15 years one-stop China custom CNC machining parts factory

393 |

Published by VMT at Jun 18 2025 | Reading Time:About 9 minutes

393 |

Published by VMT at Jun 18 2025 | Reading Time:About 9 minutes

In today’s manufacturing industry, precision, speed, and consistency are non-negotiable. Yet, many manufacturers still struggle with frequent production errors, long lead times, and high labor costs. These issues often stem from outdated manual processes or inefficient programming workflows. Imagine dealing with delayed deliveries, inconsistent product quality, or wasted materials—problems that could easily erode your brand reputation and profit margins. That’s where CNC machining programming comes in. This powerful solution transforms traditional manufacturing, automating complex operations, enhancing accuracy, and reducing costs. In this article, we will explain what CNC machining programming is, how it works, its different types, and the essential skills needed—providing you with everything you need to optimize your CNC machining parts production.

CNC machining programming is the process of creating code instructions that direct CNC machines to manufacture parts with precision and efficiency. It includes part design, tool path planning, code generation, and machine setup. This programming is essential for consistent, high-quality results in CNC machining services and manufacturing operations.

Having understood the importance of CNC machining programming, let’s now take a closer look at its structure, how the process works, the types of programming available, and the skills required to succeed in a CNC machining environment. Whether you’re a beginner or a manufacturing professional, this guide will help you unlock the full potential of CNC machining services.

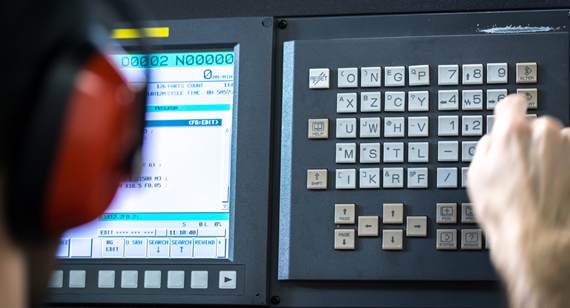

CNC (Computer Numerical Control) programming is the process of developing a sequence of machine-readable instructions (usually G-code) that tell a CNC machine how to create a part. These instructions control cutting tools, movement paths, speed, depth, and more. CNC programming ensures precision, repeatability, and optimal machining operations, making it a critical part of modern CNC machining factories.

CNC machining programming breaks down the entire machining process into the following key steps:

Step 1: Part Design

The process begins with designing a 3D model of the part using CAD (Computer-Aided Design) software. This model outlines the exact dimensions, geometry, and features of the component to be manufactured.

Step 2: Generate Tool Paths

CAM (Computer-Aided Manufacturing) software is used to convert the CAD model into tool paths. These are the precise routes the cutting tools will follow to shape the part.

Step 3: Generate CNC Programming

Tool paths are then translated into G-code and M-code, which instruct the CNC machine on every movement and operation—such as drilling, cutting, or milling.

Step 4: CNC Machine Preparation

Operators prepare the CNC machine by selecting tools, mounting the workpiece, and setting up coordinates and origins for the machining process.

Step 5: Program Execution

The finalized code is uploaded to the CNC machine, which executes the instructions to manufacture the part, ensuring speed and accuracy.

CNC (Computer Numerical Control) machining is the process of using computer-controlled tools to shape, cut, or finish a workpiece according to precise specifications. Whether you’re a manufacturer, engineer, or product developer, understanding the foundational elements of CNC machining is essential to ensure high-quality CNC machining parts and efficient production workflows. Below are the key components and stages that define the basics of CNC machining:

1. Planning

Every successful CNC machining process starts with careful planning. This includes understanding the part’s requirements, material selection, and defining production goals. During this stage, machinists analyze the desired tolerances, finishes, and material behavior (such as thermal expansion or hardness) to determine the best machining strategy.

2. Part Design

The design phase involves using CAD (Computer-Aided Design) software to create a 2D or 3D model of the part. This model serves as the blueprint for machining and must be detailed with exact dimensions, geometries, and technical notes. Precise design is crucial for reducing errors during manufacturing and optimizing tool paths in later stages.

3. Programming

In this step, CNC machining programming comes into play. CAM (Computer-Aided Manufacturing) software converts the CAD design into G-code or other machine-readable formats. These codes instruct the CNC machine how to move, where to cut, what speeds to use, and how deep to drill. The effectiveness of the CNC machining programming types used—whether manual, CAM-based, or conversational—directly affects machining accuracy and cycle time.

4. Machine Setup

Before actual machining begins, operators set up the CNC machine. This includes loading the correct cutting tools, positioning the raw material (also called the workpiece), and calibrating the machine’s coordinates. Proper setup ensures that the machine interprets the programming instructions accurately and consistently.

5. Machining Operations

The CNC machine executes the program, using high-speed rotating tools to perform processes such as milling, turning, drilling, or grinding. During this phase, the machine follows the programmed tool paths precisely, transforming the raw material into the final product. Operators may supervise this stage to monitor tool wear and performance.

6. Quality Control and Inspection

Once the machining is complete, the finished part undergoes inspection. Precision measuring tools like calipers, micrometers, or coordinate measuring machines (CMMs) are used to verify that all dimensions meet the original specifications. This step is essential to guarantee that the CNC machining services deliver consistent and defect-free components.

