15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2026 01 30

2026 01 30 For aluminum parts manufacturing through CNC machining and industrial extrusion, 6060 aluminum alloy stands out as the good choice when aesthetics, complex geometry, and superior surface finish are non-negotiable. As a heat-treatable 6xxx series (Al-Mg-Si

66

66

Read more

Read more

VMT

VMT  2026 01 29

2026 01 29 You may have heard of the most versatile aluminum alloy 6061-T6, manufactured structural parts from automotive parts, industrial equipment to different kinds of hardware. It surely has high strength, and an affordable price due to its universal supply. However, there must be some other uses that it cannot meet really high strength. This is what this article will discuss— 7075-T6 aluminum —also known as "aircraft grade aluminum," stands as one of the highest strong alloy. It offers a strength-to-weight ratio that rivals many steels, making it a considered option for aerospace, defense, and high-stress industrial applications. But what’s about its characteristics and limitation? Is there any better alternative material for 7075-T6? What about its machining? This guide explores everything you need to know about material 7075 T6 aluminum.

66

66

Read more

Read more

VMT

VMT  2026 01 28

2026 01 28 In this comprehensive guide, we will dive deep into 6061-T6 aluminum—the most widely used and popular supply state of the 6061 alloy—detailing its properties, applications, and manufacturability (including its performance in CNC machining, welding, and bending).

66

66

Read more

Read more

VMT

VMT  2026 01 27

2026 01 27 In the world of high-performance manufacturing, finding a material that balances light weight, high strength, and extreme environmental resistance is critical. 5083 Aluminum Alloy stands out as the premier choice for engineers facing the harshest conditio

66

66

Read more

Read more

VMT

VMT  2026 01 26

2026 01 26 You might be familiar with the brilliant luster of standard chrome plating. Its ability to provide a durable, corrosion-resistant silver finish is well-suited for various industrial parts. Yet, in the realms of precision engineering and high-end design, black chrome is emerging as a surface process for those seeking not only a unique smoke-grey or deep-black aesthetic but also durable and non-reflective performance. But how does this process differ from conventional plating? What chemical additives are required to manipulate its performance? What about color changes and texture? What about the price? These are the key points this article will share with you.

66

66

Read more

Read more

VMT

VMT  2026 01 25

2026 01 25 In this guide, we will dive deep into what makes 1018 steel unique, properties and composition, material selection about 1018 steel with other alloys, its machining and surface protection, heat treatment and hardening by carburizing.

66

66

Read more

Read more

VMT

VMT  2026 01 24

2026 01 24 Both Silicon Bronze and Brass have a wide range of grades due to fine-tuning the content of their alloying elements showing different in their properties. For instance, Naval Brass (C46400) contains tin, which provides excellent resistance to saltwater dezincification and meets the strength requirements for most marine hardware. In such cases, despite High-Silicon Bronze (C65500) having superior properties, Naval Brass is often the more pragmatic choice. When can Silicon Bronze and Brass be interchanged? What are their differences in processing and manufacturing? How do they differ in aesthetics and surface treatment? These are the key points this article will share with you.

66

66

Read more

Read more

VMT

VMT  2026 01 23

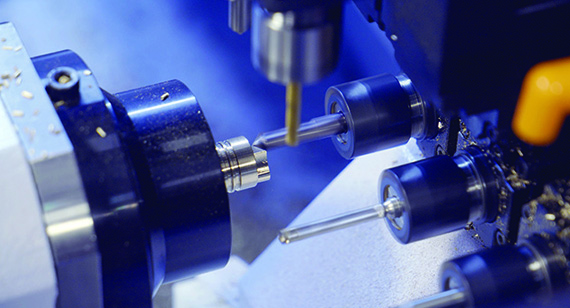

2026 01 23 In the field of precision CNC machining, selecting the right material is key to balancing part quality with production costs. If you are producing high volumes of complex parts—such as fasteners, hydraulic/pneumatic components, timing gears, miniature shafts, or precision bushings—11SMn30 (EN 1.0715) steel may be your best CNC machining carbon steel. As a non-alloy, low-carbon free-cutting steel, 11SMn30 is renowned for its exceptional machinability. This article explores its material properties, the pros and cons of processing, environmental considerations, and how it helps you achieve cost-effectiveness in CNC machining.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!