15 years one-stop China custom CNC machining parts factory

704 |

Published by VMT at Jan 30 2025 | Reading Time:About 6 minutes

704 |

Published by VMT at Jan 30 2025 | Reading Time:About 6 minutes

When it comes to machining and manufacturing, precision is key. Whether you’re working on CNC parts or custom machining, the choice between countersinks and counterbores can significantly affect the performance and appearance of the finished product. Both hole types are used for specific purposes, yet they are often confused due to their similar appearance. How do they differ, and when should each be used? Understanding the differences between countersinks and counterbores is crucial for any machinist or engineer looking to optimize their machining processes and designs. In this article, we will break down what each term means, explore their unique applications, and help you make informed decisions for your CNC machining needs.

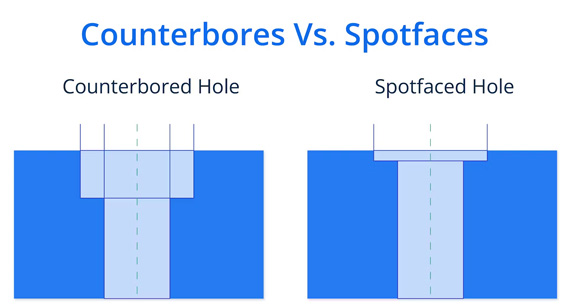

Spotface are designed to create a conical shape at the top of a hole, allowing flat-head screws to sit flush with the surface. Counterbores, on the other hand, create a cylindrical cavity to accommodate a screw or bolt head. Knowing when to use each can improve both the functionality and aesthetics of your CNC prototype machining projects.

Now that we've defined countersinks and counterbores, let’s dive deeper into their specific functions, applications, and the best practices for using them in machining processes. Whether you're working on automotive parts, aerospace components, or general manufacturing, understanding the nuances of these hole types can lead to better design and more efficient production.

In the world of CNC machining, precision is paramount, and every detail counts. Counterbores and countersinks are two important features in machining processes that, despite their similar purpose—accommodating fasteners—serve distinct functions. While both are used to modify the shape of a drilled hole to fit screws, bolts, or other fasteners, understanding their unique characteristics and applications is essential for achieving the right results in your CNC parts and custom CNC machining projects.

Whether you're working in automotive, aerospace, or general manufacturing, knowing when and how to use a counterbore or countersink can significantly impact the design, functionality, and aesthetic quality of your finished product. These features, often found in CNC machining services, serve both practical and cosmetic purposes, depending on the specific needs of the project.

As you continue reading, you’ll discover the differences between these two hole types, how they are depicted in engineering drawings, and the various tools and techniques involved in creating them during machining operations.

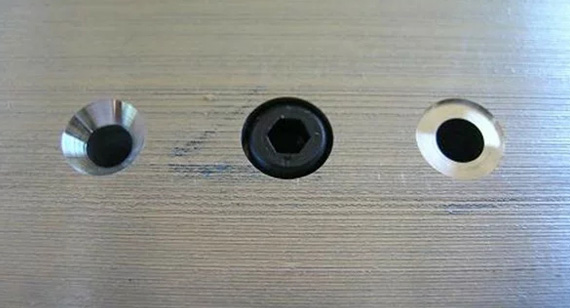

A counterbore hole is a hole that has been drilled with an additional, flat-bottomed, cylindrical recess at the top of the hole. This recess is wider than the original hole and allows for a screw, bolt, or other fastener to sit inside it, typically with the fastener’s head flush with or just below the surface of the material. The key feature of a counterbore is the cylindrical shape that allows it to accommodate the head of a screw or bolt, making it ideal for fasteners that need to be recessed into the material, creating a smooth surface without protrusions.

In CNC machining parts and custom machining projects, counterbore holes are often used when you need to secure a fastener in a way that prevents it from interfering with other components. They are essential for applications that demand a neat, flush finish, or where additional components (like washers or nuts) are needed to ensure a secure fit. Counterbores are typically used in conjunction with hexagonal bolts or screws, offering a secure, low-profile attachment.

