15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 09 16

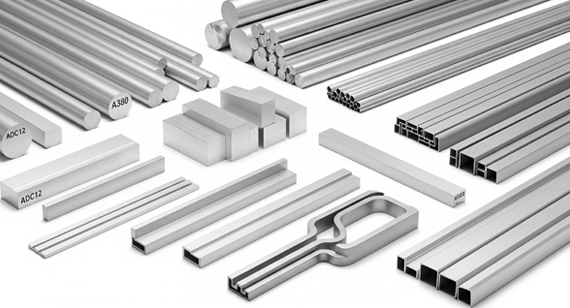

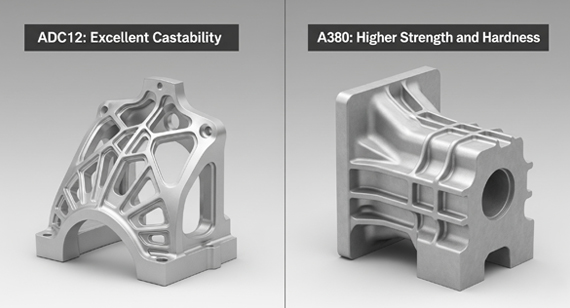

2025 09 16 ADC12 aluminum, A380 aluminum, and 6063 aluminum differ mainly in composition, strength, and applications. ADC12 alloy is widely used for die casting, A380 aluminum offers excellent strength-to-weight balance for automotive and aerospace parts, and 6063 aluminum is preferred for extrusion, especially in architectural and decorative applications. Choosing depends on casting, extrusion, or machining needs.

66

66

Read more

Read more

VMT

VMT  2025 09 15

2025 09 15 The differences between 4032 aluminum alloy and 2618 aluminum alloy lie in their composition and properties. 4032 alloy, with its higher silicon content, offers improved wear resistance and dimensional stability, while 2618 alloy offers superior strength and toughness, making it suitable for high-temperature, high-stress applications like racing engines. Choosing which aluminum alloy to use depends on whether you need durability or demand extreme performance.

66

66

Read more

Read more

VMT

VMT  2025 09 13

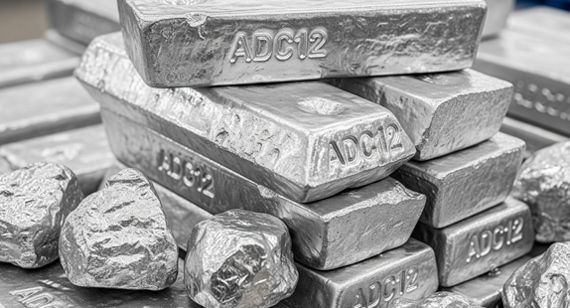

2025 09 13 ADC12 aluminum alloy is a die-casting material known for excellent machinability, high corrosion resistance, dimensional stability, and good strength. It is widely used in automotive, electronics, and industrial applications where lightweight, durable, and cost-effective parts are required.

66

66

Read more

Read more

VMT

VMT  2025 09 12

2025 09 12 VG10 stainless steel is a high-quality Japanese steel known for its hardness, corrosion resistance, and excellent edge retention. It is widely used in knives, tools, and CNC machined parts, offering a perfect balance of strength and durability. This makes VG10 steel an ideal choice for projects requiring precision and long-lasting performance.

66

66

Read more

Read more

VMT

VMT  2025 09 11

2025 09 11 MC66 steel is a high-performance stainless steel known for its excellent hardness, wear resistance, and corrosion protection. It is widely used in CNC machining parts, knives, and industrial components due to its strength and durability. MC66 stainless steel combines toughness with machinability, making it ideal for demanding applications.

66

66

Read more

Read more

VMT

VMT  2025 09 10

2025 09 10 ADC12 aluminum and A380 aluminum are both popular die casting alloys with similar properties. The main difference lies in composition: ADC12 is preferred in Asian markets, while A380 dominates North America. Each offers unique casting performance, cost advantages, and machining suitability.

66

66

Read more

Read more

VMT

VMT  2025 09 09

2025 09 09 440C stainless steel is a high-carbon martensitic stainless steel known for its excellent hardness, wear resistance, and moderate corrosion resistance. It is widely used in knives, surgical instruments, and precision CNC machined parts. Combining strength and durability, 440C stainless steel offers a cost-effective solution for demanding applications.

66

66

Read more

Read more

VMT

VMT  2025 09 08

2025 09 08 420 stainless steel is a hardenable martensitic steel known for high wear resistance, while 316 stainless steel is an austenitic grade with excellent corrosion resistance. Choose 420 for cutting tools and wear parts; select 316 for marine, chemical, or medical applications.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!