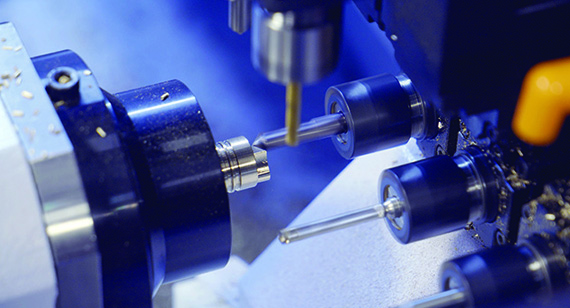

15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2026 01 23

2026 01 23 In the field of precision CNC machining, selecting the right material is key to balancing part quality with production costs. If you are producing high volumes of complex parts—such as fasteners, hydraulic/pneumatic components, timing gears, miniature shafts, or precision bushings—11SMn30 (EN 1.0715) steel may be your best CNC machining carbon steel. As a non-alloy, low-carbon free-cutting steel, 11SMn30 is renowned for its exceptional machinability. This article explores its material properties, the pros and cons of processing, environmental considerations, and how it helps you achieve cost-effectiveness in CNC machining.

66

66

Read more

Read more

VMT

VMT  2026 01 22

2026 01 22 This article introduces “aluminum 5754”. It offers a balanced profile of strength and workability alongside "marine-grade" corrosion resistance. It is not only frequently formed into car body panels, floorings, and tanks through stamping, bending, or welding but also stands out as one of the most popular 5xxx series materials for CNC machining.

66

66

Read more

Read more

VMT

VMT  2026 01 21

2026 01 21 Choosing the correct alloy early in product development saves time, cost and headaches. For parts whose primary manufacturing demands are sheet-metal forming — extensive bending, stretching or deep drawing — and that must resist corrosive environments, Aluminum 3003 often offers the best combination of formability, corrosion resistance and cost. And only when the CNC shop’s role is limited to secondary operations such as drilling, countersinking or light contouring and further complete the parts with various surface finishes, 3003 delivers excellent outcomes for a final product. This guide explains when 3003 aluminum is appropriate for your manufacturing, how to design for it, what to expect in CNC secondary processing, finishing options and procurement advice—based on VMT’s shop experience.

66

66

Read more

Read more

VMT

VMT  2026 01 20

2026 01 20 This article is intended for engineers and manufacturing customers in the CNC machining and metalworking fields. From here, you can get a clear understanding that: what is the basics about aluminum alloy 5052? How does aluminum alloy 5052 strengthen its strength? What are processing ways to alloy 5052’s annealed O, H12, H18, H24, H32, H34 tempers? What are the pros and cons as well as uses for each temper? About several manufacturing ways, what you may pay attention to when you deal with the processing? Below information will assist you in making decisions regarding quotations, process selection, and quality control.

66

66

Read more

Read more

VMT

VMT  2026 01 19

2026 01 19 6061 aluminum alloy (Al-Mg-Si) is currently the most widely used and versatile heat-treatable aluminum alloy for everyday parts such as tube systems, bike parts, electronic housings, small brackets. It achieves a good balance between strength, corrosion resistance, weldability, good formality, and machinability, while also being lightweight and durable. From construction and transportation to aerospace and consumer uses, 6061 aluminum alloy plays a vital role in modern manufacturing.

66

66

Read more

Read more

VMT

VMT  2026 01 18

2026 01 18 In this article, we will take a deep dive into the unique charm of the 7050 aluminum alloy (Al-Zn-Mg-Cu series). We will provide a multi-dimensional decoding of its chemical composition, key properties, performance comparisons with other common alloys, and market price factors to help you fully understand 7050 aluminum alloy.

66

66

Read more

Read more

VMT

VMT  2026 01 17

2026 01 17 High-lead tin bronze, renowned for its application in self-lubricating bearings, is a highly machinable material with excellent wear resistance and good thermal conductivity. Although it generally falls within the medium-strength range, this does not hinder its exceptional performance in harsh, polluted industrial environments. From marine to automotive components, the self-lubricating properties provided by lead make this alloy particularly effective in preventing the interference of dirt and debris on the surface, ensuring reliable operation. Additionally, the tin content determines the hardness and toughness of high-lead tin bronze while heterogeneous of the alloy is also affected by the material's Tin content. Read on for a more detailed and comprehensive understanding of high-lead tin bronze.

66

66

Read more

Read more

VMT

VMT  2026 01 16

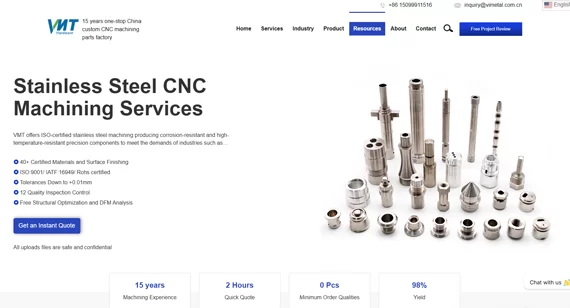

2026 01 16 In modern manufacturing, high-precision stainless steel CNC machining is critical to ensuring product performance and project success. From complex aerospace structural components to precision medical device parts, selecting the right manufacturer directly impacts quality and efficiency. Leading Stainless Steel CNC Machining Manufacturers not only offer strict tolerance control and multi-material processing capabilities, but also provide unique machining advantages and local rapid-response services. This article highlights 30 top manufacturers worldwide, covering China, the USA, and other countries, helping you quickly identify reliable partners for efficient and dependable production.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!