15 years one-stop China custom CNC machining parts factory

203 |

Published by VMT at Jan 03 2025 | Reading Time:About 8 minutes

203 |

Published by VMT at Jan 03 2025 | Reading Time:About 8 minutes

In the competitive world of CNC machining manufacturing, achieving flawless surface finishes is paramount to delivering high-quality, polished CNC machined parts that meet stringent industry standards. However, manufacturers often grapple with choosing between electrolytic polishing and mechanical polishing, each offering distinct advantages and challenges. Imagine investing significant resources into CNC machining, only to find that the surface finish doesn't meet your expectations, leading to increased costs, delays, and dissatisfied customers. This common problem can be exacerbated by selecting an inappropriate polishing method, ultimately impacting the overall success of your CNC machining services. Understanding the nuances between electrolytic and mechanical polishing is crucial to making an informed decision that aligns with your production needs, budget, and quality requirements.

When deciding between electrolytic polishing and mechanical polishing for your CNC machined parts, consider factors such as surface finish quality, production volume, material compatibility, and cost-effectiveness. Electrolytic polishing offers superior corrosion resistance and a mirror-like finish, making it ideal for high-precision applications, while mechanical polishing provides versatility and eco-efficiency, suitable for a wide range of materials and part complexities.

Choosing the right polishing method can transform your CNC machining operations, enhancing both the aesthetic and functional qualities of your parts. To delve deeper into making the best choice between electrolytic and mechanical polishing, let’s explore the intricacies of each technique, their benefits, ideal applications, and key considerations that will guide you toward optimal decision-making for your CNC machining factory.

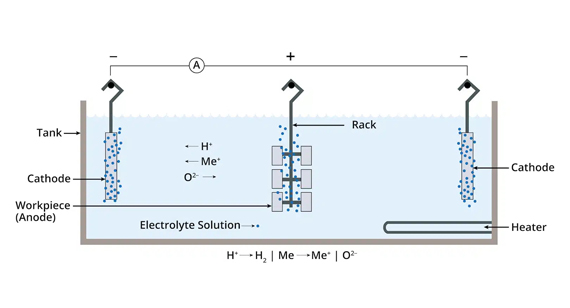

Electrolytic polishing, also known as electropolishing, is an advanced surface finishing technique widely used in CNC machining manufacturing to achieve high-gloss, smooth surfaces on metal parts. This process involves immersing the CNC machined part into an electrolytic bath containing a specific chemical electrolyte, typically a mixture of acids such as phosphoric, sulfuric, or nitric acid. An electrical current is then applied between the workpiece (acting as the anode) and a cathode, causing selective material removal from the part’s surface.

The fundamental principle behind electrolytic polishing is the electrochemical dissolution of the metal’s surface layers. The areas of the workpiece exposed to the electrolyte experience a uniform removal of microscopic peaks and protrusions, resulting in a significantly smoother and more reflective surface. This method not only enhances the aesthetic appeal of the CNC machined parts but also improves their functional properties by increasing corrosion resistance and reducing surface roughness, which is critical in industries such as medical devices, aerospace, and food processing.

Electrolytic polishing is particularly effective for complex geometries and intricate designs where mechanical polishing might be challenging to apply uniformly. Additionally, the process can be fine-tuned by adjusting parameters such as electrolyte composition, temperature, current density, and polishing time to achieve the desired surface finish. However, electrolytic polishing requires precise control over process conditions and the handling of hazardous chemicals, necessitating specialized equipment and trained personnel. Despite these challenges, the superior surface quality and enhanced material properties make electrolytic polishing a preferred choice for high-end CNC machined parts that demand both precision and durability.

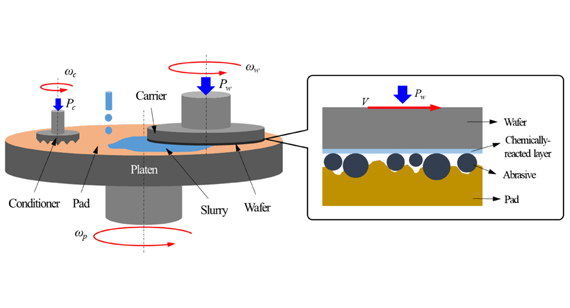

Mechanical polishing is a conventional surface finishing method employed in CNC machining manufacturing to achieve smooth, reflective surfaces on CNC machined parts through the physical removal of material using abrasive tools. This process typically involves the use of abrasive compounds, polishing wheels, and mechanical action to eliminate surface imperfections, tool marks, and scratches left from the machining process.

The mechanical polishing process begins with coarse abrasives to remove larger surface defects and progressively moves to finer abrasives to achieve a high level of smoothness and shine. Buffing wheels, typically made of materials like felt or cotton, are impregnated with polishing compounds that facilitate the removal of microscopic surface irregularities. By applying controlled pressure and movement, operators can refine the surface finish of CNC machined parts, enhancing their aesthetic appeal and functional performance.

Mechanical polishing offers several advantages, including versatility in handling various materials such as metals, plastics, and composites, and the ability to customize surface finishes based on specific application requirements. It is particularly suitable for parts with simple geometries or those requiring only a moderate level of surface refinement. Additionally, mechanical polishing can be easily integrated into automated production lines, ensuring consistent and repeatable results across large batches of parts.

However, mechanical polishing has its limitations. It may not be as effective for intricate or complex geometries where uniform polishing is difficult to achieve, and excessive polishing can lead to overheating and distortion of the workpiece. Furthermore, the process can be labor-intensive and may require significant operator skill to achieve optimal results. Despite these challenges, mechanical polishing remains a fundamental finishing technique in CNC machining factories, providing essential surface refinement that enhances the overall quality and performance of CNC machined parts.

When considering mechanical polishing for CNC machined parts, several important factors must be taken into account to ensure optimal results and maintain the integrity of the components. First and foremost is the selection of appropriate abrasive materials and polishing compounds. The choice of abrasives—ranging from coarse grit for initial surface leveling to fine grit for achieving a high-gloss finish—plays a critical role in determining the effectiveness and quality of the polishing process. Using the wrong type of abrasive can either fail to remove surface imperfections adequately or, conversely, cause unnecessary material removal that may alter part dimensions and tolerances.

Another key consideration is the control of polishing parameters such as speed, pressure, and duration. Excessive speed or pressure can lead to overheating, which may cause thermal distortion or softening of the workpiece material, especially in plastics and softer metals. Conversely, insufficient speed or pressure may result in incomplete polishing, leaving behind residual surface defects that compromise the part’s appearance and performance. Maintaining consistent and controlled polishing conditions is essential for achieving uniform surface finishes and preventing damage to the CNC machined parts.

The design of the CNC machining fixture also significantly impacts the effectiveness of mechanical polishing. A well-designed fixture ensures that the part is held securely and uniformly, allowing for even polishing across all exposed surfaces. Fixtures should be designed to provide adequate support and accessibility, minimizing areas that are difficult to reach and ensuring that polishing tools can move freely around the part without obstruction.

Additionally, environmental factors such as cleanliness and lubrication must be managed effectively. Clean surfaces free from contaminants and debris facilitate more efficient and consistent polishing, while appropriate lubrication with water, oil, or specialized polishing compounds reduces friction, prevents heat buildup, and aids in the removal of abrasive particles from the surface. Regular maintenance of polishing equipment and adherence to safety protocols are also vital to ensure a safe and productive polishing environment.

By carefully addressing these considerations, manufacturers can maximize the benefits of mechanical polishing, producing CNC machined parts with superior surface finishes that meet both aesthetic and functional requirements. Proper management of abrasive selection, polishing parameters, fixture design, and environmental factors ensures that mechanical polishing contributes positively to the overall quality and reliability of CNC machining manufacturing processes.