A countersink is a conical-shaped recess that is cut into the top of a hole. The primary purpose of a countersink is to allow a flat-head screw (or tapered fastener) to sit flush with the surface of the material. This is particularly important in applications where a protruding screw head would interfere with the operation or aesthetics of the component. Spotface are designed to match the shape of flat-head screws, ensuring that the screw is flush with or slightly below the surface for both functional and visual purposes.

Spotface are commonly used in CNC prototype machining, where aesthetics or smooth surfaces are important, as well as in industries like aerospace and automotive, where secure, flush-fitted fasteners are crucial for both structural integrity and appearance. The conical shape of a countersink is typically measured by its angle, which matches the angle of the screw head, and is usually found in applications where minimal surface disruption is necessary.

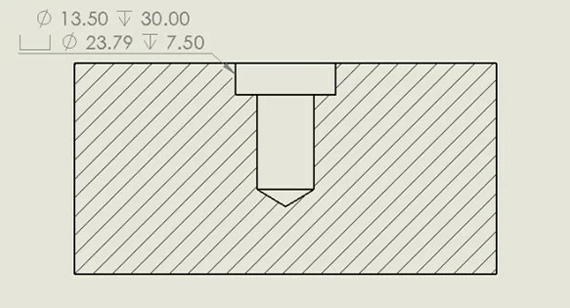

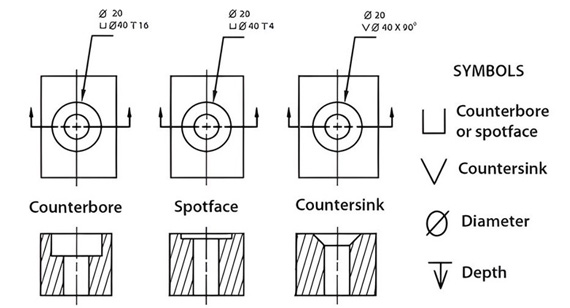

In engineering drawings, counterbores are typically represented using a specific symbol to convey their dimensions and characteristics. This ensures that both the manufacturer and the machinist are on the same page when it comes to the design specifications for the hole. A counterbore symbol is drawn as a circle with another circle inside it, indicating the diameter of the counterbore recess. The larger circle represents the outer diameter, while the smaller circle denotes the diameter of the drilled hole beneath the counterbore.

Additionally, depth specifications are crucial, as counterbores are often designed to ensure that the fastener head sits flush with the surface or is recessed slightly. These depth measurements are typically indicated alongside the counterbore symbol, guiding the machinist on how deep to machine the recess.

For CNC machining professionals, understanding how to read these symbols accurately is key to ensuring the finished part meets both design and functional requirements. Counterbores are particularly useful in applications requiring strong, flush fastener placement—such as in CNC prototype machining or CNC machining services where precision is paramount.

A spotface hole is a type of shallow, flat-bottomed recess that is machined onto the surface of a part. Its purpose is to create a smooth, even surface around a hole where a fastener, such as a bolt or nut, will be installed. Unlike a counterbore, which has a cylindrical recess, a spotface is typically much shallower and is designed to remove any surface imperfections or burrs, providing a flat area for the fastener to sit securely.

Spotfacing is often used when the surface around a hole is uneven, as it allows for a clean, smooth area for securing a fastener. This process is common in applications where precision and a perfect fit are essential, such as in CNC machining parts for aerospace or automotive industries. The spotface helps ensure that the fastener can be properly torqued and provides a solid, flush surface for mounting.

Spotfaceing is the process of creating a conical-shaped recess around a hole, designed to accommodate a flat-head screw. The primary function of countersinking is to allow screws to sit flush with the surface of the material, providing a cleaner, more aesthetic appearance, while also ensuring that the screw doesn’t protrude and interfere with the rest of the assembly. The angle of the conical recess usually matches the angle of the screw's head, allowing the screw to sit securely in place.

In CNC machining services and custom CNC machining, countersinking is often employed in parts where appearance, functionality, and smooth surfaces are critical. It is frequently used in CNC prototype machining when prototype parts need to be assembled with precision and a neat finish. Spotface are particularly valuable in applications that require a secure, flush fitting of fasteners, which helps to prevent accidental disengagement or interference with other components.