7. Finishing

Depending on the application, additional finishing processes may be required—such as polishing, anodizing, heat treatment, or painting. These processes enhance the part’s durability, appearance, and functionality, making them suitable for end use in demanding environments like aerospace, automotive, or electronics industries.

8. End of Process

The final part is either assembled into a larger system or packaged and delivered to the customer. Proper documentation and traceability are often maintained to support future reproduction and quality audits.

Mastering these basics lays the groundwork for more advanced techniques and helps manufacturers and CNC machining factories deliver reliable, high-quality results. For companies seeking top-notch CNC machining services, understanding this workflow ensures better communication, reduced errors, and faster turnaround times. Let us know if you want to explore specific aspects such as CNC machining programming skills or how to optimize tool paths for better efficiency.

CAM (Computer-Aided Manufacturing) software for CNC is a vital tool that bridges the gap between design and manufacturing. It takes digital 3D models created in CAD (Computer-Aided Design) software and transforms them into precise instructions—usually in the form of G-code—that CNC machines can interpret and execute. For businesses using CNC machining services or operating CNC machining factories, CAM software is essential for increasing production speed, reducing manual labor, and improving part accuracy.

How CAM Software Works in CNC Machining

At its core, CAM software automates the process of converting design data into machine movements. Here’s how it typically works:

Advantages of CAM Software in CNC Machining

Popular CAM Software Used in CNC Machining

If you’re seeking reliable CNC machining services or building programming capabilities in-house, consider these leading CAM software options:

Why CAM Software Matters to CNC Machining Factories

In competitive markets, speed, precision, and scalability are non-negotiable. CAM software allows CNC machining factories to automate programming, reduce turnaround times, and consistently produce high-quality parts. It plays a critical role in streamlining workflows, minimizing errors, and ensuring that even the most complex designs can be manufactured with confidence.

For manufacturers looking to improve their CNC machining programming skills or enhance output, mastering CAM software is a game-changer. Want to know which CAM software is best for your specific machining needs or how to integrate it into your current CNC system? Let us guide you through it—explore more about our professional CNC machining programming services here.

Are you wondering who’s behind the precision of every CNC-machined component? The answer lies with the CNC programmer—a highly skilled specialist responsible for turning design ideas into precise machine instructions. CNC programmers are the brainpower behind modern manufacturing, transforming CAD models into G-code programs that CNC machines follow to produce high-quality, accurate parts. Whether you're managing CNC machining factories or relying on CNC machining services, understanding the role of a CNC programmer is crucial for ensuring production efficiency and part quality.

A CNC programmer is responsible for converting CAD designs into CNC machine instructions (G-code) using programming skills and CAM software. They optimize tool paths, select appropriate cutting tools, and ensure the CNC machining process runs efficiently, accurately, and safely.

CNC Programmers: The Backbone of CNC Machining Operations

In the world of CNC machining programming, the CNC programmer is more than just a coder—they are engineers, analysts, and problem-solvers. Their main responsibility is to translate the vision of a product designer or engineer into precise commands that a CNC machine can execute. These professionals ensure that CNC machining parts are produced with exceptional quality, within tolerance, and in the most time- and cost-efficient way possible.

Their work touches every aspect of the manufacturing cycle, from analyzing technical drawings to post-machining quality checks. A skilled CNC programmer understands machining theory, material properties, and tooling techniques, all of which are essential for creating effective programs that reduce waste, improve cycle times, and maintain part integrity.

Key Responsibilities of a CNC Programmer

Reading and Interpreting Blueprints: CNC programmers analyze CAD files and engineering drawings to understand part geometries, tolerances, and special requirements.

The Impact of a CNC Programmer on CNC Machining Services

In CNC machining services, a good programmer ensures you receive high-quality, on-time parts. Their role is pivotal in reducing errors, achieving consistency, and meeting tight deadlines—especially in sectors like aerospace, automotive, medical devices, and electronics where precision is critical. CNC machining factories rely heavily on experienced programmers to handle both standard production and complex custom parts.

Additionally, as automation and digital transformation continue to evolve, CNC programmers are now expected to understand modern technologies like IoT integration, real-time data monitoring, and adaptive machining—all part of smart manufacturing initiatives.

Sharpening the Edge: CNC Programming Skills That Matter

To succeed in this role, a CNC programmer must possess:

Want to improve your internal team’s CNC machining programming skills or need help with a complex project? Discover how VMT’s expert programmers can boost your production performance.

Explore our CNC Programming and Machining Services for tailored, precision-driven solutions.

In modern manufacturing, CNC programming is the key to turning design concepts into real-world components with unmatched precision and repeatability. Without accurate CNC machining programming, even the most advanced machines cannot produce reliable parts. For companies depending on CNC machining services or operating CNC machining factories, efficient programming isn't just important—it’s essential for productivity, quality control, and business competitiveness.

CNC programming is crucial because it converts digital part designs into precise instructions that CNC machines follow. It ensures accurate, repeatable, and efficient machining of complex parts, reduces human error, and enables high-volume production in industries like aerospace, automotive, and medical manufacturing.

CNC Programming: The Heart of Precision Manufacturing

CNC programming is the engine behind automated production. It defines every movement of a CNC machine—how deep to cut, what speed to turn the spindle, which direction to move the tool, and when to change operations. Without effective programming, CNC machines are powerless. This is why skilled CNC programming is the core of successful CNC machining services.