Electrolytic polishing and mechanical polishing are two distinct surface finishing techniques used in CNC machining manufacturing, each employing different mechanisms and offering unique advantages and limitations. Understanding the fundamental differences between these methods is crucial for selecting the most appropriate polishing approach for specific applications and achieving the desired surface quality on CNC machined parts.

Mechanism of Action:

Surface Finish Quality:

Material Compatibility:

Process Control and Consistency:

Environmental and Safety Considerations:

Cost and Investment:

Applications and Ideal Use Cases:

In summary, while both electrolytic polishing and mechanical polishing are valuable surface finishing techniques in CNC machining manufacturing, the choice between them depends on factors such as the desired surface finish quality, material compatibility, production volume, cost considerations, and specific application requirements. Electrolytic polishing excels in delivering high-precision, corrosion-resistant finishes for complex and high-end parts, whereas mechanical polishing offers versatility and cost-efficiency suitable for a wide range of materials and production scenarios. Evaluating these differences enables manufacturers to make informed decisions that enhance the quality and performance of their CNC machined parts.

Electrolytic polishing, or electropolishing, is a sophisticated surface finishing process utilized in CNC machining manufacturing to achieve exceptionally smooth and reflective surfaces on metal parts. The process involves several critical steps and parameters that must be meticulously controlled to ensure optimal results and maintain the integrity of the CNC machined parts.

1. Preparation of the Workpiece: Before the electrolytic polishing process begins, the CNC machined part must be thoroughly cleaned to remove any contaminants, oils, or residues that could interfere with the polishing process. This cleaning is typically achieved through degreasing agents or solvent cleaning to ensure a pristine surface is ready for polishing.

2. Setup of the Electrolytic Bath: The workpiece is submerged in an electrolytic bath containing a specific electrolyte solution, usually a mixture of acids such as phosphoric acid, sulfuric acid, and sometimes nitric acid. The composition of the electrolyte is carefully selected based on the material of the workpiece and the desired polishing outcome.

3. Electrical Configuration: In the electrolytic polishing setup, the workpiece acts as the anode, while a cathode made of a non-reactive metal, such as stainless steel, is placed in proximity within the electrolyte bath. An electrical current is applied between the anode and cathode, initiating the electrochemical reactions necessary for material removal.

4. Polishing Process: As the electrical current flows through the electrolyte, metal ions from the workpiece dissolve into the solution. The process preferentially removes material from the high points and rough areas of the surface, effectively leveling microscopic peaks and valleys. This selective removal results in a smoother, more uniform surface.

5. Control of Polishing Parameters: Several key parameters must be precisely controlled to ensure effective electrolytic polishing:

6. Post-Polishing Treatment: After the electrolytic polishing process is complete, the workpiece is removed from the electrolyte bath and thoroughly rinsed with water to remove any residual acid. It is then dried and may undergo additional cleaning or passivation steps to further enhance corrosion resistance and surface integrity.

7. Quality Inspection: The final step involves inspecting the polished surface to ensure it meets the required specifications. Surface roughness measurements, visual inspections, and other quality control techniques are employed to verify that the electrolytic polishing has achieved the desired surface finish and that the CNC machined parts meet the necessary quality standards.

By meticulously controlling these steps and parameters, electrolytic polishing effectively enhances the surface quality of CNC machined parts, providing benefits such as improved corrosion resistance, smoother finishes, and enhanced aesthetic appeal. This process is integral to producing high-performance components required in industries where precision and surface integrity are paramount.

For Electrolytic Polishing to Work, Several Items and Conditions are Critical:

Electrolytic polishing is a nuanced process that requires a precise interplay of various components and conditions to achieve optimal results. Each element plays a vital role in ensuring the effectiveness, efficiency, and safety of the polishing operation within CNC machining manufacturing. Below are the critical items and conditions that must be meticulously managed for successful electrolytic polishing:

Electrolyte

The electrolyte is the chemical solution in which the CNC machined part is immersed during electrolytic polishing. Its composition is fundamental to the process, as it dictates the rate of material removal, the quality of the surface finish, and the overall efficiency of polishing. Common electrolytes used in electropolishing include mixtures of phosphoric acid, sulfuric acid, and sometimes nitric acid, tailored to the specific metal being polished. The concentration and proportion of these acids must be carefully controlled to optimize the electrochemical reactions, ensuring uniform material removal without causing excessive etching or surface damage.

Cathode

In the electrolytic polishing setup, the cathode is a non-reactive metal electrode placed in the electrolyte bath alongside the workpiece, which serves as the anode. The cathode must be made from a material that does not dissolve or react under the conditions of the polishing process, typically stainless steel. The proximity and surface area of the cathode relative to the workpiece are critical factors that influence the distribution of the electrical current and the uniformity of material removal. Proper cathode placement ensures that the electric field is evenly distributed across the workpiece’s surface, preventing localized over-polishing and ensuring a consistent finish.

Anode (Metal Part to be Electropolished)

The anode in the electrolytic polishing process is the CNC machined part itself. As the anode, it undergoes controlled oxidation and dissolution in the electrolyte bath. The material properties of the workpiece, such as its composition, surface hardness, and initial surface finish, significantly affect how it reacts during electropolishing. Metals with high corrosion resistance, like stainless steel and titanium, are particularly well-suited for electrolytic polishing, as they form stable oxide layers that enhance surface smoothness and integrity. The surface condition of the anode before polishing—free from defects, scratches, and contaminants—is essential for achieving a uniform and high-quality polished finish.

Electrolyte Temperature (Typically 77°C – 83°C)

Temperature control is a critical condition in electrolytic polishing, with the electrolyte bath typically maintained between 77°C to 83°C (170°F to 181°F). Maintaining this temperature range is vital for several reasons:

Current Dwell Time

Current dwell time refers to the duration for which the electrical current is applied to the workpiece during the polishing process. This parameter is crucial for controlling the amount of material removed and achieving the desired surface finish. The dwell time must be optimized based on the electrolyte composition, current density, and material properties of the workpiece. Insufficient dwell time may result in incomplete polishing, leaving surface imperfections, while excessive dwell time can lead to over-polishing, excessive material removal, and potential distortion of the part’s geometry. Precise control of current dwell time ensures that the polishing process is conducted efficiently, achieving a uniform and high-quality finish without compromising the part’s dimensional accuracy.

Current Density (Varies by Electrolyte; Typical Range is 140 - 250 Amps per Square Foot)

Current density, measured in amps per square foot, is a critical parameter that influences the rate and uniformity of material removal during electrolytic polishing. It represents the amount of electrical current applied per unit area of the workpiece’s surface. The optimal current density depends on several factors, including the type of electrolyte used, the material properties of the workpiece, and the desired surface finish. A typical current density range for electrolytic polishing is between 140 to 250 amps per square foot.

Key Considerations:

Careful calibration and monitoring of current density are essential for controlling the electrolytic polishing process, ensuring that the CNC machined parts achieve the desired surface quality without compromising their structural integrity or dimensional accuracy.

Mechanical polishing is a fundamental surface finishing process in CNC machining manufacturing, designed to enhance the surface quality of CNC machined parts through the physical removal of material using abrasive tools and compounds. This method is widely employed across various industries to achieve smooth, reflective surfaces that meet both aesthetic and functional requirements. The mechanical polishing process involves several key steps and considerations to ensure effective and consistent results.

