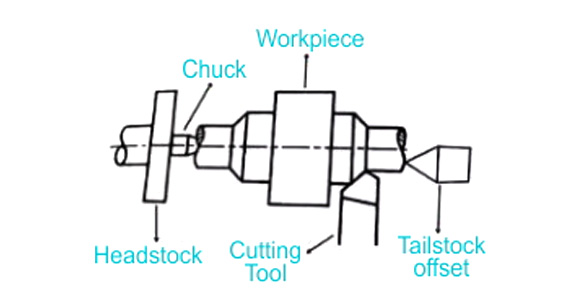

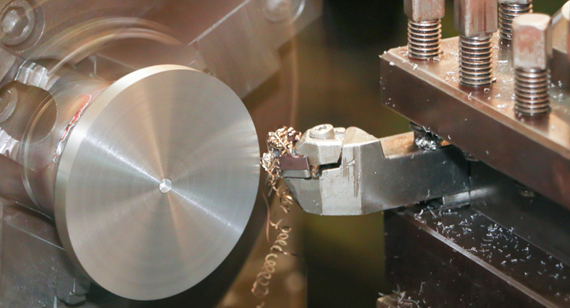

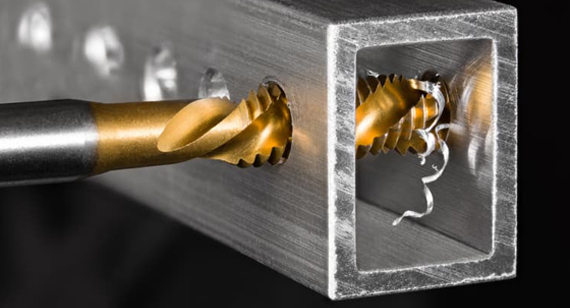

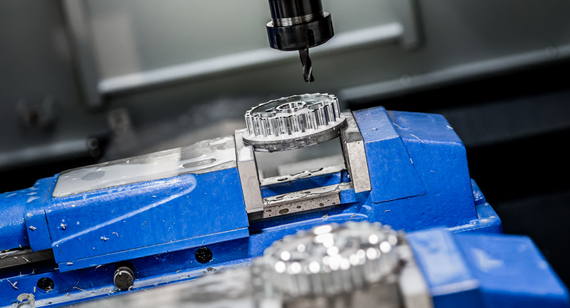

Turning is a subtractive manufacturing process where a rotating workpiece is shaped using a stationary cutting tool. Most commonly performed on a lathe or CNC turning center, the operation removes material from cylindrical or conical surfaces to achieve precise diameters, lengths, and contours. It's used across a wide range of industries to create components like shafts, bushings, fasteners, fittings, and connectors. With advancements in CNC technology, turning can now handle more complex geometries and tighter tolerances than ever before.

Unlike milling, which involves multiple axes and rotary tools, turning relies on the rotation of the workpiece itself. This fundamental difference makes turning particularly suitable for round or symmetrical parts. In CNC turning shops, the process is highly automated, resulting in improved repeatability, faster production, and lower labor costs—especially for custom CNC turning and CNC prototype turning projects.

At its core, turning uses a simple principle: the workpiece spins while the tool remains fixed. However, in modern CNC turning systems, this process is meticulously programmed and controlled for exceptional accuracy. Here’s how a typical CNC turning operation unfolds:

CNC turning shops often combine operations to maximize efficiency. The use of precision CNC turned parts in industries such as aerospace, medical, and automotive underscores the importance of selecting the right operation for each project.

We'll take a deep dive into the various types of turning operations so you can understand when and why each is used—and how they fit into your design or manufacturing process.

Turning is far more than a single, uniform process—it encompasses a wide variety of machining operations tailored to meet specific geometric, dimensional, and surface finish requirements. Whether you're working on prototyping or high-volume production, understanding these turning operations helps ensure that your part is machined with the right technique, reducing time, cost, and rework. Modern CNC turning services combine several operations in one sequence to maximize productivity and precision. Below, we break down the 15 most commonly used types of turning operations, each with its unique applications and benefits.

Facing

Facing is one of the most fundamental and widely used types of turning operations performed on a lathe or CNC turning center. It involves removing material from the end of a rotating workpiece to produce a flat surface perpendicular to the part’s axis. In both manual and CNC machining, facing is typically the first operation, preparing the workpiece for further precision turning by establishing a clean, square reference face.

The cutting tool moves radially, either from the outer edge toward the center or vice versa, depending on the machining strategy. The tool is usually mounted perpendicular to the workpiece’s axis on a cross-slide or CNC turret. For best results, the surface speed, feed rate, and depth of cut must be precisely controlled to prevent tool wear or surface irregularities.

Advantages

Disadvantages

Applications

Facing may be a basic operation, but it sets the foundation for the success of all subsequent turning procedures. In CNC turning services, it is often the first and most repeated step for batch production, helping ensure dimensional accuracy and functional integrity across parts. Would you like me to move on to the next turning operation, such as Straight Turning?

Straight Turning

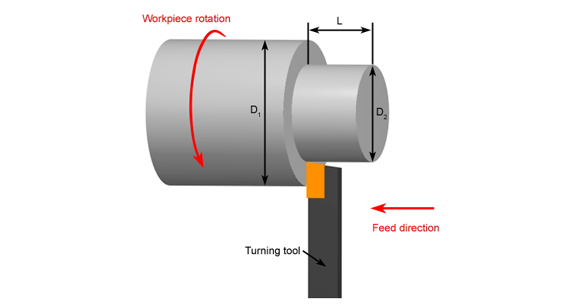

Straight turning is one of the core types of turning operations used to reduce the diameter of a cylindrical workpiece to a specified size. This process involves feeding the cutting tool parallel to the rotational axis of the part. As the workpiece spins, material is removed uniformly from its outer surface, resulting in a smooth, even cylindrical section.

This operation is commonly used when producing shafts, rods, or any parts requiring precise external diameters. The cutting depth, speed, and feed rate can be adjusted depending on the material and finish requirements. Straight turning can be performed manually or through advanced CNC turning machines, which allow for better precision and automation.

Advantages

Disadvantages

Applications

Straight turning is a foundational operation in modern CNC turning services. Whether you’re producing a single prototype or thousands of production units, this process is critical for parts requiring precision diameters and excellent surface finish. Shall we move on to the next turning operation, Taper Turning?

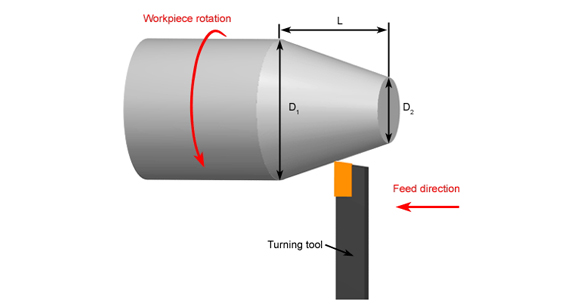

Taper turning is a fundamental type of turning operation where the diameter of the workpiece gradually decreases (or increases) along its length, forming a conical shape. Unlike straight turning, which maintains a constant diameter, taper turning creates an angular profile by adjusting the tool path relative to the workpiece axis. This is commonly required for applications that involve parts needing to fit into other components with a snug, angled connection—such as tapered shafts, pins, or pipe threads.