CNC machining programming allows for complex geometries, tight tolerances, and consistent results across thousands of units. From one-off prototypes to high-volume production runs, every part relies on a well-written program to achieve its design specifications. Errors in the program can result in defects, waste, machine crashes, or production delays—costing time and money.

Key Reasons CNC Programming Matters

1. Precision and Accuracy

A properly written CNC program ensures the machine performs exactly as required. This level of precision is critical in industries like aerospace and medical, where even a 0.01mm error can result in part failure.

2. Repeatability

Whether it’s 10 units or 10,000, CNC programming enables the exact same process to be repeated without variation. This consistency is vital for quality control and compliance with industry standards.

3. Efficiency

Through optimized tool paths, spindle speeds, and cutting strategies, CNC programming reduces machining time, tool wear, and material waste. That translates to lower production costs and faster lead times—essential for competitive CNC machining factories.

4. Supports Complex Designs

Modern CNC machining programming types and software (like CAM systems) allow programmers to handle intricate geometries that would be impossible or impractical with manual machining.

5. Reduces Human Error

Automated machining eliminates many of the risks of manual intervention, as long as the programming is accurate. Well-verified CNC code reduces costly mistakes and machine downtime.

6. Supports Smart Manufacturing

In today’s Industry 4.0 environment, CNC programming integrates with digital workflows, sensors, and real-time monitoring, forming the backbone of advanced, data-driven manufacturing systems.

A Crucial Skill in the CNC Industry

From prototyping to full-scale production, skilled CNC machining programming is the invisible hand that guides machine tools to create high-performance parts. As demand grows for faster turnaround and tighter tolerances, CNC programming skills have become more valuable than ever.

Whether you're a buyer of CNC machining services or managing a CNC machining factory, investing in strong programming capabilities is a direct path to improved performance, fewer errors, and satisfied customers.

Next: Learn more about the important codes used in CNC machining programming and how they drive machine behavior.

CNC machines rely on a specialized language called G-code to interpret instructions and carry out precise operations. For anyone involved in CNC machining programming—whether in a factory setting or ordering CNC machining services—understanding the most important CNC codes is critical for producing accurate, consistent, and safe parts. These codes direct everything from machine movement to tool changes, speeds, and feed rates. They are the foundation of all CNC machining programming types and must be used correctly to achieve optimal machining results.

Important CNC programming codes include G-codes for motion, M-codes for machine functions, F-codes for feed rates, S-codes for spindle speeds, T-codes for tool selection, D-codes for tool diameter offsets, and N-codes for line numbering. These codes work together to control CNC machines and ensure accurate, repeatable, and safe machining operations.

Introduction to CNC Programming Codes

In CNC machining, G-code is the universal language that communicates instructions to machines. But G-code isn't just one set of commands—it includes various letter-based codes, each serving a specific function. These include:

Let's break them down one by one so you can understand how each fits into the CNC machining programming process.

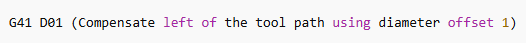

D Codes – Tool Diameter Compensation

D-codes are used in CNC programming to adjust for the tool’s diameter when cutting paths are generated using the center of the tool. This is particularly important when using CAM software that outputs a centerline tool path but the actual part must reflect the edge of the tool.

Why it matters:

Example:

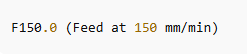

F Codes – Feed Rates

F-codes set the feed rate, or how fast the tool moves through the material. Choosing the correct feed rate is essential for maintaining surface finish quality, tool life, and machining efficiency.

Why it matters:

Example:

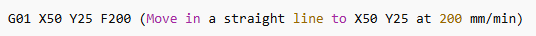

G Codes – Machine Motion and Function

G-codes are the most fundamental part of CNC programming. These codes control the movement and operational mode of the machine.

Common G-codes include:

Why it matters:

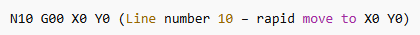

Example:

M Codes – Machine Control Functions

M-codes control miscellaneous machine operations that are not related to motion, such as starting/stopping spindles or turning coolant on/off.

Common M-codes include:

Why it matters:

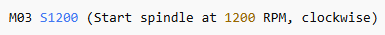

Example:

N Codes – Line Numbers

N-codes are optional in many modern CNC machines, but they’re used to number each line of code, which helps with editing, debugging, and referencing specific commands in longer programs.

Why it matters:

Example:

S Codes – Spindle Speeds

S-codes set the spindle speed in revolutions per minute (RPM). The right spindle speed depends on the material, tool, and type of machining being performed.

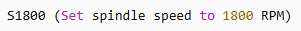

Why it matters:

Example:

T Codes – Tool Selection

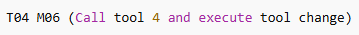

T-codes are used to select specific tools from the machine’s tool turret or magazine. This is often paired with an M06 command to execute a tool change.

Why it matters:

Example:

Understanding these codes is fundamental to mastering CNC machining programming. Whether you’re programming manually or using advanced CAM software, these codes define the actions your CNC machine will take. Misuse can lead to errors, machine crashes, or poor-quality parts, so precision in programming is just as important as precision in machining.

Next: Want to learn how to write your own CNC code or explore examples of manual and CAM-based programming? Click through to discover detailed step-by-step guides and real-world applications.