1. Preparation of the Workpiece: Before mechanical polishing begins, the CNC machined part must be thoroughly cleaned to remove any residual machining fluids, oils, or debris that could interfere with the polishing process. Cleaning can be achieved through degreasing, solvent rinsing, or other appropriate cleaning methods, ensuring that the surface is free from contaminants that might affect the abrasive action or the final finish quality.

2. Selection of Abrasive Materials: The choice of abrasive materials is critical for achieving the desired surface finish. Abrasives range from coarse grit, used for initial surface leveling and the removal of major imperfections, to fine grit for achieving high levels of smoothness and shine. Common abrasives used in mechanical polishing include:

3. Polishing Techniques: Mechanical polishing can be performed manually or through automated systems, depending on the production volume and part complexity.

4. Polishing Process: The mechanical polishing process typically follows a multi-step approach:

5. Control of Polishing Parameters: Maintaining optimal polishing conditions is essential for achieving uniform and high-quality finishes. Key parameters include:

6. Lubrication and Cooling: Proper lubrication with water, oil, or specialized polishing compounds reduces friction between the abrasive materials and the workpiece, preventing overheating and facilitating the removal of abrasive particles from the surface. Effective lubrication ensures a smoother polishing process and enhances the overall quality of the surface finish.

7. Quality Control and Inspection: After mechanical polishing, the CNC machined parts undergo thorough inspection to verify that the surface finish meets the required specifications. Surface roughness measurements, visual inspections, and other quality control techniques are employed to ensure that the polishing process has achieved the desired level of smoothness and reflectivity.

8. Maintenance of Polishing Equipment: Regular maintenance of polishing tools and equipment is vital to ensure their effectiveness and longevity. This includes cleaning polishing wheels, replacing worn abrasives, and calibrating automated polishing systems to maintain consistent performance.

By meticulously executing these steps and maintaining control over polishing parameters, manufacturers can produce CNC machined parts with superior surface finishes that meet the stringent quality standards of various industries. Mechanical polishing not only enhances the aesthetic appeal of parts but also improves their functional performance by reducing surface roughness, minimizing friction, and increasing corrosion resistance. This process is integral to delivering high-quality, polished CNC machined parts that satisfy both aesthetic and operational requirements.

Electropolishing is a highly effective surface finishing technique within CNC machining manufacturing, offering numerous benefits such as enhanced corrosion resistance and superior surface smoothness. However, the success of the electropolishing process hinges on several critical considerations that must be carefully managed. These factors ensure that the process is performed efficiently, safely, and yields the desired outcomes for polished CNC machined parts. Below are the key considerations that manufacturers should address to optimize the electropolishing process.

1. Surface Condition of the Workpiece

The initial surface condition of the CNC machined part plays a significant role in the effectiveness of the electropolishing process. Parts with a rough surface, tool marks, or surface imperfections may require additional preparation steps before electropolishing can be applied successfully. Ensuring that the workpiece is free from contaminants, debris, and machining residues is essential for achieving a uniform and high-quality polished finish.

Key Considerations:

Addressing the surface condition prior to electropolishing ensures that the process can effectively remove microscopic surface irregularities, resulting in a smooth, reflective finish that meets the desired quality standards.

2. Process Control

Effective process control is paramount in electropolishing to achieve consistent and reliable results. Variations in key process parameters can lead to inconsistent finishes, over-polishing, or under-polishing of the CNC machined parts. Implementing stringent control measures ensures that the electropolishing process operates within optimal conditions, enhancing both the quality and efficiency of the surface finish.

Key Considerations:

By maintaining strict process control, manufacturers can minimize variability in the electropolishing process, ensuring that each CNC machined part achieves the desired surface finish and quality attributes consistently.

Electropolishing offers a multitude of benefits that make it a preferred surface finishing method for CNC machined parts across various industries. This electrochemical process not only enhances the aesthetic appeal of parts by providing a smooth, mirror-like finish but also significantly improves their functional properties. Below, we explore the key advantages of electropolishing, highlighting why it is an essential step in achieving high-quality, durable, and reliable components in CNC machining manufacturing.

Improved Corrosion Resistance

One of the most significant benefits of electropolishing is the enhancement of corrosion resistance in CNC machined parts. The electrochemical process removes a thin layer of material from the surface, eliminating surface impurities and creating a uniform, passive oxide layer. This oxide layer acts as a barrier, protecting the underlying metal from environmental factors such as moisture, chemicals, and atmospheric conditions that can lead to corrosion. By improving corrosion resistance, electropolishing extends the lifespan of parts used in harsh environments, including marine applications, chemical processing equipment, and medical devices where sterility and durability are paramount.

Advantages:

This improved corrosion resistance not only enhances the longevity and reliability of the parts but also reduces maintenance costs and the need for frequent replacements. For industries that demand high-performance, precision-engineered components, such as aerospace and automotive, electropolishing ensures that CNC machined parts can withstand rigorous operational stresses without degrading over time. Additionally, the corrosion-resistant surfaces maintain their integrity and appearance, providing consistent performance and aesthetic appeal throughout the product’s lifecycle.

Deburred Edges

Deburring is a critical step in the machining process, as it involves removing sharp edges and burrs that can pose safety hazards or interfere with the assembly and functionality of CNC machined parts. Electropolishing excels in deburring by effectively removing these unwanted protrusions without the need for additional mechanical processes. The electrochemical reaction smooths out the edges and eliminates sharp corners, resulting in safer, more comfortable handling and reducing the risk of injuries during installation or use.

Advantages:

Moreover, deburred edges contribute to the overall quality and fit of assembled components, ensuring that parts fit together seamlessly without catching or misaligning. In industries such as automotive, medical devices, and consumer electronics, where precision and safety are paramount, electropolishing provides a reliable method for achieving clean, burr-free edges that enhance both the performance and appearance of CNC machined parts. This process not only improves the functional aspects of the parts but also enhances their aesthetic qualities, making them more appealing and professional in appearance.

Improved Cleanliness

Electropolishing significantly enhances the cleanliness of CNC machined parts by removing microscopic contaminants and impurities from the surface. The process eliminates surface oxides, residues, and scale that can accumulate during machining, creating a pristine, smooth surface that is free from debris and contaminants. This level of cleanliness is particularly important in industries that require high levels of hygiene and sterility, such as medical device manufacturing, food processing equipment, and pharmaceutical machinery.

Advantages:

Clean surfaces are not only essential for maintaining product integrity and performance but also play a crucial role in preventing microbial growth and contamination in sensitive applications. Electropolishing ensures that CNC machined parts meet stringent cleanliness standards, reducing the risk of product failure, enhancing reliability, and supporting compliance with regulatory requirements. Additionally, cleaner surfaces improve the efficiency of subsequent manufacturing processes, such as coating or painting, by providing a uniform base that promotes better adhesion and finish quality.

By achieving superior cleanliness, electropolishing enhances the overall quality and functionality of CNC machined parts, ensuring that they perform optimally in their intended applications and maintain their integrity over time.

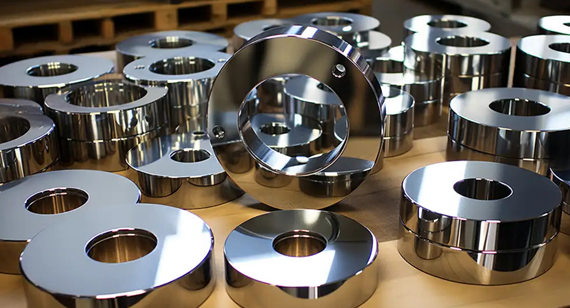

Achieved Better Surface Finish

Achieving a superior surface finish is a primary objective in CNC machining manufacturing, and electropolishing excels in delivering exceptional results. This process removes a microscopic layer of material, smoothing out surface irregularities, tool marks, and imperfections left from machining operations. The result is a highly polished, mirror-like surface that enhances both the aesthetic and functional qualities of CNC machined parts.