In CNC turning services, taper turning can be precisely programmed into the control system, allowing the operator to define the taper angle, start and end points, and even complex compound tapers. In manual turning setups, taper turning can be performed using several methods: by swiveling the compound rest, offsetting the tailstock, using a taper turning attachment, or through CNC-based automatic control.

Advantages

Disadvantages

Applications

Taper turning is a critical process in precision engineering, providing the functionality and reliability needed in tight-fit or load-transfer components. With the help of modern CNC turning shops, this operation can now be performed faster, more accurately, and more consistently than ever before. Ready for the next process? Let's explore Contour Turning next.

Contour Turning

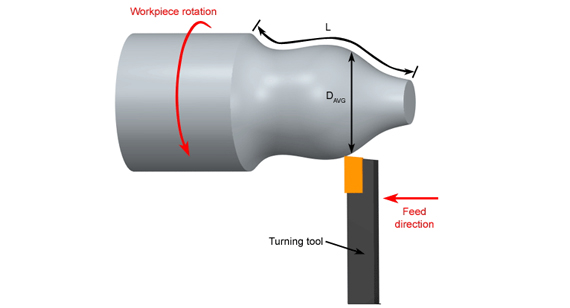

Contour turning is a type of turning operation used to machine curved or irregular profiles on the surface of a cylindrical workpiece. Unlike straight or taper turning, which deal with linear or angled surfaces, contour turning involves generating complex, smooth shapes such as fillets, radii, and compound curves. This process is especially vital when the component requires a blend of different diameters or forms a 3D surface transition along its axis.

In modern CNC turning services, contour turning is executed by programming a toolpath that follows a precise geometry defined in CAD/CAM software. The CNC lathe then manipulates the tool along the X and Z axes simultaneously to follow the defined profile. This makes contour turning ideal for custom CNC turning where precision and repeatability are paramount.

Advantages

Disadvantages

Applications

Contour turning unlocks the potential of CNC technology by enabling sophisticated, multi-radius profiles on a single axis. It's an essential turning technique for industries where form, fit, and finish are critical. Next, let’s explore Grooving, another specialized turning operation with wide industrial relevance.

Grooving: What Is It and When Is It Used in CNC Turning?

Grooving is a fundamental turning operation that involves cutting a narrow channel (or groove) into the surface of a rotating workpiece using a specially shaped cutting tool. These grooves can be internal (inside a hole or bore), external (on the outer diameter), or on the face of the part (face grooving). The groove geometry can be square, round, V-shaped, or custom-shaped depending on the application's requirements.

In modern CNC turning services, grooving operations are performed with precise toolpaths controlled by computer numerical code, allowing for tight tolerances, repeatability, and versatility. Grooving is especially important in the production of CNC turned parts that require retaining rings, O-rings, snap rings, or other functional features that must sit securely in a recessed area.

Advantages

Disadvantages

Applications

Grooving is one of the most functionally important types of turning operations, providing structural, mechanical, and sealing benefits to countless industries. As we continue, the next turning process we’ll cover is Cut-Off (Parting) — a final, essential operation in most CNC turning projects.

Cutting Off (Parting Off): What Is It and Why Is It Essential in CNC Turning?

Cutting off, also referred to as parting off, is a key turning operation in which the finished part is separated from the remaining raw material or bar stock. This process involves using a narrow, sharp cutting tool to move perpendicularly into the rotating workpiece until it completely severs the component. In CNC turning services, this is typically the final operation after all other machining steps—such as facing, grooving, and threading—have been completed.

The cutting off tool is mounted at a right angle to the axis of rotation and must penetrate precisely at the pre-programmed location. In custom CNC turning, parting off is executed with high precision to ensure the final component has a clean, accurate end surface, especially important in tight-tolerance industries such as aerospace and medical manufacturing.

Advantages

Disadvantages

Applications

Parting off is one of the concluding but most critical types of turning operations, ensuring parts are cleanly separated for quality assurance and downstream processing. Next, we’ll explore threading—a specialized operation that plays a vital role in the mechanical functionality of many CNC turned parts.

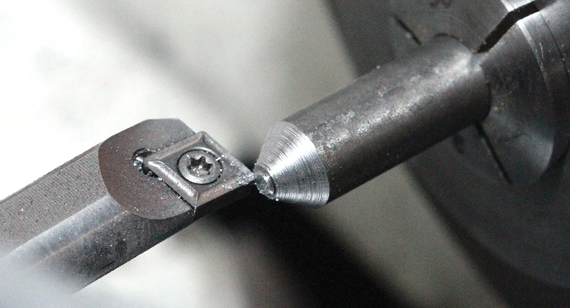

Threading: What Is Threading in Turning and Why Is It Important?

Threading is a turning operation used to create helical grooves or ridges—commonly known as threads—on the outer or inner surfaces of a cylindrical part. These threads allow parts to connect, fasten, or move relative to each other, and are found in a wide range of mechanical components like screws, bolts, shafts, and fittings. In CNC turning services, threading is often performed using specialized tools programmed to follow the exact pitch, depth, and profile of the required thread type.

Threading can be external (on the outside of a workpiece) or internal (within a bore), and it is typically executed using either a single-point tool or thread milling attachments. CNC turning machines excel at threading due to their high precision, repeatability, and ability to produce both metric and imperial thread forms.

Advantages

Disadvantages

Applications

Threading is a cornerstone among the types of turning operations, offering both structural and functional benefits. As a highly technical process, it showcases the precision capabilities of modern CNC turning shops. Up next, we’ll explore boring, a process used to refine internal diameters to exact dimensions and finishes.

What Is Boring in Turning and Why Is It Critical for Precision?

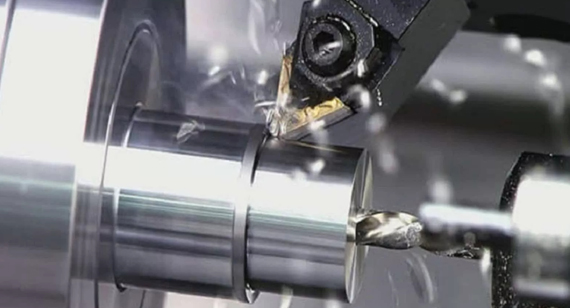

Boring is a turning operation used to enlarge and finish the internal diameter of a pre-drilled or cast hole. Unlike drilling, which creates an initial hole, boring is all about precision refinement, ensuring the final hole is smooth, straight, and dimensionally accurate. This operation is typically carried out on a lathe or CNC turning center using a single-point cutting tool known as a boring bar.

In custom CNC turning, boring is especially important when extremely tight tolerances are required—common in industries like aerospace, automotive, and medical device manufacturing. The tool enters the preformed hole and removes material along the inside surface to achieve the desired diameter, roundness, concentricity, and surface finish.

Advantages

Disadvantages

Applications

In the broader list of types of turning operations, boring plays a crucial role in fine-tuning internal features to meet demanding specifications. For industries where internal diameter accuracy can mean the difference between failure and functionality, boring remains one of the most relied-upon processes offered by modern CNC turning services. Next, we’ll cover drilling, another internal machining process, but one that starts the journey.

What Is Drilling in Turning and Why Is It Essential in Machining?

Drilling is one of the most fundamental and widely used types of turning operations. It involves the creation of a cylindrical hole by rotating a cutting tool—typically a drill bit—into a workpiece. When performed on a lathe or CNC turning center, the workpiece rotates while the drill bit remains stationary (in contrast to drilling machines, where the drill rotates). Drilling is usually the first step before operations like boring, reaming, or tapping.

