15 years one-stop China custom CNC machining parts factory

62 |

Published by VMT at Oct 13 2025 | Reading Time:About 3 minutes

62 |

Published by VMT at Oct 13 2025 | Reading Time:About 3 minutes

Has the vexing choice between pure tungsten and its alloyed counterparts kept you in a state of unease, dreading the catastrophic implications of an erroneous material selection for your pivotal components? In the exacting realm of precision engineering, to merely assume parity between these two distinct material classes, based solely on their shared elemental origin, is to invite multi-million dollar project peril. It seems an incredibly foolish assumption to make, doesn't it?

Pure tungsten and its alloys are not interchangeable; their distinct atomic arrangements and added constituents dictate wildly disparate performance envelopes. A profound comprehension of these inherent variances is, in my view, the bedrock of successful high-performance manufacturing. We understand this deeply.

The fundamental question persists: what, precisely, distinguishes pure tungsten from a tungsten alloy? It’s a question of elemental singularity versus calculated multiplicity, a question of inherent properties versus engineered enhancements.

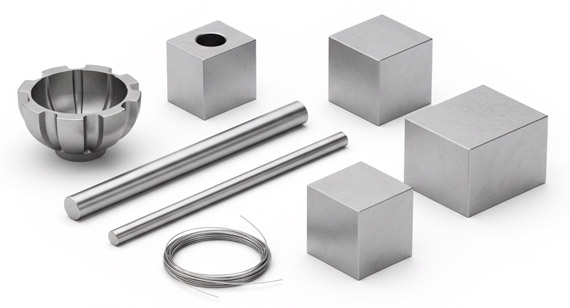

Pure tungsten, often denoted as W, is a metallic element possessing an unbelievably high melting point—the loftiest of all metals, actually! Its atomic number is 74. This refractory metal exhibits exceptional density and formidable strength at elevated temperatures, an absolutely irreplaceable truth in certain applications. We observe this time and again in our production facilities.

Tungsten alloys, however, are sophisticated metallic concoctions where tungsten acts as the paramount constituent, but other metallic or non-metallic elements—nickel, copper, iron, molybdenum, to name but a few—are intentionally incorporated. This deliberate admixture is designed to transmute tungsten's inherent characteristics, typically to ameliorate its inherent brittleness or augment specific properties like machinability or ductility.

The unblemished nature of pure tungsten dictates its extraordinary performance profile. Its singularity, a lack of foreign atoms, is truly a mind-blowing miracle in high-temperature physics.

Crystal Structure and Microscopic Features

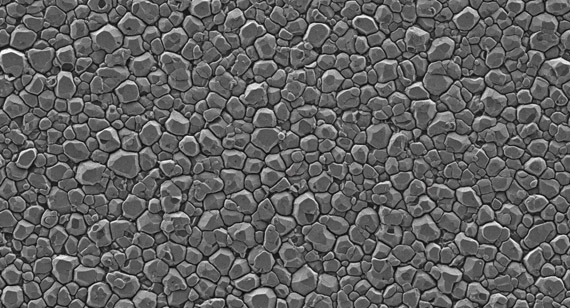

Pure tungsten's body-centered cubic (BCC) crystal lattice is remarkably stable. The grains are typically equiaxed; their boundaries, stark and unadulterated, offer minimal resistance to dislocation movement under high heat. This intrinsic structure, without the complicating presence of interstitial or substitutional impurities, enables its spectacular refractory qualities. It’s simple, yet profoundly potent.

Pure Tungsten’s Apex High-Temperature Stability

Its melting point, a staggering 3422°C (6192°F), bestows upon pure tungsten an almost mythical capacity to retain mechanical integrity in environments where other metals would simply vaporize or succumb to plastic deformation. This isn’t merely impressive; it’s definitive. It maintains its structural fortitude, resisting creep and thermal fatigue, which makes it an absolute titan in extreme thermal regimes.

