15 years one-stop China custom CNC machining parts factory

368 |

Published by VMT at Mar 04 2025 | Reading Time:About 8 minutes

368 |

Published by VMT at Mar 04 2025 | Reading Time:About 8 minutes

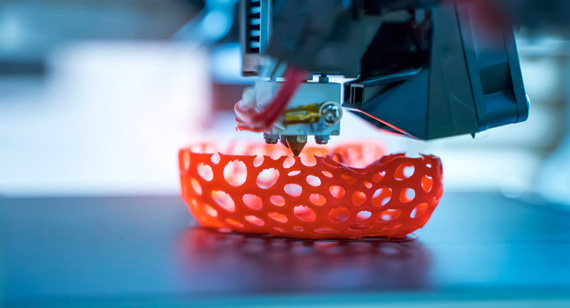

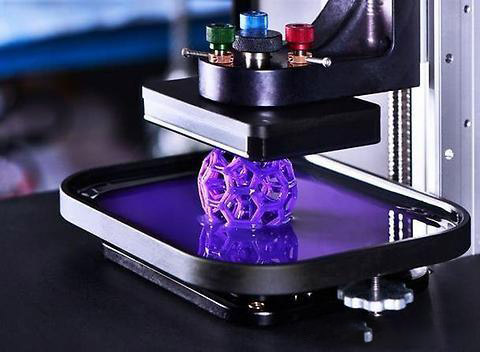

3D printing has revolutionized the manufacturing industry, offering a cost-effective, flexible, and rapid way to produce prototypes and functional parts. Whether you're an individual looking for custom 3D-printed parts or a business seeking CNC prototype machining, understanding 3D printing service costs is essential for making an informed decision.

However, 3D printing costs vary significantly based on material type, print size, complexity, post-processing, labor, and additional factors. This guide will break down how much 3D printing services cost, including key factors that influence pricing, so you can get the best value for your project.

3D printing, also known as additive manufacturing, is a process where a digital design is transformed into a physical three-dimensional object by adding material layer by layer. Unlike traditional CNC machining or injection molding, 3D printing does not require tooling, making it ideal for custom, low-volume, and complex designs.

Popular 3D Printing Methods:

3D printing costs can be high or low, depending on factors such as material, print complexity, machine type, and labor.

For businesses, outsourcing 3D printing services can save costs compared to purchasing and maintaining a 3D printer, especially for low-volume production.

3D printing service costs are typically determined by:

Understanding these key factors helps you estimate the total cost of your 3D-printed part.

How Much Do 3D Printing Components Cost?

The cost of 3D printing components varies significantly based on several factors, including material type, print complexity, machine type, labor, and post-processing requirements. Whether you’re using FDM, SLA, SLS, or MJF printing, each 3D printing service offers different pricing models that impact the final cost of a part.

A small plastic prototype may cost as little as $5–$30, while a high-detail resin model could be $50–$500. Industrial-grade metal 3D printing components can range from $500 to $10,000 or more, depending on material and precision requirements.

To determine the total cost of 3D printing, we must break down key cost factors, such as printing time, material expenses, labor costs, maintenance fees, and profit margins.

The cost of 3D-printed components depends on:

Basic Prototypes (PLA, ABS) – $5–$100 per part.

High-Detail Resin Prints – $20–$500 per part.

Metal 3D Printing (Titanium, Aluminum, Stainless Steel) – $300–$10,000 per part.

Understanding the Cost Breakdown

Several factors influence the cost of 3D printing components. These include:

Each of these factors plays a crucial role in determining the final cost of 3D-printed parts.

1. 3D Printing Costs

The base cost of 3D printing depends on the machine type, print speed, and operational efficiency.

2. 3D Printing Material Costs

Material cost is one of the biggest expenses in 3D printing. Different materials vary in price based on properties such as strength, flexibility, durability, and heat resistance.

| Material Type |

Cost Per kg/L |

Applications |

| PLA (FDM) | $15–$40/kg | Prototypes, models |

| ABS (FDM) | $20–$50/kg | Functional parts, automotive |

| PETG (FDM) | $25–$60/kg | Mechanical, food-safe applications |

| Standard Resin (SLA) | $50–$150/L | High-detail prototypes, jewelry |

| Engineering Resin (SLA) | $150–$500/L | Functional, heat-resistant parts |

| Nylon (SLS, MJF) | $50–$200/kg | Industrial parts, medical devices |

| Titanium (Metal 3D Printing) | $300–$1000/kg | Aerospace, medical implants |

3. 3D Printing Running Costs

Running a 3D printer involves more than just material costs. Other factors include:

4. 3D Printing Labor Costs

5. Maintenance Costs

6. 3D Model Costs

If a 3D model is not already available, there may be costs associated with:

For those using custom CNC machining or CNC prototype machining, 3D modeling costs are often integrated into production services.