In CNC turning services, drilling is essential for initiating internal features in a part. It can be used for creating clearance holes, pilot holes for threading, or starting points for more complex cavity machining. Though straightforward in principle, drilling in a CNC setup allows for greater precision, repeatability, and customization when working with a variety of materials, from metals to engineering plastics.

Advantages

Disadvantages

Applications

As one of the core types of turning operations, drilling provides the starting point for internal geometry. When paired with technologies like custom CNC turning, it offers not just speed, but also precision and control, setting the stage for more refined processes like boring or tapping. Let’s now explore tapping, the operation that gives those drilled holes a functional thread.

What Is Tapping in Turning and Why Is It Critical for Threaded Components?

Tapping is a turning operation used to create internal threads within a previously drilled hole. It involves the use of a tapping tool (tap) that cuts threads into the walls of the hole as it's rotated into the workpiece. In the context of CNC turning services, tapping is often automated and precisely programmed, ensuring thread consistency and accuracy, especially in high-volume production of CNC turned parts.

Tapping typically follows drilling in the machining sequence. The drilled hole acts as a pilot, while the tap defines the thread pitch, depth, and diameter. This makes tapping a vital operation in creating components that will be assembled with screws, bolts, or studs.

In CNC prototype turning or mass production, tapping is used to integrate fastening systems directly into the part, eliminating the need for inserts or secondary threading operations. It is applicable to a wide range of metals and engineering plastics, making it a versatile solution in many industries.

Advantages

Disadvantages

Applications

In summary, tapping is a critical step in the types of turning operations for producing parts that rely on secure mechanical fastenings. When integrated with CNC turning services, tapping becomes not only more accurate but also scalable and cost-efficient for both prototyping and production. Next, let’s look at knurling, a unique turning process that adds texture rather than cutting material.

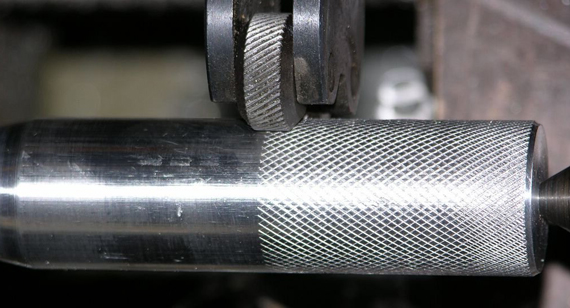

What Is Knurling in Turning and When Should You Use It?

Knurling is a specialized turning operation used to create a textured pattern on the surface of a cylindrical part. Unlike cutting processes, knurling is a form of cold working where a hardened tool presses against the rotating workpiece, displacing material to form a repetitive diamond or straight-line pattern. This surface finish improves grip, aesthetics, or mechanical engagement of the part.

In CNC turning services, knurling is typically performed using knurling wheels or dies mounted on a lathe. This process does not remove material; rather, it redistributes it to create raised ridges. The operation is often performed after other machining processes like facing or straight turning have been completed. It’s especially valuable in custom CNC turning applications where grip is crucial — such as knobs, tool handles, surgical instruments, or even decorative elements.

Knurling patterns can be categorized into three primary types:

Advantages

Disadvantages

Applications

Knurling might not alter the dimensions of a part significantly, but it dramatically enhances usability and ergonomic design. It’s one of the few types of turning operations that focuses on surface texture rather than form or internal geometry. In the next section, we’ll dive into reaming, a finishing process that brings precision to internal hole sizing and surface finish.

What Is Reaming in Turning? Understanding Its Precision Role in Machining

Reaming is a precision finishing operation used to enlarge an existing hole to a specific diameter with high accuracy and excellent surface finish. Unlike drilling or boring, which are primarily used for material removal, reaming is meant for fine-tuning the dimensions and enhancing the surface quality of a pre-drilled or bored hole. It ensures the hole is perfectly round, smooth, and within tight tolerances.

In CNC turning, reaming is typically performed after drilling, using a reamer tool mounted on a lathe or CNC turning center. The reamer enters the hole slowly and cuts a small amount of material from the walls to create a consistent, polished finish. Custom CNC turning applications often use reaming when components require precision fits—such as bearings, shafts, or pins fitting into holes.

There are various types of reamers:

Advantages

Disadvantages

Applications

In summary, reaming is a critical turning operation when the goal is to ensure tight hole tolerances and superior finish. It complements drilling and boring, and is especially valuable in industries where dimensional precision is non-negotiable. As we move forward, we'll explore another finishing technique—chamfer turning—which adds both functional and aesthetic value to CNC turned parts.

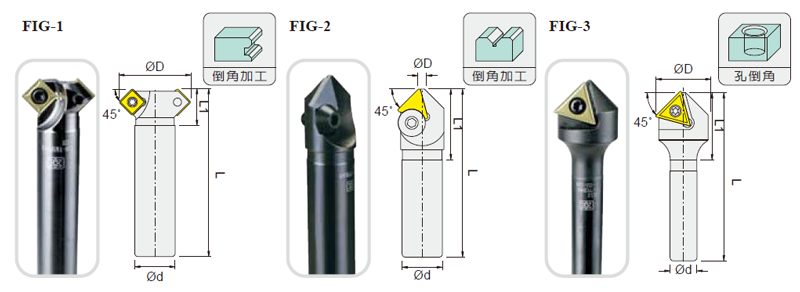

What Is Chamfer Turning and When Should It Be Used?

Chamfer turning is a turning operation that involves cutting a beveled edge or transitional slope—called a chamfer—at the end or corner of a cylindrical part. This angled edge is typically cut between 30° to 45° depending on the design requirements and is used to eliminate sharp corners, assist with assembly, or prepare parts for welding or mating.

In CNC turning, chamfering is often part of a broader machining process, added either at the beginning or the end of a program. The CNC turning tool follows a predefined toolpath, removing a small amount of material from the edge of the workpiece to create a clean, slanted surface. This operation is commonly found in custom CNC turning services for both functional and cosmetic improvements.

Chamfer turning is not limited to circular workpieces; internal and external chamfers can be added to holes, shafts, bores, and even threads. CNC turning shops often automate this process using chamfering tools or multi-function turning inserts.

Advantages

Disadvantages

Applications

Chamfer turning is a simple yet essential turning process used widely across industries that value precision, durability, and aesthetics. Whether you’re developing a CNC prototype or preparing a production run of custom CNC turned parts, chamfering helps improve fit, function, and overall part quality. Up next, we’ll look at another precision finishing operation—step turning—which is ideal for producing parts with multiple diameters or shaft sections.

What Is Step Turning and Why Is It Important in CNC Machining?

Step turning is a fundamental turning process used to create a series of concentric cylindrical features with different diameters along the length of a single workpiece. The result is a "stepped" profile where each segment or section transitions into the next through a sharp or blended edge. This process is frequently performed on a CNC lathe and is a core capability in CNC turning services for components requiring multiple functional diameters—such as shafts, axles, or piston rods.

During step turning, the workpiece is rotated while the cutting tool moves longitudinally along the axis. The cutting depth is precisely controlled to achieve various diameters. These steps may be equal or variable in size, depending on the part geometry. In modern custom CNC turning environments, this process is easily automated and highly repeatable, offering both efficiency and dimensional precision.

Advantages

Disadvantages

Applications

In CNC prototype turning or mass production, step turning plays a critical role in delivering functional, multi-diameter parts with outstanding accuracy. It is one of the most commonly used types of turning operations because of its ability to consolidate features into a single part, reducing the need for secondary machining or additional components. When planning your next project with a CNC turning shop, knowing when and how to use step turning can significantly influence performance, efficiency, and cost-effectiveness.

