15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 05 29

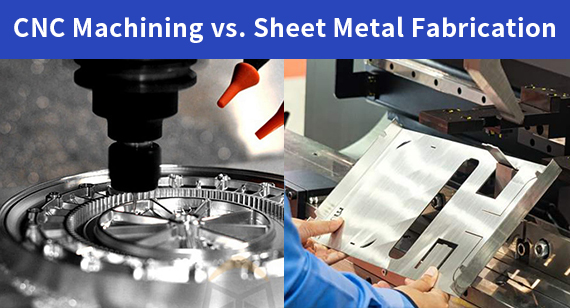

2025 05 29 Metal fabrication processes include casting, cutting, forming, welding, machining, and stamping. Each process is chosen based on material type, part geometry, and production volume. CNC machining services and sheet metal fabrication are among the most common approaches for producing precise, durable, and cost-effective metal CNC machining parts.

66

66

Read more

Read more

VMT

VMT  2025 05 28

2025 05 28 CNC machining is ideal for high-precision, complex-shaped components with tight tolerances, while sheet metal fabrication is better suited for producing lighter, simpler, and cost-effective metal parts in larger volumes. Your project’s design, material, and function determine the best method.

66

66

Read more

Read more

VMT

VMT  2025 05 27

2025 05 27 Welding is a specific joining technique within the broader process of metal fabrication, which includes cutting, shaping, machining, and assembling metal parts. While welding fuses materials together, metal fabrication encompasses the entire journey from raw material to finished product, often involving metal CNC machining and other advanced techniques.

66

66

Read more

Read more

VMT

VMT  2025 05 26

2025 05 26 Stainless steel die casting is a manufacturing process that injects molten stainless steel into molds under high pressure. It offers high corrosion resistance, heat resistance, and strength, making it ideal for complex components in aerospace, marine, medical, and industrial applications. It supports CNC machining services for enhanced precision, making it popular in stainless steel CNC machining parts production.

66

66

Read more

Read more

VMT

VMT  2025 05 23

2025 05 23 The primary difference between 18/8, 304, and 316 stainless steel lies in their chemical composition and corrosion resistance. 18/8 is a general term for stainless steel containing 18% chromium and 8% nickel, commonly equivalent to 304. 316 includes added molybdenum, offering superior corrosion resistance in harsh environments. Choose based on your specific application requirements.

66

66

Read more

Read more

VMT

VMT  2025 05 22

2025 05 22 308 stainless steel is ideal for welding applications and offers excellent corrosion resistance in moderate environments, while 316 stainless steel contains molybdenum, enhancing its strength and corrosion resistance in harsh, marine, or chemical conditions. Choose 308 for general industrial use and weldability, and 316 for superior durability in corrosive environments and CNC machining parts requiring high performance.

66

66

Read more

Read more

VMT

VMT  2025 05 21

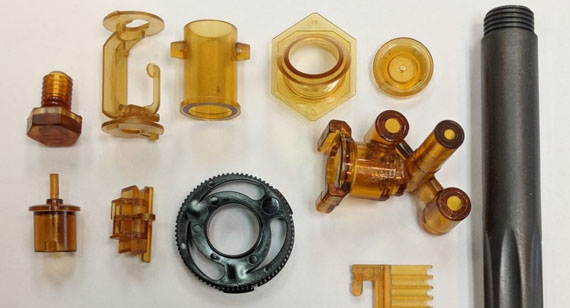

2025 05 21 Ultem® (polyetherimide or PEI) is a high-performance, amber-to-transparent thermoplastic known for its excellent mechanical strength, thermal stability, and chemical resistance. Used in aerospace, medical, and electronics industries, it is ideal for high-precision applications. Ultem offers long-term heat resistance and is commonly used in plastic CNC machining parts due to its dimensional stability and easy machinability.

66

66

Read more

Read more

VMT

VMT  2025 05 20

2025 05 20 High-Density Polyethylene (HDPE) is a thermoplastic polymer known for its high strength-to-density ratio, chemical resistance, and versatility. Commonly used in applications ranging from piping systems to food containers, HDPE's properties make it suitable for various industries, including construction, healthcare, and consumer goods.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!