7. Profit Margins for 3D Printing Services

Companies providing 3D printing services typically include markup pricing to cover:

Depending on the service provider, markup rates can range from 30% to 100% over base costs.

8. Other Hidden Costs

| Type of 3D Printing Component |

Estimated Cost |

| Basic PLA Prototype (FDM) | $5–$50 per part |

| High-Detail Resin Print (SLA/DLP) | $50–$300 per part |

| Industrial Nylon Print (SLS/MJF) | $100–$1000 per part |

| Metal 3D Printing (Titanium, Steel, Aluminum) | $500–$10,000 per part |

| Large Scale 3D Printed Prototypes | $1000+ per project |

For businesses involved in CNC machining, CNC prototype machining, and additive manufacturing, understanding 3D printing service costs helps optimize production budgets and improve efficiency.

Looking for affordable 3D printing or CNC machining services? Contact our experts today for the best pricing on custom 3D printing solutions!

The cost of 3D printing is heavily influenced by the material type used. Different materials have distinct properties, applications, and price ranges, making material selection a crucial factor in determining 3D printing service costs.

Materials fall into two primary categories: thermoplastics and thermosets. Each offers unique advantages based on strength, flexibility, durability, and post-processing needs. Additional factors, such as polishing, finishing, and manufacturing time, further influence final pricing.

To optimize custom CNC machining and CNC prototype machining, it’s essential to understand how material selection impacts 3D printing costs.

1. Thermoplastics: The Most Common 3D Printing Materials

What Are Thermoplastics?

Thermoplastics are plastics that soften when heated and harden when cooled, allowing for easy melting and reprocessing. These materials are commonly used in FDM (Fused Deposition Modeling) 3D printing, making them affordable and widely available.

Common Thermoplastic 3D Printing Materials & Their Costs

| Material |

Cost per kg |

Best Used For |

| PLA (Polylactic Acid) | $15–$40 | Prototyping, hobbyist prints, eco-friendly applications |

| ABS (Acrylonitrile Butadiene Styrene) | $20–$50 | Stronger functional parts, automotive, industrial uses |

| PETG (Polyethylene Terephthalate Glycol) | $25–$60 | Durable parts, food-safe applications, medical components |

| TPU (Thermoplastic Polyurethane) | $40–$100 | Flexible and rubber-like parts, phone cases, wearables |

| Nylon (Polyamide) | $50–$200 | High-strength industrial parts, gears, mechanical components |

| Carbon Fiber-Filled Filament | $50–$250 | Lightweight, high-strength parts, aerospace applications |

| PEEK (Polyether Ether Ketone) | $500–$1000 | High-performance aerospace and medical implants |

2. Thermosets: High-Precision Resins for SLA & Industrial 3D Printing

What Are Thermosets?

Thermosets are liquid resins that harden permanently when cured by UV light or heat. Unlike thermoplastics, they cannot be remelted or reshaped, making them ideal for high-detail, smooth-surface 3D printing applications.

Common Thermoset Resins & Their Costs

| Material |

Cost per liter |

Best Used For |

| Standard Resin | $50–$150 | Prototypes, hobbyist prints, detailed models |

| Tough Engineering Resin | $100–$300 | Durable functional parts, mechanical prototypes |

| High-Temperature Resin | $200–$500 | Heat-resistant applications, aerospace, automotive |

| Flexible Resin | $150–$400 | Soft-touch parts, ergonomic designs, wearables |

| Dental & Medical Resin | $200–$600 | Surgical guides, dental models, medical-grade parts |

| Jewelry Casting Resin | $300–$800 | Lost-wax casting, high-detail jewelry, investment casting |

Post-processing is a critical step in enhancing the final appearance, strength, and functionality of 3D-printed parts. Different levels of finishing can add to 3D printing service costs.