Advantages:

A better surface finish offers several advantages, including improved optical clarity for transparent or translucent materials like acrylic, reduced friction and wear in moving parts, and enhanced adhesion for subsequent coating or painting processes. In applications such as optical devices, display panels, and precision-engineered components, a superior surface finish is critical for performance and visual appeal. Electropolishing ensures that parts not only look professional and visually appealing but also perform reliably and efficiently in their intended roles.

Furthermore, a smooth surface finish contributes to easier cleaning and maintenance of the parts, as it minimizes the accumulation of dirt, debris, and contaminants. This is particularly beneficial in environments where cleanliness and ease of maintenance are crucial, such as in medical facilities or food processing plants. By achieving a better surface finish, electropolishing enhances the overall quality and functionality of CNC machined parts, making them more durable, efficient, and visually impressive.

Removed Heat Color and Scale

During the machining process, especially when dealing with metals, heat buildup can cause discoloration and the formation of scale on the surface of CNC machined parts. These heat-induced defects not only detract from the aesthetic appeal of the parts but can also impact their functional performance by creating uneven surface properties and potential sites for corrosion.

Advantages:

Electropolishing effectively removes heat color and scale by dissolving the oxidized layer that forms during machining. This electrochemical process targets and eliminates the discolored and scaled areas, restoring the original color and surface integrity of the metal. By removing these defects, electropolishing ensures that the surface of CNC machined parts is uniformly smooth and free from visual imperfections, enhancing both their appearance and performance.

The removal of heat color and scale is particularly important in industries where visual quality and material integrity are paramount, such as in automotive parts, aerospace components, and medical devices. Electropolishing not only improves the aesthetic qualities of the parts but also enhances their structural properties by eliminating surface defects that could lead to corrosion or other forms of material degradation. This results in CNC machined parts that are not only visually appealing but also more durable and reliable in their intended applications.

Ability to Polish Micro-Areas

Electropolishing offers the unique advantage of being able to polish micro-areas and intricate details on CNC machined parts with high precision. This capability is particularly valuable for parts that feature complex geometries, fine threads, or small cavities where mechanical polishing methods may struggle to achieve uniform results. The electrochemical nature of the process allows for consistent material removal across both large and small surface areas, ensuring that every part of the workpiece receives the same level of finish without the risk of over-polishing or introducing new defects.

Advantages:

This ability to polish micro-areas is essential in industries that demand high precision and intricate detailing, such as medical device manufacturing, electronics, and aerospace. For example, components with small grooves, channels, or sharp corners benefit from electropolishing by achieving smooth, defect-free surfaces that enhance both functionality and aesthetic appeal. In medical devices, where cleanliness and surface integrity are critical, the ability to polish micro-areas ensures that even the smallest features are free from contaminants and surface imperfections.

Moreover, electropolishing’s uniformity and consistency in material removal make it an ideal choice for parts that require tight tolerances and high dimensional accuracy. By eliminating tool marks, burrs, and microscopic imperfections, electropolishing ensures that CNC machined parts perform reliably and meet stringent quality standards. This capability not only improves the overall functionality and durability of the parts but also enhances their visual appeal, making them more attractive and professional in appearance.

Enhanced Appearance

The enhanced appearance achieved through electropolishing is one of its most compelling benefits for CNC machined parts. The process produces a smooth, mirror-like finish that significantly improves the visual appeal of the parts, making them more attractive and professional in appearance. This enhanced aesthetic quality is particularly important for components used in consumer products, medical devices, and high-end applications where the look and feel of the part are critical to its overall value and marketability.

Advantages:

Electropolishing removes surface imperfections, tool marks, and microscopic scratches that can detract from the surface’s clarity and shine. By creating a uniformly smooth surface, the process enhances the part’s reflectivity and luster, giving it a high-quality, polished look that is difficult to achieve with mechanical polishing alone. This is especially beneficial for transparent or translucent materials like acrylic, where surface imperfections can significantly impact optical clarity and aesthetic appeal.

Furthermore, an enhanced appearance can contribute to the perceived value of the product, making it more appealing to customers and end-users. In industries such as automotive, aerospace, and electronics, where the visual presentation of components is closely tied to brand reputation and customer satisfaction, electropolishing plays a crucial role in ensuring that CNC machined parts meet the highest standards of quality and aesthetics. By investing in electropolishing, manufacturers can deliver parts that not only perform exceptionally well but also look visually impressive, thereby strengthening their competitive position in the market.

Some Other Advantages

In addition to the primary benefits discussed, electropolishing offers several other advantages that enhance the overall quality and performance of CNC machined parts:

These additional advantages underscore the value of electropolishing as a comprehensive surface finishing solution in CNC machining manufacturing. By leveraging these benefits, manufacturers can enhance both the performance and appearance of their CNC machined parts, delivering products that meet the highest standards of quality and durability.

Mechanical polishing, a fundamental surface finishing technique, offers a range of benefits that make it an essential step in the production of high-quality CNC machined parts. This process involves the use of abrasive materials and mechanical action to refine surfaces, remove imperfections, and achieve desired finishes. Below, we explore the key benefits of mechanical polishing, highlighting why it remains a preferred method for achieving superior surface quality in CNC machining manufacturing.

Versatility

One of the primary advantages of mechanical polishing is its versatility. This method can be applied to a wide range of materials, including metals, plastics, and composites, making it suitable for various types of CNC machined parts across multiple industries. Whether working with stainless steel, aluminum, acrylic, or other materials, mechanical polishing can be tailored to achieve the desired surface finish. This adaptability allows manufacturers to employ the same polishing techniques for different parts, simplifying the production process and reducing the need for specialized equipment or abrasives.

Advantages:

Additionally, mechanical polishing can be used to achieve a variety of surface finishes, from matte to high-gloss, depending on the abrasives and techniques used. This flexibility enables manufacturers to customize the appearance and functionality of their parts to meet specific application requirements. For instance, a matte finish may be desirable for certain aesthetic applications, while a high-gloss finish is essential for components that require optical clarity or reflective properties.

The ability to adapt mechanical polishing to different materials and finish requirements enhances its utility in CNC machining factories, allowing for efficient production of diverse CNC machined parts without the need for multiple specialized finishing processes. This versatility not only improves production efficiency but also enables manufacturers to cater to a broader range of customer needs and industry standards, making mechanical polishing an invaluable tool in the CNC machining manufacturing arsenal.

Surface Customization

Mechanical polishing offers significant opportunities for surface customization, allowing manufacturers to achieve specific aesthetic and functional properties on CNC machined parts. By selecting appropriate abrasives, polishing tools, and techniques, it is possible to create a wide range of surface finishes tailored to the needs of different applications.

Advantages:

For example, different grit sizes can be used to achieve varying levels of smoothness, from rougher finishes for mechanical grips to ultra-smooth finishes for optical components. Additionally, surface textures can be customized to provide anti-slip properties, reduce glare, or enhance the tactile feel of parts used in consumer products. This level of customization is particularly valuable in industries such as automotive, aerospace, medical devices, and consumer electronics, where specific surface characteristics are essential for performance and user experience.

Furthermore, mechanical polishing can be combined with other finishing techniques, such as coating or anodizing, to further enhance the surface properties of CNC machined parts. For instance, a polished metal part can be coated with a protective layer to improve corrosion resistance or dyed to achieve a specific color, expanding the range of customization options available to manufacturers.

