15 years one-stop China custom CNC machining parts factory

1062 |

Published by VMT at Feb 18 2025 | Reading Time:About 4 minutes

1062 |

Published by VMT at Feb 18 2025 | Reading Time:About 4 minutes

Casting is a core manufacturing technique used to create complex metal parts and components. From automotive to aerospace, it plays a crucial role in producing high-quality products across various industries. But with numerous casting methods available, which one should you choose for your specific needs? In this article, we will explore 14 different casting processes, their advantages, disadvantages, and when each process is best suited for your project. Whether you're involved in CNC machining parts or looking for custom CNC machining, understanding these methods can optimize your product's performance and cost-efficiency.

The casting process involves pouring molten metal into a mold to shape a part. Choosing the right casting method depends on factors such as the part's complexity, material type, and volume requirements. For high-precision CNC prototype machining and casting CNC machining parts, it's essential to understand the pros and cons of each method to make informed decisions that lead to successful production outcomes.

Before diving into the different types of casting, it's important to understand the general principles of casting, which remain consistent across various methods. By familiarizing yourself with the basics, you’ll be better prepared to evaluate which casting technique is the most suitable for your needs. Let’s start by examining the different types of casting and their unique characteristics.

Casting is a versatile manufacturing process used to create parts and components by pouring molten material—usually metal—into a mold. Once the molten material cools and solidifies, it takes the shape of the mold, resulting in a finished part that can be further refined or used directly. The process can be applied to a variety of materials, including metals, plastics, ceramics, and composites. Casting is widely used in industries such as automotive, aerospace, and construction, where complex parts with intricate shapes and high precision are needed.

Casting allows for the production of parts that would be difficult or impossible to create through other methods like machining or forging. It’s particularly valuable when dealing with large, heavy parts or parts with intricate internal features, such as engine blocks, turbine blades, and various machine components. The versatility and efficiency of casting make it an essential process for creating a wide range of components used in numerous industries.

The casting process offers several significant advantages that make it one of the most commonly used manufacturing methods in industries around the world. Some of the key benefits of casting include:

Regardless of which casting method is used, there are some common elements and considerations that play a critical role in the success of the process. These elements are essential for achieving optimal results in casting projects, whether you're working with casting CNC machining parts or mass-producing components for industrial use. Key factors include:

Understanding these common elements can help ensure a smooth casting process, leading to higher-quality parts and better performance in the final product. Whether you’re designing a complex part for CNC prototype machining or using casting for mass production, these factors play a critical role in ensuring the success of your project.

Casting is a fundamental manufacturing process used to create metal or plastic parts with complex geometries, by pouring molten material into molds. There are numerous casting methods, each suited to specific applications based on the size, material, and complexity of the part being produced. Let’s explore the different types of casting processes commonly used in industries today:

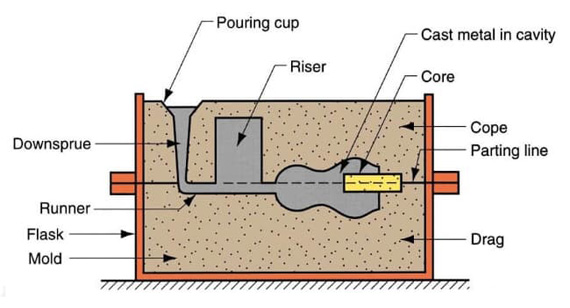

1. Sand Casting

What is Sand Casting?

Sand casting is one of the oldest and most versatile casting methods, where a mold is made from sand and then filled with molten metal. The sand mold is created around a pattern, which is removed after the metal solidifies. This process is ideal for creating large, simple to moderately complex parts in various metals.