Spotface holes serve multiple important functions in CNC machining and manufacturing processes. These include:

In industries such as automotive or aerospace, where precision is key, spotfaces ensure that every part is perfectly aligned, helping to reduce errors in assembly or operational performance. For CNC machining factory professionals, understanding the importance of spotfacing can ensure parts are manufactured to the highest standards.

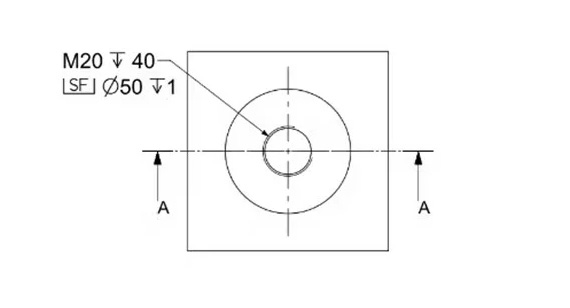

In engineering drawings, spotfaces are represented by a specific symbol that helps the machinist identify the need for a flat, smooth area around a hole. Typically, a spotface symbol is a circle with a smaller circle inside it, indicating the diameter of the spotface. Along with the symbol, the depth of the spotface is specified to guide machinists on how far to cut the recess, ensuring that it is deep enough to accommodate the fastener properly.

Dimensioning for spotfaces is an essential part of CNC machining services. Engineers specify the diameter and depth of the spotface to achieve precise results in the finished part. Spotface holes are usually shallow and have a depth much less than the overall thickness of the material. The flat-bottomed recess helps the fastener sit flush with the surface of the workpiece, preventing interference with other components during assembly.

In CNC prototype machining, the spotface hole can be crucial for ensuring that prototype components function correctly and fit together as intended. Properly dimensioning the spotface hole on engineering drawings ensures that manufacturers are able to reproduce the design exactly, reducing the risk of costly mistakes or delays in the production process.

When working with fasteners and machining, it is crucial to understand the distinctions between countersink and counterbore features, as they serve different purposes in ensuring a secure and precise fit for components. While both involve modifying holes to accommodate fasteners, each has its specific use and characteristics. This comparison highlights the differences between the two machining techniques, helping engineers and machinists make informed decisions when selecting the appropriate feature for their designs.

Function

The function of countersinking and counterboring serves distinct purposes in machining. A countersink is primarily used to create a conical recess around the top of a hole to accommodate a flat-head screw or bolt, allowing the screw to sit flush with or below the surface of the material. This ensures a smooth, aesthetically pleasing finish and prevents the screw from interfering with other parts.

In contrast, a counterbore involves drilling a cylindrical recess around the hole to accommodate a cylindrical-headed fastener, such as a bolt or a cap screw. The purpose of counterboring is to allow the fastener’s head to sit below the surface of the material, ensuring that it is recessed and won’t protrude. Counterbores are often used when the application requires a flush mount for bolts or nuts and is typically employed for larger diameter fasteners.

Depth

The depth of both a countersink and counterbore is crucial for ensuring that fasteners are seated properly and securely.

Screw Hole Adjustment

Both countersinking and counterboring allow for precise adjustment of screw holes, but each provides a different form of adjustment:

Counterbores are often used for applications requiring a precise fit for larger, cylindrical heads or when the fastener must be completely recessed.

Drawing Symbols

In engineering drawings, the symbols for countersinks and counterbores are distinctly different, allowing machinists to clearly identify the specific feature to be applied:

The surface treatment for both countersink and counterbore features often depends on the material being machined and the intended use of the part:

A Brief Table

| Counterbore |

Spotface |

|

| Functions |

Provide a cylindrical recess to fastener heads to sit flush against a surface. |

Provide a smooth seat for fastener heads to sit against. |

| Depth |

At least as deep as the fastener head’s height to completely conceal it. |

Very shallow depths, typically less than 5 mm. |

| Size |

Diameter and depth are both equally important in defining counterbore size. |

The main dimension of a spotface hole is the diameter, with the depth being a secondary dimension with loose tolerance. |

| Symbol |

⌴ |

SF |

Applications

The selection between countersinks and counterbores depends on the specific application and requirements of the assembly:

Summary Table

| Feature |

Spotface |

Counterbore |

| Function |

Creates a conical recess for flat-head screws |

Creates a cylindrical recess for cylindrical-headed fasteners |

| Depth |

Shallow, just enough for screw head angle |

Deeper, sufficient to accommodate the fastener head entirely |

| Screw Hole Adjustment |

Adjusts angle of screw head |

Adjusts depth and position of screw or bolt head |

| Drawing Symbols |

V-shape or conical symbol |

Circle within a circle |

| Surface Treatment | Anodizing, coating, or painting for corrosion resistance |

Galvanization, plating, or painting for strength and durability |

| Applications |

Small machine parts, aerospace, furniture |

Heavy-duty, automotive, and industrial uses |

Conclusion

Understanding the differences between countersinks and counterbores is crucial for selecting the right feature for your application. Whether you are working on custom CNC machining parts for the aerospace industry or creating CNC prototype machining for a machinery project, choosing between countersinking and counterboring impacts both the functionality and appearance of your components. For CNC machining services, these features are essential in ensuring that fasteners fit securely and that your parts meet precision standards.

In engineering and machining, it is essential to identify spotface and counterbore symbols correctly in technical drawings. These symbols provide crucial information regarding the types of holes to be machined and help ensure that the correct machining processes are followed. Proper identification of these symbols ensures the final part meets both functional and aesthetic requirements. Understanding how to read and interpret these symbols is critical for producing precise parts that fit securely in their assemblies.

Spotface Symbols

A spotface is a shallow, flat surface created around the top of a hole. It is often used to prepare a flat surface for the seating of a washer, nut, or bolt head. Spotfacing ensures that these components fit tightly against the surface of the material, preventing any tilting or misalignment.

In engineering drawings, the symbol for a spotface is represented by a circle with a smaller concentric circle inside it, similar to a counterbore symbol, but with an additional note indicating the depth of the spotface. Typically, the spotface depth is less than the depth of a counterbore and may only be a few millimeters deep. The symbol’s inner circle indicates the diameter of the spotface, while the outer circle shows the diameter of the original hole.

Counterbore Symbols

A counterbore is a cylindrical recess that is machined around a hole, typically to accommodate a cylindrical-headed fastener like a bolt or a cap screw. It is used when the head of the fastener needs to sit below the surface of the material, ensuring that it does not protrude or interfere with other components in the assembly.

The counterbore symbol consists of two concentric circles, where the inner circle represents the diameter of the counterbore (the cylindrical recess) and the outer circle indicates the diameter of the hole being machined. This symbol may also include an additional note specifying the depth of the counterbore, ensuring the fastener head sits flush with or below the material surface.

Counterbore symbol example: Two concentric circles with dimensions specifying the diameter of the hole and counterbore, along with the depth of the recess.

Dimensioning is a critical aspect of technical drawings, as it ensures accurate machining and proper fitment of components. For both spotfaces and counterbores, the dimensions must be precise to guarantee that fasteners or other parts fit securely and function as intended. This section outlines the steps to correctly dimension a spotface and a counterbore.

Dimensioning a Spotface

When dimensioning a spotface on a technical drawing, it is essential to include the following:

Dimensioning a Counterbore

Dimensioning a counterbore is slightly more complex due to the cylindrical nature of the feature. Here's how to properly dimension a counterbore:

Conclusion

Correctly identifying spotface and counterbore symbols and dimensioning them accurately is essential for the success of CNC machining projects. Proper dimensioning ensures that the holes are machined with precision and that the fasteners fit correctly, preventing issues like misalignment, loose fastenings, or improper fitment. For CNC machining services, ensuring proper dimensioning of spotfaces and counterbores is critical to maintaining the integrity of the final product and ensuring it performs as expected. By following the guidelines and understanding the symbols and their applications, engineers and machinists can create components that are well-aligned, secure, and functionally efficient.

The machining of spotfaces and counterbores requires precise techniques and tools to ensure that the features are created accurately and to the required specifications. Whether performed manually or using advanced CNC machinery, these processes are essential in many manufacturing applications. Below, we’ll explore the most commonly used techniques for machining spotfaces and counterbores.