The ability to tailor the surface finish through mechanical polishing enables CNC machining factories to produce highly specialized parts that meet unique customer requirements and industry standards. This customization capability not only enhances the functionality and aesthetic appeal of the parts but also adds value to the final product, making it more attractive and competitive in the market.

Eco-Efficient

Mechanical polishing is considered an eco-efficient process, particularly when compared to other polishing methods that may involve hazardous chemicals or generate significant waste. This process typically uses abrasive materials such as sandpaper, buffing wheels, or polishing compounds, which can be recycled or disposed of with minimal environmental impact when managed properly. Additionally, mechanical polishing does not require the use of electrolytes or solvents, reducing the potential for chemical contamination and the associated environmental hazards.

Advantages:

Furthermore, mechanical polishing can be optimized to minimize waste generation by using appropriate grit sizes and recycling abrasives where possible. Implementing efficient machining practices, such as selecting the right abrasives for the job and controlling polishing parameters to reduce over-polishing, contributes to a more sustainable and eco-friendly manufacturing process.

By adopting mechanical polishing as part of their CNC machining manufacturing workflow, companies can enhance their environmental sustainability while maintaining high standards of surface quality. This eco-efficient approach aligns with the growing emphasis on sustainable manufacturing practices and can contribute to reducing the overall environmental footprint of CNC machining factories. Additionally, eco-friendly polishing processes can be a selling point for customers who prioritize sustainability, further enhancing the marketability and reputation of the manufacturer’s products.

Material Removal

Mechanical polishing excels in controlled material removal, allowing for precise adjustments to the surface finish of CNC machined parts. By selecting the appropriate abrasive grit and applying consistent pressure and movement, manufacturers can achieve the desired level of smoothness and reflectivity without compromising the dimensional accuracy or structural integrity of the part. This controlled removal is essential for achieving tight tolerances and ensuring that the final surface meets specific quality standards.

Advantages:

In applications where dimensional precision is critical, such as in aerospace or medical devices, the ability to finely tune the polishing process ensures that CNC machined parts maintain their exact dimensions while achieving the necessary surface finish. Additionally, mechanical polishing allows for the removal of tool marks, burrs, and other surface defects that may have been introduced during the machining process, resulting in a clean and professional appearance.

Moreover, the precise control over material removal provided by mechanical polishing enables manufacturers to achieve specific surface characteristics tailored to the part’s functional requirements. For example, a smoother surface may reduce friction in moving components, while a more textured finish may improve grip or adhesion in other applications. This level of control enhances the overall performance and functionality of CNC machined parts, making mechanical polishing an invaluable step in the finishing process.

Improved Adhesion

Improved adhesion is another key benefit of mechanical polishing, particularly when preparing CNC machined parts for subsequent coating or painting processes. A smooth, clean surface created through mechanical polishing enhances the ability of paints, coatings, and adhesives to bond effectively with the part’s surface. This improved adhesion ensures that these coatings remain durable and resistant to peeling, chipping, or flaking, thereby extending the lifespan and aesthetic appeal of the finished product.

Advantages:

In industries such as automotive, aerospace, and consumer electronics, where protective and decorative coatings are essential, mechanical polishing plays a crucial role in ensuring that coatings adhere properly and perform reliably. The enhanced surface quality achieved through polishing allows for more uniform coating application, reducing the risk of defects and achieving a more professional and visually appealing finish.

Additionally, improved adhesion contributes to the overall performance and durability of CNC machined parts, as well-bonded coatings can provide additional protection against environmental factors, corrosion, and wear. By ensuring strong adhesion, mechanical polishing helps manufacturers deliver high-quality, long-lasting products that meet the demanding requirements of various industries.

Electropolishing is a versatile and highly effective surface finishing method that finds ideal applications across various industries due to its ability to enhance surface quality, corrosion resistance, and aesthetic appeal. CNC machined parts that undergo electropolishing benefit from improved performance, durability, and visual excellence, making this process indispensable in sectors where precision and reliability are paramount. Below are some of the key applications where electropolishing is particularly advantageous.

In the medical industry, CNC machined parts are used in a wide array of applications, including surgical instruments, implants, and diagnostic equipment. Electropolishing is essential for these components due to its ability to achieve high levels of surface cleanliness, smoothness, and biocompatibility.

Advantages:

Electropolishing ensures that CNC machined parts used in medical devices meet stringent regulatory standards for cleanliness, surface finish, and biocompatibility. The process not only enhances the functional performance of these parts but also contributes to their aesthetic appeal, making them more suitable for use in high-end medical applications where both form and function are critical.

Aerospace Components

The aerospace industry demands high-performance, precision-engineered components that can withstand extreme conditions and stresses. Electropolishing is integral to producing CNC machined parts for aerospace applications due to its ability to enhance surface integrity and corrosion resistance.

Advantages:

Electropolishing ensures that aerospace components meet the highest standards of quality and performance, enabling them to perform reliably under the demanding conditions of aviation and space exploration. The smooth, polished surfaces contribute to reduced friction, enhanced aerodynamic performance, and increased resistance to environmental degradation, making electropolishing a crucial process in the production of high-performance aerospace CNC machined parts.

Food and Beverage Equipment

In the food and beverage industry, CNC machined parts are used in equipment such as processing machinery, storage tanks, and dispensing systems. Electropolishing plays a critical role in ensuring that these parts meet the stringent hygiene and safety standards required for food-grade applications.

Advantages:

Electropolishing ensures that CNC machined parts used in food and beverage equipment maintain high levels of hygiene and durability, making them safe and reliable for use in environments where cleanliness and material integrity are paramount. The process not only enhances the functional performance of these parts but also contributes to their compliance with food safety regulations, ensuring that the equipment meets the rigorous standards required by the industry.

Pharmaceutical Equipment

Pharmaceutical manufacturing requires precise, high-quality CNC machined parts for equipment such as reactors, mixers, and dispensing systems. Electropolishing is essential for these components to meet the stringent quality and cleanliness standards of the pharmaceutical industry.

Advantages:

Electropolishing ensures that pharmaceutical equipment components meet the highest standards of cleanliness, corrosion resistance, and surface integrity, essential for producing safe and effective pharmaceutical products. The smooth, polished surfaces contribute to improved equipment performance, reduced contamination risks, and enhanced compliance with regulatory requirements, making electropolishing a critical process in the production of high-quality pharmaceutical CNC machined parts.

In the automotive industry, CNC machined parts are used in various applications, including engine components, transmission systems, and body parts. Electropolishing enhances the surface quality and durability of these parts, contributing to their overall performance and longevity.

Advantages:

Electropolishing ensures that automotive CNC machined parts meet the high standards required for performance, durability, and aesthetics. The enhanced surface quality not only improves the functional performance of these parts but also contributes to the visual appeal and marketability of automotive products, making electropolishing an indispensable process in the production of high-quality automotive CNC machined parts.

Mechanical polishing is a versatile surface finishing technique that finds ideal applications across a broad spectrum of industries due to its adaptability and cost-effectiveness. This method enhances the surface quality of CNC machined parts, making them suitable for various functional and aesthetic requirements. Below are some of the key applications where mechanical polishing is particularly advantageous.

In the automotive industry, CNC machined parts are integral to the performance and aesthetics of vehicles. Mechanical polishing enhances the surface finish of components such as engine parts, transmission systems, and body panels, contributing to both their functionality and visual appeal.

Advantages:

Mechanical polishing ensures that automotive CNC machined parts meet the high standards required for both performance and appearance. The process not only improves the functional aspects of the parts but also contributes to the visual appeal of the vehicle, making it a critical step in the production of high-quality automotive components.