Advantages

Disadvantages

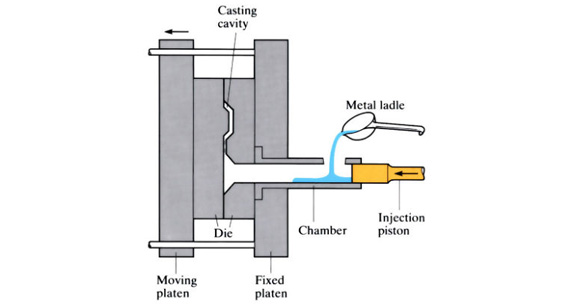

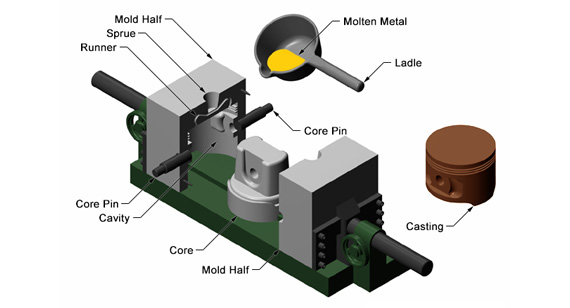

2. Die Casting (Metal Die Casting)

Die casting is a high-pressure casting process in which molten metal is injected into a steel mold, or die, under high pressure. The mold is usually made from durable materials like steel or aluminum and is typically used to create parts with fine details and tight tolerances.

Advantages

Disadvantages

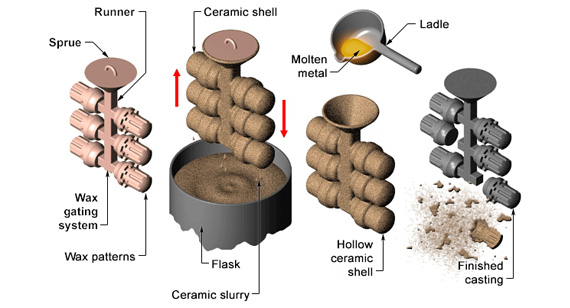

3. Investment Casting

What is Investment Casting?

Also known as lost-wax casting, this process involves creating a detailed wax pattern, which is coated in a ceramic shell. Once the shell is hardened, the wax is melted out, and molten metal is poured into the mold.

Advantages

Disadvantages

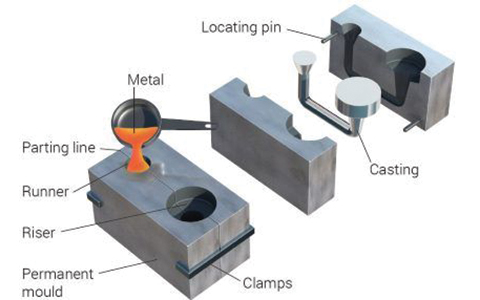

4. Gravity Die Casting

What is Gravity Die Casting?

Gravity die casting uses a permanent mold into which molten metal is poured and allowed to flow into the mold cavity using gravity. This method is commonly used for producing parts that require greater mechanical strength and a smooth finish.

Advantages

Disadvantages

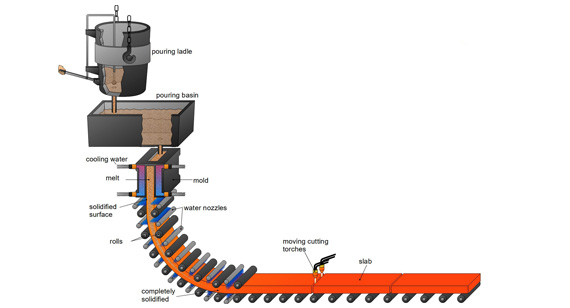

5. Continuous Casting

What is Continuous Casting?

Continuous casting is a process where molten metal is poured into a mold, cooled, and solidified as it moves along a continuous strand. It’s often used for producing billets, slabs, and blooms, which are then further processed into finished parts.