Manual Milling

Manual milling is a traditional method of machining that involves using a milling machine operated by a skilled machinist. In this technique, the machinist manually controls the movement of the cutting tool over the workpiece. While manual milling is more labor-intensive and slower than modern CNC methods, it remains an effective option for smaller production runs, prototyping, or when precision isn’t as critical.

For spotfacing and counterboring, manual milling involves selecting the appropriate cutting tool, such as a spotface cutter or counterbore tool, and manually adjusting the machine settings for depth and diameter. A dial indicator or calipers is used to ensure the desired depth and dimensions are achieved. The machinist also needs to maintain the correct feed rate to ensure smooth cutting and avoid damaging the workpiece.

CNC milling is a more advanced and automated method of machining that uses computer-controlled machines to perform precise operations. In the case of spotfaces and counterbores, CNC milling allows for extremely high precision and repeatability, making it ideal for mass production and tight-tolerance components.

In CNC milling, a computer program dictates the movement of the cutting tool along multiple axes to create complex features like spotfaces and counterbores. CNC machines can automatically adjust the cutting tool's speed, feed rate, and depth, ensuring the machined holes are precisely aligned and dimensioned. Tooling such as counterbore tools, spotface cutters, or end mills are programmed into the CNC machine to achieve the desired surface finishes and dimensional accuracy.

Both countersinking and counterboring are widely used techniques across several industries to create secure, flush-fitting holes for fasteners, bolts, and screws. These techniques are essential for parts that need to be assembled with precision. Below are some of the key industries and applications where these machining processes are commonly applied.

In the automotive industry, precision is critical for both performance and safety. Spotfaceing and counterboring are commonly used to create proper seating surfaces for bolts, screws, and other fastening components. Components such as engine blocks, suspension parts, and transmission systems require counterbores or countersinks to ensure that the fasteners do not interfere with moving parts and that they remain secure under high-stress conditions.

For example, counterbored holes are often used to secure cylinder heads to engine blocks, ensuring that bolts fit flush and are tightly secured to avoid leaks and ensure engine integrity. Countersunk holes are used to reduce the risk of fastener heads protruding and to provide a smoother surface for assembly.

Aerospace Industry

The aerospace industry relies heavily on spotfaces, countersinks, and counterbores to ensure that components are both secure and lightweight. These processes are used to ensure that fasteners, such as rivets and screws, are securely fastened without adding unnecessary weight to the aircraft structure. Counterbored holes are commonly used in aircraft wing structures, fuselages, and engine components.

In aerospace applications, spotfacing is also used to prepare a flat surface for seating washers or nuts to prevent tilting, which could cause instability or damage during operation. The high precision required in aerospace machining ensures that fasteners are correctly seated and that all components fit within tight tolerance ranges.

General Manufacturing

In general manufacturing, countersinking and counterboring are used across a wide range of industries, including electronics, machinery, and metalworking. These techniques are used to create high-quality assembly holes for securing fasteners, creating flat seating surfaces, or accommodating specialized components like studs or dowels.

For example, in the electronics industry, counterbored holes are used to ensure the secure mounting of components like transistors or capacitors to circuit boards. Spotfaceing is also used to ensure a flush finish for fasteners that need to be securely mounted without interfering with the surrounding parts.

In addition to spotfaces, counterbores, and countersinks, there are several other types of holes commonly created in machining. These holes serve different purposes based on their shape, depth, and function. Below are some of the most common types of holes used in manufacturing.

Simple Hole

A simple hole is the most basic type of hole, drilled without any additional features or modifications. It is typically created using a drill bit and can be used for a variety of purposes, such as mounting or allowing passage for bolts, screws, or liquids. While not modified by counterbores or countersinks, simple holes can be drilled to various depths and diameters based on the part’s requirements.

A through hole is a hole that passes all the way through a material, allowing fasteners, wires, or fluids to pass through. It is one of the most common types of holes created in CNC machining. Through holes can be drilled, counterbored, or countersunk, depending on the requirements of the part.

A blind hole is a hole that does not pass all the way through the material. It is commonly used in applications where components need to be mounted from one side or where a flush finish is required on the opposite side.