Building Materials

In the construction and architectural industries, CNC machined parts are used in a variety of applications, including structural components, decorative elements, and fixtures. Mechanical polishing is essential for enhancing the appearance and functionality of these parts, ensuring they meet the required standards for both aesthetics and performance.

Advantages:

Mechanical polishing ensures that CNC machined parts used in building materials are both aesthetically pleasing and functionally robust, making them suitable for use in high-end architectural projects and durable construction applications.

Consumer Goods

In the consumer goods sector, CNC machined parts are used in products such as electronics housings, appliances, and luxury items. Mechanical polishing enhances the surface finish of these parts, contributing to their aesthetic appeal and user satisfaction.

Advantages:

Mechanical polishing ensures that CNC machined parts used in consumer goods meet the high standards of aesthetics and functionality expected by consumers. The process not only improves the visual appeal of products but also enhances their usability and durability, contributing to increased customer satisfaction and brand loyalty.

Heavy Machinery

In the heavy machinery and industrial equipment sectors, CNC machined parts are used in critical applications such as engine components, hydraulic systems, and structural assemblies. Mechanical polishing enhances the surface finish of these parts, contributing to their performance, reliability, and longevity.

Advantages:

Mechanical polishing ensures that heavy machinery CNC machined parts meet the rigorous demands of industrial applications, providing smooth, durable, and reliable components that contribute to the overall performance and longevity of industrial equipment.

In various industrial sectors, CNC machined parts are used in equipment such as pumps, valves, conveyors, and robotic systems. Mechanical polishing enhances the surface quality of these parts, ensuring they meet the required standards for performance and reliability.

Advantages:

Mechanical polishing ensures that CNC machined parts used in industrial equipment are both functionally robust and aesthetically refined, contributing to the overall reliability and efficiency of industrial operations. The process not only enhances the performance of parts but also supports the maintenance of high standards in industrial manufacturing and equipment functionality.

In the realm of photoprocessing, where precision and surface integrity are paramount, electropolishing emerges as a critical surface finishing technique for CNC machined parts. The photoprocessing industry relies on highly accurate and defect-free components for applications such as lenses, optical assemblies, and high-precision instruments. Electropolishing enhances the surface quality of these parts, ensuring optimal performance and reliability. However, successful electropolishing in photoprocessing requires careful consideration of several key factors, including material suitability, equipment setup, and process parameters.

Material Suitability

Electropolishing is highly effective for materials commonly used in photoprocessing, such as stainless steel, aluminum, and certain alloys. The choice of material directly impacts the electropolishing process’s efficiency and the quality of the final surface finish. Photoprocessing components often require materials that offer both excellent machinability and superior surface characteristics after polishing.

Key Considerations:

Selecting the appropriate material is crucial for optimizing the electropolishing process in photoprocessing applications. Ensuring that the chosen materials are compatible with electropolishing enhances the efficiency of the process and the quality of the final polished surfaces, making them suitable for the high-precision demands of the photoprocessing industry.

Choosing the Right Metal

Selecting the right metal for photoprocessing applications involves balancing machinability, surface finish quality, and corrosion resistance. Stainless steel, particularly grades like 304 and 316, are commonly chosen for their excellent balance of these properties. Titanium alloys are also used in specialized applications where high strength and lightweight properties are essential.

Advantages of Common Metals:

Choosing the right metal ensures that the electropolishing process is effective and that the CNC machined parts meet the stringent requirements of photoprocessing applications. Proper material selection contributes to the overall performance, longevity, and reliability of the finished components.

Surface Condition

The initial surface condition of the CNC machined part significantly influences the outcome of the electropolishing process in photoprocessing. Parts with rough surfaces, tool marks, or surface defects may require additional preparation steps to achieve the desired polished finish.

Key Considerations:

Achieving the optimal surface condition prior to electropolishing ensures that the process can effectively smooth out microscopic surface irregularities, resulting in a high-quality, mirror-like finish that meets the precision demands of photoprocessing applications.

Equipment and Setup

Electrolyte Solution

The composition of the electrolyte solution is a critical factor in the electropolishing process for photoprocessing CNC machined parts. The electrolyte must be carefully selected based on the material of the workpiece and the desired surface finish quality.

Key Considerations:

Selecting the appropriate electrolyte solution ensures that the electropolishing process is effective and produces the desired surface finish on CNC machined parts used in photoprocessing applications.

Power Supply

The power supply setup in the electropolishing process is fundamental to controlling the electrochemical reactions that achieve surface polishing. The power supply must provide a stable and adjustable electrical current to ensure uniform material removal across the workpiece’s surface.

Key Considerations:

A well-calibrated power supply is crucial for achieving uniform and controlled electropolishing, ensuring that CNC machined parts meet the required surface finish specifications for photoprocessing applications.

Fixture Design

The design of fixtures used in the electropolishing process is critical for securing the CNC machined parts and ensuring that they are uniformly exposed to the electrolyte solution and electrical current. Proper fixture design minimizes the risk of part movement or distortion during polishing, contributing to a consistent and high-quality surface finish.

Key Considerations:

Effective fixture design ensures that CNC machined parts are held in the optimal position and orientation during electropolishing, facilitating consistent and high-quality surface finishes required for photoprocessing applications.

Process Parameters

Temperature Control

Maintaining precise temperature control in the electrolyte bath is essential for achieving consistent and effective electropolishing results. Temperature influences the rate of electrochemical reactions, material removal rate, and overall surface finish quality.

Key Considerations:

Consistent temperature control ensures that electropolishing operates under optimal conditions, facilitating uniform material removal and achieving the desired high-quality surface finish on CNC machined parts used in photoprocessing.

Duration

The duration of the electropolishing process directly impacts the degree of surface smoothing and the final finish quality of CNC machined parts. Determining the appropriate polishing time requires careful consideration of several factors, including the material properties, desired surface finish, and specific application requirements.

Key Considerations:

Balancing Act:

Optimization Strategies:

By carefully managing the duration of the electropolishing process, manufacturers can achieve the optimal balance between effective surface smoothing and maintaining the dimensional integrity of CNC machined parts, ensuring that the final polished surfaces meet the stringent requirements of photoprocessing applications.

Current Density

Current density, measured in amps per square foot, is a critical parameter in the electropolishing process that influences the rate and uniformity of material removal. It dictates how much electrical current is applied per unit area of the CNC machined part’s surface, directly impacting the efficiency and quality of the polishing process.

Key Considerations:

Impact on Polishing Process:

Optimization Strategies:

By meticulously controlling current density, manufacturers can ensure that the electropolishing process operates efficiently, achieving uniform and high-quality surface finishes on CNC machined parts tailored for photoprocessing applications.

Electropolishing and mechanical polishing are two primary methods used to enhance the surface finish of CNC machined parts. Electropolishing involves an electrochemical process to remove microscopic surface imperfections, while mechanical polishing uses abrasive tools to smooth the surface. Choosing the right method depends on factors such as cost, durability, and specific application requirements.

Introduction

Surface finishing plays a pivotal role in the performance and longevity of CNC machined parts. Two of the most prevalent polishing methods employed in CNC machining manufacturing are electropolishing and mechanical polishing. Each method offers distinct benefits and is suited to different types of applications and surface finish requirements. Electropolishing is an electrochemical process that smooths the surface at a microscopic level by removing a thin layer of material, thereby enhancing corrosion resistance and aesthetic appeal. On the other hand, mechanical polishing utilizes abrasive materials and tools to physically smooth and refine the surface, making it ideal for achieving a high-gloss finish and removing larger surface imperfections.