1. Polishing Costs

Polishing helps achieve a smoother finish by removing layer lines and imperfections.

2. Finishing Costs

3D Printing Service Pricing is Based on Six Key Parameters:

1. Material Volume – The amount of material required for the part (more material = higher cost).

2. Material Selection – Thermoplastics are cheaper, while high-performance resins and metals are expensive.

3. Surface Treatment – Basic prints are affordable, while polished, painted, or plated parts cost more.

4. Component Size – Larger parts require more material and longer printing times, increasing costs.

5. Batch Size – Bulk printing reduces per-part costs through better machine efficiency.

6. Manufacturing Time – Complex models with fine layer resolutions take longer, increasing costs.

General Price Estimates by Model Size & Material Type:

| Model Size & Complexity |

PLA (FDM) |

Resin (SLA/DLP) |

Nylon (SLS/MJF) |

Metal (DMLS, EBM) |

| Small Prototype (5x5 cm, basic design) | $5–$50 | $20–$80 | $50–$150 | $200–$800 |

| Medium-Sized Functional Part (10x10 cm, high detail) | $50–$200 | $80–$300 | $150–$500 | $800–$3,000 |

| Large Industrial Model (20x20 cm, durable material) | $200–$500 | $300–$1000 | $500–$2000 | $3,000–$10,000+ |

Conclusion: Choosing the Right Material for Cost-Effective 3D Printing

For those looking for affordable 3D printing services, custom CNC machining, or CNC prototype machining, choosing the right material and post-processing options can greatly optimize costs.

Looking for high-quality 3D printing services? Contact our experts today for the best material options and pricing!

The cost of 3D printing per hour varies significantly based on the type of 3D printer, material used, printing speed, and complexity of the object. Whether you’re using FDM, SLA, SLS, or metal 3D printing, each process has different hourly operational costs, including electricity, wear and tear, labor, and maintenance expenses.

Understanding hourly 3D printing costs helps businesses and individuals optimize 3D printing service expenses while ensuring high-quality results.

Not Always – Material Choice Depends on Application

When Should You Choose Expensive Filaments?

For general use, budget-friendly PLA and PETG filaments provide the best value.

For professional applications, high-end filaments justify the added cost.

How Much Energy Does a 3D Printer Use?

Factors Affecting Power Consumption:

To minimize electricity costs, consider energy-efficient printers and optimize printing settings for faster production.

A 3D printing cost calculator helps estimate the total price of a print job by factoring in:

Online 3D printing calculators allow users to compare costs across different services and machines.

1. 3DPrintingPro – Comprehensive Cost Estimator

2. Omni Calculator – Quick Cost Breakdown

3. Shatter Box – Business-Focused Price Tool

4. 3DAddict – Online Price Comparison for Services

Conclusion: How to Reduce 3D Printing Costs

For businesses and individuals looking for cost-effective 3D printing services, CNC prototype machining, and custom CNC machining, calculating and optimizing expenses ensures the best quality-to-cost ratio.

Need affordable 3D printing or CNC machining services? Contact our experts today for the best pricing and quality!

Traditional manufacturing methods like CNC machining, injection molding, and casting have long been the standard for producing high-quality parts. However, 3D printing (additive manufacturing) is rapidly transforming the industry by offering advantages such as faster production, lower costs, and greater design flexibility.

Unlike traditional technologies, 3D printing eliminates the need for tooling, reduces material waste, and enables on-demand manufacturing, making it ideal for prototypes, small-batch production, and complex geometries.

Let’s explore the key advantages of 3D printing over conventional manufacturing and why it’s increasingly being used in CNC machining factories, CNC prototype machining, and custom CNC machining.

1. Faster and More Cost-Effective Production

Example: A CNC machining factory needing a custom fixture can 3D print it within a day, avoiding expensive machining and material costs.

2. Just-in-Time Production: No Warehousing, No Overproduction

Example: Instead of producing 5,000 injection-molded parts and storing them, a company can 3D print smaller batches based on immediate demand, reducing waste and storage costs.

3. Fully Functional and Well-Made Modules

Example: A medical device manufacturer can 3D print a customized prosthetic limb tailored to an individual patient’s needs without additional manufacturing costs.