How to Choose the Right Turning Operation for Your CNC Project?

Choosing the correct turning operation can be the difference between a successful CNC project and one that results in wasted time, material, and budget. With so many types of turning operations available, it’s essential to match the right method to your part’s geometry, function, and performance requirements. Whether you're working with CNC turned parts for prototyping or high-volume production, each operation—facing, boring, threading, knurling, or taper turning—offers unique benefits based on design and end-use conditions.

The best way to approach this decision is by evaluating your project through several critical criteria: the type of material used, required tolerances, surface finishes, and overall geometry. Making the right call early in your custom CNC turning workflow not only ensures optimal results but also supports cost-efficiency and shorter lead times.

Material Type

The material of your workpiece plays a major role in determining the most suitable turning operation. For instance:

The machinability of your chosen material should always guide tool selection, feed rates, and even turning strategy (e.g., roughing vs. finishing passes).

Dimensional Accuracy

If your design requires tight tolerances—say, within a few microns—you’ll likely need precision-focused operations like contour turning, threading, or boring. Operations such as step turning or reaming are also valuable when achieving accurate concentric diameters or smooth bore finishes. Meanwhile, for rough or basic shaping where tolerances are looser, operations like straight turning or grooving may suffice.

In CNC prototype turning, achieving dimensional accuracy is vital, as it directly reflects how well a concept translates into a functional part.

The quality of a part’s surface finish can affect not just aesthetics, but also its performance—particularly in applications involving seals, fasteners, or moving assemblies.

Knowing the final surface requirement helps you determine how many operations are needed—and whether you should prioritize speed or finish.

Shape and Features

Lastly, evaluate the geometry of the part:

Your part's blueprint will often dictate the operation—but don't forget that some features can be combined or adjusted to reduce machining time and improve tool access.

By considering these four essential factors—material type, dimensional accuracy, surface treatment, and geometry—you can confidently select the most efficient and appropriate turning operation. Partnering with an experienced CNC turning shop ensures you receive expert guidance and quality results whether you're building one prototype or scaling for full production.

The efficiency and quality of CNC turning services depend heavily on the machine tools and accessories involved. Each component of a turning setup plays a specific role, and together, they determine precision, surface finish, cutting speed, and production capability. For manufacturers working with CNC turned parts—from prototypes to mass production—it’s crucial to understand the tools available and how they contribute to the turning process. Whether in a CNC turning shop or integrated into a larger custom CNC turning workflow, the right equipment ensures reliability, safety, and performance.

Let’s explore the essential tools and components used in modern CNC turning operations.

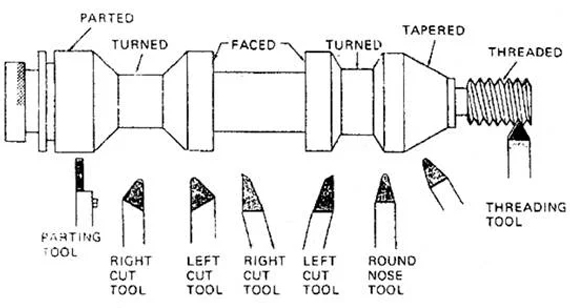

Cutting tools are at the core of any turning process. These are the instruments that remove material from the rotating workpiece. They come in different geometries, coatings, and materials depending on the application.

Tool Holders

Tool holders securely mount cutting tools to the turret or tool post of a CNC lathe. Precision and rigidity here are key to preventing vibration and tool deflection.

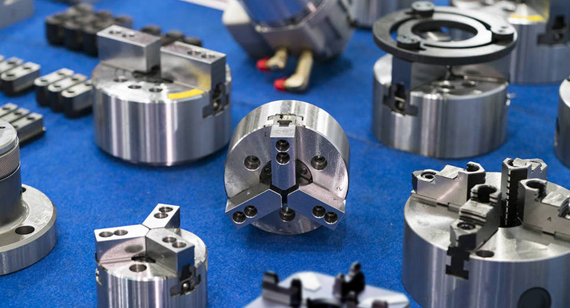

Chucks

Chucks grip the workpiece and rotate it during turning. Depending on the part's shape and precision needs, different types are used:

Tailstocks

The tailstock supports the other end of long workpieces to prevent deflection or vibration during machining. It can also be fitted with tools like drills or reamers for operations along the workpiece axis.

Centers

Centers are precision-ground tips that fit into the workpiece or tailstock to maintain alignment. They’re critical in high-precision CNC prototype turning or turning long, slender components.

Lathes

The primary machine tool for all turning operations is the lathe. In CNC turning, the lathe is controlled by software and capable of executing highly complex programs with minimal operator intervention.

Boring Bars

Used for enlarging or finishing the inside diameter of a hole, boring bars are critical when turning internal features. They must be rigid and well-supported to prevent chatter.

Grooving and Cutting Tools

Grooving tools create narrow channels on the workpiece, while cut-off tools (also known as parting tools) separate finished parts from the stock.

Threading Tools

Threading tools are used to cut external or internal threads—either manually or via CNC programming. Precision is critical here, especially in components requiring tight mechanical tolerances.

Drills

Drilling tools can be mounted in the turret or tailstock to create holes along the axis of the workpiece.

Forming Tools

Forming tools are used for shaping specific contours or profiles onto the workpiece without moving the tool laterally.

By understanding the function and selection criteria of these turning tools and components, engineers and manufacturers can optimize their CNC turning services, reduce machining errors, and increase throughput. Whether for CNC prototype turning or full-scale production, having the right tools in place is non-negotiable for quality and performance.

In CNC turning operations, cutting parameters play a pivotal role in determining the outcome of a machining process. Whether you're machining prototypes or producing large volumes of CNC turned parts, the precise selection of feed rates, cutting speeds, and depth of cut significantly influences efficiency, surface finish, tool life, and overall cost. These parameters are not chosen arbitrarily—they are based on the material, desired tolerance, tooling, and machine capability.

For anyone working with custom CNC turning or operating within a CNC turning shop, understanding these parameters is essential to avoid tool failure, maintain part integrity, and optimize cycle time.

Feed Rates

Feed rate refers to the distance the cutting tool advances along the surface of the workpiece per revolution. It's typically expressed in mm/rev or in/rev.

Feed rate directly affects:

In CNC turning services, careful feed rate optimization is crucial for parts requiring tight tolerances or fine finishes, especially in aerospace, medical, or precision engineering applications.

Depth of Cut

Depth of cut is the thickness of the material layer removed in one pass of the tool, measured perpendicular to the surface being machined.

The depth of cut is often adjusted depending on the stage of machining:

This balance between material removal rate and surface quality is a key consideration in CNC prototype turning, where initial trials help dial in the optimal settings.

Cutting Speeds

Cutting speed is the speed at which the material is removed by the cutting tool, generally expressed in meters per minute (m/min) or surface feet per minute (SFM). It depends on:

If cutting speed is too high, it can cause:

If it’s too low, it may:

Modern CNC turning machines automatically adjust speed based on tool path and load, especially in multi-pass cycles. For custom CNC turning jobs involving tough alloys like titanium or Inconel, carefully calculated speeds are critical to avoid costly mistakes.

Summary

Together, feed rate, depth of cut, and cutting speed form the foundation of an effective turning operation. These parameters are interdependent—changing one affects the others. Experienced machinists and engineers rely on these values not only to protect tools and machines but to deliver high-quality parts that meet customer specifications.