Here is a clean, easy-to-understand table summarizing the important codes used in CNC machining programming. This format is ideal for quick reference and helps reinforce key knowledge for engineers, CNC machinists, and anyone using CNC machining services or managing CNC machining factories.

| Code Type |

Code Example |

Function |

Why It Matters |

| G-Code |

G00, G01, G02, G03, G90, G91 | Controls motion and path of tools (rapid, linear, arc, positioning) | Fundamental to CNC machining programming; defines how the tool moves and shapes the part |

| M-Code |

M03, M05, M06, M08, M09 | Controls machine operations (spindle, tool change, coolant) | Manages machine behavior and auxiliary functions essential for safe and efficient machining |

| F-Code |

F150.0 | Sets feed rate (tool speed through material) | Impacts surface finish, tool life, and machining efficiency |

| S-Code |

S1800 | Sets spindle speed in RPM | Controls cutting performance; directly affects heat, finish, and tool longevity |

| T-Code |

T04 + M06 | Selects tool number and changes tool | Essential for multi-tool operations and automated production in CNC machining factories |

| D-Code |

D01 | Applies tool diameter offset | Ensures precise cuts by adjusting for actual tool diameter; vital for part accuracy |

| N-Code |

N10, N20 | Line numbering for program structure | Helps organize, edit, and troubleshoot programs easily, especially in long or complex files |

Writing your own CNC code gives you full control over the machining process. Whether you're working in a CNC machining factory or using CNC machining services, understanding how to manually create and verify code is essential for custom parts and troubleshooting. Manual programming also builds foundational knowledge that complements CAM-based and conversational programming approaches.

Export

Once you create a CNC program, it must be exported in a format your CNC machine understands—typically as G-code. Many CAM tools have an export or post-processing feature that translates tool paths into machine-ready files.

Tool Paths

Tool paths define the movement of your cutting tools. These must be carefully designed to avoid collisions, maximize efficiency, and ensure high-quality CNC machining parts. Define toolpaths with correct depths, speeds, and offsets.

Verification

Before running your program, use simulation software to verify the tool paths. This step helps identify collisions, overcuts, or programming errors, minimizing costly mistakes on the shop floor.

Download to CNC Machine

After verification, transfer the program to your CNC machine via USB, network, or direct cable. Confirm settings, load the workpiece, and perform a dry run if needed to ensure everything runs smoothly.

There are three main types of CNC machining programming: manual, CAM-based (Computer Aided Manufacturing), and conversational. Each serves different needs depending on complexity, volume, and available software or hardware.

Manual CNC Programming

Manual programming involves writing each line of G-code by hand. It’s most effective for simple parts and gives the programmer total control over every operation.

Advantages of Manual CNC Programming

Disadvantages of Manual Programming

Computer Aided Manufacturing (CAM)

CAM software automates much of the programming process by generating code based on CAD designs. It's widely used in CNC machining factories for complex parts and repeatable production.

Advantages of CAM Programs

Disadvantages of CAM Programs

Steps in CNC Programming with CAM

Using CAM for CNC programming follows a logical series of steps, ensuring accuracy and efficiency in generating G-code.

Conversational CNC Programming

Conversational programming allows operators to input parameters using a graphical interface, without needing to write full G-code. It’s commonly found on machines like Haas, Mazak, or Tormach.

Advantages of Conversational Programming

Disadvantages of Conversational Programming

Example of Conversational Programming

User Inputs:

This sequence results in a basic face milling operation with specific dimensions and tool selections—ideal for fast prototyping or in-shop adjustments.

Certainly! Below is a professional and easy-to-understand table summarizing the Types of CNC Programming, their characteristics, advantages, and common use cases. This helps manufacturers, engineers, and clients choose the most appropriate CNC machining programming type for their specific needs.

| Programming Type |

Description |

Advantages |

Common Use Cases |

| Manual CNC Programming |

Code is written by hand using G-code and M-code without software assistance | Full control, cost-effective, ideal for simple parts | Prototypes, low-volume jobs, simple geometries |

| CAM (Computer-Aided Manufacturing) |

Uses software to automatically generate CNC code from 3D models | Fast, accurate, reduces errors, handles complex geometries | Complex parts, mass production, aerospace, medical components |

| Conversational Programming |

Menu-driven programming directly on the CNC machine’s interface | Easy to use, no G-code knowledge needed, quick setup | Job shops, quick turnarounds, small batch production |

This table clearly shows how different CNC machining programming types align with different operational goals—whether it’s flexibility, speed, precision, or ease of use. Choosing the right method ensures greater efficiency and part accuracy across CNC machining factories and services.

CNC programming software is the backbone of modern manufacturing, providing the tools necessary to automate, optimize, and streamline CNC machining processes. Whether you're a small workshop or a large CNC machining factory, these software solutions enhance productivity, ensure precision, and minimize human error. From developing complex CNC machining parts to running consistent high-volume production, the benefits are substantial and measurable.

Automation and Precision

One of the primary advantages of CNC programming software is its ability to automate complex tasks. The software calculates tool paths, speeds, feeds, and depths automatically based on the part design. This not only accelerates the programming process but also ensures precision machining, helping CNC machining services meet exact tolerances. With automation, there’s less dependency on manual input, significantly reducing the chance of error and ensuring consistency across production batches.