Advantages

Disadvantages

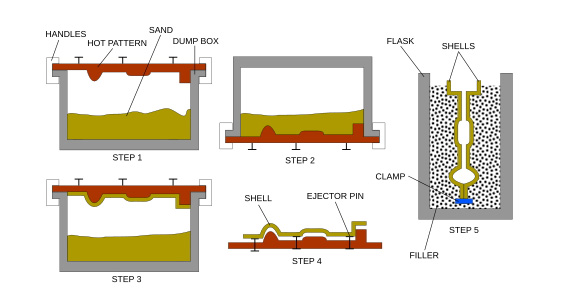

6. Shell Molding

What is Shell Molding?

Shell molding is a type of investment casting where a thin, strong shell is formed around a pattern by using a fine sand and binder mixture. This process is often used for precision metal castings in industries like aerospace.

Advantages

Disadvantages

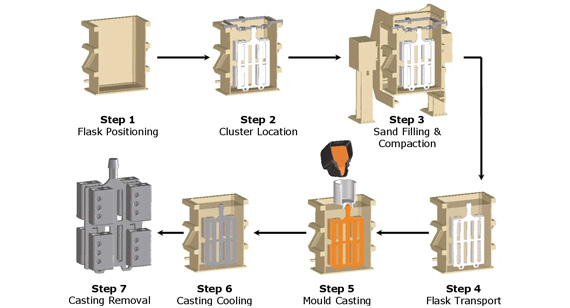

7. Lost Foam Casting

What is Lost Foam Casting?

In this process, a pattern made of foam is placed in a sand mold. The foam pattern is then vaporized by the molten metal during pouring, leaving a hollow cavity in the shape of the original foam pattern.

Advantages

Disadvantages

8. High Pressure Die Casting

What is High Pressure Die Casting?

This process is a variant of traditional die casting, where molten metal is injected into a die at very high pressure (up to 1000 bar). It’s commonly used in high-precision applications where tight tolerances are required.

Advantages

Disadvantages

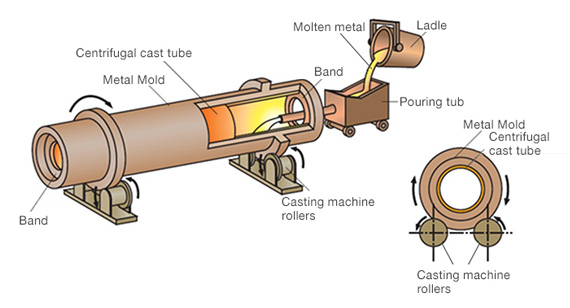

9. Centrifugal Casting

What is Centrifugal Casting?

Centrifugal casting involves pouring molten metal into a rotating mold. The centrifugal force ensures the metal is distributed evenly and forms a dense structure. This process is typically used for producing cylindrical parts.

Advantages

Disadvantages

10. Permanent Mold Casting

What is Permanent Mold Casting?

In permanent mold casting, molten metal is poured into a mold that can be used repeatedly. The mold is typically made from metal and is capable of producing parts with a fine surface finish and high dimensional accuracy.

Advantages

Disadvantages

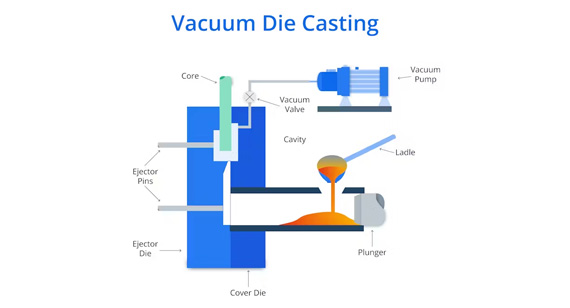

11. Vacuum Casting

What is Vacuum Casting?

Vacuum casting involves creating molds in a vacuum chamber to prevent air pockets and imperfections during the solidification of the molten material. This process is often used for high-quality prototypes.