In any CNC turning shop, the ability to configure and fine-tune these cutting parameters is what separates standard machining from optimized, efficient, and competitive production.

In CNC turning, machining is generally divided into two core phases: roughing and finishing. Each stage plays a critical role in transforming raw material into a precision part. While roughing focuses on removing the bulk of material quickly, finishing aims for dimensional accuracy and a high-quality surface finish. Understanding the difference between these two processes helps machinists and engineers select the right tools, parameters, and strategies—especially in custom CNC turning, CNC prototype turning, and mass-production environments.

Roughing vs. Finishing: A Side-by-Side Comparison

| Aspect |

Roughing |

Finishing |

| Purpose | Rapid material removal | Final shaping and accuracy |

| Cutting Depth | Deep cuts (typically 2–5 mm or more) | Shallow cuts (typically 0.2–0.8 mm) |

| Feed Rate | High feed rate | Low feed rate |

| Cutting Speed | Moderate speed | Higher speed (but lower feed) |

| Tool Used | Strong, rigid tools with durable coatings | Sharp tools with fine edge geometry |

| Surface Finish | Coarse surface finish (higher Ra values) | Smooth surface finish (lower Ra values) |

| Tolerance Accuracy | Not tight, allowances left for finishing | High precision, meets final tolerances |

| Tool Wear Rate | Higher, due to increased forces | Lower, but tools need sharper edges |

| Cycle Time | Shorter for bulk removal | Longer due to light passes and finer control |

| Chip Formation | Thick, curled chips | Thin, continuous chips |

| Use in CNC Turning | Prepares the part for finishing in fewer passes | Used for critical dimensions and surface finishes |

| Common Applications | Pre-machining, removing casting/forging surfaces | Aerospace parts, medical components, fine threads |

When and Why Each Is Used

Transition to Precision

Choosing the right time to switch from roughing to finishing depends on:

Modern CNC turning services often integrate both processes into a single automated cycle, using different tools and machining strategies to complete both stages efficiently.

Conclusion

Roughing and finishing are not competing processes—they complement each other. Understanding their differences ensures better tool life, higher productivity, and optimal part quality. Whether you're working in a CNC turning shop or prototyping high-performance components, mastering these two turning techniques is essential for success.

In CNC turning, roughing and finishing represent two essential stages of the machining process. Each phase is defined by its objectives, strategies, and outcomes. Knowing their main features helps optimize tool selection, machining time, and part quality—critical elements in modern custom CNC turning, CNC prototype turning, and large-scale CNC turning services.

Main Features of Roughing

1. Objective:

2. Cutting Parameters:

3. Tool Characteristics:

4. Output Quality:

5. Efficiency:

6. Common in:

Main Features of Finishing

1. Objective:

2. Cutting Parameters:

3. Tool Characteristics:

4. Output Quality:

5. Efficiency:

6. Common in:

Final Thoughts

By understanding the distinct characteristics of roughing and finishing, manufacturers can select the right combination of tools, parameters, and strategies. This ensures optimal results in both CNC prototype turning and mass production. For best outcomes, advanced CNC turning shops often automate the transition between these two stages, balancing speed with precision.

Both processes are crucial—roughing shapes the raw material, and finishing perfects the final part.

In CNC turning, the accuracy, surface finish, and productivity of the machining process rely heavily on the correct selection and application of turning tools. Each tool is designed for a specific function, such as shaping, threading, or forming. Whether you’re working on custom CNC turned parts or high-volume production runs, understanding these tools is essential for achieving consistent results and optimizing tool life. Below are some of the most commonly used turning tools in CNC turning services and their respective roles in the process.

Facing Tools

Chamfering Tools

Threading Tools

Forming Tools

Taper Tools

Grooving Tools

Conclusion

Choosing the right turning tools for each operation ensures efficiency, accuracy, and quality—especially when working with advanced materials or tight tolerances. By mastering the applications and benefits of these tools, CNC turning shops can offer reliable, high-performance solutions across a range of industries, from automotive to aerospace.

The success of any CNC turning operation depends largely on the material being machined. From strength and machinability to heat resistance and surface finish requirements, the properties of a material play a pivotal role in selecting tools, feeds, speeds, and even the type of turning operation. Whether you're manufacturing CNC turned parts for aerospace, medical, or industrial use, understanding the materials involved allows machinists and engineers to optimize every phase of the process—from roughing to finishing.

Let’s explore the most commonly used workpiece materials in custom CNC turning, their characteristics, and how they influence turning techniques.

Turning processes are highly versatile and capable of machining a wide variety of metals and non-metals. The key criteria for material selection include hardness, toughness, thermal conductivity, corrosion resistance, and ease of chip removal. Below are the most widely used metallic materials in CNC turning services.

Stainless Steel

Overview: Known for its corrosion resistance, strength, and aesthetic appeal, stainless steel is a popular choice in medical, food-grade, and aerospace components.

Machining Characteristics:

Grades Used in Turning: 303 (easiest to machine), 304, 316, 420, and 17-4PH.

Steel

Overview: One of the most common materials used in turning, steel offers a good balance between strength, cost, and machinability.

Machining Characteristics:

Applications: Automotive parts, industrial components, shafts, and gears.

Iron (Cast Iron)

Overview: Widely used in heavy machinery and engine components, cast iron has excellent damping properties and wear resistance.

Machining Characteristics:

Common Types: Grey iron, ductile iron.

Brass

Overview: A copper-zinc alloy, brass is easy to machine and provides excellent corrosion resistance and conductivity.

Machining Characteristics:

Common Uses: Fittings, valves, electronic connectors.

Aluminum

Overview: Lightweight and versatile, aluminum is one of the most widely used metals in CNC turning due to its machinability and excellent strength-to-weight ratio.

Machining Characteristics:

Common Alloys: 6061, 7075, 2024

Applications: Aerospace, automotive, medical, and consumer products.

Nickel Alloys

Overview: Known for their corrosion resistance and strength at high temperatures, nickel-based alloys are widely used in aerospace and energy sectors.

Machining Characteristics:

Examples: Inconel, Monel, Hastelloy

Titanium

Overview: Highly valued for its excellent strength-to-weight ratio and biocompatibility, titanium is a top choice in aerospace, medical, and defense industries.

Machining Characteristics:

Common Grades: Grade 2 (commercially pure), Grade 5 (Ti-6Al-4V)

Conclusion

Choosing the right material for a turning operation directly impacts productivity, tool life, and part quality. While metals like aluminum and brass offer easier machinability, materials like titanium and nickel alloys demand more specialized tools and parameters. By understanding these material characteristics, CNC turning shops can deliver more efficient and cost-effective solutions, especially when working on CNC prototype turning or high-precision custom CNC turning projects.

Plastics Used in CNC Turning

While metals dominate many CNC turning applications, plastics have become increasingly popular in industries that demand lightweight, corrosion-resistant, and non-conductive components. With advances in CNC turning services and improved tooling technology, it’s now possible to machine engineering plastics with high precision, making them viable for medical, aerospace, electronics, and industrial applications. Selecting the right plastic material is crucial for achieving the required mechanical, thermal, and aesthetic performance in CNC turned parts.

Let’s break down some of the most commonly used plastics in CNC turning: Polycarbonate (PC), PEEK, PEI, and PP, highlighting their characteristics, machinability, and applications.