Counterbore Hole

A counterbore hole is a hole with a cylindrical recess around its top, allowing the head of a bolt or screw to sit below the material surface. Counterbores are often used in assemblies where fastener heads need to be recessed to allow for smooth, flush mounting.

Tapered Hole

A tapered hole has a conical shape, often used for applications like funnel-shaped fittings or where a tapered pin is needed. These holes can be created using special tapered reamers or custom-machined tools.

A threaded hole is a hole with internal threads designed to accept screws, bolts, or other threaded fasteners. Threaded holes can be created using tapping or threading tools in CNC machining, allowing for secure, repeatable fastening.

Conclusion

Understanding the different types of holes and machining techniques—such as spotfacing, countersinking, and counterboring—is essential for producing high-quality components in industries like automotive, aerospace, and general manufacturing. Whether done through manual milling or advanced CNC machining, these techniques ensure secure, tight-fitting fasteners, contributing to both the performance and durability of the final product. Whether you are producing CNC machining parts or engaging in custom CNC machining, mastering these techniques allows manufacturers to meet the high demands of modern industries and deliver precision-machined components.

Spotfaceing and countersink surface machining are key operations in CNC machining that ensure precise seating for fasteners like screws, bolts, and rivets. These processes are critical for producing parts that require flush, secure fastening while maintaining the structural integrity of the surrounding material.

Counterbore Machining

Spotfaceing refers to the process of creating a conical hole that allows the head of a fastener to sit flush with, or slightly below, the surface of the material. This is done by using a countersink tool that typically has a flat tip and an angle, most commonly 90°, 82°, or 120° angles, depending on the application.

During the machining process, the cutting tool moves into the material, creating a tapered hole at the top of the original hole. The primary purpose of this is to allow fasteners to sit neatly and flush against the surface of the workpiece, which is often necessary for achieving a clean and functional finish.

Spotface Surface Machining

Spotface surface machining takes the countersink process one step further by focusing not only on the hole but also on the surface finish around the countersunk area. Achieving a smooth and precise surface is critical in many applications, particularly when parts are subject to high stresses or when the aesthetic quality of the final product matters.

When machining a countersink surface, the operation involves controlling the tool's path to ensure the surface surrounding the hole is smooth, free from burrs, and has an even finish. The angle of the countersink must also be consistent to avoid misalignment when the fasteners are inserted.

In CNC machining, selecting the appropriate tool for countersinking and countersink surface machining is essential for achieving the desired outcome. These tools come in various shapes, sizes, and materials to suit different machining needs. Below are the most common tools used for these processes.

Counterbore Tools

Spotface Surface Tools

Each of these tools is designed to meet specific needs within CNC machining, and selecting the right tool is key to achieving accurate, repeatable results.

Spotfaceing and countersink surface machining are essential processes in modern manufacturing, especially when creating parts that require flush fastener placements or high-quality surface finishes. Whether using countersink tools to create the initial hole or countersink surface tools for achieving the desired finish, the right technique and tool selection are crucial for ensuring precision and reliability in your parts.

These machining processes are widely used in various industries, including aerospace, automotive, and general manufacturing, to meet the stringent demands of product performance, aesthetics, and functionality. By understanding the intricacies of countersink and countersink surface machining, manufacturers can ensure that their CNC machining parts meet the highest standards of quality and precision.

For those looking for high-quality, custom CNC machining services, working with experienced CNC machining factories is essential. These factories can offer CNC prototype machining and custom CNC machining that includes countersinking and other precision hole-making techniques.

1. Are counterbores and spotfaces made with different tools?

2. What is the main difference between a counterbore and a spotface?

The main difference is in the purpose and the hole geometry. A counterbore creates a stepped hole with a flat bottom, typically used to accommodate the head of a fastener, while a spotface creates a flat, smooth surface around the hole, ensuring proper seating for fasteners. Spotfaces do not create a stepped hole but rather focus on smoothing the surface.

3. How are spotfaces and counterbores dimensioned?

Both spotfaces and counterbores are dimensioned by their diameter and depth. For a counterbore, you specify the diameter of the counterbore and the depth to which the tool should cut. For a spotface, you also specify the diameter of the spotface and its depth, with the additional specification of the depth of the original hole.