4. Highly Flexible Production Processes

Example: Aerospace engineers testing a new jet engine component can 3D print multiple variations to analyze performance before committing to mass production.

5. Lightweight Construction

Example: Boeing and Airbus use 3D-printed titanium and composite parts to reduce the weight of aircraft, improving fuel efficiency.

6. Undercuts: Complex Designs Without Tooling Challenges

Example: Aerospace engineers can 3D print complex cooling channels inside a turbine blade, which would be nearly impossible using traditional machining.

7. White Label Solutions

Example: A startup in the medical field can design and 3D print custom-branded orthopedic implants without investing in expensive CNC machining tools.

8. Free-Form Geometries: No Limits to Design Possibilities

Example: Jewelry designers use 3D printing to create intricate, one-of-a-kind pieces that would be too difficult or expensive to produce with traditional techniques.

9. Model Customization: Tailored Production Without Additional Costs

Example: Dental professionals can 3D print customized Invisalign aligners and surgical guides, ensuring precise patient treatment without high production costs.

10. Direct Thread Printing from M5 Onwards

Example: Industrial manufacturers producing custom robotic arms can 3D print parts with pre-threaded holes, reducing post-processing time.

Conclusion: Why 3D Printing is the Future of Manufacturing

3D printing is redefining production processes by offering cost-effective, highly flexible, and rapid manufacturing. While traditional methods like CNC machining and injection molding remain essential for large-scale production, 3D printing excels in prototyping, small-batch manufacturing, and complex designs.

For businesses needing custom CNC machining, CNC prototype machining, and advanced manufacturing solutions, integrating 3D printing with traditional technologies provides the best of both worlds.

Looking for expert 3D printing and CNC machining services? Contact us today to discuss your project!

As industries strive for eco-friendly manufacturing solutions, 3D printing is emerging as a sustainable alternative to traditional methods like vacuum casting, injection molding, and CNC machining. Compared to vacuum casting, which requires molds, material waste, and additional processing, 3D printing reduces waste, eliminates unnecessary tooling, and consumes less energy, making it a more environmentally friendly choice.

From reducing material waste to minimizing energy consumption and transportation emissions, 3D printing offers a more sustainable approach to production. This article explores why 3D printing is greener than vacuum casting and how it benefits industries such as automotive, aerospace, and medical manufacturing.

1. Almost Waste-Free Production

Example: In vacuum casting, excess silicone molds and urethane materials become non-recyclable waste, whereas 3D printing only consumes the exact amount of material required for the object.

2. Reuse of Surplus Material – Up to 80% Depending on the Printing Technology

Example: In MJF 3D printing, excess nylon powder from one batch can be reused in the next print, reducing overall material waste by up to 80%.

3. Simple Manufacturing of Spare Parts Speeds Up Repairs and Extends Product Life

Example: An automotive company can 3D print a replacement gear for a vehicle on-site, instead of waiting weeks for a part to be cast or machined.

4. Local Manufacturing Eliminates Long-Distance Transport and Reduces Carbon Emissions

Example: Instead of importing vacuum-cast parts from China, a German manufacturer can 3D print components locally, cutting down on carbon emissions associated with shipping.

5. Small Batches Manufactured with SLS or MJF Use Less Energy Than Injection Molding

Example: A startup producing custom phone cases can use SLS 3D printing instead of injection molding, eliminating mold costs and reducing energy consumption.

6. No Need for Chemical Cutting Fluids in 3D Printing

Vacuum casting and CNC machining require cutting fluids, lubricants, and chemicals to shape materials, leading to water consumption and pollution.

3D printing eliminates the need for these harmful chemicals, significantly reducing:

This makes additive manufacturing a cleaner and more eco-friendly option.

Example: Aerospace manufacturers using 3D printing avoid the use of coolants and lubricants required in CNC milling processes, reducing industrial wastewater contamination.

7. Lightweight Construction in Automotive & Aerospace Reduces Fuel Consumption

Example: Boeing and Airbus use 3D-printed titanium components in aircraft, reducing weight and improving fuel efficiency by up to 15%.

Conclusion: 3D Printing is the Future of Sustainable Manufacturing

Compared to vacuum casting, CNC machining, and injection molding, 3D printing offers a more eco-friendly and sustainable manufacturing process.

For businesses looking for custom CNC machining, CNC prototype machining, or sustainable production solutions, integrating 3D printing can significantly lower costs and environmental impact.