Understanding the nuances between these two polishing techniques is essential for manufacturers aiming to optimize the quality of their CNC machined parts. Electropolishing is often preferred in industries where corrosion resistance and a pristine surface finish are paramount, such as in medical devices, pharmaceuticals, and high-precision engineering components. Mechanical polishing, conversely, is widely used in applications where surface texture and visual appeal are critical, including consumer electronics, automotive parts, and decorative hardware.

This article provides an in-depth comparison of electropolishing and mechanical polishing, examining their cost implications, finish durability, surface finish quality, and suitability for specific applications. By the end of this guide, manufacturers will have a clear understanding of which polishing method best aligns with their production requirements and quality standards, ensuring the delivery of superior CNC machined parts that meet or exceed client expectations.

Cost Considerations

When choosing between electropolishing and mechanical polishing, cost is a significant factor that manufacturers must carefully evaluate. The overall cost of each polishing method can vary widely based on several factors, including the complexity of the part, the volume of production, the required surface finish quality, and the specific industry standards that must be met.

Electropolishing

Electropolishing generally involves higher initial costs compared to mechanical polishing due to the need for specialized equipment and chemicals. The process requires an electrochemical setup, including power supplies, electrolytes, and precise control systems to ensure consistent material removal. Additionally, the operational costs can be elevated by the need for skilled technicians to manage and monitor the electropolishing process effectively. However, the investment in electropolishing can be justified by the superior surface finish quality, enhanced corrosion resistance, and extended longevity of the CNC machined parts. For high-value components where surface integrity is critical, the higher cost of electropolishing is often offset by the reduced need for maintenance and longer service life of the parts.

Mechanical Polishing

In contrast, mechanical polishing typically involves lower initial and operational costs. The equipment required for mechanical polishing, such as abrasive wheels, buffing machines, and polishing compounds, is generally less expensive and more widely available than electropolishing setups. Additionally, mechanical polishing processes can be quicker to implement and require less specialized training, further reducing costs. However, while mechanical polishing is cost-effective for producing high-gloss finishes and removing larger surface imperfections, it may not achieve the same level of microscopic surface smoothness or corrosion resistance as electropolishing. This can result in increased maintenance costs and shorter part lifespans in environments where surface integrity is critical.

In summary, electropolishing is a higher-cost option that delivers superior surface quality and corrosion resistance, making it ideal for high-value and precision applications. Mechanical polishing offers a more cost-effective solution for achieving excellent surface finishes in less demanding applications. Manufacturers must weigh these cost considerations against the specific requirements of their CNC machining parts to determine the most economically viable and performance-enhancing polishing method.

Process

Electropolishing

Electropolishing is an advanced surface finishing technique that enhances the quality and performance of CNC machined parts by using an electrochemical process to remove a thin, uniform layer of material from the surface. This method is particularly effective in achieving a high level of surface smoothness and cleanliness, making it ideal for applications where corrosion resistance and aesthetic appeal are paramount.

Process Overview

The electropolishing process involves immersing the CNC machined part into an electrolytic bath composed of a mixture of acids, typically phosphoric and sulfuric acids. An electrical current is applied, causing the surface of the metal to dissolve at a controlled rate. The process effectively removes microscopic surface imperfections, such as pits and burrs, resulting in a polished and mirror-like finish. The extent of material removal can be precisely controlled by adjusting the electrical parameters and bath composition, allowing manufacturers to achieve the desired level of surface smoothness and finish quality.

Advantages of Electropolishing

Applications of Electropolishing

Electropolishing is widely used in various industries to enhance the performance and appearance of CNC machined parts. Common applications include:

Overall, electropolishing is a vital finishing process in CNC machining manufacturing, offering unparalleled surface quality and performance enhancements that meet the rigorous demands of high-precision and high-stakes industries.

Mechanical Polishing

Mechanical polishing is a widely used surface finishing technique that involves the physical removal of material from the surface of CNC machined parts using abrasive tools and materials. Unlike electropolishing, which relies on an electrochemical process, mechanical polishing is a purely mechanical operation that can be tailored to achieve a variety of surface finishes based on the desired outcome.

Process Overview

The mechanical polishing process typically involves the use of abrasive pads, wheels, or compounds to smooth and refine the surface of the machined parts. The CNC machine may employ rotating tools or buffing pads that come into contact with the workpiece, gradually removing surface irregularities and achieving a high-gloss finish. The process can be performed manually or automated, depending on the complexity and volume of the parts being polished. Various abrasive materials, such as diamond, silicon carbide, or aluminum oxide, are selected based on the hardness and material of the CNC machined parts to ensure effective polishing without causing damage.

Advantages of Mechanical Polishing

Applications of Mechanical Polishing

Mechanical polishing is employed across a variety of industries to improve the appearance and performance of CNC machined parts. Common applications include:

Mechanical polishing is a versatile and efficient method for achieving high-quality surface finishes on CNC machined parts, making it an essential process in many manufacturing environments where both functionality and aesthetics are important.

Finish Durability

The durability of the surface finish achieved through electropolishing and mechanical polishing is a crucial consideration for manufacturers. The longevity and resilience of the finish can significantly impact the performance and maintenance requirements of CNC machined parts over their service life.

Electropolishing

Electropolished finishes are renowned for their exceptional durability and resistance to wear and corrosion. The electrochemical process not only smooths the surface but also creates a uniform passive oxide layer that protects the underlying metal from environmental factors. This makes electropolished surfaces highly resistant to oxidation, chemical exposure, and mechanical abrasion. The enhanced corrosion resistance ensures that the surface remains intact and maintains its finish quality even in harsh or corrosive environments, reducing the need for frequent maintenance and extending the lifespan of the CNC machined parts. Additionally, the microscopic smoothness achieved through electropolishing minimizes the accumulation of contaminants and residues, further enhancing the durability and cleanliness of the surface.

Mechanical Polishing

Mechanical polishing, while effective in achieving high-gloss and smooth finishes, may not offer the same level of durability as electropolishing. The physically smoothed surface created by abrasive tools can be susceptible to wear and scratching, especially in applications where parts are subjected to frequent movement or contact. Over time, mechanical polishing can result in the development of micro-scratches and surface imperfections, which can compromise the aesthetic quality and potentially reduce the corrosion resistance of the parts. However, with proper maintenance and the use of high-quality abrasives, the durability of mechanically polished finishes can be significantly enhanced. For applications where the parts are not exposed to harsh conditions or heavy mechanical stresses, mechanical polishing can provide a sufficiently durable finish that meets the desired performance and aesthetic standards.

In summary, electropolishing offers superior finish durability, making it ideal for applications requiring long-term performance and resistance to environmental factors. Mechanical polishing provides a durable finish suitable for less demanding applications, where surface aesthetics and functionality are important but extreme durability is not a primary concern.

Surface Finish

The quality of the surface finish is a fundamental aspect that differentiates electropolishing and mechanical polishing. The desired level of smoothness and appearance plays a significant role in determining which polishing method is most appropriate for a given CNC machined part.

Electropolishing

Electropolishing excels in producing exceptionally smooth and mirror-like surface finishes. The electrochemical process removes a uniform and controlled layer of material from the surface, eliminating microscopic surface imperfections such as pits, burrs, and roughness. This results in a highly reflective and pristine surface that not only enhances the aesthetic appeal of the part but also improves its functional properties by reducing surface friction and preventing contamination. The fine level of smoothness achieved through electropolishing is particularly beneficial for applications that require precise fitting, high cleanliness standards, and minimal surface roughness, such as in medical devices, aerospace components, and high-precision engineering parts.