4. What is the difference between a spotface and a counterbore?

A spotface is used to create a flat, smooth area around the top of a hole, while a counterbore is used to create a larger, stepped hole that accommodates the head of a fastener. Spotfaces do not have a stepped geometry and are primarily concerned with surface flatness, while counterbores are focused on hole enlargement for specific fastener head sizes.

5. When would you utilize a spotface for a hole?

A spotface is used when a flat surface is required around a hole for the proper seating of a fastener or for aesthetic or functional reasons, particularly in cases where a smooth, even surface is necessary to ensure an even distribution of load or pressure around the fastener.

6. What is the difference between counterbore and spotface in Inventor?

In Inventor, the difference is similar to the physical machining differences. A counterbore is a feature that creates a stepped hole, while a spotface creates a flat surface around the top of the hole. The software allows you to model these features with specific geometries for 3D part design and ensures accuracy in CNC machining operations.

7. What is the difference between a counterbore and a countersink hole?

A counterbore hole has a flat-bottomed, stepped shape, while a countersink hole has a conical shape, allowing a fastener head to sit flush with or below the material surface. The counterbore is designed to accommodate larger screw heads, while countersinks are designed for screws that need to fit flush into the material.

8. What is a spotface hole?

A spotface hole is a hole with a flat, machined area around it, ensuring the fastener head or other components can sit flush against the surface. Spotfaces are typically used to make a uniform, smooth surface for proper seating of bolts, nuts, or screws.

9. When to use a counterbore?

A counterbore is used when you need to create a hole that accommodates the head of a fastener such as a bolt, screw, or nut. It is particularly useful for situations where the fastener needs to be flush with the surface or recessed slightly for a clean, uniform finish.

10. When would you require the use of a countersink hole?

You would use a countersink hole when a fastener (typically a screw) needs to sit flush or below the surface of the material. Spotfaceing is often used in aerospace, automotive, and other industries where fastener aesthetics or functional clearance are important.

11. What is the spotface process?

The spotface process involves machining a flat surface around the top of a hole to allow the proper seating of fasteners or to provide a flat, smooth area for another component. Spotfaces are often used to create a smooth surface for bolts, washers, or nuts to seat against securely.

12. How to callout spotface?

A spotface callout typically includes the diameter of the spotface and the depth to which the machining should occur. The dimensions are specified on engineering drawings using standard hole callout formats. It’s important to note the hole’s diameter and the depth of the flat, machined surface.

13. Why would you countersink holes?

Spotfaceing is performed to allow a fastener head to sit flush with the material’s surface. This is essential in applications where surface smoothness and fastener clearance are critical, such as in aerospace, automotive, and construction industries.

14. When would you require the use of a countersink hole?

You require a countersink hole when you need to insert a fastener with a countersunk head so that it can sit flush with or below the surface of the material. This ensures that the fastener does not protrude from the surface and maintains the integrity and aesthetics of the part.

15. What is the disadvantage of countersink?

One disadvantage of countersinking is that it requires more precision in machining to ensure that the fastener fits correctly. Also, if done incorrectly, the countersink can weaken the surrounding material by removing too much material, potentially leading to cracks or structural weakness.

16. What does a countersink look like?

A countersink has a conical shape, typically with angles ranging from 82° to 120°. The conical shape allows a fastener's head to sit flush or below the surface, making it ideal for applications where a smooth, neat appearance is required.

17. Can you countersink with a regular drill bit?

While a regular drill bit can create a hole, it cannot create the specific conical shape required for a proper countersink. You need a specialized countersink tool that has a conical tip to form the proper angle and depth for the fastener head to sit flush.

18. What is the symbol for a counterbore hole?

The symbol for a counterbore hole is a circle with two concentric circles within it, indicating the stepped hole geometry. This symbol is used in engineering drawings to show where the counterbore is to be machined.

19. How deep should a countersink hole be?

The depth of a countersink hole depends on the fastener used and the specific application. Typically, the depth should be deep enough to allow the fastener’s head to sit flush with the material or slightly below it. The depth can vary based on the size of the fastener and the desired aesthetic or functional requirements.