The Unassailable Niche of Pure Tungsten in Specific Applications

Certain applications, utterly unforgiving in their demands, mandate pure tungsten. Its unparalleled electron emission properties render it indispensable for filament applications in incandescent bulbs and vacuum tubes. Moreover, its extreme density and atomic number make it the material of choice for X-ray targets and radiation shielding, where absolute attenuation is non-negotiable. Its resistance to erosion in plasma environments, too, marks it as irreplaceable for plasma spray nozzles.

But let's be real, pure tungsten, while phenomenal, isn't always the optimal choice. Its inherent brittleness and formidable hardness pose significant fabrication challenges. This is where the profound ingenuity of alloying enters the fray, a calculated alteration of destiny for the metal.

Inclusion of Alloying Elements and Their Mechanism

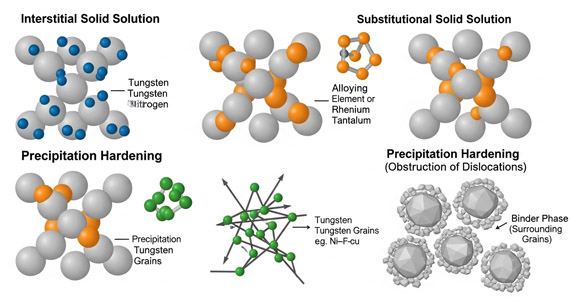

Introducing judicious proportions of other elements—nickel, iron, copper, cobalt, or even rare earths—into the tungsten matrix serves a singular purpose: to tune its properties. These elements can form solid solutions, precipitate as distinct phases, or act as binders. They impede dislocation motion, refine grain size, or provide a ductile matrix that encapsulates the tungsten grains. Each addition is a precisely calibrated adjustment, a nuanced whisper to the material’s soul.

Common Tungsten Alloy Varieties and Nomenclature Protocols

The world of tungsten alloys is diverse! Think of Heavy Tungsten Alloys (HTA), often tungsten-nickel-iron (W-Ni-Fe) or tungsten-nickel-copper (W-Ni-Cu), celebrated for their density and machinability. Then there are Tungsten-Copper (W-Cu) alloys, which synergistically blend tungsten's refractoriness with copper's conductivity. Tungsten-Molybdenum (W-Mo) alloys are also prominent, offering enhanced high-temperature strength and corrosion resistance. The nomenclature usually reflects the primary alloying constituents, guiding one through their very essence.

The Delicate Art of Balancing Ductility, Strength, and Wear Resistance

The core objective of alloying tungsten is to strike a precise equilibrium. Pure tungsten, for all its strength, is brittle; it shatters. By introducing ductile binders, such as nickel and iron, the alloy achieves enhanced fracture toughness and elongation. Simultaneously, the inherent hardness of tungsten is often preserved, or even amplified in some cases, to ensure superior wear resistance. This careful balancing act is where true material science expertise shines, an ongoing quest for optimized performance.

To truly dissect the choice, one must plunge into the quantifiable data, the cold, hard numbers that delineate superiority in specific contexts. Myriad characteristics diverge, often dramatically.

Mechanical Attributes: Hardness, Tensile Strength, Fracture Toughness

The mechanical landscape between pure tungsten and its alloys is markedly different. Pure tungsten possesses an extraordinarily high hardness. Yet, its inherent brittleness leads to poor fracture toughness. Tungsten alloys, particularly HTAs, sacrifice a minute portion of pure tungsten's ultimate tensile strength for a monumental gain in ductility and fracture toughness, which makes them far more forgiving under shock loads. We’ve seen firsthand how a slight shift here can prevent a downright catastrophic failure.

Pure Tungsten vs. Tungsten Heavy Alloy (W-Ni-Fe) - Mechanical Properties

| Property | Pure Tungsten (Typical) | Tungsten Heavy Alloy (W-Ni-Fe, 90%W) (Typical) |

| Hardness (HV) | 350-450 | 250-320 |

| Tensile Strength (MPa) | 700-1100 | 800-1200 |

| Elongation (%) | < 1 | 10-25 |

| Fracture Toughness (KIC MPa√m) | < 10 | 40-70 |

Physical Attributes: Density, Melting Point, Electrical and Thermal Conductivity

While density remains high for both, pure tungsten boasts the highest. Melting point, another key differentiator, is higher for pure tungsten due to its singular composition. The introduction of other elements in alloys can slightly—but measurably—alter these physical constants. Conductivity, for instance, often improves with copper additions.