Mechanical Polishing

Mechanical polishing offers a versatile approach to achieving a range of surface finishes, from matte to high-gloss. The quality of the finish depends largely on the abrasives used, the polishing techniques employed, and the skill of the operator. Mechanical polishing can effectively remove larger surface imperfections and provide a consistent surface texture. However, the level of smoothness achieved may not be as fine or uniform as that obtained through electropolishing. While mechanical polishing can produce excellent visual finishes and enhance the tactile feel of CNC machined parts, it may leave behind minor scratches or surface irregularities that are not completely eliminated by the abrasive process. This makes mechanical polishing suitable for applications where a high-gloss finish is desired for aesthetic purposes but does not require the extreme smoothness and precision of electropolished surfaces.

In conclusion, electropolishing provides superior surface finish quality with unparalleled smoothness and reflectivity, making it ideal for high-precision and high-aesthetic applications. Mechanical polishing offers a flexible and effective means of achieving a variety of surface finishes, suitable for applications where visual appeal and functional smoothness are important but do not require the utmost level of finish precision.

Application-Specific Requirements

Different industries and applications have unique requirements that dictate the choice between electropolishing and mechanical polishing. Understanding these specific needs is essential for selecting the most appropriate polishing method to achieve optimal performance and functionality of CNC machined parts.

Electropolishing

Electropolishing is particularly suited for applications that demand high levels of cleanliness, corrosion resistance, and precise surface finishes. Industries such as medical devices, pharmaceuticals, aerospace, and food processing benefit from electropolished parts due to the following reasons:

Mechanical Polishing

Mechanical polishing is ideal for applications where surface texture, visual appeal, and functional smoothness are important, but extreme surface precision and corrosion resistance are not the primary concerns. Common industries and applications include:

By aligning the polishing method with the specific requirements of the application, manufacturers can ensure that CNC machined parts meet the desired performance, durability, and aesthetic standards.

Understanding the distinctions between electropolishing and mechanical polishing is essential for manufacturers seeking to optimize their surface finishing processes. While both methods aim to enhance the surface quality of CNC machined parts, they achieve this through fundamentally different mechanisms and offer varying benefits and limitations.

Process Mechanism

Surface Finish Quality

Corrosion Resistance

Cost and Complexity

Environmental and Safety Considerations

Application Suitability

Electrolytic polishing and mechanical polishing are two essential surface finishing techniques in CNC machining manufacturing, each offering distinct advantages tailored to specific applications and requirements. Electrolytic polishing excels in delivering superior surface finishes with enhanced corrosion resistance, making it ideal for high-precision, high-performance applications such as medical devices, aerospace components, and optical assemblies. Its ability to uniformly polish complex geometries and remove micro-areas with precision ensures that CNC machined parts meet the highest standards of quality and functionality.

On the other hand, mechanical polishing provides unparalleled versatility and cost-effectiveness, making it suitable for a wide range of materials and part complexities across various industries. Its adaptability in achieving different surface finishes, combined with eco-efficient practices, allows manufacturers to enhance both the aesthetic and functional qualities of CNC machined parts efficiently and economically. Mechanical polishing is particularly beneficial for applications requiring customizable finishes, high-volume production, and diverse material compatibility.

When choosing between electrolytic polishing and mechanical polishing, manufacturers must carefully evaluate factors such as surface finish quality, production volume, material compatibility, and cost considerations. For applications demanding exceptional precision, uniformity, and corrosion resistance, electropolishing is the optimal choice. Conversely, for versatile, cost-effective, and adaptable polishing needs across diverse materials and production scales, mechanical polishing stands out as the preferred method.

Ultimately, the decision between electrolytic polishing and mechanical polishing should be guided by the specific requirements of the CNC machined parts, the operational capabilities of the CNC machining factory, and the desired balance between cost, efficiency, and finish quality. By understanding the strengths and limitations of each polishing technique, manufacturers can make informed choices that enhance the performance, durability, and visual appeal of their CNC machined parts, ensuring their success in competitive markets.

1. Can Electropolishing be Used on All Metals?

Electropolishing is primarily effective on metals such as stainless steel, aluminum, and certain alloys. While it is highly effective for these materials, non-conductive materials like plastics and ceramics are not suitable for electropolishing due to their inability to participate in electrochemical reactions. Additionally, some metals may require specific electrolyte compositions to achieve optimal results.

2. Which Method is Faster?

Electropolishing generally achieves a superior surface finish more quickly than mechanical polishing, especially for complex geometries and high-precision applications. However, the overall speed depends on factors such as part size, surface condition, and the specific requirements of the finish. Mechanical polishing may be faster for simpler, less intricate parts where high precision is not as critical.

3. What is the Difference Between Electropolishing and Electroplating?

Electropolishing involves the electrochemical removal of material from a workpiece’s surface to achieve a smooth finish, whereas electroplating involves depositing a layer of material onto the workpiece’s surface to enhance its properties or appearance. While both processes use electrical currents and electrolytes, their objectives and outcomes are fundamentally different.

4. When to Use Electropolishing?

Electropolishing is ideal for applications requiring high-precision surface finishes, enhanced corrosion resistance, and clean, smooth surfaces. It is particularly suited for industries such as medical devices, aerospace, optics, and food processing, where surface integrity and hygiene are paramount.

5. What are the Alternatives to Electropolishing?

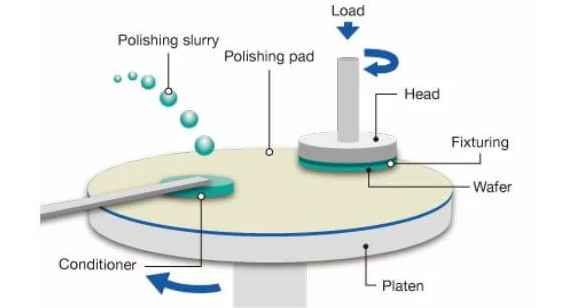

Alternatives to electropolishing include mechanical polishing, vibratory polishing, laser polishing, and chemical mechanical polishing (CMP). Each method offers different advantages and is suitable for specific applications depending on the desired surface finish, material compatibility, and production requirements.

6. Is Passivation Necessary After Electropolishing?

Passivation is often recommended after electropolishing to enhance the corrosion resistance of the workpiece further. Passivation involves treating the metal surface with an acid solution to remove free iron and promote the formation of a protective oxide layer, complementing the effects of electropolishing.

7. What is the Purpose of Chemical Mechanical Polishing?

Chemical mechanical polishing (CMP) combines chemical etching with mechanical abrasion to achieve exceptionally smooth and uniform surfaces. CMP is widely used in semiconductor manufacturing and other high-precision industries to create defect-free surfaces with controlled surface roughness.

8. What is the Cheapest Way to Polish Metals?

Mechanical polishing is generally the most cost-effective method for polishing metals, especially for high-volume production runs. It requires minimal initial investment in equipment compared to electropolishing and offers flexibility in handling various materials and surface finish requirements.

9. Does Electropolishing Remove Burrs?

Yes, electropolishing can effectively remove burrs and sharp edges from CNC machined parts by selectively removing material from high points and irregularities on the surface. This deburring capability enhances the safety and functionality of the finished parts.

10. How Long Does Electropolishing Take?

The duration of the electropolishing process varies based on factors such as part size, material, surface condition, and desired finish quality. Typically, electropolishing can take anywhere from a few minutes to several hours per batch, depending on the complexity and requirements of the application.

11. Does Electropolishing Remove Rust?

Electropolishing can remove rust and surface oxides from metal parts by dissolving the oxidized layers during the polishing process. This restoration of the metal surface enhances its corrosion resistance and restores its original appearance.

By addressing these FAQs, manufacturers and engineers can gain a deeper understanding of CNC machining and polishing processes, enabling them to make informed decisions that enhance the quality, efficiency, and reliability of their CNC machined parts.