Increase Efficiency

CNC software boosts operational efficiency by shortening setup times, optimizing machining strategies, and allowing for fast program modifications. Built-in libraries and templates speed up repetitive tasks. This leads to faster turnaround times, especially critical in high-demand environments such as automotive or aerospace CNC machining factories. Efficiency also means better resource utilization—less material waste, less downtime, and optimal tool usage.

Flexible Manufacturing

Modern CNC programming software is adaptable to different materials, machine types, and industries. You can switch between creating aluminum CNC machining parts and titanium components with minor adjustments in the program. The flexibility extends to part complexity as well—whether you're machining simple brackets or intricate medical device components, the software can handle the variation without needing major reprogramming efforts.

Consistency and Repeatability

Once a CNC program is created and tested, it can be saved and reused repeatedly. This ensures that every part produced is consistent in quality and dimension, regardless of the batch size. For CNC machining services that require strict compliance with client specifications, repeatability is a critical feature. CNC programming software removes variability from the process, leading to higher customer satisfaction and fewer reworks.

Reduce Human Error

Manual programming is time-consuming and more susceptible to errors. CNC software includes features such as simulation, error detection, and toolpath visualization, which catch mistakes before the machine begins cutting. This reduces the risk of crashes, tool breakages, and material wastage—saving both time and money. For CNC machining factories, this also means safer operation and less dependency on highly specialized programmers for routine tasks.

Advanced Machining Capabilities

With CNC programming software, manufacturers can tackle advanced projects such as 5-axis machining, multi-surface contouring, and complex pocketing. These capabilities open up opportunities to serve high-value industries like aerospace, medical, and consumer electronics. The software’s powerful features make it possible to machine parts that would be difficult or impossible with manual methods, giving CNC machining services a competitive edge in the global market.

CNC machining programming is the driving force behind precision manufacturing in nearly every modern industry. By automating production and enabling repeatable, high-accuracy processes, CNC programming allows factories and workshops to produce complex, high-quality parts at scale. From life-saving medical devices to advanced aerospace components, the versatility and reliability of CNC machining services make them indispensable. Let’s explore how different industries leverage CNC machining programming to achieve excellence in production.

Healthcare Industry

The healthcare sector demands the highest level of precision, hygiene, and material reliability—and CNC machining delivers just that. CNC machining programming enables the production of medical implants, surgical tools, dental components, and custom prosthetics with ultra-tight tolerances. Titanium, stainless steel, and biocompatible plastics are commonly used materials, machined with consistency thanks to detailed G-code and advanced CAM software. CNC machining parts used in medical devices must not only be dimensionally accurate but also meet strict regulatory requirements. The flexibility of CNC programming types, including CAM and conversational methods, ensures that both prototyping and high-volume production can be handled efficiently. Hospitals and medical device manufacturers rely heavily on CNC machining factories that can provide fast, scalable, and traceable machining services.

In consumer electronics, aesthetics, precision, and miniaturization are critical. CNC machining programming is instrumental in manufacturing casings, heat sinks, connectors, and internal structural components for smartphones, laptops, and wearables. The use of lightweight metals like aluminum and magnesium alloys, as well as plastics, is common—and the exacting demands of design tolerances are met through high-precision CNC programming. CAM software plays a big role here, allowing rapid toolpath generation and design iteration. CNC machining services for this sector benefit from flexible manufacturing, where short runs of customized designs can be programmed and delivered with speed. In an industry where innovation moves fast, CNC programming ensures that design and functionality are never compromised.

Aerospace and Aircraft

Aerospace is one of the most demanding industries when it comes to CNC machining. Components like turbine blades, structural brackets, and landing gear parts must be manufactured to tight tolerances, using high-strength materials like titanium, Inconel, and carbon fiber composites. CNC programming allows these complex parts to be machined efficiently using 5-axis and multi-axis machining techniques. Here, CNC machining programming skills are vital for creating safe, optimized tool paths that prevent material waste and tool wear. The use of simulation and verification in CAM software ensures that parts meet both performance and safety standards. CNC machining factories serving the aerospace industry must deliver not only quality but also rigorous documentation and process traceability—tasks that modern CNC programming supports seamlessly.

The automotive industry relies on CNC machining for everything from engine blocks and transmission housings to dashboards and lighting components. With a strong emphasis on efficiency and scalability, CNC machining programming types like CAM and automated toolpath generation are key to managing high-volume production lines. CNC programming software also supports real-time monitoring and optimization, helping reduce cycle times and maintain consistency across thousands of units. CNC machining parts in this sector often require multi-operation sequences—turning, milling, drilling—combined within a single program. This enhances production flow and reduces machine downtime. The ability to update programs for different car models or customization requests also highlights the flexibility of CNC machining services in automotive manufacturing.