Pure Tungsten vs. Tungsten Heavy Alloy (W-Ni-Fe) - Physical Properties

| Property | Pure Tungsten (Typical) | Tungsten Heavy Alloy (W-Ni-Fe, 90%W) (Typical) |

| Density (g/cm³) | 19.3 | 17.0-18.5 |

| Melting Point (°C) | 3422 | ~1500 (Binder phase) |

| Thermal Conductivity (W/m·K) | 160-170 | 80-120 |

| Electrical Resistivity (nΩ·m) | 52-55 | 100-150 |

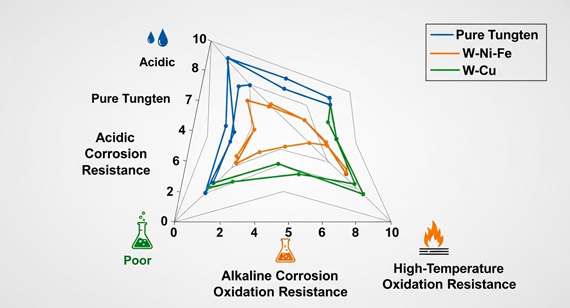

Chemical Stability and Corrosion Resistance Comparative Analysis

Pure tungsten exhibits commendable chemical inertness, especially against certain acids, but it oxidizes readily at very high temperatures. Tungsten alloys' chemical resistance varies wildly, depending on the specific alloying elements. Some, like W-Mo, offer superior resistance to specific corrosive media, while others, particularly those with a higher binder content, might be more susceptible to chemical attack than pure tungsten. It’s an incredibly intricate chemical tapestry.

This is the pivotal question, the crux of the matter. Making the correct call here avoids both over-engineering and under-performance. It truly dictates project success.

Core Application Domains for Pure Tungsten and the Underlying Rationale

Pure tungsten finds its indomitable niche where extreme heat resistance, exceptional density, and specific electrical properties are non-negotiable. Think vacuum furnace components, particularly heating elements and heat shields, where no other material can sustain such temperatures. Its role in X-ray targets, as an electron source, and in certain nuclear applications is paramount. It’s for when you truly need the absolute, unadulterated strength of the element itself.

Extensive Application of Tungsten Alloys in Aerospace, Medical, and Military Sectors

Tungsten alloys, by virtue of their enhanced machinability and mechanical characteristics, infiltrate a broader spectrum of high-demand industries. In aerospace, HTAs are used for balance weights in aircraft and helicopters due to their density and vibration damping. The medical field employs them for radiation shielding in oncology and collimators in imaging. For military applications, their high density and kinetic energy make them exceptional for armor-piercing projectiles and counterweights. Wait, I need to clarify that point—the ability to be machined into intricate forms is precisely what broadens their applicability so immensely across these critical sectors. A single noun: Versatility.

Specific Case Studies: How Performance Requirements Dictate Material Selection

Consider a scenario: an R&D engineer requires a heating element for a vacuum furnace operating consistently at 2000°C. Pure tungsten is the only sensible choice due to its melting point and creep resistance. Now, imagine a procurement manager sourcing balance weights for an aircraft wing. Here, a tungsten heavy alloy (W-Ni-Fe) is ideal. Its high density is maintained, but its superior machinability and toughness make it far more economical and reliable to produce and install than brittle pure tungsten. Another example? A medical facility needs shielding for an X-ray machine; pure tungsten for the direct target, but W-Ni-Cu for the intricate collimator due to the need for precise machining.

The journey from raw material to finished component is complex. Understanding the processing nuances and cost implications from a source manufacturer's standpoint is, frankly, indispensable.

The Fabrication Hurdles and Technical Prerequisites for Pure Tungsten

Working with pure tungsten is a formidable task. Its extreme hardness and inherent brittleness make traditional machining processes incredibly challenging, requiring specialized tools, slow speeds, and precise cooling. Grinding, EDM (Electrical Discharge Machining), and advanced sintering techniques are often employed. The initial investment in tooling and the specialized expertise required elevate fabrication costs substantially. It's not for the faint of heart, this work.

