15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 10 07

2025 10 07 Machining nickel-based superalloys presents formidable challenges due to their unique properties, necessitating advanced strategies, specialized tooling, and rigorous process control. Success hinges on a deep understanding of material characteristics, meticulous planning, optimized cutting parameters, and comprehensive quality assurance. As a source manufacturer, our expertise transforms these inherent difficulties into high-quality, precise, and reliable components.

66

66

Read more

Read more

VMT

VMT  2025 10 04

2025 10 04 This article serves as your authoritative guide. We will dissect 14-gauge steel, clarifying its precise dimensions, exploring its versatile applications, and detailing the manufacturing considerations that truly matter. Precision, I tell you, is everything.

66

66

Read more

Read more

VMT

VMT  2025 10 03

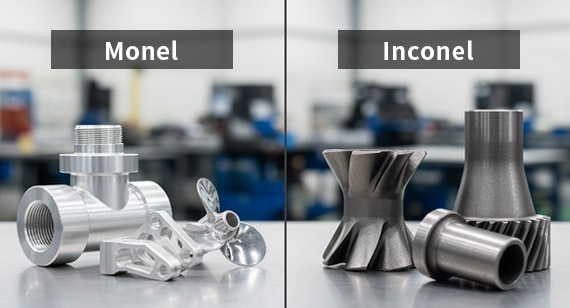

2025 10 03 Monel and Inconel are both high-strength, corrosion-resistant nickel alloys vital for demanding applications. Monel, primarily nickel and copper, excels in marine environments, resisting saltwater and acids. Inconel, a nickel-chromium superalloy, withstands extreme heat, pressure, and oxidation, making it indispensable for aerospace and high-temperature industrial uses.

66

66

Read more

Read more

VMT

VMT  2025 10 02

2025 10 02 Choosing between 7075 aluminum and 4140 steel for precision CNC machining hinges on balancing specific project demands like weight, strength, cost, and environmental resistance. 7075 offers superior strength-to-weight for aerospace and defense, while 4140 provides exceptional hardness and fatigue resistance crucial for heavy-duty industrial applications and tooling. VMT specializes in processing both, ensuring optimal performance.

66

66

Read more

Read more

VMT

VMT  2025 10 01

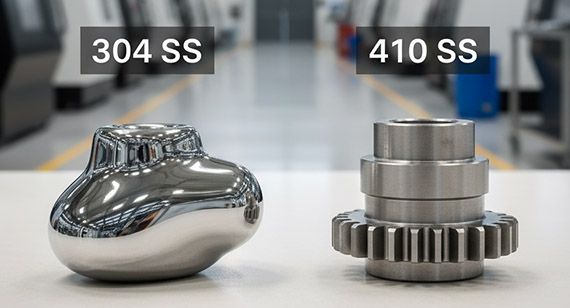

2025 10 01 When differentiating between 304 and 410 stainless steel, understanding their core metallurgical classifications is key. 304 is an austenitic stainless steel, known for its excellent corrosion resistance and ductility, while 410 is a martensitic stainless steel, distinguished by its high strength, hardness, and heat treatability. The optimal selection hinges entirely on the specific performance requirements of your application, balancing factors like environmental exposure, mechanical stress, and manufacturing processes.

66

66

Read more

Read more

VMT

VMT  2025 09 30

2025 09 30 When choosing stainless steel for precision parts, 410 and 316 represent distinct classes with specific strengths. 410 is a martensitic alloy known for its hardness and strength, particularly after heat treatment, making it suitable for high-wear applications. 316, an austenitic alloy, offers superior corrosion resistance, especially against chlorides, and excellent weldability, ideal for demanding chemical environments. Understanding these core differences is essential for long-term project success.

66

66

Read more

Read more

VMT

VMT  2025 09 29

2025 09 29 904L stainless steel is a high-alloy super austenitic stainless steel known for its exceptional resistance to various forms of corrosion. Its unique composition, including high levels of nickel, chromium, molybdenum, and copper, provides superior performance in highly aggressive environments, making it a preferred material for critical applications across industries where standard stainless steels fall short.

66

66

Read more

Read more

VMT

VMT  2025 09 27

2025 09 27 Kovar is a critical iron-nickel-cobalt alloy known for its controlled thermal expansion properties, making it ideal for hermetic sealing with glass and ceramic. Achieving successful Kovar CNC machining requires deep technical expertise to manage its unique hardness, toughness, and thermal characteristics, ensuring dimensional accuracy and surface integrity for high-reliability applications.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!