Interested in sustainable 3D printing solutions? Contact us today for eco-friendly and cost-effective 3D printing services!

The cost of 3D printing services varies based on location, material type, print complexity, and service provider. Whether you need a local 3D printing shop, an online 3D printing service, or a hobbyist printer, prices range from a few dollars for simple prototypes to thousands of dollars for industrial-grade parts.

To find the best 3D printing service near you, consider local makerspaces, professional print shops, and online platforms that offer competitive pricing.

Let’s explore the pricing breakdown and factors affecting 3D printing service costs near you.

Most Affordable 3D Printers for Home & Business Use

1. Budget-Friendly 3D Printers (Under $500) – For Hobbyists & Small Projects

2. Mid-Range 3D Printers ($500–$2000) – For Small Business & Professionals

3. Industrial 3D Printers ($2000–$50,000) – For Manufacturing & CNC Machining Services

Hobbyists can choose budget-friendly FDM or resin printers for small projects.

Businesses should invest in mid-range printers for higher accuracy and reliability.

Industrial 3D printing services use high-end machines for aerospace, automotive, and medical applications.

Online 3D printing services provide access to professional-grade materials and technologies, often at better rates than local shops.

Cost Breakdown by Printing Technology

| 3D Printing Technology |

Cost Per Print |

Best For |

| FDM (Fused Deposition Modeling) | $5–$100 | Prototypes, mechanical parts |

| SLA (Stereolithography) | $20–$500 | High-detail miniatures, jewelry, medical parts |

| SLS (Selective Laser Sintering) | $100–$1000 | Strong nylon components, industrial parts |

| MJF (Multi Jet Fusion) | $150–$2000 | High-strength prototypes, low-volume production |

| DMLS/SLM (Metal 3D Printing) | $500–$10,000 | Aerospace, medical implants, automotive |

FDM is the cheapest online service option for hobbyists and rapid prototyping.

SLA and SLS printing are best for professional applications requiring high detail and durability.

Metal 3D printing is the most expensive but essential for specialized industries like aerospace and medical.

Popular Online 3D Printing Services & Their Prices:

Many hobbyists offer affordable 3D printing services through local marketplaces, social media, and online platforms.

Where to Find Hobbyist 3D Printing Services:

Hobbyist 3D printing services are ideal for personal projects, cosplay, prototypes, and small production runs.

Conclusion: Finding the Best 3D Printing Service for Your Budget

Looking for high-quality 3D printing services near you? Contact us today for the best pricing and materials!

How Much Does It Cost to 3D Print at Home?

Owning a home 3D printer can be an exciting and cost-effective way to produce prototypes, hobby models, and functional parts. However, 3D printing costs go beyond just purchasing the printer—they include material costs, electricity, maintenance, and additional expenses like post-processing and repairs.

For hobbyists and small businesses, understanding the total cost of home 3D printing is crucial for determining whether it’s a better investment than using a 3D printing service.

Let's break down the full cost of home 3D printing, including printing material costs, electricity consumption, and other hidden expenses.

Printing Material Costs

The cost of 3D printing materials depends on the type of printer you use. The two most common home 3D printing technologies are:

Each material has different pricing and properties, affecting the overall cost of home 3D printing.

Material Costs for FDM 3D Printers

FDM (Fused Deposition Modeling) is the most affordable 3D printing method for home users. It works by melting plastic filament and layering it to form an object.

Common FDM Filaments & Their Costs

| Material |

Cost per kg |

Best Used For |

| PLA (Polylactic Acid) | $15–$40 | Easy-to-print, prototypes, hobby models |

| ABS (Acrylonitrile Butadiene Styrene) | $20–$50 | Stronger functional parts, automotive use |

| PETG (Polyethylene Terephthalate Glycol) | $25–$60 | Tough and impact-resistant parts |

| TPU (Flexible Filament) | $40–$100 | Rubber-like objects, phone cases |

| Nylon (Polyamide) | $50–$200 | Industrial-grade, durable parts |

| Carbon Fiber-Filled Filament | $50–$250 | High-strength, lightweight applications |

Average home users spend $20–$50 per kg of filament, which can produce 20–30 small models or 3–5 large models.