Advantages

Disadvantages

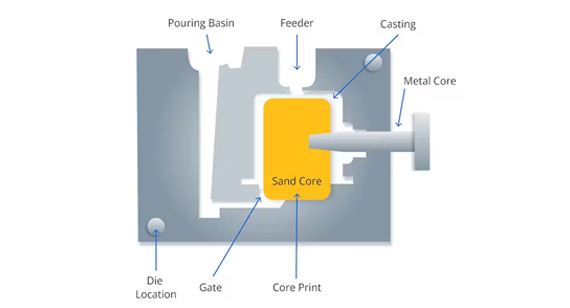

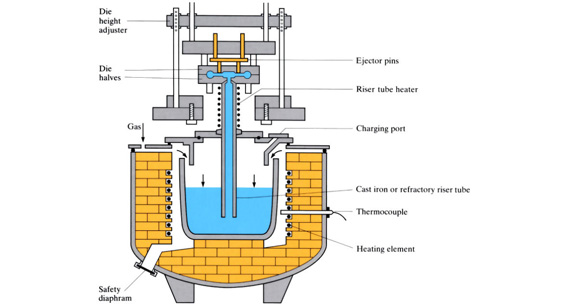

12. Low Pressure Casting

What is Low Pressure Casting?

In low-pressure casting, molten metal is introduced into the mold cavity under low pressure (typically 1 to 2 bars). This process is often used for parts that require good dimensional accuracy and surface finish.

Advantages

Disadvantages

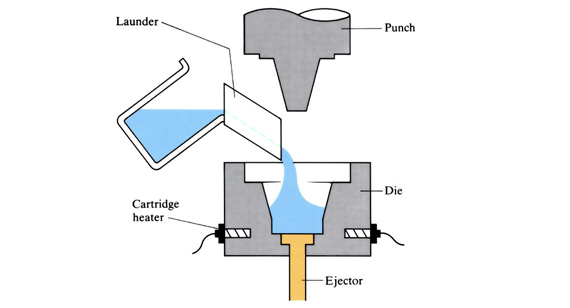

13. Squeeze Die Casting

What is Squeeze Die Casting?

Squeeze die casting is a variation of pressure die casting where a high-pressure squeeze is applied to molten metal in the die. This forces the metal into all the corners of the mold, ensuring uniformity.

Advantages

Disadvantages

14. Plaster Casting

What is Plaster Casting?

Plaster casting is a process where a pattern is made from wax or another material, and the mold is created using a plaster-based material. Once the plaster solidifies, the pattern is melted out, and molten metal is poured into the mold.

Advantages

Disadvantages

These various casting processes provide flexibility, allowing manufacturers to choose the most appropriate method based on their part’s complexity, material, and production requirements. Each casting technique has its distinct set of advantages and disadvantages, making it crucial for companies to select the right one for optimal performance. Whether you are sourcing casting CNC machining parts for prototype development or mass-producing components, understanding the casting process options is critical for success.

Casting is a crucial manufacturing process that involves shaping materials, typically metals or plastics, into specific forms by pouring them into molds. Once the material cools and solidifies, it takes the shape of the mold cavity. The casting process can vary depending on the method used, but the general procedure remains similar. Understanding how casting works will give you valuable insights into creating high-quality parts for a variety of industries.

The casting process can be broken down into several key steps that help transform raw materials into finished products. Below are the essential stages of casting production:

Plate Making

Plate making is the first step in the casting process, especially for certain methods like sand casting. In this step, a pattern of the final product is created. This pattern can be made from various materials, including metal, wood, or plastic. For sand casting, the plate or mold is typically made of sand and is used to shape the molten metal. For other casting techniques, a metal plate might be used to create a detailed impression.

Mold Making

The next step is mold making, which involves creating a cavity in a material that can hold molten metal or other substances. The type of mold used depends on the casting process being employed. For example, sand casting requires a sand mold, while investment casting uses a ceramic shell. The mold must be designed with precision to ensure the final part has the correct dimensions and features.