Machinability Advantages and Limitations of Tungsten Alloys

Tungsten alloys, especially those with binder phases like W-Ni-Fe, are significantly more forgiving than pure tungsten. They can often be machined using conventional methods, albeit still demanding robust machinery and tooling. This enhanced machinability translates directly to reduced processing times and lower overall manufacturing costs per part. Yet, even alloys have their limits; they are still dense, still hard, demanding respect from the machinist.

Weighing Procurement Price, Machining Expense, and Overall Value

This is where the procurement manager’s pains truly resonate. The raw material cost of pure tungsten might be higher or lower than a specific alloy, depending on market fluctuations and the alloying elements. However, the subsequent machining costs—the labor, the tooling, the rejected parts—can dramatically tilt the scales. An initially cheaper raw material might lead to exorbitant fabrication expenses, making the "cheaper" option ultimately far more expensive. We, as a source manufacturer, are uniquely positioned to offer transparency and optimized solutions, truly.

Tungsten Material Cost & Machinability Comparison

| Material Type | Raw Material Cost (Relative) | Machinability (Relative to Steel) | Processing Complexity |

| Pure Tungsten | Moderate to High | Very Poor (0.01-0.05) | Extreme |

| Tungsten Heavy Alloy (W-Ni-Fe) | Moderate to High | Fair to Good (0.1-0.3) | Moderate to High |

| Tungsten-Copper (W-Cu) | Moderate to High | Fair (0.05-0.15) | High |

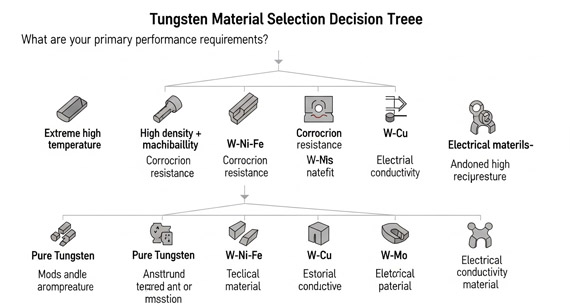

So, how does one navigate this labyrinth of choices, making an informed decision? It truly boils down to a systematic approach.

Prioritizing Key Performance Parameters

Begin by meticulously defining your non-negotiable performance parameters. Is it the absolute highest melting point? Or is it superior ductility and fracture toughness? Is density paramount, or perhaps electrical conductivity? This initial, unyielding introspection is vital. If a component absolutely *must* endure 2500°C without creep, then pure tungsten may well be your only recourse. If it needs to be machined into an incredibly complex shape and withstand impact, then an alloy is undeniably the path.

Contemplating Application Environment and Expected Component Longevity

The operational environment significantly influences material selection. Is the component exposed to corrosive agents? What are the ambient temperatures? What kind of mechanical stresses—cyclic, static, impact—will it endure? Furthermore, how long must this component reliably perform? A longer expected service life might justify the higher upfront cost and complexity of a more robust, specialized material. After all, failure is rarely an option.

Consulting Source Experts for Tailored Solutions

Honestly, this is where we come in. As a source manufacturer with profound technical expertise, we don't just supply parts; we supply solutions. Our engineers possess an intimate knowledge of pure tungsten and its myriad alloys, understanding not just their theoretical properties but their practical applications and processing idiosyncrasies. We can analyze your specific project demands, scrutinize your operational constraints, and, crucially, offer transparent pricing. Our objective? To guide you towards the most cost-effective, high-performance material solution, ensuring your high-quality parts are precisely what you require, without over-specifying or compromising. This often means providing high-quality parts at a cost you never thought imaginable.

The distinction between pure tungsten and tungsten alloys is fundamental for precision engineering. While pure tungsten excels in extreme high-temperature stability, density, and specific electrical properties, its inherent brittleness poses manufacturing challenges. Tungsten alloys, through the strategic inclusion of other elements, achieve enhanced ductility, machinability, and tailored mechanical properties, broadening their application across aerospace, medical, and military sectors. Careful consideration of performance priorities, environmental conditions, and expert consultation from a source manufacturer are vital to optimize material selection for cost-effectiveness and project success.