Material Costs for Resin 3D Printers

SLA (Stereolithography) and DLP (Digital Light Processing) 3D printers use liquid resins instead of filaments. These printers offer higher precision and smoother finishes but cost more per print.

Common Resin Types & Their Costs

| Resin Type | Cost per liter | Best Used For |

| Standard Resin | $50–$150 | High-detail prototypes, miniatures |

| Tough Engineering Resin | $100–$300 | Strong, impact-resistant parts |

| Flexible Resin | $150–$400 | Rubber-like objects, soft-touch applications |

| High-Temperature Resin | $200–$500 | Heat-resistant applications |

| Dental/Medical Resin | $200–$600 | Surgical guides, dental models |

| Jewelry Casting Resin | $300–$800 | Investment casting, fine details |

Average resin 3D printing costs range from $50–$200 per liter, producing 10–20 small models or 3–5 medium-sized models.

Electricity Costs

Electricity consumption varies based on printer type, print duration, and heated components (e.g., heated beds, curing stations, high-power lasers).

Estimated Electricity Costs Per Hour

Total Electricity Cost for Common Prints

Electricity costs are minimal for small home 3D printers but increase with longer, high-power prints.

Aside from materials and electricity, 3D printing at home involves extra costs for maintenance, repairs, and post-processing.

1. Printer Maintenance & Repairs

2. Post-Processing Costs

3. Software & Design Costs

3D printing at home requires occasional extra spending on maintenance, software, and finishing.

Want to Compare 3D Printing Costs? Try These Tools

These services help home users and businesses determine whether it's cheaper to print at home or use a professional 3D printing service.

Looking for affordable 3D printing solutions? Contact us for expert guidance on materials, pricing, and custom CNC machining!

For custom CNC machining and CNC prototype machining, 3D printing is an excellent alternative for prototyping, reducing costs, and improving production efficiency.

Need high-quality 3D printing services? Contact us for the best pricing on CNC machining and 3D printing today!

Is 3D Printing Getting Cheaper?

Yes, 3D printing is becoming more affordable due to advancements in technology, increased competition, and wider availability of low-cost materials and printers.

Overall, hobbyist and small-business 3D printing are more affordable than ever, while industrial 3D printing remains expensive but is becoming more cost-effective.

How Much Does 3D Printing Cost Per Gram?

Example: A 100g PLA print would cost $2–$10, while a metal print of the same weight could cost $200–$1000.

Is the 3D Printing Business Profitable?

Yes, 3D printing businesses can be profitable, but profitability depends on:

Many businesses generate profit by offering custom 3D printing, prototyping, or product development services.

How Much Does It Cost to Have Someone 3D Print Something?

Basic FDM prints start at $5–$50, depending on material and size.

For small projects, local makerspaces or hobbyist services may offer cheaper rates than industrial services.

How Much Does 3D Printing Cost Per kg?

FDM printing is the most cost-effective, while resin and metal 3D printing are significantly more expensive.

How Much Does a 3D Printer Cost Per Hour?

The longer a print takes, the higher the cost—choosing optimal print settings helps reduce expenses.

How Much Does 3D Printing PLA Cost?

PLA remains one of the most affordable and widely used 3D printing materials.

Why is 3D Printing So Expensive?

For prototyping and small-batch production, 3D printing is often more cost-effective than traditional manufacturing.

How Much Does 1 kg of Filament Cost?

PLA and ABS are the most affordable, while high-performance filaments are much more expensive.

How Long Does It Take to Print 1 Kg of Filament?

Printing time depends on model size, infill density, and printer settings.

How Much is PLA Per Ton?

Manufacturers using large-scale 3D printing can save money by purchasing PLA in bulk.

Why is PLA More Expensive?

Despite being more expensive than traditional plastics, PLA’s ease of use and eco-friendliness make it a top choice.

How Many Feet is 1 kg of PLA?

Knowing filament length helps estimate how many prints can be completed per spool.

How Much is PLA in Euro?

PLA prices in Europe are similar to US prices, with slight variations based on import taxes and supplier location.

Final Thoughts on 3D Printing Costs

3D printing costs depend on printer type, material selection, and project complexity. Hobbyist printing is becoming cheaper, while industrial 3D printing remains costly but is improving in affordability.

Looking for cost-effective 3D printing or CNC machining services? Contact us for expert guidance and competitive pricing!