Certainly! Below is a professional and easy-to-read table outlining the Applications of CNC Programming in Various Industries. This format helps illustrate how CNC machining programming supports precision manufacturing across diverse sectors:

| Industry |

Application of CNC Programming |

Common CNC Machining Parts |

| Healthcare |

Producing high-precision medical components and surgical instruments with strict tolerances and biocompatible materials | Orthopedic implants, surgical tools, dental prosthetics, medical enclosures |

| Consumer Electronics |

Manufacturing compact, lightweight components with tight tolerances and aesthetic finishes | Smartphone frames, heat sinks, connectors, casings |

| Aerospace & Aircraft |

CNC programming enables production of complex, high-strength parts that meet aerospace regulations and safety standards | Engine components, turbine blades, brackets, housings |

| Automotive |

Facilitates mass production of consistent and high-precision parts for vehicle systems | Engine blocks, gear components, suspension parts, dashboards |

| Industrial Equipment |

Supporting durable, high-tolerance components for heavy-duty machinery and automation systems | Machine housings, gears, spindles, custom brackets |

| Defense & Military |

CNC ensures accuracy and reliability in mission-critical components | Firearm parts, drones, armored vehicle parts |

| Telecommunications |

Producing intricate parts for transmission, signal, and networking systems | Enclosures, antennas, heat exchangers, PCB holders |

| Energy Sector |

Machining robust parts for power generation and exploration in challenging environments | Turbine housings, valves, pump components, wind and solar connectors |

This table demonstrates the flexibility and importance of CNC machining programming skills in serving different sectors—each with unique demands for precision, durability, and scalability.

CNC machining programming plays a pivotal role in the performance, accuracy, and reliability of any machining operation. Whether you're a seasoned professional or new to CNC machining factories, mastering the art and science of programming is essential to achieving high-quality CNC machining parts. By focusing on efficiency, precision, and smart practices, CNC machining services can reduce errors, improve cycle times, and deliver consistent results. Here are some essential tips to help you succeed in CNC programming across various programming types and industries.

Master the Basics

Before diving into advanced features or complex toolpaths, it's crucial to have a solid understanding of CNC programming fundamentals. This includes learning how G-codes and M-codes work, understanding coordinate systems, feed rates, spindle speeds, and knowing how to read and write basic CNC code. Understanding your machine’s capabilities, tools, and limitations gives you a foundation to build reliable programs. No matter which CNC machining programming types you use—manual, CAM-based, or conversational—these core principles apply. Many CNC machining services invest in ongoing training for their programmers to keep this knowledge sharp and up-to-date.

Fine-Tune Programs

No CNC program is perfect the first time. Fine-tuning involves reviewing simulations, adjusting toolpaths, optimizing cut depths, and reducing unnecessary tool changes. Utilize verification tools in your CNC programming software to simulate the entire machining process before running it on the machine. This saves material, prevents damage, and improves productivity. Fine-tuning also includes revisiting old programs to improve their efficiency based on new tooling or machine upgrades. At CNC machining factories, even small improvements to a program can lead to significant time and cost savings when scaled across hundreds of parts.

Understand Pay Types

CNC programming often includes calculating time-based cost estimates—commonly referred to as "pay types" in production environments. This refers to how programs are evaluated in terms of machine time, tool wear, labor input, and material usage. A successful CNC programmer not only writes effective code but also understands how program choices affect profitability. For CNC machining services quoting projects or planning production runs, having this insight helps balance speed, quality, and cost. It’s also useful when planning different programming strategies (e.g., roughing vs. finishing) based on budget or customer needs.

Make Programs Simple

Simplicity equals reliability. Well-structured programs are easier to debug, maintain, and reuse. Avoid unnecessary complexity, especially in tool changes, loops, and custom macros. Use clear comments and logical sequencing so that operators and fellow programmers can easily understand the code. Whether you're using manual CNC programming or CAM software, keeping things simple allows for faster training, smoother machine setup, and easier troubleshooting. In CNC machining factories where multiple shifts and operators are involved, readable and efficient programs reduce the risk of misinterpretation and machine errors.

Real-Time Monitoring and Adjustments

Modern CNC programming software often includes integration with real-time monitoring systems. These systems track tool performance, machine conditions, part progress, and anomalies during production. Being able to monitor the machining process in real time allows for proactive adjustments, reducing scrap rates and extending tool life. CNC machining services that adopt smart monitoring can adapt quickly to part deviations or tool wear, ensuring that CNC machining parts meet quality standards consistently. Programmers who are involved in real-time analysis can also feed performance data back into future programs, creating a cycle of continuous improvement.

In the world of modern manufacturing, Computer-Aided Manufacturing (CAM) CNC machines are the powerhouse tools that bring digital designs to life with speed and precision. Each machine type is engineered for specific operations, materials, and production volumes. Choosing the right type of CNC machine is essential for optimizing workflow, cost, and output quality. CNC machining programming plays a critical role in each machine’s performance—defining tool paths, speeds, and operations to match the material and design complexity. Below, we explore the most common types of CAM CNC machines used across CNC machining services and factories worldwide.

CNC milling machines are among the most versatile and widely used in CNC machining factories. They remove material using rotary cutters and can perform a wide range of operations including facing, pocketing, profiling, and drilling. Available in 3-axis, 4-axis, and 5-axis configurations, they are ideal for machining complex CNC parts from metals, plastics, and composites. CAM software automates toolpath generation, allowing for efficient and precise programming.

CNC turning machines, or lathes, rotate the workpiece while a cutting tool removes material. These machines are perfect for producing cylindrical or round components like shafts, bolts, and bushings. Turning centers can be equipped with live tooling to perform additional milling or drilling operations, expanding their versatility. With the right CNC machining programming skills, these machines deliver high-speed and accurate production for high-volume runs.