Choosing Metal Alloys

Choosing the right metal alloy is essential to ensure the final part performs well in its intended application. Factors such as strength, durability, and resistance to heat or corrosion must be considered. Common materials used in casting include aluminum, brass, steel, and iron. The specific properties of each alloy will determine the casting process used and its overall effectiveness in meeting design requirements.

Melting and Pouring Alloys

Once the metal has been selected, it must be heated to a molten state, which requires the use of specialized furnaces. The temperature at which the alloy is melted will depend on its composition. Once molten, the metal is poured into the prepared mold, filling the cavity and taking the shape of the mold. The pouring process must be carefully controlled to prevent air pockets or defects in the casting.

Finishing

After the molten metal has solidified, the part is removed from the mold, and the finishing process begins. This may involve cleaning the part, removing excess material (like gates and runners), and smoothing the surface. The casting may also undergo processes such as heat treatment or machining to achieve the desired mechanical properties and surface finish.

Casting materials are critical to determining the strength, durability, and performance of the final product. The material selected should match the intended use of the component, as different materials have unique properties. Here are the most commonly used materials in casting:

Metals

Metals are the most common materials used in casting processes. They are ideal for applications that require strength, durability, and heat resistance. Common metals used in casting include iron, steel, aluminum, zinc, and copper alloys.

Alloys

Alloys, mixtures of metals, are often used in casting to enhance specific properties like strength, corrosion resistance, or electrical conductivity. Common casting alloys include aluminum alloys, bronze, and brass. These materials are chosen based on the needs of the final product, such as its mechanical strength, weight, and thermal properties.

Ceramics

Ceramics are often used in casting processes like investment casting. They can handle high temperatures and provide an excellent surface finish. Ceramics are used for casting parts in industries such as aerospace and automotive, where high precision and complex geometries are required.

Plastics

Certain casting processes, like vacuum casting, use plastics to create prototypes or low-volume parts. Plastics are advantageous because they can be easily molded and are generally lower in cost. Some commonly used plastics in casting include polyurethane and epoxy resins.

Composites

Composites combine materials like metals, ceramics, or plastics to produce parts with unique properties, such as improved strength-to-weight ratios. These materials are often used in aerospace or automotive industries where performance is critical.

Rubber

Rubber casting is used to create flexible parts and is often employed in the production of seals, gaskets, or vibration dampeners. This material is used in casting methods like molding, and it offers excellent flexibility and resilience.

Glass

Glass casting is used to create decorative and functional glass objects, including windows, containers, and art pieces. Glass is melted and poured into molds to take its final form. Glass casting offers excellent optical clarity and durability.

Concrete

Concrete is used in casting for large, heavy-duty items like precast structures, pipes, and foundations. Concrete casting is ideal for mass production of large-scale components that need to endure significant weight and stress.

Conclusion

Casting is a highly versatile manufacturing method with applications across many industries, from automotive and aerospace to healthcare and construction. The process of casting involves several steps, including plate making, mold making, alloy selection, melting, pouring, and finishing. The material selected for casting plays a significant role in determining the quality and durability of the final product. By carefully choosing the right materials and casting process, manufacturers can create high-quality, reliable parts for various applications.

If you need high-quality casting solutions, consider outsourcing your casting requirements to VMT CNC Machining Services. With our extensive expertise in casting and CNC machining parts, we can help you produce custom parts to meet your exact specifications. Whether you need a prototype or a high-volume production run, we offer tailored solutions that ensure precision, quality, and cost-effectiveness. Contact us today to learn more about how our casting services can benefit your project.

1. What is the best casting process for complexly designed parts?

For complex designs, investment casting and lost foam casting are often the best options. These methods allow for high precision and intricate detail, making them ideal for producing parts with complex geometries. Investment casting, in particular, can create highly detailed parts with smooth surfaces, which are often required for aerospace or medical components.

2. Which casting process is most cost-effective for high-volume production?

For high-volume production, die casting is typically the most cost-effective method. This process uses a metal die to mold parts under high pressure, which allows for the production of large quantities of uniform and precise components. It’s commonly used for producing automotive parts, household items, and other high-volume applications.