Polycarbonate (PC)

Overview: Polycarbonate is a transparent, high-impact-resistant plastic known for its strength and dimensional stability. It's widely used as a glass substitute in lenses, enclosures, and transparent shields.

Machining Characteristics:

Key Properties:

Applications:

PEEK (Polyether Ether Ketone)

Overview: PEEK is a high-performance thermoplastic with exceptional mechanical and chemical resistance. It's often used in high-heat and high-load environments, making it a favorite in aerospace, medical, and automotive industries.

Machining Characteristics:

Key Properties:

Applications:

PEI (Polyetherimide, e.g., Ultem)

Overview: PEI is an amorphous, high-strength plastic known for its heat resistance, rigidity, and flame retardance. It’s often used when both electrical insulation and structural performance are required.

Machining Characteristics:

Key Properties:

Applications:

PP (Polypropylene)

Overview: Polypropylene is a versatile, low-cost thermoplastic with excellent chemical resistance and fatigue strength. It’s commonly used in laboratory, chemical handling, and packaging applications.

Machining Characteristics:

Key Properties:

Applications:

Conclusion

In custom CNC turning, the choice of plastic materials should align with the functional and environmental requirements of the final product. While polycarbonate offers transparency and impact strength, materials like PEEK and PEI shine in demanding, high-temperature environments. For cost-sensitive or chemically aggressive settings, PP serves as an ideal solution. With the right approach to machining and material selection, plastics can offer exceptional performance and manufacturability in modern CNC prototype turning projects and production runs alike.

Composites, Ceramics, and Cutting Tool Materials in Turning Operations

Composites and Ceramics in Turning

Composites and ceramics are increasingly used in high-performance applications due to their superior strength-to-weight ratios, wear resistance, and thermal properties. However, these materials present unique challenges in CNC turning operations due to their hardness and brittleness.

Composites

Overview: Composites are engineered materials made from two or more constituent materials with different physical or chemical properties. Common composites include carbon fiber-reinforced polymers (CFRPs) and glass fiber-reinforced polymers (GFRPs).

Machining Considerations:

Applications:

Why it Matters: When working with custom CNC turning of composite materials, careful tool selection and optimized cutting parameters are essential to preserve material integrity and extend tool life.

Ceramics

Overview: Ceramic materials such as alumina (Al₂O₃) and silicon nitride (Si₃N₄) are used where high temperature resistance, chemical inertness, and wear resistance are critical. These are often found in aerospace, energy, and biomedical fields.

Machining Considerations:

Applications:

Why it Matters: Ceramics require precision equipment and skilled CNC turning services, often involving secondary processes such as grinding or polishing after rough shaping.

Cutting Tool Materials in CNC Turning

The effectiveness of any CNC turning operation heavily depends on the material used for the cutting tool. Below are the most common tool materials used for turning various types of workpieces:

High-Speed Steel (HSS)

Overview: Known for toughness and affordability, HSS is suitable for general-purpose turning, especially for small batches and softer materials like aluminum and plastics.

Pros:

Limitations:

Carbide

Overview: Carbide tools, made from tungsten carbide with a cobalt binder, offer a great balance between hardness and toughness.

Pros:

Applications: Ideal for turning steel, stainless steel, cast iron, and non-ferrous metals.

Ceramic Cutting Tools

Overview: Ceramic inserts are harder than carbide and used for high-speed finishing of hardened materials.

Pros:

Limitations:

Cermets

Overview: A combination of ceramic and metallic materials, cermets are ideal for fine turning and semi-finishing operations.

Pros:

Applications: Often used for finishing operations in high-volume automotive and aerospace production.

Cubic Boron Nitride (CBN)

Overview: Second only to diamond in hardness, CBN tools are used for turning hardened steels (>45 HRC).

Pros:

Limitations:

Polycrystalline Diamond (PCD)

Overview: PCD is ideal for turning non-ferrous and composite materials due to its extreme hardness and resistance to wear.

Pros:

Limitations:

Tool Steel

Overview: Used for special forming and turning tools, tool steels (like A2, D2) are durable and can be heat-treated for added hardness.

Pros:

Limitations:

Conclusion

The selection of tool materials is critical for optimizing turning operations, reducing downtime, and achieving desired surface finishes. Each material brings distinct advantages depending on the application, whether you're producing CNC turned parts from metal, plastic, ceramic, or composite. For complex requirements, experienced CNC turning shops like VMT help identify the best tool-workpiece combination to deliver precision, efficiency, and value.

Turning is one of the most widely used subtractive machining processes in the manufacturing industry, particularly in the production of round or cylindrical components. Whether it's performed manually or through advanced CNC turning services, turning offers numerous advantages for part manufacturers — but it also comes with some challenges that must be carefully considered before selecting it for your project.

Advantages of Turning

Turning operations are highly efficient when it comes to creating rotational parts with tight tolerances, precise finishes, and repeatable outcomes. With the rise of CNC turning shops and automation, this process has become indispensable in a wide range of industries, including aerospace, automotive, medical, and more.

High Precision

Turning is ideal for producing parts with tight dimensional tolerances. CNC lathes are capable of achieving accuracy levels within ±0.005 mm, which makes them suitable for precision components in aerospace and medical applications.

Fine Surface Finish

With the right cutting parameters and tooling, turning can achieve a surface roughness of less than 0.8 µm Ra. This smoothness reduces or eliminates the need for additional finishing processes, making it a cost-effective solution for certain aesthetic or functional requirements.

Versatility

Turning isn’t limited to just cutting cylindrical shapes. It supports multiple operations such as threading, boring, grooving, and knurling. You can process a wide variety of materials, from soft plastics to hardened steels and exotic alloys like titanium and Inconel.

Smooth Surface Finish

Unlike milling, which can leave tool marks due to toolpaths, turning creates clean, continuous cuts. This results in superior surface integrity, which is especially important in sealing or bearing surfaces.

Efficiency of Mass Production

Turning operations, especially when automated through CNC turning centers, are highly efficient for batch production. Once the setup is complete, machines can produce hundreds or thousands of identical parts with consistent quality and minimal supervision.

Efficiency of Automation

Modern CNC turning equipment integrates with CAD/CAM systems, allowing for quick programming, simulation, and toolpath optimization. This reduces lead times and human error, streamlining production for both prototypes and mass-manufactured parts.

Limitations of Turning Operations

Despite its many strengths, turning has certain limitations that manufacturers need to account for. These drawbacks often come into play when handling complex geometries, working with tough materials, or managing costs in low-volume production.

Expensive Equipment

CNC turning machines are a significant investment. High-end models with multi-axis capabilities, automatic tool changers, and live tooling features can cost tens of thousands of dollars. Additionally, ongoing maintenance and software upgrades add to long-term costs.

Tool Wear

Cutting tools used in turning — especially carbide or ceramic inserts — are subject to wear, particularly when working with hard metals or at high cutting speeds. Tool replacement and management increase operational costs and can cause production delays.

Material Limitations

Turning is best suited for cylindrical or symmetrical parts. Irregular, non-rotational geometries are more efficiently produced by milling or additive manufacturing methods. Also, brittle or layered materials like composites can chip or delaminate during turning.

Limitations of Complex Shapes

While some multi-axis CNC turning centers can handle more intricate shapes, traditional lathes struggle with complex 3D geometries or undercuts. For components requiring extensive contouring or pocketing, milling or 5-axis machining may be more suitable.

Setup Time and Limitations

For custom CNC turning or low-volume production, setup time (such as fixture design, tool loading, and programming) can be disproportionately high. This makes turning less ideal for prototypes unless using flexible or hybrid machines with quick-change systems.