CNC drilling machines are designed specifically to create holes with high accuracy and repeatability. They're often integrated into multi-tasking machines but can also operate as standalone systems. These machines are crucial for parts requiring precise hole dimensions, depths, and placements—common in automotive and aerospace components. CAM CNC programming defines hole patterns, depths, and tool changes efficiently.

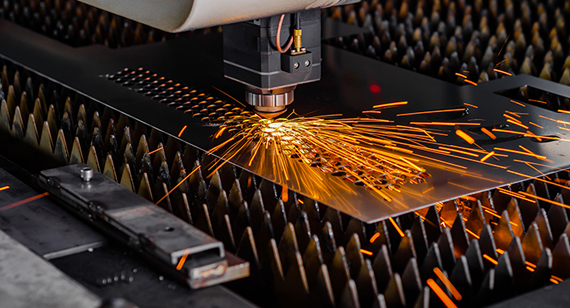

Laser cutting machines use a high-powered laser beam to slice through materials with extreme precision and minimal waste. These machines are perfect for cutting thin metals, plastics, and even wood. CAM software controls the laser’s movement, speed, and power, ensuring clean cuts and tight tolerances. CNC machining services often use laser cutting for intricate shapes or where minimal material distortion is required.

Water Jet Cutting

Water jet CNC machines use high-pressure streams of water—sometimes combined with abrasive materials—to cut through metal, stone, and glass. They are ideal for applications where heat-affected zones (HAZ) must be avoided. Unlike laser cutting, water jet machines are cold-cutting, making them suitable for heat-sensitive materials. CAM programming enables accurate path planning for complex cuts.

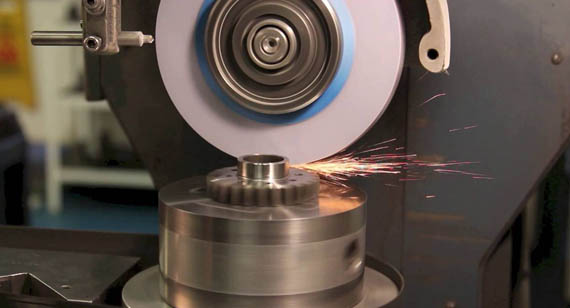

Used primarily for surface finishing and tight tolerance grinding, CNC grinders shape parts using abrasive wheels. These machines are used in tooling, mold-making, and precision engineering industries. CAM programming for grinding must be very precise to ensure surface flatness, exact dimensions, and repeatability across batches.

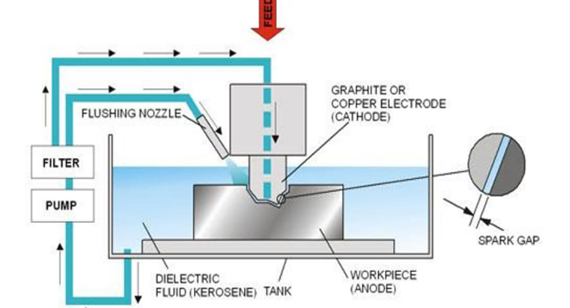

CNC Electrical Discharge Machining (EDM)

EDM machines cut conductive materials using electrical discharges or sparks. They are excellent for creating intricate cavities, sharp corners, and hard-to-machine features that are impossible to achieve through traditional machining. There are two main types: wire EDM and sinker EDM. CNC programming for EDM must factor in spark gap compensation and flushing strategies.

CNC Plasma Cutting

Plasma cutting machines use a jet of ionized gas at high temperatures to cut through conductive metals such as steel, aluminum, and copper. They are commonly used in fabrication shops and metalworking factories for cutting thick sheets or plates. CAM CNC programming allows the operator to define cutting paths, pierce points, and nesting for optimal material usage.

CNC stamping machines use a die and press system to form, punch, or emboss material into desired shapes. While less common in prototyping, they are essential for mass production of sheet metal parts. Programming involves sequencing die operations, press timings, and material feed rates.

CNC engraving machines are used to carve detailed designs, logos, serial numbers, or text onto metal, plastic, or wood parts. They are widely used in the jewelry, aerospace, and branding industries. CAM software converts vector graphics into G-code that controls the machine’s movement for detailed, precise engravings.

Here is a clear and concise table summarizing the Types of CAM CNC Machines, their functions, and typical applications. This format helps readers quickly understand the role each machine plays in modern CNC machining services:

| Type of CNC Machine |

Function |

Typical Applications |

| CNC Milling |

Rotating cutters remove material from a stationary workpiece | Complex part machining, mold making, prototyping |

| CNC Turning |

Spins the workpiece while a tool cuts into it | Shafts, bushings, cylindrical parts |

| CNC Drilling |

Precision hole making with rotating drill bits | Aerospace, automotive, electronics (accurate hole patterns) |

| CNC Laser Cutting |

High-powered laser beam slices through materials | Sheet metal cutting, intricate profiles, signage |

| Water Jet Cutting |

High-pressure water (with or without abrasives) cuts materials | Heat-sensitive materials, stone, glass, composites |

| CNC Grinding |

Abrasive wheels shape and finish parts with high accuracy | Surface finishing, mold tools, precision component grinding |

| CNC EDM (Electrical Discharge) |

Removes material via electrical discharges (spark erosion) | Intricate die cavities, aerospace components, hard materials |

| CNC Plasma Cutting |

Ionized gas cuts through conductive metals at high temperatures | Heavy-duty metal fabrication, construction, custom metalwork |

| CNC Stamping |

Press and die system shapes or punches metal sheets | Mass production of sheet metal parts, automotive panels |

| CNC Engraving |

Carves detailed text or graphics into surfaces | Branding, jewelry, part identification, aerospace part marking |

This table is an excellent reference for manufacturers or customers seeking the right CNC machining programming solution based on material, complexity, and end-use.