1. What is the primary difference in crystal structure between pure tungsten and its alloys?

Pure tungsten predominantly exhibits a body-centered cubic (BCC) crystal lattice, characterized by its homogeneous grain structure. Tungsten alloys, however, introduce additional elements that can alter this structure, forming solid solutions, distinct precipitate phases, or a ductile binder matrix around the tungsten grains. This structural modification fundamentally influences mechanical properties like ductility and fracture toughness.

2. Why is pure tungsten generally more brittle than tungsten alloys?

Pure tungsten's inherent brittleness stems from its strong metallic bonds and BCC crystal structure, which limits dislocation movement at room temperature. It lacks the 'give' or plastic deformation capacity found in other metals. Tungsten alloys, particularly those incorporating ductile binders like nickel and iron, introduce phases that can absorb energy, inhibit crack propagation, and provide a pathway for plastic flow, thereby significantly improving ductility and toughness.

3. Can pure tungsten be machined using conventional CNC methods?

Conventional CNC machining of pure tungsten is exceptionally challenging and often not practical. Its extreme hardness and brittleness lead to rapid tool wear, poor surface finish, and a high risk of material chipping or cracking. Specialized techniques such as Electrical Discharge Machining (EDM), grinding, or laser machining are typically required, which contribute to higher processing costs and longer lead times.

4. Which type of tungsten material is best for high-temperature furnace applications?

For applications demanding the highest possible temperature resistance, such as heating elements, heat shields, or structural components within vacuum furnaces, pure tungsten is generally the superior choice. Its unparalleled melting point (3422°C) and exceptional creep resistance at extreme temperatures are unmatched by its alloys, which often have lower melting points due to the presence of binder phases.

5. How do tungsten alloys improve machinability without sacrificing too much density?

Tungsten alloys, particularly those with a nickel-iron or nickel-copper binder phase (e.g., W-Ni-Fe or W-Ni-Cu heavy alloys), maintain a high tungsten content (typically 85-97%). The binder phase, being more ductile and softer than pure tungsten, facilitates chip formation and reduces tool wear during machining. This allows for more conventional machining processes while only slightly reducing the overall density compared to pure tungsten.

6. What are common applications for Tungsten Heavy Alloys (HTA) like W-Ni-Fe?

Tungsten Heavy Alloys (HTA) are widely used where high density, good mechanical strength, and enhanced machinability are critical. Common applications include radiation shielding in medical (collimators, patient protection) and industrial settings, balance weights in aerospace (aircraft, helicopters) and automotive industries, kinetic energy penetrators in military applications, and vibration-damping components.

7. How does VMT CNC Machining ensure the quality and purity of its tungsten materials?

As a source manufacturer, VMT CNC Machining maintains stringent quality control protocols throughout the entire production process, from raw material sourcing to final inspection. This includes comprehensive material certification, chemical analysis (e.g., ICP-MS, XRF) to verify purity and composition, microstructural analysis (e.g., SEM, metallography) to assess grain structure and defects, and rigorous mechanical testing (e.g., hardness, tensile strength) to confirm performance specifications. We have an unwavering commitment to high-quality parts.

8. How can I get a transparent and competitive quote for my specific tungsten component needs?

To receive a transparent and competitive quote, please contact our professional engineering team with your project specifications. We require details such as component dimensions, required material properties (e.g., density, strength, temperature resistance), application environment, quantity, and any relevant engineering drawings. Our deep technical expertise as a source manufacturer enables us to provide optimized material recommendations and fair pricing.

Call to Action: Still wrestling with the formidable decision between pure tungsten and its diverse alloys? Connect with our seasoned engineering ensemble immediately for a complimentary, bespoke material consultation, and leverage our inimitable standing as a source manufacturer, benefiting from our utterly transparent pricing and profound technical expertise to fashion unparalleled, high-quality parts solutions for your project. Simply click here to commence your inquiry without delay!