Final Thought

Turning remains one of the most powerful and precise methods in the CNC machining world. Understanding its advantages and disadvantages helps manufacturers choose the right approach for producing CNC turned parts, ensuring optimal quality, lead time, and cost efficiency. If your project involves cylindrical components, VMT’s custom CNC turning services offer the expertise and equipment needed to meet even the most demanding specifications.

Creating high-quality CNC turned parts isn’t just about using the right machines — it starts at the design stage. Poor design decisions can lead to machining inefficiencies, increased costs, and part rejections. That’s why understanding how to optimize your design for turning operations is essential, especially when working with professional CNC turning services like VMT. These tips can help streamline manufacturing, reduce errors, and improve part performance.

Try to Maintain Even Wall Thickness

Wall thickness plays a critical role in both part stability and machining performance. Uneven wall thickness can lead to issues such as tool deflection, vibration, chatter, and uneven heat dissipation during the turning process. These factors increase the risk of dimensional inaccuracies, warping, or even part failure. Whenever possible, maintain consistent wall thickness throughout the part — especially in hollow or cylindrical sections — to enhance machining efficiency and structural integrity. For thin-walled parts, using support structures or internal features to reinforce the geometry can also help reduce deformation.

Avoid Making Complex Designs

Although modern CNC turning centers offer high levels of automation and multi-axis capabilities, overly complex part geometries can still increase the difficulty and cost of machining. Features like deep undercuts, internal grooves, sharp corners, and intricate contours often require custom tooling, special setups, or secondary operations. These increase cycle time, cost, and potential for errors. As a rule of thumb, stick to rotationally symmetrical designs, simplify transitions, and limit tight tolerances to only functional areas. This keeps the turning process faster and more reliable — especially in CNC prototype turning.

Select Standard Turning Thread Sizes

Custom or non-standard thread dimensions not only increase tooling costs but also complicate the turning process. Standard threads — such as UNC, UNF, ISO metric, or BSP — are widely supported by commercial tooling, making them faster and cheaper to machine. Whenever possible, design threaded features using industry-standard specifications, and avoid threads that require specialty inserts or taps. Also, ensure proper thread reliefs and runouts are included in the CAD model to help avoid over-cutting or incomplete threading.

Processing with One Setup

The fewer times a part needs to be re-mounted during machining, the better. Each time a part is re-clamped, the risk of alignment errors increases — which can cause dimensional inconsistencies or scrapped parts. To ensure high accuracy and repeatability, design your part so that all or most turning operations can be completed in a single setup. Consider features like symmetry, access to both faces, and minimizing the need for secondary machining processes. Multi-spindle or sub-spindle lathes further help in executing complex operations in one pass, reducing cycle time and labor.

Summary

By applying these design principles during the planning phase, you can maximize efficiency, minimize manufacturing risks, and lower production costs. Whether you’re producing small-batch CNC turned parts or looking to scale through a custom CNC turning shop, designing for manufacturability (DFM) is essential. Partnering with an experienced CNC machining factory like VMT ensures your designs are not only machinable — but also optimized for quality and turnaround.

Turning is one of the most versatile and widely used machining processes in modern manufacturing. Whether producing precision shafts or intricate threads, turning operations enable the creation of components across countless industries. From small-scale CNC prototype turning to full-scale production of complex assemblies, its impact spans everything from cars to spacecraft. Below, we explore how this foundational technique serves key industries by delivering reliable, accurate, and cost-effective parts.

In the automotive sector, turning plays a critical role in manufacturing components that demand high accuracy and durability. Engine parts, axles, crankshafts, brake discs, steering columns, and transmission shafts are just a few examples of parts commonly produced using CNC turning services. These parts often require tight tolerances and excellent surface finishes to ensure optimal performance, safety, and compliance with industry standards. Because turning is ideal for rotationally symmetrical parts, it’s particularly well-suited to high-speed production of cylindrical components used in internal combustion engines and drivetrain systems.

Key benefits of turning in automotive applications:

The aerospace industry demands extreme precision, traceability, and material integrity, and turning is vital in meeting those expectations. Aircraft landing gear components, engine turbines, fuselage fasteners, hydraulic valve spools, and instrumentation shafts are all parts that benefit from custom CNC turning. In aerospace, even the slightest error can compromise the safety or performance of an aircraft, which is why CNC turned parts must meet stringent specifications.

Materials like titanium, Inconel, and lightweight aluminum are often used, requiring robust tooling and cutting parameters. High-performance CNC turning shops with 5-axis or Swiss-style lathes are often deployed to handle complex geometries and exacting standards.

Precision is critical in the medical field — both for the performance and safety of components. Turning operations are used extensively in the production of surgical instruments, orthopedic implants, dental components, and medical connectors. These parts often require smooth finishes, precise tolerances, and compatibility with biocompatible materials like stainless steel, titanium, and medical-grade plastics.

Thanks to CNC prototype turning, medical device manufacturers can rapidly iterate and validate designs before moving into full-scale production. The flexibility of turning also supports the manufacture of patient-specific implants and devices.

Military and Defense Industry

In military and defense applications, turning is essential for producing mission-critical components that must endure harsh environments and extreme mechanical loads. Applications range from weapon systems and vehicle drive shafts to communication equipment and aerospace-grade components. These parts are often made from specialized alloys, such as heat-resistant steels and titanium, which are best machined using advanced CNC turning technology.

The ability to produce parts with high accuracy, repeatability, and robustness is a key reason why defense contractors rely on experienced CNC turning factories to meet demanding project specifications. Additionally, turning supports rapid response manufacturing, which is crucial for field operations or defense logistics.

Conclusion

Across these industries, turning is more than just a method — it's a cornerstone of reliable and scalable manufacturing. Whether you’re building a medical device prototype, assembling an aircraft engine, or designing high-tolerance automotive parts, turning operations provide the precision and flexibility needed for success. For companies looking to bring complex parts to life, partnering with a skilled CNC turning service provider like VMT ensures quality, speed, and consistent performance across all applications.

In modern manufacturing, CNC turning operations rely heavily on advanced software to ensure precision, repeatability, and efficiency. The software ecosystem used in custom CNC turning typically includes CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and simulation tools. These platforms are crucial for everything from designing part geometries to simulating toolpaths and optimizing machining parameters.

Commonly Used Software in CNC Turning:

These integrated platforms reduce setup time, improve tool life, and enable CNC turning services to handle complex geometries and tight tolerances efficiently.

Like any industrial process, CNC turning presents a range of safety risks if not properly managed. High-speed rotating parts, sharp cutting tools, and flying metal chips can create hazardous conditions for operators and equipment.

Key CNC Turning Hazards:

Proper training, machine guarding, personal protective equipment (PPE), and safety interlocks are critical for minimizing these risks in any CNC turning shop.

While turning operations are essential for manufacturing, they can have physical and material-related side effects depending on the process parameters, tooling, and materials used.

Common Side Effects:

These effects can be mitigated by using the right CNC turning tools, choosing optimal cutting parameters, and leveraging post-processing steps like polishing or coating.

Although CNC turning is more environmentally controlled than many traditional manufacturing methods, it still poses some ecological challenges.

Environmental Considerations:

Efforts to improve sustainability include adopting dry turning (no coolant), using biodegradable coolants, and sourcing recycled materials for CNC turned parts. Many CNC turning factories are also moving toward energy-efficient machinery and closed-loop recycling systems to reduce their ecological footprint.