3. Can all types of metals be used in the casting process?

Not all metals are suitable for every casting process. While metals like aluminum, brass, and steel are commonly used, some materials with higher melting points, like certain stainless steels and titanium alloys, may require specialized casting processes and equipment. The selection of metal is highly dependent on the casting process being used and the required mechanical properties of the final part.

4. Why does sand casting have a rougher surface quality?

Sand casting tends to produce parts with rougher surfaces because the mold is made from sand, which doesn't offer as smooth a finish as other materials, such as metal or ceramics. After the metal is poured and solidifies, the mold is broken apart, leaving behind a rough surface that often requires additional post-processing, such as grinding or machining, to achieve a smooth finish.

5. Does the casting process affect the strength of the final product?

Yes, the casting process can significantly affect the strength of the final product. Factors such as the cooling rate, alloy selection, and mold design can influence the material's properties. For example, if the metal cools too quickly, it may lead to internal stresses or imperfections, which can weaken the part. Proper design and process control are essential to ensure that the final product meets the required strength specifications.

6. What is the definition of casting?

Casting is a manufacturing process where a liquid material (typically metal, plastic, or concrete) is poured into a mold to form a specific shape. Once the material cools and solidifies, it takes the shape of the mold cavity, creating a solid part. This process is commonly used for producing complex and high-volume parts.

7. What is casting in engineering?

In engineering, casting refers to the process of shaping material by pouring it into a mold and allowing it to solidify. It is widely used in the manufacturing of parts that require intricate shapes and high strength, such as engine blocks, valves, and gears. Casting is particularly effective for mass production and can accommodate a wide range of materials, including metals, plastics, and ceramics.

8. What are the types of casting?

There are several types of casting, including:

Sand casting

Die casting

Investment casting

Gravity die casting

Continuous casting

Shell molding

Lost foam casting

High pressure die casting

Centrifugal casting

Permanent mold casting

Vacuum casting

Low pressure casting

Squeeze die casting

Plaster casting Each of these methods has unique advantages, depending on the material being used and the complexity of the part design.

9. What is casting in art?

In art, casting is the process of creating sculptures or other artworks by pouring a liquid material (such as molten metal, plaster, or resin) into a mold. Once the material has hardened, the mold is removed, revealing the final form. This technique is often used to reproduce sculptures, create custom pieces, or produce detailed art with high precision.

10. What is spellcasting in magic?

Spellcasting in magic refers to the act of performing rituals or using incantations to invoke supernatural forces. It is commonly seen in fictional works such as fantasy novels, movies, or video games, where individuals use spells to perform magical actions, such as altering reality, summoning creatures, or healing.

11. What is the difference between crafting and casting?

Crafting involves the creation of objects by hand, using tools and materials such as wood, metal, or fabric. It is a more manual, artistic process. Casting, on the other hand, involves pouring a material into a mold to shape it, which is generally a more industrial and automated process. While crafting focuses on artistic creation, casting is often used in manufacturing and mass production.

12. What is the difference between casting art and plastic arts?

Casting art refers specifically to the method of creating sculptures and art objects by pouring materials like metal, plaster, or resin into molds. Plastic arts, however, is a broader term that encompasses any visual art that involves shaping or modeling materials like clay, plastic, or metal, which can include sculpture, pottery, and other media.

13. Is the ring forged or cast?

Rings can be both forged and cast, depending on the desired design and material. Casting is often used for rings with intricate designs or mass production, while forging is used for rings that require enhanced strength or are made from solid metal. The choice between the two processes depends on factors such as cost, design complexity, and material properties.

14. What is the difference between casting and pattern?

In the casting process, a pattern is the replica of the final part, usually made of metal, wax, or another material. It is used to create the mold into which molten material is poured. Casting, on the other hand, is the actual process of pouring molten material into the mold to form the final part. The pattern is used in the preparation stage, while casting is the core production process.