15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 08 22

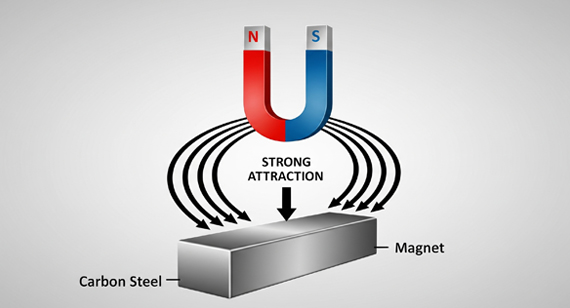

2025 08 22 Steel can be magnetic depending on its composition and structure. Carbon steel and ferritic or martensitic stainless steels are magnetic, while austenitic stainless steels are generally non-magnetic. Heat treatment, alloying, and crystal structure affect steel magnetism. Understanding these properties ensures proper selection for CNC machining parts and industrial applications.

66

66

Read more

Read more

VMT

VMT  2025 08 21

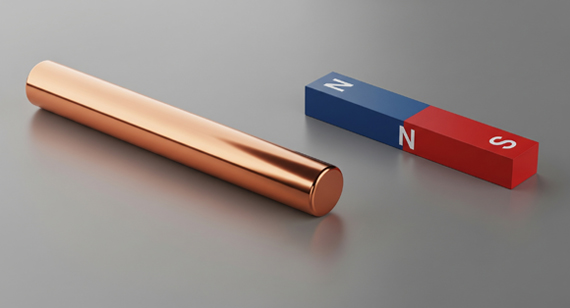

2025 08 21 Copper is not magnetic. It is classified as diamagnetic, meaning it weakly repels magnetic fields instead of attracting them. This property comes from its electron structure, making pure copper unsuitable for magnetic applications but highly valuable for conductivity and nonmagnetic environments.

66

66

Read more

Read more

VMT

VMT  2025 08 20

2025 08 20 Most metals conduct electricity because of their free electrons. The best conductors are silver, copper, and gold, followed by aluminum and brass. Factors such as temperature, impurities, and alloying can affect conductivity. For precision applications, CNC machining services can help manufacture conductive parts with the right balance of strength and electrical performance.

66

66

Read more

Read more

VMT

VMT  2025 08 19

2025 08 19 The key difference between 6061 aluminum T6, T651, and T6511 is stress relief and dimensional stability. T6 is heat-treated and naturally aged, T651 is stress-relieved by stretching, and T6511 is stress-relieved by stretching and minor straightening. These differences affect machinability, performance, and cost for aluminum CNC machined parts.

66

66

Read more

Read more

VMT

VMT  2025 08 18

2025 08 18 Iron comes in multiple forms—pure iron, pig iron, wrought iron, cast iron, stainless steel, carbon steel, alloy steel, tool steel, ductile iron, and gray cast iron. Each has distinct properties and applications. Understanding their differences ensures optimal material selection for construction, manufacturing, and CNC machined parts production.

66

66

Read more

Read more

VMT

VMT  2025 08 15

2025 08 15 Metals that are magnetic include iron, cobalt, nickel, most steels, and certain rare earth metals. These materials exhibit ferromagnetism, meaning they are strongly attracted to magnets and can become magnets themselves.

66

66

Read more

Read more

VMT

VMT  2025 08 15

2025 08 15 6061-T6 is heat-treated aluminum without stress relief, 6061-T651 is stress-relieved T6 for improved stability, and 6061-T6511 is stress-relieved with controlled straightness for extruded shapes. Choosing depends on dimensional tolerance needs, part size, and machining requirements.

66

66

Read more

Read more

VMT

VMT  2025 08 14

2025 08 14 Yes, carbon steel is generally magnetic because it contains iron, a ferromagnetic material. Its magnetism depends on carbon content, crystal structure, and heat treatment. Most carbon steels used in CNC machining parts will strongly attract magnets, making them suitable for applications requiring magnetic properties.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!