Yes, turning is considered one of the most cost-effective CNC machining operations, particularly for cylindrical or symmetrical components. When compared to other methods like grinding or EDM, turning offers faster production rates and lower setup costs for standard parts.

Why Turning Is Cost-Effective:

For manufacturers working on custom CNC turning projects or large-volume CNC prototype turning, turning provides the perfect balance of performance, speed, and economic feasibility.

At first glance, a turning center and a lathe may appear to serve the same function—both rotate a workpiece while a cutting tool removes material. However, there are critical differences between the two, particularly when it comes to capability, automation, and versatility. Understanding the distinction between a traditional lathe and a CNC turning center is essential when choosing the right solution for CNC turning services, especially in complex or high-volume machining.

A lathe is a basic machine tool typically used for standard turning operations. Manual lathes require skilled machinists to operate levers and dials to control cutting actions. While they are ideal for straightforward projects and one-off components, they lack automation and advanced tooling features.

On the other hand, a CNC turning center is a more advanced, computerized version of a lathe. It often comes equipped with multiple axes (including live tooling for milling and drilling), automated tool changers, bar feeders, and part catchers. These features allow for multi-functional machining in one setup, improving productivity, precision, and part consistency. Turning centers are ideal for producing CNC turned parts with complex geometries, tight tolerances, and intricate designs.

In short, lathes are best for simpler, low-volume jobs, while turning centers are suited for high-precision, high-efficiency custom CNC turning operations.

Alternative Technologies for Turning

When selecting a machining method, turning is often the go-to for cylindrical parts. However, alternative processes like milling and grinding can be better suited in certain scenarios—particularly when different shapes, finishes, or tolerances are required. Let’s explore these two major alternatives and when they may be more beneficial than turning.

Milling is a machining process where a rotating cutting tool moves across a stationary workpiece to remove material. While turning shapes parts by spinning them, milling shapes parts by moving the cutter. Milling is ideal for creating flat surfaces, slots, pockets, and complex 3D shapes—features that are difficult to achieve through turning. It is especially useful for non-cylindrical parts or when the workpiece has multiple surfaces that require machining.

In a CNC milling factory, automated milling machines can achieve high levels of detail and precision, making them a powerful complement or alternative to turning. For example, CNC prototype machining often involves a combination of turning and milling to achieve the desired results.

Grinding is a finishing process that uses an abrasive wheel to achieve extremely fine surface finishes and tight tolerances. It is typically used after turning or milling to enhance precision or remove minimal material from hard surfaces. Grinding can achieve surface finishes as low as Ra 0.1 µm, which turning cannot match.

In applications such as aerospace or medical component manufacturing, grinding is often chosen for its consistency and surface integrity—especially when working with heat-treated metals or ceramics. While it is slower and more expensive than turning, it is irreplaceable when surface quality and tolerance precision are critical.

In conclusion, while turning is highly efficient and versatile for many cylindrical parts, milling and grinding offer unique strengths that may better serve specific applications. Knowing when to use each method—individually or in combination—ensures optimized performance, reduced costs, and improved part quality across your CNC machining services.

When your project demands precision, efficiency, and reliability, selecting the right partner is as crucial as the design itself. At VMT, we specialize in providing custom CNC turning services that meet the evolving needs of industries ranging from aerospace and automotive to medical and robotics. Whether you’re working on a prototype, a low-volume batch, or a full production run, our team is committed to delivering CNC turned parts that match your exact specifications.

Your Vision, Our Expertise

Choosing VMT means more than just outsourcing a machining job—it means forming a partnership with a dedicated CNC turning shop that prioritizes quality, innovation, and speed. We don’t just operate machines—we bring your ideas to life with advanced technology and engineering know-how. From material selection and DFM (Design for Manufacturability) feedback to post-processing and finishing, we work closely with you at every stage.

End-to-End CNC Turning Services

Our CNC prototype turning and production capabilities allow us to handle a wide range of part geometries and materials. Whether you’re using stainless steel, titanium, brass, or advanced plastics, our state-of-the-art turning centers ensure high precision and consistency. Equipped with multi-axis CNC lathes, automated tooling, and rigorous quality inspections, we guarantee parts that exceed expectations.

Why VMT?

Get Started Today

VMT is more than just a CNC machining factory—we’re your solution partner for everything from rapid prototyping to full-scale custom CNC turning production. Let’s make your project a reality with expert machining services you can trust. Contact us today for a free quote and discover the difference precision makes.

Turning is a foundational machining process that delivers high precision, excellent surface finishes, and adaptability across a wide range of industries. From facing and threading to taper turning and boring, each type of turning operation serves a specific purpose, making it essential to choose the right method based on your material, tolerance, and part design. By understanding the capabilities, tools, and parameters involved, and partnering with an experienced CNC turning service provider like VMT, you can ensure your components are produced with accuracy, efficiency, and reliability—every time.

1. What is the average cost per hour of turning?

The cost per hour for CNC turning varies based on factors like machine type, material, and complexity. On average, it ranges from $40 to $150 per hour, with high-precision or advanced 5-axis turning centers costing more.

2. Which turning operation can produce a narrow cut?

Parting-off (cut-off) operations are used to produce narrow, precise cuts to separate a part from the stock. It requires a thin cutting tool and high accuracy to maintain clean edges.

3. Are turning and boring the same process?

No. Turning is typically done on external surfaces, while boring enlarges or finishes an internal cylindrical surface. Boring is a secondary operation often performed after drilling.

4. Which turning operation is used specifically for sizing?

Straight turning is the primary operation used for sizing shafts and cylindrical components to precise diameters and lengths.

5. Do turning and drilling do the same thing?

Not exactly. Turning is performed on external surfaces using a stationary tool and rotating workpiece. Drilling creates internal holes using a rotating tool and stationary workpiece.

6. How many types of turning operations are there?

There are more than 15 turning operations, including facing, taper turning, contour turning, grooving, threading, boring, chamfering, knurling, and more.

7. What are the 7 lathe operations?

The basic 7 lathe operations are:

8. What are the 10 lathe operations?

The 10 commonly used lathe operations are:

9. What are the different types of CNC operations?

CNC operations include turning, milling, drilling, tapping, reaming, boring, threading, engraving, and grinding, depending on the part geometry and material.

10. How many types of CNC turning are there?

CNC turning encompasses manual turning, automatic turning, multi-axis turning, Swiss-type turning, and live tooling operations for more complex geometries.

11. What are the 5 operations that can be performed on a CNC lathe?

Five common operations include:

12. What are the methods of CNC turning?

The methods include:

13. What are the 3 main operations used in CNC milling centers?

The main CNC milling operations are:

14. What is a taper turning operation?

Taper turning involves producing a conical surface by gradually reducing or increasing the diameter of the workpiece along its length. It’s commonly used for shafts and spindles.

15. What is a chamfering operation?

Chamfering removes the sharp edge at the end of a component at a specific angle, typically 45°, to ease assembly or improve aesthetics and safety.

16. What is the difference between step turning and taper turning?

Step turning creates multiple cylindrical surfaces of different diameters along the length of the part, while taper turning creates a gradual change in diameter.

17. What is a knurling operation?

Knurling is used to produce a patterned texture (cross or straight lines) on cylindrical surfaces to improve grip or visual appeal, typically on knobs or tool handles.

These insights offer a well-rounded understanding of types of turning operations, helping you choose the most efficient method for your CNC turned parts project.