Get It from VMT: CNC Machining Programming and CNC Machining Services You Can Trust

When it comes to precision, reliability, and efficiency in manufacturing, VMT is your trusted partner for CNC machining programming and CNC machining services. With years of expertise, cutting-edge technology, and a customer-first mindset, we deliver high-quality CNC machining parts tailored to your industry and application needs.

At VMT, we understand that the success of your product starts with accurate CNC machining programming. Our team of experienced CNC programmers and engineers utilizes industry-leading CAM software to ensure each project—from prototype to full-scale production—is programmed with the utmost accuracy. Whether you require manual programming for simple components or advanced multi-axis CAM solutions for complex parts, VMT is fully equipped to deliver with speed and precision.

Our CNC machining factories are outfitted with modern CNC milling, turning, EDM, grinding, and laser cutting machines, capable of handling a wide range of materials including aluminum, steel, titanium, brass, and engineering plastics. We serve global clients across aerospace, medical, automotive, electronics, and energy sectors, helping them reduce lead times and improve product quality with consistent, repeatable results.

Why Choose VMT?

No matter the complexity of your CNC machining parts, our services are designed to bring your designs to life with precision, efficiency, and cost-effectiveness.

Ready to start your CNC machining project?

Contact VMT today to request a quote or speak with one of our experts about your specific CNC machining programming needs. Explore our full capabilities and see why leading global brands choose VMT as their preferred CNC manufacturing partner.

In the ever-evolving world of manufacturing, CNC machining programming stands at the heart of precision, efficiency, and innovation. Whether it's manual CNC programming, CAM software-based solutions, or conversational programming, each method plays a critical role in ensuring the creation of high-quality CNC machining parts that meet the exacting standards of industries like aerospace, automotive, healthcare, and more.

With the power of CNC machining services at your disposal, manufacturers can streamline production processes, reduce errors, and bring complex designs to life with speed and accuracy. The vast array of CNC machines—from CNC milling and turning to laser cutting and EDM—offers unparalleled versatility, allowing for intricate operations on a wide range of materials.

Choosing the right CNC machining programming type, whether for low-volume prototypes or high-volume mass production, is crucial to achieving optimal results. The key is to understand the demands of your project and partner with a trusted CNC machining service provider that can meet those requirements with precision and expertise.

At VMT, we are committed to delivering world-class CNC machining programming and services that empower your manufacturing processes. Our advanced technology, skilled programmers, and dedication to quality ensure that every project—no matter how complex—is executed to perfection.

If you need further information, have questions, or are ready to get started with your next CNC machining project, don’t hesitate to reach out to VMT CNC Machining Services today.

1. How to create CNC coding?

Creating CNC coding involves writing instructions in G-code or M-code that direct the CNC machine’s movements and operations. This can be done manually by experienced programmers or automatically through CAM software, which converts 3D part designs into precise toolpaths.

2. What is the best CNC programming software for beginners?

For beginners, user-friendly software like Fusion 360, Vectric, and Carbide Create offers intuitive interfaces and helpful tutorials. These programs provide powerful CAM capabilities while simplifying the programming process.

3. What programming language does a CNC machine use?

The primary language used is G-code, a standardized set of commands that control machine movements, speeds, and tool changes. Some machines also use M-codes for auxiliary functions.

4. Can CNC programmers make a lot of money?

Yes, skilled CNC programmers are in high demand across multiple industries, and experienced professionals can earn competitive salaries due to their specialized expertise in optimizing manufacturing processes.

5. Is CNC programming difficult?

While learning CNC programming requires technical knowledge of machining processes and coding, many resources and software tools simplify the learning curve. With practice and training, it becomes manageable and rewarding.

6. Can you CNC machine titanium?

Absolutely. Titanium is widely machined using CNC technology in aerospace, medical, and automotive sectors. However, it requires careful programming and appropriate tooling due to its hardness and heat sensitivity.

7. Is G-code difficult to learn?

G-code is relatively straightforward to learn, especially with beginner-friendly guides and software. Mastery comes with hands-on experience and understanding of machine operations.

8. What are the basics of CNC system programming?

The basics include understanding machine coordinates, writing G-code commands for tool movements, defining feed rates and spindle speeds, and programming tool changes and safety commands.

9. Do CNC machines need programming?

Yes, CNC machines rely on precise programming to automate machining processes, ensure repeatability, and produce accurate parts. Without programming, manual operation is impractical for complex tasks.

10. What is the most commonly used CNC language today?

G-code remains the most widely used CNC programming language globally due to its standardization and versatility across different machine types.

11. What programs do most CNC machines use?

Most CNC machines use CAM software such as Mastercam, Fusion 360, HyperMILL, and SolidWorks CAM to generate G-code for machining.

12. Can you use Python for CNC?

Python can be used in CNC for scripting, automation, and interfacing with CAM software but is not a direct language for machine control. It enhances CNC programming by supporting data handling and custom toolpath generation.